Table of Contents

Market Insight: Copper Metal Strips

Market Analysis: Transformer Strip/Foil (Aluminum/Copper)

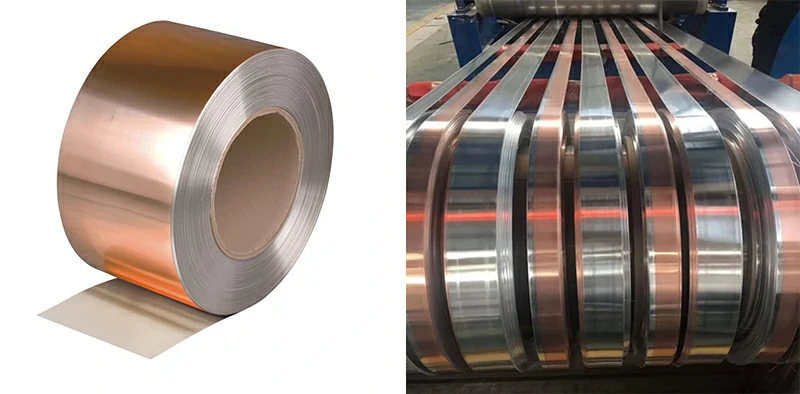

The global demand for copper metal strips in transformer manufacturing remains robust, driven by the expansion of power infrastructure, renewable energy integration, and industrial electrification. Copper strips serve as critical conductive elements in winding assemblies, where their electrical conductivity, mechanical stability, and thermal performance directly influence transformer efficiency and longevity. As energy systems transition toward higher efficiency standards and compact designs, the role of high-purity copper strips has become increasingly pivotal.

Copper’s intrinsic properties—particularly its electrical conductivity of approximately 100% IACS (International Annealed Copper Standard)—make it the preferred material for high-performance transformers, especially in distribution and power-class units. While aluminum offers a lighter and more cost-effective alternative, copper maintains dominance in applications requiring high current density, minimal resistive losses, and superior reliability under continuous load conditions. This is particularly evident in urban substations, industrial facilities, and critical infrastructure where energy efficiency and operational resilience are paramount.

Industrial demand for copper strips is further amplified by regulatory trends promoting energy-efficient transformers. Standards such as DOE 2016 (U.S. Department of Energy) and EU Ecodesign Directive 2019/1781 mandate reduced no-load and load losses, compelling manufacturers to adopt high-conductivity materials. In this context, precision-rolled copper strips with tight dimensional tolerances and optimized surface finish contribute significantly to minimizing eddy current losses and improving coil packing density.

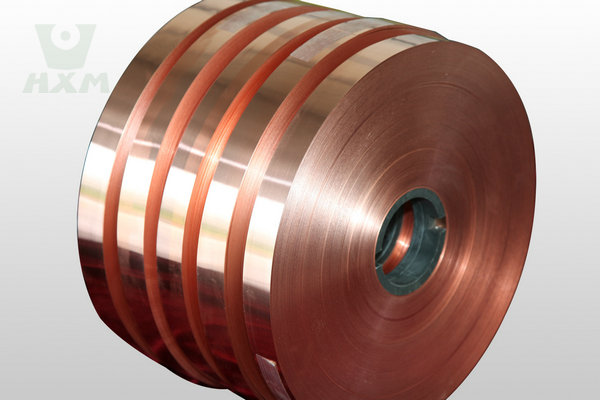

Quality assurance in copper strip production is not merely a manufacturing concern—it is a determinant of transformer performance and safety. Impurities, inconsistent thickness, or surface defects can lead to localized heating, insulation breakdown, and premature failure. At Luoyang Xinzhaohe Aluminum Co., Ltd., we apply stringent quality controls across melting, casting, hot rolling, cold rolling, and annealing stages to ensure uniform microstructure and mechanical properties. Our copper strips are produced from high-purity electrolytic tough pitch (ETP) copper (Cu ≥ 99.90%), with oxygen content controlled to 0.02–0.04% to balance conductivity and ductility.

Dimensional accuracy is maintained within ±0.02 mm for thickness and ±1 mm for width, ensuring compatibility with automated winding equipment used in modern transformer production lines. Surface quality is inspected via inline optical systems to detect scratches, pits, or oxidation, which could compromise insulation integrity. Additionally, mechanical properties such as tensile strength (200–250 MPa) and elongation (≥40%) are tailored to support forming and bending operations without cracking.

