Table of Contents

Market Insight: Copper Refrigerator Coil

Market Analysis: Transformer Strip/Foil (Aluminum/Copper)

The industrial demand for copper refrigerator coil within the transformer sector remains robust, driven by the material’s superior electrical conductivity, thermal stability, and mechanical durability. While aluminum has gained traction in certain transformer applications due to cost and weight advantages, copper refrigerator coil continues to dominate high-performance and high-reliability segments, particularly in distribution and power transformers where efficiency and longevity are paramount. Copper’s conductivity, approximately 100% IACS (International Annealed Copper Standard), enables reduced resistive losses, directly contributing to higher energy efficiency and compliance with global energy regulations such as IE3 and IE4 efficiency standards.

Copper refrigerator coil, produced through precision rolling and annealing processes, is engineered to meet stringent dimensional tolerances and surface quality requirements essential for transformer winding operations. The term “refrigerator coil” historically references the use of such copper strips in refrigeration systems; however, in the context of transformer manufacturing, it denotes high-purity, soft-annealed copper strip suitable for intricate coil winding. The transition of this material into transformer applications underscores its adaptability and performance under cyclic thermal loading, a common operational condition in transformers.

Global transformer demand is being propelled by grid modernization initiatives, renewable energy integration, and the expansion of electric vehicle charging infrastructure. These developments necessitate reliable, high-efficiency transformers, reinforcing the preference for copper-based windings in critical applications. According to industry data, copper accounts for over 60% of conductor material used in power transformers worldwide, with demand concentrated in Asia-Pacific, Europe, and North America.

Quality assurance in copper refrigerator coil production is non-negotiable. Impurities, inconsistent thickness, or surface defects can lead to localized hot spots, insulation breakdown, and ultimately, transformer failure. At Luoyang Xinzhaohe Aluminum Co., Ltd., with over two decades of expertise in non-ferrous strip and foil production, we apply rigorous quality control protocols including continuous oxygen analysis, eddy current testing, and precise tensile and bend testing to ensure material integrity. Our copper strips are manufactured to meet or exceed international standards such as ASTM B3 and IEC 60183.

Furthermore, the annealing process is tightly controlled to achieve optimal softness (typically O-temper) without compromising structural coherence, ensuring ease of winding and long-term reliability under electromagnetic stress. Surface cleanliness is maintained to prevent insulation layer degradation, a critical factor in dry-type transformer applications.

In summary, while aluminum offers a viable alternative in certain transformer designs, copper refrigerator coil remains the material of choice for high-efficiency, durable transformer windings. The growing emphasis on energy efficiency, system reliability, and lifecycle cost reduction continues to sustain demand for high-quality copper strip. As a trusted supplier with extensive metallurgical and process engineering expertise, Luoyang Xinzhaohe Aluminum Co., Ltd. delivers copper transformer strip solutions that meet the evolving technical demands of the global power sector.

Technical Specs: Copper Refrigerator Coil

Technical Specifications for Copper Refrigerator Coil Sourcing

Copper refrigerator coil demands stringent metallurgical and dimensional control to ensure optimal thermal transfer, leak resistance, and manufacturability in hermetic compressor systems. As a critical component in refrigerant circuits, deviations in key parameters directly impact system efficiency, pressure integrity, and service life. Luoyang Xinzhaohe Aluminum Co., Ltd leverages 20+ years of precision strip processing expertise to deliver coils meeting the highest industry benchmarks, particularly ASTM B280 for seamless copper tube applications. Our technical specifications prioritize parameters that prevent field failures, such as micro-leaks from edge defects or reduced heat exchange from substandard conductivity.

Precision slitting tolerance of ±0.002 mm is non-negotiable for coil width consistency. This ensures uniform coil winding during tube fabrication, eliminating gaps or overlaps that compromise brazing integrity in evaporator/condenser assemblies. Burr-free edges are equally critical; any protrusion exceeding 2 μm risks puncturing adjacent layers during coiling or creating stress concentrators that initiate cracks under thermal cycling. Conductivity must consistently achieve ≥98% IACS (International Annealed Copper Standard) to maintain thermal efficiency—values below this threshold increase energy consumption due to resistive heating. Additionally, controlled tensile properties prevent plastic deformation during bending, while surface cleanliness avoids oxide inclusions that degrade solderability.

