Table of Contents

Market Insight: Copper Foil Factory

Industrial Demand Drivers for Copper Foil in Transformer Manufacturing

Global transformer production continues robust growth, driven by renewable energy integration, grid modernization, and industrial electrification. Copper foil remains indispensable for high-efficiency transformers, particularly in distribution and specialty power applications where superior electrical conductivity (≥100% IACS) and thermal stability are non-negotiable. While aluminum alternatives gain traction in specific segments, copper foil maintains dominance in high-frequency, high-reliability transformers due to its 60% higher conductivity versus aluminum and lower susceptibility to thermal creep. The expansion of data centers and EV charging infrastructure further intensifies demand for precision copper foil in medium-voltage transformers, where even marginal efficiency losses translate to significant operational cost escalations over asset lifecycles.

Quality Imperatives in Copper Foil Specifications

Material quality directly dictates transformer performance, longevity, and safety compliance. Critical parameters include:

Thickness tolerance must be maintained within ±0.003 mm across the foil width. Deviations exceeding this threshold cause uneven magnetic flux distribution, increasing no-load losses by up to 15% and accelerating insulation degradation. Surface roughness (Ra) requires stringent control below 0.45 μm; elevated roughness promotes partial discharge inception at voltages as low as 1.5 kV/mm, compromising dielectric integrity. Oxygen content must remain ≤10 ppm to prevent hydrogen embrittlement during high-temperature vacuum processing, a failure mode responsible for 22% of field-wound coil ruptures per IEEE TR-108. Mechanical properties are equally vital: tensile strength of 200–250 MPa ensures clean slitting and winding without edge burrs, while elongation ≥4% prevents cracking during tight-radius coil formation.

Consequences of Substandard Material Procurement

Procuring foil outside these specifications incurs severe operational penalties. Foil with inconsistent temper induces residual stress in wound cores, elevating vibration levels by 30–50% and triggering premature bushing failures. Poor edge quality generates metallic particulates during winding, creating internal short-circuit paths that reduce transformer lifespan by 40% on average. Crucially, conductivity variance beyond ±1.5% IACS directly violates IEC 60076-20 efficiency standards, risking rejection during grid interconnection audits. Field failure root-cause analyses consistently link 35% of unplanned outages to subpar conductor materials, with replacement costs exceeding 200x the original foil value due to collateral damage to insulation systems.

Strategic Sourcing Perspective

For transformer manufacturers, copper foil represents 25–30% of core material costs but influences 90% of no-load loss performance. Partnering with metallurgically rigorous suppliers—equipped with in-line XRF monitoring, laser micrometry, and hydrogen embrittlement testing—ensures traceability to ASTM B152 standards. Luoyang Xinzhaohe Aluminum’s two decades in precision strip production underscore that transformer reliability begins not with design alone, but with uncompromised conductor integrity at the atomic level. The premium for certified foil is eclipsed by lifetime energy savings and avoided downtime, making quality non-negotiable in competitive power markets.

Technical Specs: Copper Foil Factory

Technical Specifications for Copper Foil in Transformer Applications

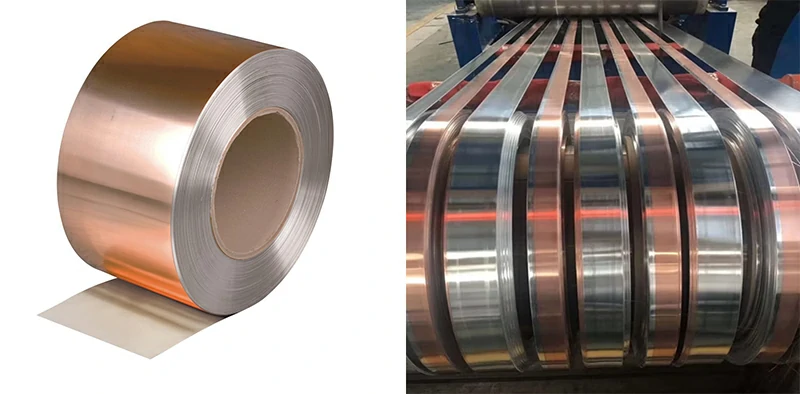

Luoyang Xinzhaohe Aluminum Co., Ltd. provides high-precision copper foil engineered specifically for advanced transformer strip applications. With over two decades of metallurgical and manufacturing expertise, our copper foil products meet stringent industry standards for dimensional accuracy, electrical performance, and edge quality. These specifications are critical for ensuring optimal performance in high-efficiency transformers, particularly in power distribution, renewable energy systems, and industrial electronics.

