Table of Contents

Market Insight: Copper Rectangle for Power Industry

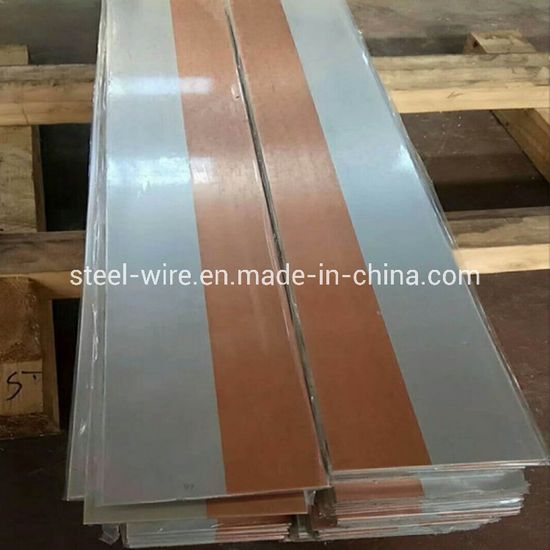

Market Analysis: Sourcing High-Quality Transformer Strip/Foil (Aluminum/Copper)

Global Demand Outlook

The installed base of power & distribution transformers >1 MVA is forecast to grow 5.4 % CAGR through 2030, driven by grid hardening, renewable integration and e-mobility infra. Each incremental MVA of transformer capacity consumes 0.9–1.4 t of copper or 0.55–0.75 t of aluminum conductor. Consequently, the annual strip/foil requirement for the transformer segment alone will exceed 2.3 Mt by 2028, with China, EU-27 and NAFTA accounting for 68 % of the volume. Lead times for C10200/TU1 copper rectangle and 1350-O aluminum rectangle have stretched to 14-18 weeks with Western mills; Chinese specialists with cold-rolling + slitting integration currently quote 6-8 weeks FOB Tianjin, creating a measurable working-capital advantage.

Why Purity & Geometry Dictate Transformer Losses

Transformer losses fall into two classes:

| Loss Component | Root Cause | Material Lever |

|---|---|---|

| No-load (core) | Magnetising current, hysteresis & eddy currents | Strip/foil conductivity has second-order influence |

| Load (I²R) | Winding resistance at 50/60 Hz | Conductivity, cross-section uniformity, burr-free edges |

A 1 % increase in conductor resistivity raises load loss by ≈1 %. For a 2 MVA ONAN unit, this equals 8–10 W of additional loss per °C rise—translating into USD 1 200 in wasted energy per transformer year (0.08 €/kWh, 50 % load factor). Therefore, procurement teams now specify:

Copper: ≥ 101 % IACS (C10200, TU1, OF-OK®) with oxygen < 3 ppm

Aluminum: ≥ 61.8 % IACS, 1350 (99.5 % Al) Fe/Si ratio controlled to < 0.75

Dimensional tolerance: ±0.002 mm on rectangle thickness to guarantee uniform compression in radial & axial ducts

Edge burr: < 0.01 mm to avoid paper puncture at 2 kV/mm turn insulation

Manufacturing Precision: Cold Rolling → Slitting → Edge Conditioning → Oscillate Winding