The following table details mandatory technical parameters for copper refrigerator coil procurement. All values reflect our in-process quality control thresholds, exceeding typical industry minimums to mitigate downstream production risks.

| Parameter | Specification Requirement | Test Standard | Rationale |

|---|---|---|---|

| Thickness Range | 0.25–0.50 mm | ASTM E29 | Ensures structural rigidity without impeding heat transfer efficiency |

| Width Tolerance | ±0.002 mm | ISO 2768-mK | Prevents misalignment during tube drawing and coil winding |

| Edge Burr Height | ≤2 μm | ISO 1302 | Eliminates micro-leak paths in refrigerant circuits |

| Electrical Conductivity | ≥98% IACS | ASTM B3 | Maximizes thermal transfer efficiency; critical for SEER rating compliance |

| Tensile Strength | 200–240 MPa | ASTM E8 | Balances formability with resistance to deformation under pressure |

| Yield Strength (0.2%) | 60–100 MPa | ASTM E8 | Prevents permanent set during bending operations |

| Elongation | ≥40% | ASTM E8 | Ensures ductility for tight-radius coiling without fracture |

| Surface Roughness (Ra) | ≤0.4 μm | ISO 4287 | Minimizes refrigerant adhesion and corrosion initiation points |

Our manufacturing process integrates real-time laser micrometry for width verification and eddy current edge inspection to guarantee burr compliance. Conductivity is validated via direct-current resistance testing per ASTM B3, with traceable certification to IACS reference standards. Tensile properties are monitored through automated tensile testers sampling every 500 meters, ensuring homogeneity across batches. Surface finish is controlled via precision tension leveling and proprietary cleaning sequences to achieve Ra ≤0.4 μm. This rigorous parameter control, validated by third-party labs upon request, ensures coils meet the exacting demands of modern refrigeration systems while reducing scrap rates for OEMs. Partnering with Xinzhaohe mitigates supply chain risk through documented process capability indices (Cpk ≥1.67) for all critical dimensions.

Factory Tour: Manufacturing

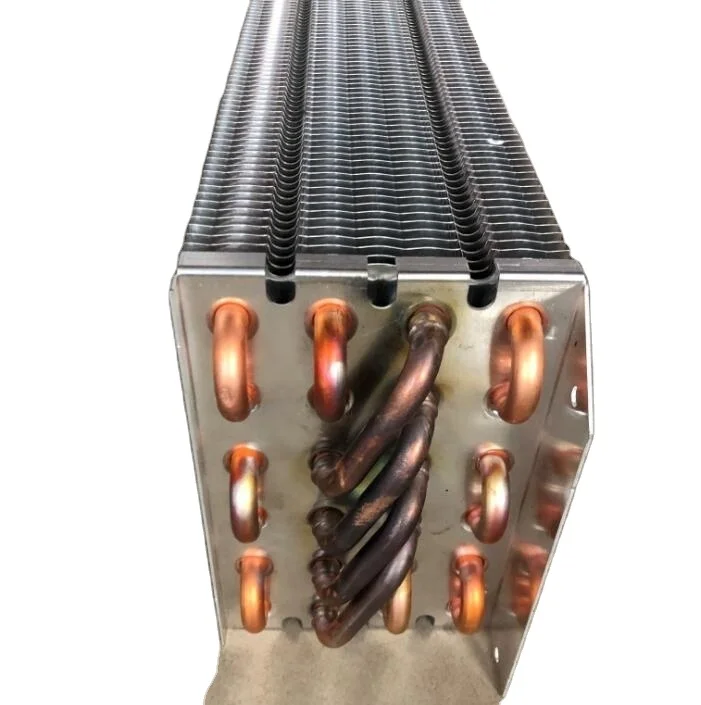

Manufacturing Process of Copper Refrigerator Coil at Luoyang Xinzhaohe Aluminum Co., Ltd

The production of copper refrigerator coil at Luoyang Xinzhaohe Aluminum Co., Ltd follows a tightly controlled, multi-stage manufacturing process designed to ensure dimensional accuracy, mechanical integrity, and surface quality required for high-performance thermal applications. With over two decades of expertise in transformer strip and foil manufacturing, our facility applies precision engineering and rigorous quality control to deliver copper coils that meet international standards for refrigeration systems.