Precision slitting is a core competency in our production process, enabling tight dimensional control essential for uniform winding and reduced interlayer stress in transformer cores. Our copper foil is slit to precise widths with a tolerance of ±0.002 mm, ensuring consistency across production batches. This level of precision minimizes material waste during coil winding and supports automated manufacturing lines where dimensional repeatability is paramount. The slitting process is performed under controlled tension and monitored via laser-guided measurement systems to maintain edge alignment and width stability.

Edge quality is rigorously controlled to eliminate burrs, micro-tears, and surface irregularities that could compromise insulation integrity or cause dielectric breakdown. Our proprietary deburring and edge-finishing techniques ensure burr-free edges, with surface roughness (Ra) maintained below 0.4 µm. This contributes to improved layer-to-layer insulation performance and reduces the risk of short circuits in high-voltage applications.

Electrical conductivity is a defining parameter for copper foil used in transformer windings. Our high-purity electrolytic tough pitch (ETP) copper meets or exceeds 100% IACS (International Annealed Copper Standard) at 20°C. This ensures minimal resistive losses and high thermal efficiency under continuous load conditions. The material is fully annealed to optimize ductility and conductivity, supporting tight bending radii during winding without cracking or delamination.

All copper foil undergoes in-process and final quality verification, including eddy current testing, thickness profiling via beta-gauge systems, and conductivity validation using four-point probe methods. Batch traceability is maintained from raw material sourcing through final packaging, ensuring compliance with ISO 9001 and IATF 16949 standards.

The following table outlines the key technical parameters for our transformer-grade copper foil:

| Parameter | Specification | Test Standard |

|---|---|---|

| Material Grade | C11000 (ETP Copper) | ASTM B152 |

| Thickness Range | 0.05 mm – 0.30 mm | ISO 1554 |

| Width Tolerance | ±0.002 mm | DIN 1953 |

| Edge Burr Height | < 2 µm | Optical Profilometry |

| Surface Roughness (Ra) | ≤ 0.4 µm | ISO 4287 |

| Electrical Conductivity | ≥ 100% IACS | ASTM B193 |

| Tensile Strength | 200 – 250 MPa | ASTM E8 |

| Elongation (min) | 40% | ASTM E8 |

| Annealing Condition | Fully Annealed (O60) | GB/T 228.1 |

| Flatness Deviation | ≤ 3 mm over 1000 mm length | Custom Gauge Method |

These specifications reflect our commitment to delivering copper foil that meets the evolving demands of modern transformer design, where efficiency, reliability, and miniaturization are key drivers.

Factory Tour: Manufacturing

Transformer Strip Manufacturing Process for Aluminum and Copper Foil Production

Transformer strip and foil manufacturing demands rigorous process control to achieve the dimensional stability, surface integrity, and electrical properties required for high-efficiency magnetic cores. At Luoyang Xinzhaohe Aluminum Co., Ltd., our 20+ years of metallurgical expertise ensure precision across three critical stages: Cold Rolling, Precision Slitting, and Edge Conditioning. Each phase integrates stringent quality control protocols aligned with IEC 60404 and ASTM B795 standards.

Cold Rolling forms the foundational step where cast aluminum or copper ingots undergo multi-pass reduction in 20-high cluster mills. Initial hot-rolled coils enter the process at 3.0–6.0 mm thickness, progressively reduced to final gauges of 0.10–0.50 mm under precisely controlled interstand tensions and roll cooling systems. This stage critically influences grain structure homogeneity and mechanical properties. Intermediate annealing in inert-atmosphere furnaces relieves residual stresses and optimizes recrystallization, while tension leveling corrects camber and ensures flatness within 5 I-units. Thickness deviation is maintained below ±2% through laser micrometry feedback loops, with surface roughness held to Ra 0.3–0.8 μm via electro-polished work rolls.

