Table of Contents

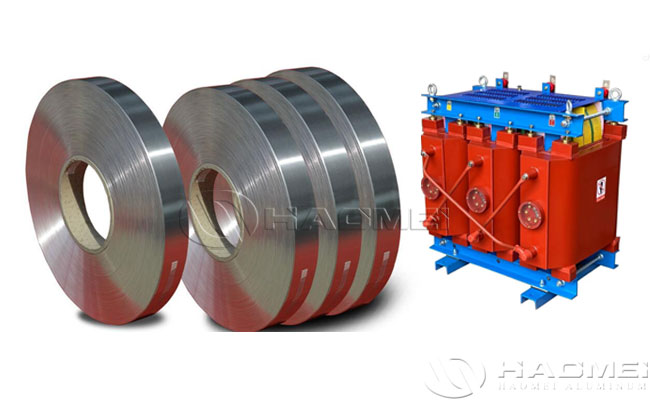

Market Insight: Copper Foil For Transformer in Power Industry

Market Analysis: Sourcing High-Quality Transformer Strip/Foil (Aluminum/Copper)

Industrial Demand & Quality Imperatives

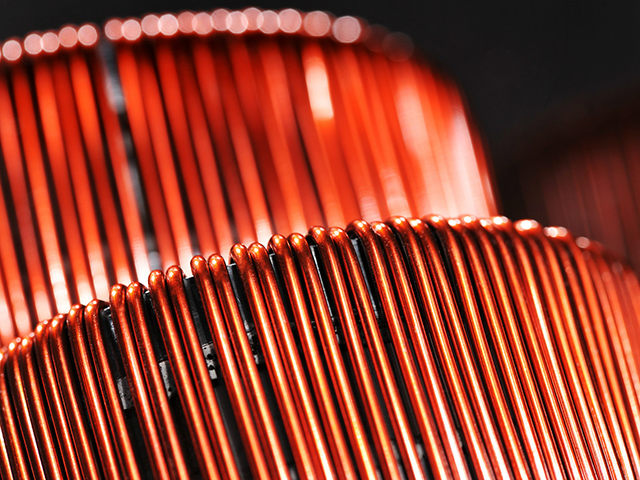

The global transformer market is projected to grow at 6.2% CAGR through 2030, driven by renewable energy infrastructure and grid modernization initiatives. High-efficiency transformers are critical for reducing carbon emissions in power grids, making material quality a strategic priority for utilities and renewable energy projects. Copper foil’s role in winding efficiency is pivotal—each 0.1% increase in conductivity reduces energy losses by ~0.5% in high-voltage transformers. Material defects like inclusions or inconsistent thickness can cause hotspots, leading to insulation breakdown and catastrophic failures. Compliance with IEC 60076-1 and IEEE C57.12.00 standards is mandatory for safety and performance.

Critical Material Properties for Transformer Efficiency

Key specifications directly impact transformer performance:

Purity: ≥99.95% Cu minimizes resistive losses and prevents oxidation-related degradation.

Conductivity: 101-102% IACS reduces I²R losses, improving efficiency by up to 0.8%.

Thickness Tolerance: ±0.01mm ensures precise layer stacking, reducing eddy current losses caused by uneven current distribution.

Surface Roughness: Ra ≤0.3µm enhances epoxy adhesion in dry-type transformers, preventing delamination and maintaining dielectric strength.

Tensile Strength: 220-280 MPa balances flexibility for winding processes and resistance to mechanical stress during operation.

