Table of Contents

Market Insight: Copper Roof Strip

Market Analysis: Transformer Strip/Foil (Aluminum/Copper) – Copper Roof Strip Demand and Quality Imperatives

The term “copper roof strip” within transformer manufacturing specifically denotes the high-conductivity copper strip employed in the critical top connection section of wound transformer coils, particularly in distribution and power transformers. This component forms the electrical interface between the winding and the bushing or terminal assembly, demanding exceptional performance under continuous thermal and electromagnetic stress. Global industrial demand for this specialized copper strip remains robust, driven by the relentless expansion of electrical infrastructure, renewable energy integration requiring robust grid connections, and the replacement cycle for aging transformers. While aluminum strip offers cost advantages in bulk conductor applications, copper maintains dominance in the roof strip position due to its superior electrical conductivity (approximately 100% IACS minimum required), higher thermal conductivity, and greater mechanical strength at elevated operating temperatures. These properties are non-negotiable for ensuring low resistive losses, efficient heat dissipation away from the critical bushing interface, and long-term structural integrity under cyclic thermal loading.

Quality consistency in copper roof strip is paramount, directly impacting transformer reliability, efficiency, and lifespan. Substandard material introduces significant failure risks. Key quality parameters include strict chemical composition control (oxygen-free electrolytic tough pitch copper, C10100/C10200 per ASTM B152, with phosphorus content tightly controlled to prevent embrittlement), precise dimensional tolerances (thickness, width, edge straightness), and flawless surface integrity. Microscopic surface defects, scratches, or embedded oxides act as initiation points for partial discharge under high electrical stress, potentially leading to catastrophic insulation failure. Inconsistent resistivity increases I²R losses, contributing to localized hot spots and accelerated insulation aging. Variations in mechanical properties, such as insufficient yield strength, can cause deformation during winding or clamping, compromising the critical electrical contact and thermal path. The consequences of quality lapses extend beyond immediate field failures; they manifest as reduced transformer efficiency (impacting operational costs and carbon footprint), shortened service life necessitating premature replacement, and significant reputational damage for both the transformer manufacturer and the end-user utility.

The transformer supply chain increasingly mandates stringent quality documentation and traceability for critical components like roof strip. Leading manufacturers require certified material test reports (MTRs) verifying chemistry, mechanical properties, and electrical resistivity, alongside process certifications (e.g., ISO 9001, IATF 16949). Reputable suppliers implement rigorous in-process controls, including continuous surface inspection systems and statistical process control for dimensional accuracy. While price pressure exists, discerning buyers recognize that the minimal cost difference between marginal and premium copper strip is vastly outweighed by the lifecycle cost implications of transformer failure. For critical applications, especially in high-reliability grids or harsh environments, the investment in certified, high-purity copper strip with proven consistency is an essential risk mitigation strategy. Luoyang Xinzhaohe Aluminum leverages its two-decade metallurgical expertise across both aluminum and copper conductor technologies to advise clients on optimal material selection, emphasizing that uncompromising quality in the roof strip segment is foundational to transformer performance and grid stability.

Technical Specs: Copper Roof Strip

Technical Specifications for Copper Roof Strip

Luoyang Xinzhaoanghe Aluminum Co., Ltd., with over two decades of specialized experience in the production and supply of precision transformer strips and foils, provides high-performance copper roof strip solutions engineered for critical electrical and structural applications. Our copper roof strips are manufactured to meet stringent industry standards, ensuring optimal conductivity, mechanical integrity, and dimensional accuracy required in roofing systems with integrated lightning protection or grounding functions.

The copper roof strip is produced from high-purity electrolytic tough pitch (ETP) copper (Cu-ETP1, C11000), ensuring a minimum conductivity of 98% IACS. This high level of electrical conductivity is essential for efficient dissipation of lightning currents and grounding performance in architectural and industrial roofing systems. Each strip undergoes rigorous quality control to maintain uniform metallurgical properties throughout the coil length, minimizing resistive losses and ensuring long-term reliability under varying environmental conditions.