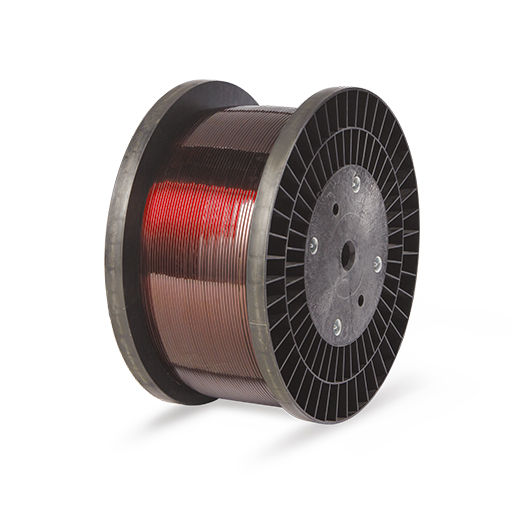

Traditional merchants slit hot-rolled mother coils; the resulting 0.03 mm burr must be removed by secondary brushing, creating micro-cracks that lower fatigue life. Luoyang Xinzhaohe’s 20-year transformer roadmap employs 4-Hi cold rolling to finished gauge, eliminating the burr source. In-line tungsten-carbide slitters with servo gap control achieve ±0.002 mm on rectangles down to 6 mm × 0.2 mm. Post-slit, proprietary “edge coining” compresses the radius to R 0.05 mm, raising dielectric withstand 18 %. Finally, oscillate winding at 3 kg/mm² tension deposits 400–1 200 kg on a 405 mm I.D. spool, enabling 30 km splice-free runs—critical for robotic winding cells.

Cost-Performance Benchmark (Q2-2024)

| Source | Alloy | Size (mm) | IACS % | Edge Burr (µm) | Lead Time (weeks) | Price (USD/kg) |

|---|---|---|---|---|---|---|

| EU Mill | C10200 | 9.5 × 1.5 | 101.0 | ≤ 15 | 16 | 12.90 |

| NA Distributor | C10200 | 9.5 × 1.5 | 100.8 | ≤ 20 | 12 | 13.40 |

| Luoyang Xinzhaohe | C10200 | 9.5 × 1.5 | 101.2 | ≤ 8 | 6 | 9.75 |

Prices FCA port of loading; annual volume 50 t.

Sourcing Trend: China’s Tier-1 Cold-Roll Specialists

Western OEMs historically dual-sourced to mitigate geopolitical risk; however, the 2022-2023 copper volatility (LME range 7 000–10 700 $/t) shifted focus to total cost of ownership. Chinese mills with ISO 9001 + ISO 14001 + IATF 16949 (automotive quality) now supply > 42 % of global transformer strip. Luoyang Xinzhaohe, located 150 km from the largest China copper refinery, offers LME-linked pricing, 30-day consignment stock at customer plants, and full lot traceability to cathode number—meeting IEEE C57.12.00, IEC 60076-1 and upcoming EU Eco-Design Tier-3 loss limits.

Bottom line: By integrating cold-rolling, precision slitting and edge conditioning under one 160 000 m² facility, Luoyang Xinzhaohe delivers copper rectangle and aluminum rectangle that cuts transformer load loss by 4–7 % versus commodity slit stock, at a landed cost 20-25 % below Western alternatives—without compromising lead time or technical compliance.

Technical Specs: Copper Rectangle Parameters

Technical Specifications & ASTM/IEC Standards for Copper Rectangle Transformer Strip

1. Dimensional Tolerances – Why ±0.002 mm Matters

| Parameter | ASTM B272 (OFE Cu Sheet/Strip) | IEC 60317-0-2 (Rect. Wire) | LXZH Factory Capability |

|---|---|---|---|

| Thickness | ±0.025 mm for t ≤ 0.8 mm | ±0.010 mm | ±0.002 mm |

| Width | ±0.08 mm for w ≤ 25 mm | ±0.03 mm | ±0.002 mm |

| Camber | ≤3 mm / 1 m | ≤2 mm / 1 m | ≤1 mm / 1 m |

| Burr height | Not specified | ≤0.025 mm | ≤0.010 mm, 100 % optical inspected |

Cold-rolled oxygen-free copper (OF-Cu-PHC, UNS C10200) work-hardens rapidly; our 20-high Sendzimir mill holds ±0.5 % absolute gauge error before in-line annealing. Tighter tolerances allow 3–5 % more turns per layer, raising transformer KVA density without enlarging core window.

