Table of Contents

Market Insight: Copper Foil Shielding

Market Analysis: Transformer Strip/Foil (Aluminum/Copper) – Copper Foil Shielding Demand

Industrial demand for copper foil shielding within power and distribution transformers is experiencing sustained growth, driven primarily by global grid modernization, renewable energy integration, and the proliferation of high-voltage direct current (HVDC) transmission systems. Copper foil serves a critical function as electrostatic shielding between windings and core structures, mitigating stray flux, controlling electric field distribution, and preventing partial discharge that can lead to catastrophic insulation failure. The transition towards higher efficiency transformers (e.g., DOE Level IV, IE4), compact designs for urban substations, and ultra-high-voltage (UHV) applications exceeding 1000 kV places unprecedented demands on shielding performance. These trends necessitate copper foils with exceptional consistency in critical parameters, directly influencing transformer reliability and lifespan. Demand is particularly acute in regions with aggressive grid upgrade programs and expanding data center infrastructure requiring highly stable power.

The paramount importance of copper foil shielding quality cannot be overstated, as it directly impacts transformer integrity and operational safety. Substandard foil introduces multiple failure vectors. Surface imperfections, such as excessive roughness (Ra > 0.2 μm) or micro-protrusions, create localized high-field points that initiate partial discharge, progressively degrading solid insulation like pressboard or Nomex. Inadequate mechanical properties, specifically insufficient tensile strength or elongation, lead to foil tearing during winding processes or under electromagnetic forces during short-circuit events, compromising shield continuity. Dimensional instability, including thickness variation exceeding ±0.005 mm or poor flatness, results in air gaps within the insulation system, fostering partial discharge and thermal hotspots. Crucially, impurities (e.g., sulfur compounds > 5 ppm, oxygen content > 200 ppm) or inadequate surface cleanliness promote electrochemical corrosion at the foil-oil interface, generating conductive particles and acidic byproducts that accelerate insulation aging and potentially cause dielectric breakdown. Industry-observed failure modes consistently trace back to shielding defects originating from non-conforming foil.

Stringent international standards, including IEC 60286 (formerly IEC 60137) for bushings and transformer components, ASTM B301 for hard-drawn copper wire (relevant for material purity and mechanical benchmarks), and specific OEM technical specifications, define the exacting requirements for transformer shielding foil. Key quality metrics encompass:

| Parameter | Critical Threshold | Impact of Non-Conformance |

|---|---|---|

| Purity (Cu+Ag) | ≥ 99.99% (4N) | Increased resistivity, corrosion risk |

| Thickness Tolerance | ±0.003 mm to ±0.005 mm | Field distortion, partial discharge |

| Surface Roughness | Ra ≤ 0.15 μm | Partial discharge initiation |

| Tensile Strength | 220 – 280 MPa | Foil tearing during handling/winding |

| Elongation | ≥ 3% | Reduced ductility, cracking under stress |

| Edge Quality | Burr-free, smooth | Insulation puncture risk |

Procurement based solely on lowest cost ignores the profound lifecycle cost implications. A transformer failure due to shielding-induced insulation breakdown entails not only the significant replacement cost of the unit (often exceeding $1 million for large power transformers) but also extended grid downtime, lost revenue, and potential safety hazards. Investing in copper foil from suppliers with rigorous process control, certified metallurgical testing (including IACS conductivity verification, surface profilometry, and chemical analysis), and deep transformer application expertise is a fundamental risk mitigation strategy. Luoyang Xinzhaohe Aluminum Co., Ltd leverages its two decades of precision strip manufacturing experience to deliver copper shielding foil meeting the most demanding transformer OEM specifications, ensuring the dielectric integrity essential for grid stability and asset longevity. Quality in this critical component is non-negotiable for operational reliability.