Dimensional precision is a core attribute of our copper roof strip offering. Utilizing state-of-the-art precision slitting lines, we achieve a slit width tolerance of ±0.002 mm, enabling seamless integration into automated roofing assembly processes and ensuring consistent lap joints or connection interfaces. This tight tolerance minimizes material waste during installation and enhances the overall system reliability by eliminating gaps or misalignments that could compromise electrical continuity or weather resistance.

Edge quality is strictly controlled to deliver burr-free edges after slitting. Our advanced deburring and edge conditioning processes eliminate micro-tears and raised edges, which could otherwise act as stress concentration points or interfere with connection hardware. Burr-free edges also enhance operator safety during handling and reduce wear on downstream processing equipment such as rollers or crimping tools.

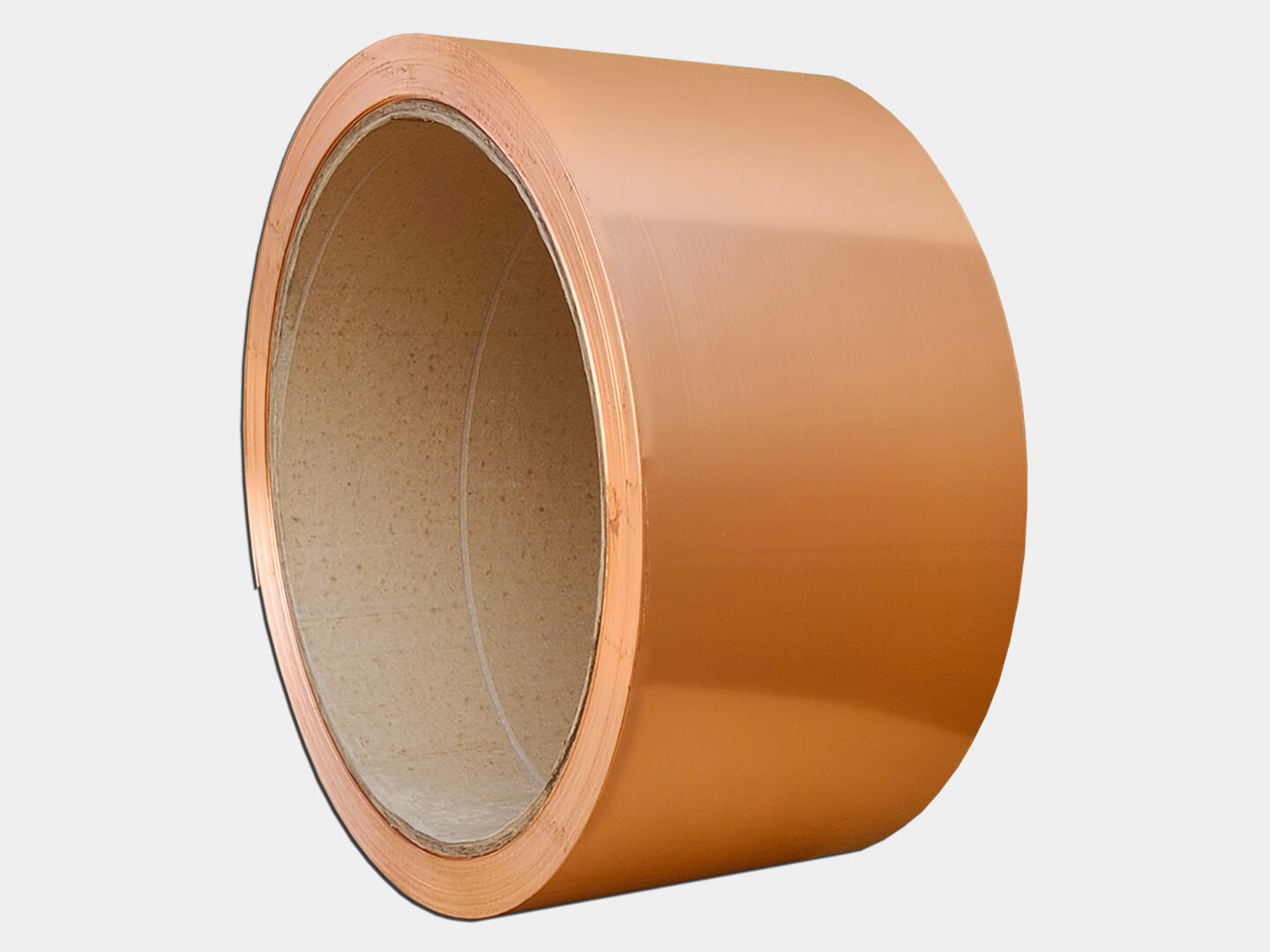

All copper roof strips are supplied in coil form with protective film coating to prevent surface oxidation and mechanical damage during transit and storage. The strips are available in standard thicknesses ranging from 0.1 mm to 1.0 mm and widths from 10 mm to 100 mm, customizable to project-specific requirements. Annealed tempers (soft temper) are standard, providing excellent formability for complex roof geometries, while half-hard tempers can be supplied upon request for enhanced mechanical strength.

The following table outlines the key technical parameters for our copper roof strip product line:

| Parameter | Specification |

|---|---|

| Material | Cu-ETP1 (C11000) |

| Purity | ≥ 99.90% Cu |

| Conductivity | ≥ 98% IACS |

| Thickness Range | 0.1 mm – 1.0 mm |

| Width Range | 10 mm – 100 mm |

| Slitting Tolerance | ±0.002 mm |

| Edge Quality | Burr-free, micro-smooth finish |

| Temper | O (Annealed/Soft), H02 (1/2 Hard) on request |