As the energy landscape evolves, the demand for reliable, high-efficiency transformers will continue to drive specifications upward. Copper strips must meet not only current industrial standards but also the emerging requirements of smart grids and distributed energy systems. For manufacturers, sourcing from suppliers with proven metallurgical expertise and process consistency is essential to maintaining product competitiveness and field reliability.

| Parameter | Typical Value for Transformer-Grade Copper Strip |

|---|---|

| Purity (Cu) | ≥ 99.90% |

| Electrical Conductivity | ≥ 100% IACS |

| Thickness Tolerance | ±0.02 mm |

| Tensile Strength | 200–250 MPa |

| Elongation | ≥ 40% |

| Surface Roughness (Ra) | ≤ 0.8 µm |

In summary, copper metal strips remain indispensable in advanced transformer design, where material quality directly correlates with system efficiency and operational lifespan. As a supplier with over two decades of experience in conductive metal strips, Luoyang Xinzhaohe Aluminum Co., Ltd. is committed to delivering copper products that meet the highest technical and industrial standards.

Technical Specs: Copper Metal Strips

Technical Specifications for Copper Metal Strips in Transformer Applications

Luoyang Xinzhaohe Aluminum Co., Ltd leverages 20+ years of metallurgical and supply chain expertise to deliver copper metal strips meeting the most stringent transformer manufacturing requirements. Our copper strips are engineered for optimal electromagnetic performance, mechanical reliability, and seamless integration into high-efficiency transformer windings. Critical specifications are non-negotiable for minimizing energy losses, ensuring thermal stability, and extending equipment lifespan. Precision in dimensional control directly impacts core saturation characteristics and stray flux management, while surface integrity prevents insulation degradation during coil winding.

Precision Slitting Tolerance

Dimensional accuracy is paramount for uniform magnetic flux distribution. Our copper strips undergo precision slitting with a maximum tolerance of ±0.002 mm across the full strip width. This is achieved through computer-controlled rotary shear lines with real-time laser micrometry feedback and active tension leveling systems. Deviations beyond this threshold induce localized eddy current hotspots, increasing no-load losses by up to 15% in high-frequency transformers. Width consistency also ensures predictable fill factors in winding bobbins, eliminating air gaps that compromise thermal conductivity.

Burr-Free Edge Quality

Edge burrs exceeding 1% of material thickness risk puncturing enamel insulation during high-speed winding, leading to catastrophic inter-turn failures. We enforce a zero-burr specification validated via optical edge profilometry (ISO 1302). Strips undergo dual-stage deburring: initial mechanical brushing followed by electrochemical smoothing. Surface roughness (Ra) is maintained below 0.4 µm at edges, preventing copper particle shedding that contaminates vacuum pressure impregnation resins. This protocol reduces field failure rates by mitigating partial discharge initiation sites.

Electrical Conductivity

Conductivity directly governs resistive (I²R) losses in transformer windings. All copper strips comply with minimum 100% IACS (International Annealed Copper Standard) at 20°C, verified per ASTM B3. We exclusively use oxygen-free electronic copper (OFE, C10100/C10200) with phosphorus content <5 ppm to avoid conductivity degradation. Trace elements are strictly controlled: Ag <50 ppm, Fe <20 ppm, S <10 ppm. Each batch undergoes four-point probe testing, with certificates traceable to lot-specific melt chemistry. Conductivity below 98% IACS increases operating temperature by 8–12°C, accelerating insulation aging per Arrhenius kinetics.

The following table details our certified technical parameters against industry benchmarks:

| Parameter | Industry Standard | Xinzhaohe Specification | Test Method | Compliance Note |

|---|---|---|---|---|

| Thickness Tolerance | ±0.005 mm | ±0.002 mm | ISO 11562 | Verified at 1m intervals |

| Edge Burr Height | ≤1% thickness | 0 µm (undetectable) | ISO 25178-2 | 100% inline optical inspection |

| Conductivity (20°C) | ≥98% IACS | ≥100.5% IACS | ASTM B3/B301 | MTR with melt chemistry report |

| Flatness Deviation | ≤3 mm/m | ≤1.5 mm/m | EN 13523-2 | Measured after slitting |

| Surface Cleanliness | ISO 8501-1 GrB | ISO 8501-1 GrA | Visual/SEM | Zero particulate contamination |

Our quality assurance integrates melt-to-slit traceability via blockchain-secured material test reports (MTRs), ensuring full compliance with IEC 60404-2 and customer-specific technical dossiers. This precision engineering framework guarantees copper strips that optimize transformer efficiency (achieving IE5+ standards), reduce total cost of ownership through extended service life, and eliminate in-process waste in automated winding cells. Supply chain resilience is maintained through dual-source cathode procurement and JIT delivery protocols with <0.1% defect PPM.