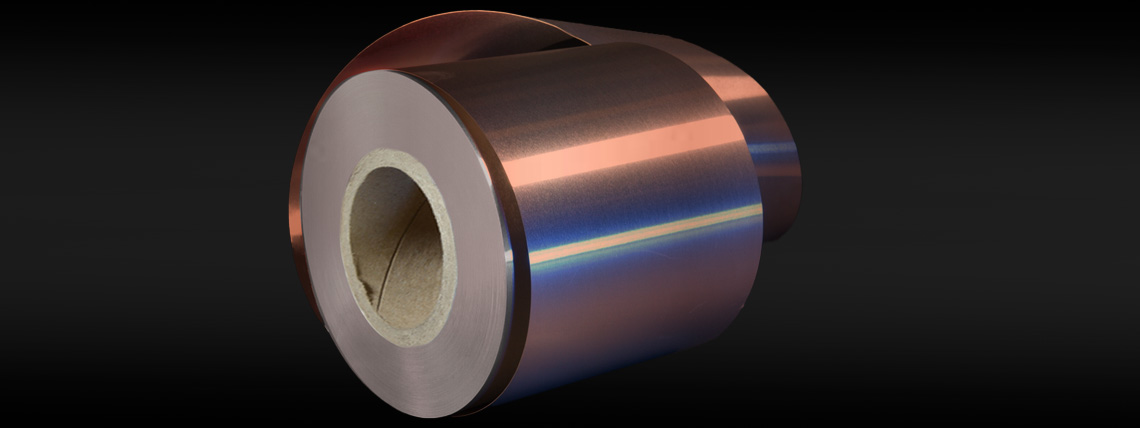

Technical Specs: Copper Foil Shielding

Technical Specifications for Copper Foil Shielding

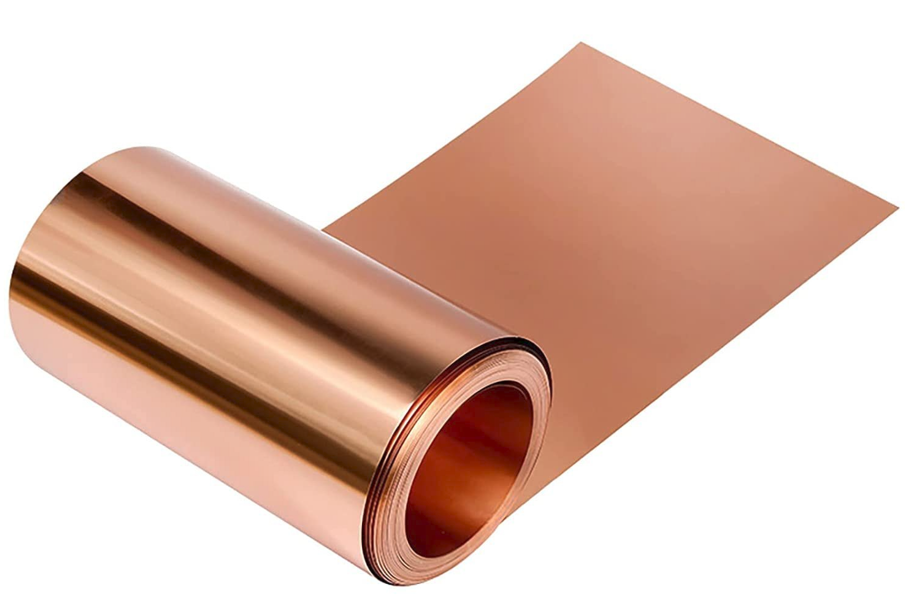

Luoyang Xinzhaohe Aluminum Co., Ltd. delivers high-performance copper foil shielding solutions engineered for critical electromagnetic interference (EMI) suppression in power transformers, high-frequency inductors, and sensitive electronic systems. With over two decades of metallurgical expertise and precision manufacturing, our copper foils meet stringent industrial requirements for dimensional accuracy, edge quality, and electrical performance. The following technical specifications define the core parameters essential for reliable integration into transformer strip and foil assemblies.