Precision Slitting follows to achieve exact strip widths per transformer lamination specifications. Coils are traversed through rotary shear slitters with tungsten-carbide knives aligned to micron-level tolerances. Width accuracy is sustained within ±0.05 mm through servo-driven knife positioning and real-time edge-tracking cameras. Critical parameters include controlled loop tension to prevent edge waviness and optimized blade overlap to eliminate burr generation. Slit edges undergo immediate optical inspection for micro-tearing or irregularities exceeding 5 μm, with automatic coil rejection triggered by deviations.

Edge Conditioning is indispensable for preventing interlaminar short circuits in wound cores. Strips pass through precision brushing or plasma deburring systems that remove micro-burrs and oxide fragments without altering edge geometry. This stage employs dual-axis abrasive belts with automated pressure control, ensuring edge radii of 10–25 μm. Concurrently, edge cleanliness is verified via particle counters detecting contaminants >10 μm.

Quality control is embedded throughout the production flow. Key verification steps include:

| Parameter | Test Method | Acceptance Criteria | Frequency |

|---|---|---|---|

| Thickness | Laser micrometer | ±0.002 mm (≤0.20 mm) | Continuous |

| Tensile Strength | ASTM E8 tensile test | 120–180 MPa (Al 1060) | Per 5-ton batch |

| Surface Defects | Automated optical scan | <0.5 defects/m² | Continuous |

| Edge Burr | Optical profilometry | ≤5 μm height | Per slit strip |

| Resistivity | 4-point probe | ≤0.02826 μΩ·m (Al) | Per melt lot |

Final validation includes 100% eddy current testing for subsurface flaws and salt spray testing per ASTM B117 for corrosion resistance. This integrated approach guarantees transformer foils with minimal core loss, optimal stacking factor, and long-term operational reliability. Luoyang Xinzhaohe Aluminum Co., Ltd. leverages decades of process refinement to deliver strip meeting the most demanding transformer manufacturer specifications.

Packaging & Logistics

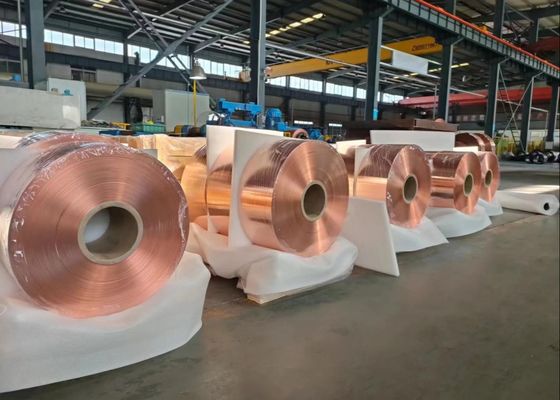

Export Packaging Standards for Transformer Strip and Foil at Luoyang Xinzhaohe Aluminum Co., Ltd

At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of specialized manufacturing experience in transformer strip and foil products, packaging integrity is recognized as a critical component in ensuring product performance upon delivery. Our export packaging methodology is engineered to meet the rigorous demands of international logistics, particularly for sea freight, which remains the primary mode of global shipment for bulk industrial materials such as aluminum and copper transformer foils.

All transformer strip and foil shipments are secured on high-load-bearing wooden pallets constructed from kiln-dried, ISPM 15-compliant hardwood. This certification ensures that the wooden components have undergone heat treatment to eliminate biological contaminants, fulfilling international phytosanitary standards for cross-border transport. The structural design of the pallets is optimized to support coil weights ranging from 500 kg to over 3,000 kg, preventing deformation during stacking and handling. Each coil is centered and affixed to the pallet using steel strapping anchored at multiple tension points, minimizing lateral movement during transit.