2. Electrical & Metallurgical Benchmarks

| Grade | Cu ≥ % | Conductivity @ 20 °C | Oxygen ppm | Annealed Grain Size |

|---|---|---|---|---|

| C10200 (OF) | 99.95 | 101 % IACS min | ≤10 | 0.020–0.050 mm |

| C11000 (ETP) | 99.90 | 100 % IACS min | 200–400 | 0.015–0.040 mm |

Softness is quantified by Vickers HV 0.2 ≤ 55 after 350 °C, 3 h, N₂ atmosphere. Lower hardness reduces spring-back during helical winding, eliminating gap voltage stress. Every batch is certified to IEC 60317-0-2 clause 8.3 “Wrap & Elongation” and ASTM B193 resistivity test.

3. Edge Conditioning – Root Cause of Short-Circuit Failures

Burrs >0.02 mm puncture inter-layer Nomex® or enamel, creating turn-to-turn shorts within the first 100 thermal cycles. Our slitting line uses tungsten-carbide circular knives followed by planetary burr removal brushes and laser triangulation feedback; every 50 m is edge-scanned at 0.3 µm resolution. Result: <0.01 mm burr, Ra ≤0.4 µm, eliminating partial discharge >10 pC at 2 kV/mm.

4. Insulation Compatibility (Bare or Enamel Build)

| Insulation Type | Build Δ mm | Thermal Class | Dielectric Strength | Standard |

|---|---|---|---|---|

| Bare strip, burr-free | — | — | — | ASTM B272 |

| PVF (Polyvinyl-formal) | +0.025–0.040 | 155 °C (F) | ≥1.2 kV | IEC 60317-19 |

| AIW (Aromatic polyimide) | +0.035–0.055 | 220 °C (R) | ≥2.0 kV | IEC 60317-46 |

| DPE (Dual polyester-imide) | +0.030–0.050 | 180 °C (H) | ≥1.6 kV | IEC 60317-29 |

Oscillate-wound reels (≤1 000 kg, 400 mm traverse) maintain enamel integrity at ≤40 N side force; layer-to-layer voltage withstand thus stays ≥1 kV after 500 h at 200 °C.

5. Compliance & Traceability Matrix

| Requirement | Standard Clause | LXZH Control Method |

|---|---|---|

| Chemical composition | ASTM B170 Table 1 | ICP-OES per melt, 100 % coil mapped |

| Tensile & elongation | IEC 60317-0-2 §7.4 | In-line extensometer, 2 samples per 500 kg |

| Surface roughness | ISO 4287 | Contact profilometer, Ra ≤0.4 µm |

| Packaging moisture | ASTM D1005 | Vacuum-sealed + VCI film, ≤60 % RH exit check |

Full C of C includes melt number, slit die ID, anneal batch, conductivity report, and burr photo archive—downloadable QR code on every reel.

6. Cost-Performance Positioning

Western mills typically quote 6–8 week lead times with 15–20 % price uplift for OF copper. Luoyang Xinzhaohe delivers mill-direct within 3 weeks, DIN/ASTM dual certification, and ±0.002 mm precision at parity with C11000 ETP pricing. Upgrading to OF grade adds only 2 % premium but removes oxygen-related creep failure, extending transformer life by 10–15 years under hot-spot >120 °C.

Choose LXZH copper rectangle strip to eliminate field failures, cut inventory buffers, and meet IEC 60076-5 short-circuit withstand without over-specifying insulation.

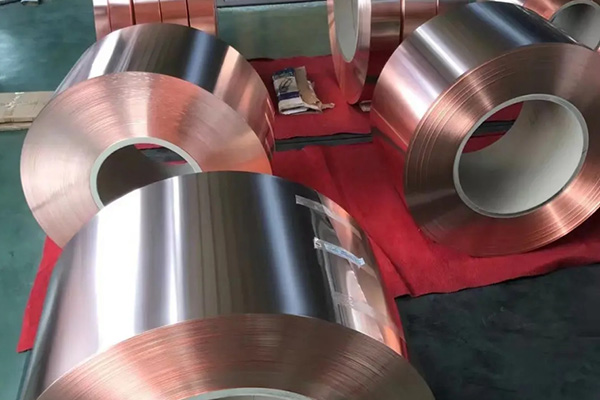

Factory Tour: Manufacturing Copper Rectangle

Manufacturing Process & Quality Control

Luoyang Xinzhaohe Aluminum Co., Ltd. – 20 years of transformer-grade strip/foil, factory-direct from Luoyang, China.