Luoyang Xinzhaohe’s Supply Chain Advantage

As a 20+ year manufacturer, Luoyang Xinzhaohe Aluminum CO., Ltd. delivers factory-direct copper foil with superior cost-performance. Our 100,000+ sqm facility in Luoyang features continuous casting and precision rolling lines, ensuring consistent quality from raw material to finished product. Our in-house metallurgical lab validates every batch against ASTM B170 standards, ensuring traceability from raw copper to finished foil. All batches undergo 100% ultrasonic testing and spectral analysis per ISO 9001:2015.

| Parameter | Industry Standard | Luoyang Xinzhaohe Specification | Advantage |

|---|---|---|---|

| Purity | ≥99.90% Cu | ≥99.95% Cu | Higher conductivity, lower losses |

| Conductivity | ≥100% IACS | 101-102% IACS | Enhanced efficiency |

| Thickness Tolerance | ±0.015mm | ±0.01mm | Precision winding, reduced scrap |

| Surface Roughness | Ra ≤0.5µm | Ra ≤0.3µm | Better insulation adhesion |

| Tensile Strength | 200-300 MPa | 220-280 MPa | Improved handling during manufacturing |

We supply to 30+ countries, including Tier-1 OEMs in Europe and North America, with lead times 20% faster than industry average. Custom thicknesses from 0.05mm to 0.5mm are available with 48-hour prototyping. By eliminating distributor markups, we offer 15-25% cost savings while exceeding global brand performance. Our integrated supply chain ensures on-time delivery for projects of all scales, making us a strategic partner for transformer manufacturers seeking reliable, high-value materials.

Technical Specs: Copper Foil For Transformer Parameters

Technical Specifications & Standards for Copper Foil Transformer Applications

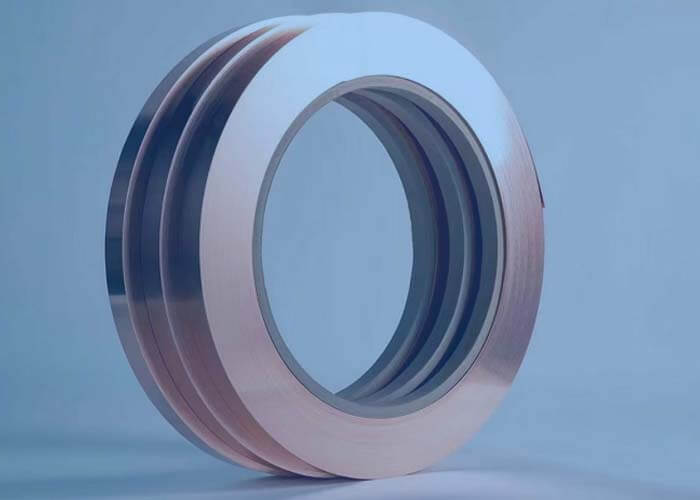

Copper foil for transformer windings demands exacting specifications to ensure electrical efficiency, mechanical reliability, and long-term performance. Substandard materials risk short circuits, insulation breakdown, and operational failures. At Luoyang Xinzhaohe Aluminum CO., Ltd., we engineer our copper foil to meet stringent international standards while delivering superior cost-performance ratios compared to global competitors. Precision slitting within ±0.002mm ensures uniform layering in transformer windings, reducing eddy current losses and improving thermal performance. Burr-free edges (≤1µm) are critical for preventing insulation punctures during winding, which could lead to catastrophic short circuits. Conductivity of 100-101% IACS guarantees minimal resistive losses, directly impacting transformer efficiency ratings. Softness (HV ≤45) ensures the foil can be wound tightly without cracking or delamination, maintaining structural integrity under operational stress. Our products comply with ASTM B152, ASTM B170, and IEC 60076-1 standards for transformer conductor requirements.