Copper foil shielding must exhibit exceptional dimensional consistency to ensure uniform winding tension and dielectric integrity during coil fabrication. Our precision slitting process achieves a width tolerance of ±0.002 mm, ensuring tight registration in multi-layer winding configurations. This level of control minimizes edge misalignment and reduces the risk of inter-turn shorting or localized field concentration. The slit edges are processed through a proprietary deburring system that eliminates micro-burrs and edge irregularities, resulting in a burr-free profile as verified by optical profilometry and scanning electron microscopy (SEM). Surface roughness (Ra) is maintained below 0.45 µm to support smooth layer-to-layer contact and reduce partial discharge risks.

Electrical conductivity is a critical performance metric for shielding efficiency. Our electrolytic tough pitch (ETP) copper foils achieve a minimum conductivity of 98% IACS (International Annealed Copper Standard) at 20°C, measured in accordance with ASTM B3 and ASTM E1019. This high conductivity ensures low resistive losses and effective eddy current dissipation, enhancing overall transformer efficiency. Foils are supplied in temper conditions ranging from soft (annealed) to 1/4 hard, allowing customization based on formability and mechanical stability requirements.

All copper foils undergo continuous cleaning and passivation to remove residual oxides and contaminants, ensuring optimal adhesion in varnish-impregnated windings. The foils are free from laminations, pinholes, and surface defects, as confirmed by 100% inline optical inspection. Thickness ranges from 0.03 mm to 0.20 mm, with standard widths from 20 mm to 300 mm, customizable per client specifications. Tensile strength ranges between 200–250 MPa for annealed foils and up to 320 MPa for work-hardened variants, supporting robust handling during automated winding processes.

The table below summarizes key technical parameters for our copper foil shielding products.

| Parameter | Specification | Test Standard |

|---|---|---|

| Material | ETP Copper (C11000) | ASTM B152 |

| Thickness Range | 0.03 – 0.20 mm | ASTM E29 |

| Width Tolerance | ±0.002 mm | ISO 9001 |

| Edge Quality | Burr-free, no micro-tearing | SEM Analysis (1000x) |

| Surface Roughness (Ra) | ≤ 0.45 µm | ISO 4287 |

| Electrical Conductivity | ≥ 98% IACS | ASTM B3, ASTM E1019 |

| Temper Options | Soft (Annealed), 1/4 Hard | ASTM B9 |

| Tensile Strength | 200 – 320 MPa (varies by temper) | ASTM E8 |

| Defect Inspection | 100% Optical Inspection | In-house Protocol |

| Packaging | Anti-corrosion film, rigid core, sealed carton | Customizable per shipment |

These specifications reflect Luoyang Xinzhaohe’s commitment to delivering copper foil shielding that meets the highest standards of electrical and mechanical performance in demanding power and electronic applications.

Factory Tour: Manufacturing

Manufacturing Process for Copper Foil Shielding

Luoyang Xinzhaohe Aluminum Co., Ltd leverages 20+ years of metallurgical expertise to produce precision copper foil shielding for transformer applications. Our process begins with high-purity electrolytic tough pitch (ETP) copper cathodes, melted and cast into ingots meeting ASTM B115 standards. These undergo homogenization annealing to eliminate segregation before hot rolling to intermediate thicknesses. The core cold rolling phase employs computer-controlled 6-high mills with work rolls ground to sub-micron tolerances. Reduction ratios are precisely managed between 70–95% per pass, with interpass annealing in oxygen-free nitrogen atmospheres to maintain ductility and prevent surface oxidation. Critical parameters include roll gap accuracy (±2μm), tension control (±0.5%), and emulsion coolant systems maintaining 45–55°C temperatures. This achieves the target foil thickness (0.05–0.25mm) with surface roughness Ra ≤0.3μm and residual stress below 15 MPa, ensuring dimensional stability during transformer winding.