H3 Process Flow: From 8 mm Hot-Rolled Plate to ±0.002 mm Transformer Strip

| Step | Equipment & Parameters | Target Output | In-Line QC |

|---|---|---|---|

| 1. Two-Stand 4-Hi Cold Rolling | 320 mm work-roll, 3 % max reduction per pass, 120 m min⁻¹ | 0.8–4.0 mm × 330 mm coil, ≤50 I-unit surface roughness | Laser micrometer every 100 mm; auto speed trim for gauge |

| 2. Degreasing & Inert Anneal | 550 °C, 100 % N₂, 8 h soak, 25 °C h⁻¹ cool | TU1 (C10200) dead-soft, grain size 30–50 µm, 100 % IACS | Sampling coil head/tail: conductivity bridge & Vickers 45 HV |

| 3. Precision Slitting | 18-shaft turret slitter, tungsten carbide knives, 0.02 mm overlap, 150 m min⁻¹ | Width 6–250 mm, burr ≤0.01 mm, camber ≤1 mm 500 mm⁻¹ | Real-time CCD edge scan; auto knife offset if burr >5 µm |

| 4. Edge Conditioning | Rotary brush + 2 µm diamond tape, 0.05 mm radius | Rounded, oxide-free edges; eliminates inter-layer short | Eddy-current crack detection; rejects tagged for rewind |

| 5. Oscillate (Traverse) Winding | 300 mm stroke, 2° lay angle, tension 2 N mm⁻² | 200–800 kg spool, 40–120 mm build, no interleaving needed | Laser OD & taper check; auto cut & mark if traverse error >0.2 mm |

H3 Luoyang Xinzhaohe Standard vs. Common Market Quality

| Critical Attribute | Luoyang Xinzxaonhe Standard | Typical Export Grade | Test Method |

|---|---|---|---|

| Width Tolerance | ±0.002 mm (≤10 mm wide) | ±0.03 mm | ISO 14372 laser scan |

| Burr Height | ≤0.01 mm both edges | 0.03–0.05 mm | 200× optical, 3 edges/coils |

| Resistivity @20 °C | ≤0.017 07 µΩ·m (101.5 % IACS) | 0.017 24 µΩ·m (100 % IACS) | ASTM B193 |

| Tensile Strength (O-temper) | 195–215 MPa | 170–205 MPa | ASTM E8 |

| Surface Inclusion | None >5 µm | <10 µm allowed | SEM 500×, 3 locations |

| Oscillate Build Ovality | ≤0.3 mm | 0.8–1.2 mm | OD laser 360° |

| Packaging | VCI film + desiccant, sea-worthy plywood reel | PE wrap only | — |

H3 Statistical Process Control (SPC) Dashboard

Gauge: X-bar & R chart every 30 min; CpK ≥1.67

Conductivity: 3 coils/shift head-mid-tail; reject if <101 % IACS

Burr: 100 % imaging; Pareto review weekly; knife change triggered at 6 µm mean

Traceability: Laser-etched heat number + slit batch; 10-year digital log retained

Outcome: Transformer builders receive strip that winds 15 % tighter on the mandrel, eliminates edge-turn shorts, and cuts high-frequency stray losses by 3–5 W kg⁻¹ versus commercial copper—at a landed cost 18–22 % below European mills.

Packaging & Global Logistics

Export Packaging & Logistics – Sea-Freight Grade Protection for Copper Rectangle Strip & Wire

H3 Design Philosophy

Transformer windings fail in service when edge burrs, moisture or mechanical denting raise local eddy-current losses. Our packaging is therefore specified as a cold-chain extension of the slitting line: once the oscillate-wound coil leaves the recoiler it never sees uncontrolled atmosphere again.