| Coil Inner Diameter | 200 mm, 300 mm, or 508 mm |

| Surface Protection | Polyethylene film coating |

| Standards Compliance | ASTM B187, GB/T 14594 |

All production batches are subject to in-line and final quality inspections, including eddy current testing, tensile testing, and conductivity verification, ensuring consistent product performance across all shipments. Luoyang Xinzhaohe Aluminum Co., Ltd. supports global sourcing requirements with reliable lead times, full material traceability, and technical documentation packages.

Factory Tour: Manufacturing

Manufacturing Process for Architectural Copper Roof Strip

Luoyang Xinzhaohe Aluminum CO., Ltd leverages its 20+ years of precision metal strip production expertise, including specialized copper processing capabilities, to manufacture high-integrity copper roof strips meeting stringent architectural requirements. Our process integrates advanced cold rolling, precision slitting, and critical edge conditioning, underpinned by rigorous quality control protocols throughout.

Cold Rolling Process

The foundation of strip quality begins with cold rolling high-purity copper ingots (typically C11000 or C12200) into master coils. Utilizing multi-stand reversing mills with precise roll gap and tension control, we achieve the target thickness within tight tolerances (±0.02 mm for standard roof strips). Critical parameters include controlled reduction per pass to optimize grain structure and mechanical properties, maintaining surface finish Ra values below 0.4 µm to ensure aesthetic uniformity after patination. Tension leveling during rolling minimizes coil set and ensures flatness essential for subsequent processing. This stage establishes the strip’s core mechanical properties, including the required temper (typically H02 or H04 for roof applications) providing the necessary rigidity and formability during installation.