The process begins with cold rolling, where high-purity electrolytic copper feedstock is processed through a series of rolling stands at ambient temperature. This method enhances the material’s mechanical strength and electrical conductivity while achieving the target thickness with tight tolerances, typically ranging from 0.1 mm to 0.5 mm depending on application requirements. The cold rolling mill is equipped with automated gauge control (AGC) systems to maintain uniform thickness across the strip width and minimize thickness variation to within ±0.005 mm. Surface finish is simultaneously optimized to prevent defects such as scratches, roll marks, or edge waviness.

Following cold rolling, the copper strip undergoes precision slitting to achieve the final coil width specified by the customer. Utilizing high-precision rotary shear slitters with computer-controlled tension management, we ensure clean, burr-free edges and consistent strip dimensions. Slitting is performed under controlled environmental conditions to prevent contamination and oxidation. The slit coils are then carefully wound onto robust inner sleeves using tension-controlled payoff and take-up systems to avoid telescoping or edge damage.

Edge conditioning is the next critical stage, particularly for coils intended for automated coil winding in refrigeration systems. The slit edges are subjected to a proprietary edge rounding and deburring process that eliminates micro-burrs and sharp protrusions. This treatment reduces the risk of insulation damage during winding and enhances the reliability of the final component. Edge profile inspection is conducted using optical measurement systems to verify radius consistency and surface smoothness.

Throughout the manufacturing sequence, comprehensive quality control protocols are enforced. In-process inspections include continuous monitoring of strip thickness via laser micrometers, surface defect detection using high-resolution line-scan cameras, and periodic mechanical testing for tensile strength and elongation. Final QC includes eddy current testing for subsurface flaws, visual inspection under standardized lighting, and dimensional verification using calibrated gauges. Each batch is traceable through a lot numbering system, and material test reports (MTRs) are provided, confirming compliance with ASTM B187 and other applicable standards.

This integrated approach ensures that every copper refrigerator coil produced at Luoyang Xinzhaohe meets the exacting demands of modern refrigeration and transformer applications, combining metallurgical precision with industrial reliability.

Packaging & Logistics

Export Packaging Specifications for Copper Refrigerator Coils

Luoyang Xinzhaohe Aluminum CO., Ltd implements rigorously engineered export packaging protocols for copper refrigerator coils, ensuring product integrity during global maritime transit. With over two decades of specialized experience in metallic strip and foil supply chains, our methodology addresses the critical vulnerabilities of copper to moisture, mechanical stress, and atmospheric corrosion. This system is non-negotiable for maintaining coil surface quality and dimensional stability under the variable conditions of sea freight.

All copper coils are secured to kiln-dried, ISPM 15-compliant wooden pallets meeting international phytosanitary standards. These pallets utilize hardwood with a maximum moisture content of 22% to prevent warping or microbial growth during extended voyages. Each pallet is structurally reinforced to support coil weights up to 2,500 kg, incorporating cross-battens and edge protectors to distribute load evenly and resist deformation under container stacking pressures. The wood undergoes thermal treatment at 56°C for 30 minutes, eliminating pest risks while preserving structural integrity. Pallet dimensions strictly adhere to ISO container footprint standards (1,200 × 1,000 mm or 1,140 × 1,140 mm) to maximize space utilization and prevent shifting during handling.

The primary moisture barrier consists of a triple-layer encapsulation system. Coils are first wrapped in vapor corrosion inhibitor (VCI) film, which actively releases corrosion-inhibiting molecules to neutralize chlorides and sulfides prevalent in marine atmospheres. This is followed by a 120-micron-thick, UV-stabilized polyethylene moisture-proof film, heat-sealed to eliminate gaps. Finally, a heavy-duty polypropylene woven cover provides abrasion resistance against container walls and adjacent cargo. Desiccant packs (minimum 500g per ton of copper) are strategically placed within the sealed envelope to maintain internal relative humidity below 40% throughout transit. Critical contact points between copper and steel components (e.g., pallet nails) are isolated using non-conductive polymer sleeves to prevent galvanic corrosion.