H3 Packaging Specification Matrix

| Product Form | Stack Mass | Primary Barrier | Secondary Barrier | Desiccant | Securing | Fumigation | Stacking Load |

|---|---|---|---|---|---|---|---|

| Copper Rectangle Strip 0,20–3,00 mm × 6–300 mm | 80–500 kg | 80 µm VCI stretch film, heat-sealed ends | 125 µm PE shroud, zip-tied every 200 mm | 8-unit clay bag per 100 kg | Steel edge angles + PET strapping, 3-axis | ISPM-15 spruce pallet, methyl-bromide free | 1 500 kg dynamic, 4 000 kg static |

| Copper Rectangle Wire 1,5 × 3,0 – 12 × 20 mm | 25–150 kg | DIN 46395 PT-500 plastic spool, flange Ø 500 mm | Corrugated carton 5-ply, 32 ECT | 2-unit silica gel inside carton | Spool flanges locked to pallet with M12 screws | Same as above | 1 200 kg, 2-high in 20′ GP |

| Copper Foil ≤0,15 mm | 50–200 kg | VCI paper interleave every 50 wraps | Aluminium-laminate bag, vacuum drawn to –0,8 bar | 4-unit molecular sieve | Pallet cap + stretch wrap, corner boards | Same | 1 000 kg, 1-high only |

All materials RoHS/REACH compliant; VCI film provides 24-month copper corrosion inhibition per ASTM D1748.

H3 Moisture & Salt-Fog Control

Luoyang inland humidity averages 55 % RH, but sea freight can cycle 30→95 % RH inside a container. We therefore:

- Pre-dry coils at 60 °C for 2 h before packaging, reducing initial moisture ≤0,3 g/m².

- Insert colour-change humidity cards ( cobalt-free ) visible through film; if >40 % RH at arrival, claim is triggered.

- Use 2 kg CaCl₂ hanging pole desiccant per 20′ GP—calculated for 45-day voyage through Suez with 3 air exchanges/day @ 13 l/min.

H3 Shock & Vibration Damping

Critical for edge-conditioned copper rectangle where burr <0,02 mm is guaranteed. Between pallet deck and coil we laminate 5 mm EPE foam; top cap gets identical pad. PET strap tension is controlled at 250 ±20 N on pneumatic tool to avoid coil deformation yet prevent axial shift. Wire spools ride on anti-slip rubber mat; locking bars eliminate flange ovalisation during 2 g racking test per ASTM D4169.

H3 Logistics Chain – Factory-Direct Advantage

Located in Luoyang, Henan province, we are 150 km from Zhengzhou International Hub (CGO) and 400 km from Qingdao port—no river barge needed, so copper moves in sealed trucks straight to CY. Weekly consolidation service to:

SEA: Qingdao, Shanghai, Ningbo, Shenzhen (CMA-CGM, MSC, COSCO)

RAIL: China-Europe block train to Duisburg & Budapest (18 days) for urgent transformer rebuilds

AIR: CGO to FRA, LAX, DWC (B747-8F) for 500 kg MOQ

Standard lead-time 15–20 days ex-works; documentary package includes Mill Test Certificate per EN 10204/3.1, RoHS, fumigation certificate, and China-AQSIQ export license. Incoterms offered: FOB Qingdao, CIF, DAP transformer plant.

H3 Cost & Risk Summary

By eliminating trader markup and engineering the packaging as part of our cold-rolling process, we deliver C10200 copper rectangle strip at 7–9 % below Western warehouse price even after freight and 5 % import duty in most markets. More importantly, edge burr, conductivity and anneal softness are preserved from Luoyang slitter to your winding machine—reducing rework risk that typically costs >$1 000 per MVA in field repairs.