Precision slitting follows cold rolling under strict environmental controls (22±1°C, 50±5% RH). Foils are processed through servo-driven turret slitters with carbide-tipped circular knives and backup rolls. Width tolerances are held to ±0.05mm across coils up to 1,250mm wide, verified via non-contact laser micrometers at 10m intervals. Tension is dynamically adjusted using load cells to prevent edge waviness or center buckling, maintaining flatness deviation under 0.5mm/m. Slit edges are continuously monitored via machine vision systems detecting micro-tears or irregularities exceeding 10μm.

Edge conditioning is critical for transformer reliability, as burrs cause dielectric breakdown. We utilize dual-stage edge grinding with diamond-coated abrasive belts operating at 15–25m/s. The first pass removes 5–10μm material to eliminate knife marks, followed by a polishing pass at 5–10m/s achieving edge radii of 3–8μm. All foils undergo 100% edge inspection via optical profilometry, rejecting any segment with burrs >5μm or edge irregularities exceeding 3% of foil thickness. This process ensures smooth edges that prevent insulation damage during coil layering.

Rigorous quality control is embedded at each stage. In-process checks include:

| QC Parameter | Test Method | Frequency | Acceptance Criteria |

|---|---|---|---|

| Thickness Uniformity | Beta-gauge + Micrometer | Continuous + 1/m² | ±2% of nominal thickness |

| Tensile Properties | ASTM E8/E8M | Per melt batch | Yield: 60–90 MPa; Elongation: ≥3% |

| Surface Defects | Visual + Eddy Current | 100% | No pits >20μm depth |

| Edge Quality | Optical Profilometry | 100% | Burr height ≤5μm |

Final coils undergo vacuum packaging with desiccants to prevent oxidation during transit. Our integrated manufacturing approach—combining cold rolling precision, slit-width repeatability, and burr-free edges—delivers copper foil shielding that meets IEC 60404-6 and IEEE C57.12.00 standards for transformer electromagnetic compatibility and thermal performance.

Packaging & Logistics

Export Packaging for Copper Foil Shielding – Ensuring Integrity in Global Shipments

At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of specialized experience in the production and export of transformer strips and foils, we recognize that effective packaging is not merely a logistical necessity but a critical component in preserving product integrity during international transit. For copper foil shielding—material that demands high electrical performance and surface purity—packaging must address mechanical protection, environmental exposure, and long-term stability, particularly under sea freight conditions.

All copper foil shielding products designated for export are systematically prepared using industrial-grade wooden pallets constructed from kiln-dried, ISPM 15-compliant hardwood. These pallets are engineered to meet international phytosanitary standards, ensuring unrestricted customs clearance across global markets. The structural rigidity of the pallets supports uniform load distribution, minimizing the risk of deformation during handling, stacking, and containerized transport. Each coil is securely fastened to the pallet using high-tensile steel strapping, anchored at multiple stress points to prevent lateral or vertical displacement throughout the shipping cycle.

Immediately following palletization, the entire assembly is wrapped in multi-layer moisture-proof composite film. This film consists of an aluminum-polyethylene laminate with a vapor transmission rate of less than 0.5 g/m²·day, effectively creating a hermetic barrier against humidity, salt-laden air, and condensation—common hazards in maritime logistics. The wrapping process is executed under controlled ambient conditions to eliminate trapped moisture, and sealed seams are thermally bonded to ensure continuity. Additionally, desiccant packs are strategically placed beneath the outer wrap to absorb any residual atmospheric moisture, further enhancing protection during extended voyages.

To reinforce anti-corrosion performance, copper foils are coated with a temporary protective oil layer prior to winding, compatible with downstream customer processing. This layer, combined with the moisture barrier, mitigates oxidation and maintains surface quality over shipment durations that may exceed 30 days. All packaged units are labeled with UV-resistant, tamper-evident markings indicating product specifications, batch numbers, handling instructions, and orientation indicators to guide proper storage.