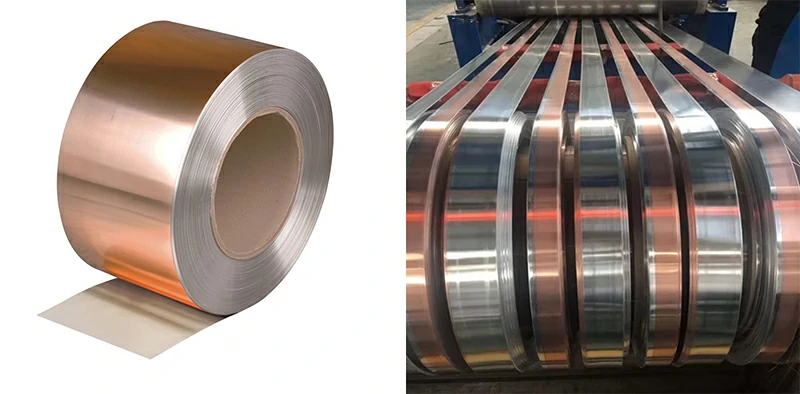

Precision Slitting

Master coils undergo precision slitting on servo-controlled rotary shear lines to achieve the final roof strip width. Our process employs hardened, ground tungsten carbide rotary knives with computerized knife positioning, ensuring width tolerances held to ±0.10 mm across the coil width. Critical to architectural performance is the minimization of edge burr; we maintain burr height consistently below 0.02 mm through precise knife clearance control (typically 2-5% of material thickness) and optimized strip tension management. Laser micrometers provide real-time width monitoring, with automatic feedback adjusting knife positions to maintain consistency. Slit strip is wound under controlled tension to prevent telescoping and edge damage, ready for the final critical step.

Edge Conditioning

Unconditioned slit edges pose significant risks during roof installation and long-term performance, including handling injuries, tear initiation, and accelerated corrosion. Our dedicated edge conditioning process employs precision brushing or light grinding techniques to uniformly remove micro-burrs and create a controlled edge radius. This treatment eliminates sharp edges while maintaining dimensional integrity, crucial for safe handling and preventing stress concentration points that could lead to edge cracking under thermal cycling or wind uplift. The conditioned edge significantly enhances the strip’s durability and weathering characteristics in the exposed roof environment.

Integrated Quality Control

Quality assurance is embedded at every manufacturing stage. Incoming copper billet chemistry is verified via OES spectroscopy against ASTM B370 standards. During cold rolling, continuous surface inspection systems (laser or camera-based) detect defects down to 0.1 mm, while online thickness gauges (X-ray or beta gauge) ensure dimensional compliance. Post-slitting, 100% of strip width is verified, with edge burr measured using optical comparators or profilometers on statistically sampled lengths. Final inspection includes mechanical property verification (tensile strength, yield strength, elongation per ASTM E8), flatness assessment (I-Units), and comprehensive surface evaluation per ASTM E3022 standards for architectural metals. All critical parameters are documented, providing full traceability for each production lot to ensure consistent delivery of roof strips meeting architectural specifications and longevity expectations.

Packaging & Logistics

Export Packaging for Copper Roof Strip – Ensuring Integrity in International Shipments

At Luoyang Xinzhaohe Aluminum Co., Ltd., with over two decades of experience in the production and global distribution of transformer-grade metal strips, we recognize that proper export packaging is a critical component in preserving product quality during maritime transport. For copper roof strip shipments destined for international markets, our packaging methodology is engineered to mitigate environmental exposure, mechanical stress, and logistical risks inherent in sea freight.

All copper roof strip products are systematically secured on high-strength wooden pallets constructed from kiln-dried hardwood. These pallets are designed to ISO 15527 standards, ensuring structural integrity under dynamic loading conditions encountered during containerized shipping. The use of treated wood complies with ISPM 15 regulations, which govern the phytosanitary treatment of wooden packaging materials for international trade, thereby preventing the cross-border spread of pests and ensuring customs clearance in all major markets.

Prior to palletization, each coil or flat strip unit is wrapped in multi-layer moisture-proof composite film. This film incorporates a metallized polyethylene barrier with a vapor transmission rate of less than 0.5 g/m²·24h at 38°C and 90% RH, effectively shielding the copper surface from humidity, salt air, and condensation—common hazards in marine environments. The sealed enclosure prevents oxidation and maintains the metallurgical surface finish critical for downstream processing and roofing applications.