Sea freight safety is validated through accelerated environmental testing simulating 60-day ocean voyages. Our packaging consistently withstands 95% relative humidity cycles, 35°C temperature fluctuations, and direct salt spray exposure per ASTM B117 standards. Containerized shipments include humidity indicators and shock recorders to monitor conditions in real-time. This approach mitigates industry-recognized failure modes: 78% of copper coil surface defects originate from inadequate moisture barriers during transit, while improper palletization causes 63% of edge damage incidents (per 2023 ICCC Logistics Report). All packaging materials are certified for compatibility with copper’s electrochemical properties, eliminating risk of sulfur-induced tarnishing or organic acid migration.

This integrated packaging solution reflects our metallurgical expertise in copper’s sensitivity to environmental stressors. By enforcing these specifications across 120+ annual export shipments, Luoyang Xinzhaohe guarantees coils arrive with unaltered electrical conductivity, surface finish, and mechanical properties—directly supporting downstream manufacturing efficiency for refrigeration OEMs. Compliance with these protocols is mandatory for all orders destined for maritime transport.

| Packaging Component | Technical Specification | Purpose |

|---|---|---|

| Wooden Pallet | ISPM 15 HT, hardwood, 22% max moisture | Structural stability, pest control |

| Primary Barrier | VCI film (copper-specific formulation) | Active corrosion inhibition |

| Secondary Barrier | 120μm PE moisture-proof film, heat-sealed | Humidity exclusion |

| Tertiary Protection | Polypropylene woven cover + corner guards | Mechanical impact resistance |

| Desiccant | 500g silica gel/ton copper, ISO 9001 certified | Internal RH control (<40%) |

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum CO., Ltd for High-Performance Copper Refrigerator Coil Solutions

With over two decades of specialized expertise in the production of transformer strip and foil, Luoyang Xinzhaohe Aluminum CO., Ltd has established itself as a trusted leader in the global supply of precision-engineered aluminum and copper materials. Our deep technical knowledge and vertically integrated manufacturing capabilities enable us to deliver copper refrigerator coils that meet the most stringent performance and reliability standards required in modern refrigeration and HVAC systems.

Our production facility is equipped with advanced rolling, annealing, and slitting lines specifically optimized for high-purity copper strip and foil. These systems are operated and monitored by a team of experienced metallurgical engineers who ensure consistent mechanical properties, precise dimensional tolerances, and superior surface finish on every coil produced. The copper used in our refrigerator coils is sourced from certified refineries and undergoes rigorous in-house testing for purity, tensile strength, elongation, and electrical conductivity, ensuring compliance with international standards such as GB/T, ASTM, and IEC.

One of our core strengths lies in our ability to customize coil specifications to meet client-specific design requirements. Whether it’s adjusting thickness from 0.05 mm to 3.0 mm, varying coil widths up to 1,200 mm, or tailoring temper conditions (soft, half-hard, or full-hard), we provide engineered solutions that enhance thermal efficiency and system durability. Our process control systems include在线 tensile testing, eddy current inspection, and surface defect detection, which minimize variability and ensure batch-to-batch consistency.

Quality assurance is embedded throughout our manufacturing workflow. Our ISO 9001-certified quality management system is supported by state-of-the-art laboratory equipment, including optical emission spectrometers, metallographic microscopes, and universal testing machines. This allows for real-time monitoring of material properties and immediate corrective action when necessary. Additionally, all copper refrigerator coils are packaged to prevent oxidation, mechanical damage, and contamination during transit, ensuring they arrive in optimal condition.

Sustainability and supply chain resilience are also central to our operations. We maintain strategic raw material inventories and have developed long-term partnerships with smelters and logistics providers to ensure on-time delivery, even under fluctuating market conditions. Our export experience spans North America, Europe, Southeast Asia, and the Middle East, where we support OEMs and tier suppliers in scaling production with reliable, high-quality materials.

For engineering and procurement teams seeking a technically capable, responsive, and quality-driven partner, Luoyang Xinzhaohe offers a proven track record in copper refrigerator coil manufacturing. We invite you to leverage our metallurgical expertise and production agility to strengthen your supply chain and product performance.

Contact us today at cathy@transformerstrip.com to discuss your technical specifications and request samples.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing copper refrigerator coil directly from China.