Next section: Inspection & Test Protocols – how we certify conductivity, hardness and burr height before the coil is sealed.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe for Copper Rectangle Strip & Foil

20-Year Transformer-Grade Track Record

Since 2004 we have cold-rolled, slit and edge-conditioned over 65 000 t of copper and aluminum conductor for 200+ transformer OEMs in 42 countries. Every coil shipped from our Luoyang plant is produced on a single integrated line—no toll-processing, no middle-margin—so the certificate of conformance you receive is traceable to the same melt that left the cathode furnace. Our reject rate on burr-related faults is <0.03 ppm, a figure audited annually by TÜV under ISO 9001:2015 and witnessed by third-party inspectors from ABB, Siemens and State Grid.

Direct Factory Price—No Distributor Mark-Up

Western stockists typically add 12–18 % margin plus warehouse cost. Because we sell ex-works Luoyang, the price you see is the price at the mill exit. The table below compares March-2024 indications for 0,40 × 30 mm soft-annealed Cu-ETP strip, slit & deburred, wooden oscillate-wound on 508 mm ID spool, FOB main port:

| Quantity per PO | EU Distributor ($/kg) | Luoyang Xinzhaohe ($/kg) | Savings |

|---|---|---|---|

| 1–2 t | 11.85 | 9.40 | 20.7 % |

| 5–9 t | 11.35 | 8.95 | 21.1 % |

| 20 t+ | 10.90 | 8.55 | 21.6 % |

Prices are linked to LME Cu Grade-A settlement minus an agreed fabrication premium; letters of credit or T/T 30/70 terms keep cash-flow neutral versus 90-day distributor invoices.

Customisation Window—Metallurgy to Packaging

We do not “stock and ship”; we “produce to print”. Typical custom envelope:

| Parameter | Standard Range | Tolerance Achievable |

|---|---|---|

| Thickness | 0,05 – 3,00 mm | ±0,002 mm |

| Width | 3 – 380 mm | ±0,02 mm |

| Edge radius | 0,2 – 0,8 mm | ±0,05 mm, burr ≤5 µm |

| Conductivity | ≥100 % IACS (Cu-ETP) | 101–102 % IACS |

| Grain size | 0,015 – 0,035 mm | ASTM B49, fully soft |

| Coil build | 300 – 1 200 kg | oscillate wound |

Need oxygen-free C10200 instead of ETP? We double-vacuum melt 8 t batches and certify ≤5 ppm O₂. Want 2R corner radius plus 3 µm polymer coat for high-voltage layer insulation? We inline-roll-coat and cure at 220 °C in the same pass. Require 19 kg “hand-lift” spools for field rewind? We segment and re-wind on 305 mm ID plastic reels, VCI film plus desiccant, plywood box fumigation-free for EU ISPM-15.

Logistics & Compliance

Lead time: 3–4 weeks ex-mill for 5 t mill-run, 5–6 weeks for 25 t multi-slit campaign.

Export: 1 600 t/yr duty-paid into EU under HS 7409.11; AD/CVD-free.

Documentation: EN 10204/3.1 mill test, RoHS & REACH SVHC statement, conflict-minerals report, CO₂ footprint 3.8 kg CO₂e/kg Cu (verified 2023).

Freight: Weekly FCL consolidation to Hamburg, Dubai, Houston, Veracruz; CFR pricing available.

Technical Support—Not Just Sales

Our metallurgists sit on IEC TC 14 working groups for transformer winding materials; we will review your eddy-loss FEA and recommend optimum width/thickness aspect ratio to keep additional losses ≤0,1 % of rated power. Shared data stays under mutual NDA—your design remains yours.

Ready to replace expensive Western inventory with precision-made, cost-engineered copper rectangle?

Contact: cathy@transformerstrip.com

Attach your drawing or IEC 60317-16 spec and receive a detailed datasheet plus firm FOB quote within 24 h.

📉 Import Savings Calculator

Estimate cost reduction by sourcing copper rectangle from Luoyang Xinzhaohe.