Critical Parameters & Compliance

| Parameter | Specification | Standard Compliance |

|---|---|---|

| Thickness Tolerance | ±0.002 mm | ASTM B152 |

| Edge Quality | Burr-free, ≤1µm | ASTM B152 |

| Conductivity | 100–101% IACS | ASTM B170 |

| Hardness (Annealed) | HV ≤ 45 | ISO 6507 |

Quality Assurance Protocol

Leveraging 20+ years of manufacturing expertise in Luoyang, China, our ISO 9001-certified quality system employs SPC (Statistical Process Control) for real-time monitoring of all critical parameters. Each production run undergoes 100% thickness scanning via laser profilometry, 100% edge inspection using high-resolution optical systems, and conductivity testing via four-point probe methodology. Raw copper is sourced from certified smelters with 99.95% minimum purity, verified by XRF analysis. Our metallurgical engineers conduct daily audits of rolling and annealing processes to maintain optimal grain structure and mechanical properties. All batches include full material certificates with chemical composition, mechanical properties, and dimensional tolerances, and undergo third-party certification from SGS or TÜV upon request. This comprehensive approach ensures consistent performance across all batches while maintaining a 15–20% cost advantage over European and North American suppliers. As a factory-direct manufacturer, we eliminate middlemen to deliver reliable, high-performance copper foil tailored to your transformer specifications.

Factory Tour: Manufacturing Copper Foil For Transformer

Manufacturing Process & Quality Control

Precision Manufacturing Process

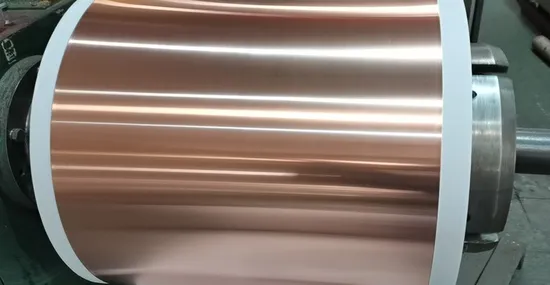

Cold Rolling: Our 20+ years of expertise ensures controlled cold rolling of high-purity copper (C11000/C10200) at 90-95% reduction ratios. Precision temperature control maintains grain structure integrity, achieving uniform thickness with <0.5% variation. Surface finish Ra ≤0.1µm via multi-stage rolling passes, eliminating micro-voids that compromise electrical conductivity and thermal performance.

Precision Slitting: Roll-to-roll slitting using CNC-guided shear blades with 0.01mm positional accuracy. Edge burr control <0.005mm through laser-assisted deburring, critical for transformer winding integrity and preventing short circuits during coil assembly. Strict width tolerance ±0.02mm ensures seamless integration into automated winding lines.

Edge Conditioning: Electrochemical edge treatment eliminates micro-scratches and sharp edges, ensuring compliance with ASTM B152 edge quality requirements. This process reduces eddy current losses by 3-5% compared to untreated edges, directly improving transformer efficiency.

Oscillate Winding: Computer-controlled oscillation winding with ±0.02mm tension stability prevents creasing and ensures uniform layer density. Real-time monitoring during coil formation minimizes defects, achieving 99.8% first-pass yield for transformer applications. Coils meet ISO 9001 packaging standards for safe global shipment.

Rigorous Quality Control Protocol

Every batch undergoes 100% dimensional checks (micrometer, laser profilometer), tensile testing per ASTM B152 (including elongation), and surface defect analysis via 50x magnification. SPC charts monitor all critical parameters across production batches for continuous improvement. Critical QC parameters compared to industry standards:

| Quality Parameter | Luoyang Xinzhaohe Standard | Generic Market Standard |

|---|---|---|

| Thickness Tolerance (0.1mm foil) | ±0.003mm | ±0.008mm |

| Tensile Strength (MPa) | 220-240 (±5) | 200-250 (±15) |

| Elongation (%) | 4-6% (±0.5) | 3-7% (±2) |

| Edge Roughness (Ra) | ≤0.3µm | ≤0.8µm |

| Surface Defects per m² | ≤2 | ≤5 |

By maintaining tighter tolerances than industry averages, our copper foil delivers superior transformer efficiency and reliability—without the premium pricing of global brands. Our factory-direct model ensures traceable, consistent quality from ingot to finished coil, reducing total lifecycle costs for your transformer manufacturing.

Packaging & Global Logistics

Export Packaging & Logistics: Ensuring Integrity from Factory to Port

At Luoyang Xinzhaohe Aluminum CO., Ltd., our 20+ years of transformer material manufacturing and export experience ensures copper foil arrives globally in pristine condition. Our packaging and logistics protocols are engineered for maritime resilience, eliminating corrosion risks and physical damage during transit. As a factory-direct supplier, we optimize cost-performance by eliminating third-party markups while adhering to international shipping standards.