The wrapped coils are then firmly affixed to the pallet using galvanized steel strapping, tensioned to industry-standard specifications (typically 800–1,200 N), and secured with edge protectors to prevent strap indentation on coil edges. This restraint system ensures load stability during vessel motion, crane handling, and intermodal transfers. Additional corner boards made from laminated fiberboard are applied to enhance rigidity and protect against impact damage during stacking.

For containerized shipments, palletized loads are arranged to maximize cubic utilization while maintaining clearance from container walls, reducing the risk of localized moisture accumulation. Desiccant packs are optionally deployed within the container, depending on voyage duration and climatic zones traversed, to further control internal humidity.

Our packaging protocol is validated through accelerated aging tests and real-world shipment monitoring, including humidity logging and post-transit visual inspection. This data-driven approach ensures continuous improvement and compliance with the highest standards of material preservation.

By integrating robust wooden pallets with advanced moisture-resistant encapsulation, Luoyang Xinzhaohe Aluminum Co., Ltd. ensures that copper roof strip arrives at its destination in optimal condition, ready for immediate processing or installation. This level of packaging precision reflects our commitment to reliability, quality assurance, and customer satisfaction in global supply chain operations.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe for Precision Copper Roof Strip Solutions

Luoyang Xinzhaohe Aluminum Co., Ltd leverages 22 years of specialized metallurgical expertise to deliver engineered copper roof strip solutions meeting the exacting demands of architectural and industrial roofing applications. Despite our aluminum-centric nomenclature, our facility operates dedicated copper production lines certified to ISO 9001:2015 and ISO 14001:2015 standards, ensuring material integrity from raw billet to finished strip. Our technical mastery extends beyond basic fabrication to granular control of copper’s metallurgical properties, critical for roofing performance under thermal cycling and environmental exposure.

Our 45,000 m² manufacturing campus integrates vertical production capabilities spanning continuous casting, precision cold rolling, and controlled annealing. We maintain strict adherence to ASTM B370 specifications for architectural copper, with in-house capacity to produce strips from 0.2mm to 3.0mm in thickness and widths up to 1,250mm. Critical to roofing applications, we achieve ±0.02mm thickness tolerance and surface roughness (Ra) values of 0.4–0.8μm through proprietary roll grinding protocols and laser-based online monitoring. Our annealing furnaces utilize nitrogen-hydrogen atmospheres to prevent oxidation, ensuring consistent temper (H00/H02) and optimal grain structure for formability during seaming and expansion joint installation.

Quality assurance is embedded at every process stage. Every copper coil undergoes 100% eddy current testing for subsurface defects, coupled with spectrographic analysis verifying elemental composition against C11000/C12200 standards. Batch traceability is maintained via blockchain-secured digital logs tracking melt chemistry, rolling passes, and final mechanical properties. This rigor minimizes field failures related to stress cracking or inconsistent patina development—common pain points in copper roofing systems.

Supply chain resilience is engineered into our operations. We hold strategic copper cathode inventories covering 45 days of production, mitigating LME price volatility through fixed-price contracts with certified smelters. Our JIT logistics system guarantees 15-day lead times for standard orders, with FOB Qingdao or CIF port options. Dedicated export teams manage HS code 7410.11 compliance, including mill test reports, customs documentation, and corrosion-resistant packaging for ocean transit.

For roofing contractors and material specifiers, our value transcends supply. Our metallurgical engineers provide pre-project consultations on alloy selection (e.g., phosphorus-deoxidized C12200 for enhanced solderability), thermal expansion calculations, and compatibility assessments with dissimilar metals. We supply technical data sheets detailing tensile strength (200–250 MPa), elongation (40–50%), and accelerated weathering test results per ASTM G154.

Partner with a manufacturer that treats copper roof strip as a performance-critical component, not a commodity. Contact Cathy Zhang, International Sales Director, to request metallurgical test reports or discuss project-specific tolerances. Email cathy@transformerstrip.com with your technical specifications and volume requirements for a precision-engineered solution within 24 hours. Luoyang Xinzhaohe transforms raw copper into roofing reliability—backed by two decades of supply chain discipline and materials science excellence.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing copper roof strip directly from China.