Our packaging protocol aligns with ISO 2230 and IECQ QC 080000 standards, reflecting our commitment to supply chain reliability. It has been validated through accelerated aging tests simulating tropical and marine environments, confirming performance under 95% relative humidity at 40°C over 60-day exposure periods. This validation ensures that copper foil shielding arrives at destination facilities with unchanged dimensional tolerances, surface finish, and electrical characteristics.

For our international partners, this comprehensive packaging system translates into reduced claims, minimized rework, and confidence in material readiness upon receipt. At Luoyang Xinzhaohe, we view packaging not as a final step, but as an extension of our metallurgical precision—ensuring that every meter of copper foil shielding performs as engineered, from production line to end application.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe: Your Strategic Source for Precision Copper Foil Shielding

Luoyang Xinzhaohe Aluminum Co., Ltd leverages over two decades of specialized metallurgical expertise and integrated manufacturing to deliver mission-critical copper foil shielding solutions for demanding transformer and electromagnetic applications. Our facility represents a vertically controlled production ecosystem, uniquely positioned to ensure material consistency, performance integrity, and supply chain resilience for global industrial partners. We transcend standard supplier relationships by embedding deep technical collaboration into every engagement.

Our production infrastructure centers on advanced rolling and annealing technologies dedicated exclusively to high-purity copper and aluminum transformer strips and foils. The copper foil line operates under stringent atmospheric controls, utilizing precision 4-high and 6-high rolling mills capable of achieving final thicknesses down to 0.006 mm with exceptional flatness and edge uniformity. Continuous bright annealing furnaces, meticulously calibrated for oxygen-free environments, guarantee optimal electrical conductivity (≥100% IACS) and controlled tensile strength tailored to specific shielding requirements. This granular process control directly translates to superior electromagnetic interference (EMI) attenuation and thermal stability in end-use components. Key dimensional capabilities are summarized below.

| Parameter | Standard Range | Precision Capability |

|---|---|---|

| Thickness | 0.010 mm – 0.200 mm | Down to 0.006 mm |

| Width | 50 mm – 1200 mm | ±0.1 mm tolerance |

| Tensile Strength | 150 – 350 MPa | ±3 MPa control |

| Elongation | 3% – 15% | ±1% control |

| Surface Roughness | Ra ≤ 0.4 µm | Ra ≤ 0.2 µm (opt.) |

Metallurgical excellence is non-negotiable. Our in-house laboratory conducts rigorous incoming cathode copper analysis (99.99%+ Cu min) and implements real-time process monitoring via XRF, tensile testers, microhardness probes, and surface profilometers. Every production batch undergoes comprehensive electrical resistivity validation and interfacial adhesion testing per ASTM B244 and IEC 60404-1 standards. This systematic approach eliminates performance variability, ensuring shielding foils meet exacting OEM specifications for high-frequency transformer and inductor assemblies.

Supply chain robustness is engineered into our operational model. We maintain strategic raw material inventories and operate dual production lines to mitigate disruption risks, consistently achieving 98.5% on-time delivery globally. Our logistics network integrates seamlessly with major maritime and rail hubs, offering optimized containerized shipping solutions with documented lead times. Crucially, our engineering team collaborates directly with client R&D departments to develop custom alloy tempers or surface treatments addressing unique thermal management or solderability challenges, transforming sourcing into a value-engineering partnership.

For procurement leaders requiring copper foil shielding that guarantees electromagnetic performance and supply continuity, Luoyang Xinzhaohe provides the technical authority and operational maturity demanded by Tier-1 industrial manufacturers. Contact our Technical Sourcing Manager Cathy directly to discuss your specific material requirements and receive a precision capability assessment. Initiate a supply chain solution built on metallurgical certainty: cathy@transformerstrip.com.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing copper foil shielding directly from China.