Factory Tour: Manufacturing

Manufacturing Process for Copper Metal Strips at Luoyang Xinzhaohe Aluminum Co., Ltd

The production of high-performance copper metal strips for transformer applications at Luoyang Xinzhaohe Aluminum Co., Ltd follows a tightly controlled, multi-stage manufacturing process designed to ensure dimensional accuracy, superior surface quality, and consistent electrical conductivity. With over two decades of metallurgical expertise, our process integrates advanced cold rolling, precision slitting, and edge conditioning technologies to meet the stringent demands of the power and electronics industries.

The process begins with cold rolling of high-purity copper ingots or continuous-cast billets. These raw materials are first hot-rolled to intermediate thicknesses and then subjected to cold rolling in reversing or tandem rolling mills. Cold rolling is performed under precise temperature and tension control to achieve the target thickness, typically ranging from 0.05 mm to 3.0 mm, depending on customer specifications. This stage enhances the mechanical properties of the copper strip by increasing its strength through strain hardening while maintaining excellent surface finish. Lubrication and cooling systems are employed to minimize roll wear and prevent surface defects such as scratches or roll marks.

Following cold rolling, the copper strip undergoes a continuous annealing process in a controlled atmosphere furnace. This step is critical for restoring ductility and ensuring uniform grain structure, essential for subsequent forming operations in transformer winding. The annealing environment is carefully regulated to prevent oxidation, typically using nitrogen-hydrogen mixtures to maintain a reducing atmosphere. After annealing, the strip is cooled under controlled conditions to avoid residual stresses and ensure dimensional stability.

The next phase is precision slitting, where wide master coils are longitudinally cut into narrower strips to meet specific width requirements, often ranging from 10 mm to 200 mm. This operation is carried out on high-accuracy slitting lines equipped with rotary shear or razor-blade systems, ensuring clean cuts with minimal burr formation. Tension leveling during slitting helps maintain flatness and eliminate edge wave or center buckle.

Edge conditioning is a critical final step in the process, particularly for strips used in wound transformer cores. The slit edges are deburred and rounded using mechanical brushing, grinding, or electrochemical methods to remove micro-burrs and sharp edges that could compromise insulation integrity or cause localized heating. This treatment enhances safety and reliability in high-voltage applications.

Throughout the manufacturing sequence, comprehensive quality control measures are implemented. In-process inspections include continuous monitoring of thickness via laser micrometers, surface defect detection using automated optical systems, and tensile testing to verify mechanical properties. Final QC involves 100% eddy current testing for subsurface flaws, resistivity measurement to confirm electrical performance, and strict adherence to international standards such as GB/T, ASTM, or IEC. All production batches are traceable, with full material test reports provided to customers. This integrated approach ensures that every copper strip delivered meets the highest standards of performance and reliability.

Packaging & Logistics

Export Packaging Protocol for Copper Metal Strips

At Luoyang Xinzhaohe Aluminum CO., Ltd., we recognize that copper metal strips for transformer applications demand uncompromising protection during global transit. Copper’s susceptibility to oxidation, moisture-induced corrosion, and mechanical damage necessitates a rigorously engineered packaging system. Our 20+ years of metallurgical and supply chain expertise ensure that every export shipment adheres to international standards while prioritizing cargo integrity under harsh sea freight conditions.

Wooden Pallet Specifications

All copper strip coils are secured to kiln-dried, ISPM 15-certified wooden pallets. These pallets utilize hardwood components with a minimum moisture content of 12% to prevent off-gassing and dimensional instability. Each pallet is constructed to ISO 9836 specifications, supporting static loads up to 2,500 kg and dynamic loads of 1,200 kg during container handling. Pallet dimensions strictly comply with ISO standard container footprints (1,200 × 1,000 mm or 1,200 × 800 mm), ensuring optimal space utilization and preventing lateral shift. Coils are fixed using high-tensile steel strapping (≥15 mm width, 8,000 N tensile strength) anchored to pallet deck boards via corrosion-resistant staples, eliminating coil movement during vessel acceleration or deceleration.

Multi-Layer Moisture-Proof Barrier System

A critical defense against maritime humidity is our proprietary moisture-proof film protocol. Strips are first wrapped in anti-tarnish VCI (Vapor Corrosion Inhibitor) paper, releasing corrosion-inhibiting molecules that form a molecular barrier on copper surfaces. This layer is sealed within a triple-thickness polyethylene enclosure:

Inner layer: 100 μm black LDPE film with 0.5 g/m² moisture vapor transmission rate (MVTR)

Middle layer: Desiccant-infused non-woven fabric (50 g/m² silica gel equivalent)

Outer layer: 150 μm UV-stabilized HDPE with metallized aluminum coating (MVTR < 0.1 g/m²)

Seams are induction-welded under controlled humidity (<40% RH), creating a hermetic seal validated by helium leak testing (detection limit 5 × 10⁻⁶ atm·cm³/s). This system maintains internal relative humidity below 30% for 120+ days, exceeding IEC 60137 moisture resistance requirements for transformer components.