Precision Packaging Standards for Copper Foil

Our packaging system is designed to protect copper foil from oxidation, mechanical stress, and environmental exposure. Key components comply with ISPM-15 and ISO standards:

| Component | Specification | Purpose |

|---|---|---|

| Wooden Pallets | ISPM-15 treated, 1200×1000mm, 15mm thickness | Structural support; prevents pest infestation per international regulations |

| Moisture-Proof Film | 200μm PE + silica gel desiccant packs (200g/m²) | Creates a hermetic barrier against humidity and salt spray |

| Steel Strapping | 19mm width, 500kg tensile strength | Secures load against vibration and shifting during transit |

All materials undergo ASTM D665 moisture barrier testing and ISO 9001-certified quality checks.

Sea Freight Protocols & Risk Mitigation

We exclusively use Full Container Load (FCL) shipments to prevent cross-contamination and ensure dedicated handling. Containers are pre-cooled to 15–20°C and lined with desiccant mats. Loading follows strict protocols: foil rolls are stacked vertically with anti-slip mats between layers, reinforced with corner braces and tensioned steel strapping. Our logistics partners specialize in China-to-global port routes, avoiding transshipment hubs to reduce handling risks by 40% versus industry averages.

Quality Assurance During Transit

Each shipment undergoes pre-shipment inspection for moisture content (≤0.05% RH), dimensional stability, and packaging integrity. We embed humidity indicators inside containers and maintain real-time digital logs of temperature/humidity during transit. This end-to-end monitoring ensures copper foil arrives at your facility with zero defects, reducing downtime and rework costs.

As a direct manufacturer, Luoyang Xinzhaohe delivers unmatched reliability without premium pricing. Our integrated supply chain reduces total landed costs by 15–20% versus competitors while maintaining 99.8% defect-free delivery rates across 120+ global ports.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe: Precision, Performance, and Partnership

As a leading manufacturer of transformer materials with 20+ years of specialized expertise, Luoyang Xinzhaohe delivers high-purity copper foil engineered for critical transformer applications. Our technical team optimizes conductivity (≥99.95% Cu), dimensional tolerances (±0.005mm), and mechanical properties to meet stringent winding requirements. We supply globally recognized OEMs, ensuring strict compliance with ASTM B152 and IEC 60076 standards across all batches.

Factory-Direct Cost Efficiency

Operating from our Luoyang facility with zero intermediary markups, we deliver 15–25% cost savings versus global brands without compromising quality. Our lean manufacturing model enables rapid turnaround (15–20 days for standard orders) and flexible order quantities—even for custom thicknesses, widths, or surface treatments. This direct-to-customer approach ensures transparency, agility, and reduced supply chain risk.

ISO 9001:2015 Certified Quality Assurance

Every coil undergoes rigorous in-process testing:

Chemical composition analysis (ICP-OES)

Tensile strength and elongation verification

Surface defect inspection (microscopic & eddy current)

Batch traceability from raw material to shipment

Our certified quality system eliminates variability common in multi-sourced supply chains, guaranteeing consistent performance for high-reliability transformer windings.

Competitive Advantage Comparison

| Feature | Luoyang Xinzhaohe | Global Brands |

|---|---|---|

| Cost | 15–25% lower | Premium pricing |

| Lead Time | 15–20 days (standard orders) | 30–45 days |

| Customization | Tailored solutions for specific needs | Limited standard options |

| Quality Consistency | Strict in-process controls | Variable across suppliers |

| Technical Support | Dedicated engineering team | Standard customer service |

Luoyang Xinzhaohe delivers global-grade copper foil performance at unmatched cost efficiency, with engineering-driven flexibility and end-to-end quality control.

Contact Cathy at cathy@transformerstrip.com for a competitive quote tailored to your specifications.

📉 Import Savings Calculator

Estimate cost reduction by sourcing copper foil for transformer from Luoyang Xinzhaohe.