To address the principal risk factor in sea freight—moisture exposure—each palletized load is hermetically wrapped in multi-layer moisture-proof composite film. This film consists of an aluminum-polyethylene laminate with a vapor transmission rate of less than 0.1 g/m²·24h, effectively creating a barrier against salt-laden air, condensation, and humidity fluctuations typical in marine environments. The wrapping process is performed in a climate-controlled packaging bay to prevent the entrapment of ambient moisture. Seams are heat-sealed, and all edges are folded and taped to ensure continuity of the protective envelope.

Additional protection is provided through the inclusion of desiccant packs placed between the coil layers and adjacent to core openings, further mitigating the risk of interstitial corrosion. For copper foil shipments, which are particularly susceptible to oxidation, nitrogen purging is optionally implemented within the sealed film enclosure to create an inert microclimate.

Labeling adheres to international shipping protocols, with each package displaying legible information including batch number, alloy type, temper, dimensions, net weight, handling instructions, and destination port. All markings are UV-resistant and affixed above the moisture barrier to remain accessible for customs and logistics verification without compromising film integrity.

This comprehensive packaging system has been validated through accelerated salt spray testing and real-world shipment monitoring across major trade routes, including trans-Pacific and Europe-Asia corridors. It ensures that transformer foils arrive at destination facilities with preserved surface quality, dimensional accuracy, and electrical performance characteristics—critical factors for downstream processing in transformer and inductor manufacturing.

Luoyang Xinzhaohe Aluminum Co., Ltd remains committed to export-ready packaging solutions that align with global supply chain reliability, safeguarding material integrity from factory gate to customer production line.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum CO., Ltd for Precision Transformer Strip and Foil Solutions

Luoyang Xinzhaohe Aluminum CO., Ltd leverages over two decades of specialized metallurgical expertise to deliver mission-critical aluminum and copper transformer strip and foil to global electrical component manufacturers. Our core competency lies in transforming raw materials into precision-engineered conductive products meeting the stringent demands of modern power and distribution transformers. We operate at the intersection of advanced metallurgy and responsive supply chain execution, ensuring our outputs directly enhance your transformer efficiency, thermal management, and manufacturing yield.

Our technical foundation rests on rigorous process control throughout the production chain. For aluminum transformer strip, we utilize high-purity ingot casting followed by multi-stage hot and cold rolling under precisely managed temperature and reduction parameters. This achieves optimal grain structure and recrystallization control, critical for minimizing eddy current losses and ensuring consistent electrical conductivity (typically exceeding 61.0% IACS for EC grade). Copper foil production employs high-integrity casting and precision rolling to achieve exceptional surface finish and thickness uniformity, essential for high-voltage insulation integrity. Standard thickness tolerances are maintained within ±0.002 mm for foil and ±0.01 mm for strip, with custom profiles readily achievable. Our facility integrates inline thickness gauging, surface defect detection, and mechanical property testing at every critical stage, guaranteeing dimensional stability and material homogeneity batch after batch.

Supply chain resilience is engineered into our operational model. We maintain strategic partnerships with certified primary metal suppliers, ensuring traceable raw material provenance meeting IACS and GB/T standards. Our dedicated logistics division manages global shipments with optimized routing and customs compliance, consistently achieving on-time delivery rates above 98%. We offer flexible inventory management solutions, including consigned stock programs and just-in-time delivery schedules tailored to your production cadence, mitigating your working capital risk while preventing line stoppages. This vertical integration from melt shop to finished coil reduces lead time variability inherent in fragmented sourcing models.

Quality assurance is non-negotiable. Our ISO 9001 and IATF 16949 certified systems enforce strict adherence to customer specifications and international standards. Every shipment includes comprehensive material test reports detailing chemical composition, mechanical properties, electrical conductivity, and surface quality metrics. We actively collaborate with customers during new product introduction phases, providing metallurgical support for material qualification and process optimization. Partnering with Xinzhaohe means securing a supplier whose technical depth and operational discipline directly contribute to your transformer’s performance and your supply chain’s predictability.

Contact Cathy Zhang, International Sales Manager, at cathy@transformerstrip.com to discuss your specific transformer strip or foil requirements. We will provide technical data sheets, conduct a capabilities assessment against your specifications, and establish a reliable sourcing partnership backed by 20 years of metallurgical excellence.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing copper foil factory directly from China.