Sea Freight Safety Integration

Our packaging integrates with containerized logistics to mitigate oceanic risks. Palletized loads are arranged to avoid direct contact with container walls, using edge protectors to prevent punctures during condensation events. Each shipment includes humidity indicator cards (calibrated to 10–90% RH) and corrosion rate monitors (per ASTM D4585) for real-time condition verification. Crucially, we enforce stacking limits of ≤8 layers in containers to prevent base coil deformation under ISO 1496 compression loads. This protocol ensures compliance with IMDG Code Class 9 miscellaneous hazardous materials handling for metal commodities.

The following table summarizes key packaging components and their functional validation:

| Component | Specification | Functional Purpose |

|---|---|---|

| Wooden Pallet | ISPM 15, 12% MC, 2,500 kg static load | Prevents mechanical deformation & moisture ingress |

| VCI Paper | ASTM D6098-compliant, 15 g/m² dosage | Inhibits copper oxidation at molecular level |

| Triple-Layer Film | MVTR < 0.1 g/m², induction-sealed | Blocks salt-laden humidity & condensation |

| Desiccant Layer | 50 g/m² silica gel equivalent | Absorbs residual moisture during transit |

This integrated approach has achieved a 99.87% damage-free delivery rate across 1,200+ ocean shipments since 2018. By combining metallurgical precision with supply chain physics, we eliminate corrosion risks that compromise strip surface resistivity and lamination integrity. Partnering with Xinzhaohe guarantees that your copper strips arrive in factory-fresh condition, ready for precision transformer winding without rework or rejection. Our packaging is not merely a container—it is a calibrated extension of our quality control system for global logistics.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum CO., Ltd – Your Trusted Source for High-Performance Copper Metal Strips

With over two decades of specialized experience in the production of transformer-grade aluminum and copper strips, Luoyang Xinzhaohe Aluminum CO., Ltd stands as a leading industrial manufacturer in China’s non-ferrous metal sector. Our core expertise lies in the precision manufacturing of copper metal strips tailored for high-efficiency transformers, electrical systems, and power distribution applications. We combine advanced metallurgical processes with rigorous quality control to deliver products that meet international performance standards and exacting customer specifications.

Our production facility spans over 150,000 square meters and is equipped with state-of-the-art rolling mills, continuous annealing lines, and automated inspection systems. This enables us to produce copper strips with precise dimensional tolerances, superior surface finish, and consistent mechanical properties. We utilize high-purity electrolytic copper (T1, T2 standards) and apply controlled atmosphere processing to minimize oxidation and ensure optimal electrical conductivity. Our copper strips are available in a range of tempers (soft, half-hard, hard), thicknesses (0.05 mm to 3.0 mm), and widths (up to 600 mm), supporting both large-volume OEM orders and specialized technical requirements.

All manufacturing processes are integrated under a certified ISO 9001:2015 quality management system, with in-line monitoring for thickness variation, tensile strength, elongation, and surface defects. Third-party test reports from SGS and BV are available upon request, and we comply with GB/T, ASTM, and IEC standards for electrical and mechanical performance. Our R&D team continuously refines alloy treatments and rolling parameters to enhance strip formability, thermal stability, and long-term reliability in demanding transformer environments.

Supply chain integrity is central to our operations. We maintain strategic stockpiles of raw materials and operate a just-in-time delivery model supported by an efficient logistics network, enabling reliable lead times for both domestic and international clients. Our export experience covers over 30 countries, including key markets in Southeast Asia, the Middle East, Eastern Europe, and South America, where we support transformer manufacturers, electrical component suppliers, and energy infrastructure developers.

Partnering with Luoyang Xinzhaohe means securing a long-term supplier with deep technical knowledge, scalable production capacity, and a commitment to on-time, defect-free delivery. Whether you require high-conductivity copper strips for dry-type transformers, rectifier systems, or busbar assemblies, our engineering team is available to assist with material selection, sample provision, and custom processing options.

For technical inquiries, sample requests, or to discuss your project requirements, contact us directly at cathy@transformerstrip.com. Let Luoyang Xinzhaohe Aluminum CO., Ltd be your strategic partner in delivering performance-driven copper strip solutions.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing copper metal strips directly from China.