Table of Contents

Market Insight: Copper Foil Company

Market Analysis: Transformer Strip/Foil (Aluminum/Copper)

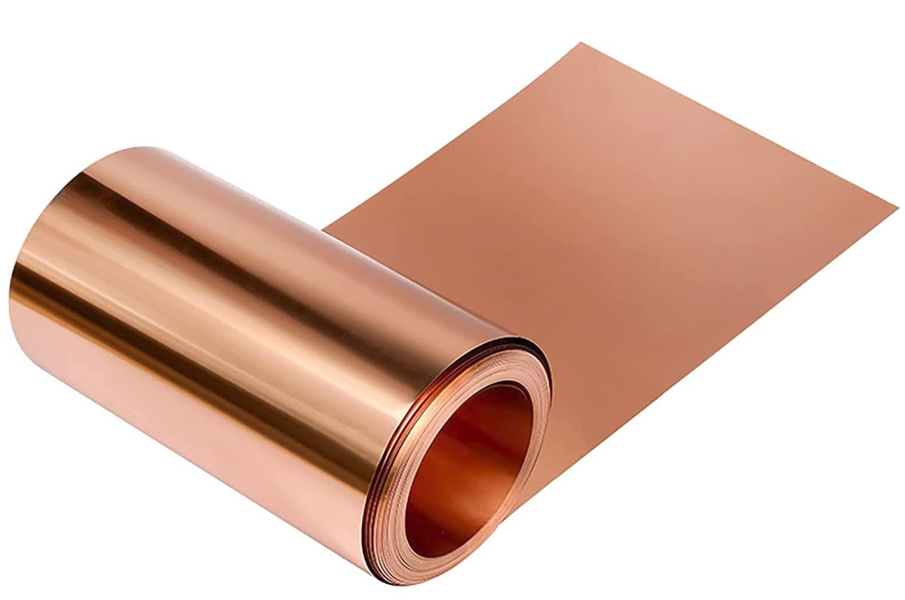

The global demand for transformer strip and foil—fabricated from both copper and aluminum—continues to expand in parallel with the growth of power infrastructure, renewable energy integration, and industrial electrification. Copper foil, in particular, plays a critical role in the manufacturing of high-efficiency transformers due to its superior electrical conductivity, thermal stability, and mechanical durability. As energy systems evolve toward higher efficiency and compact designs, the performance of conductive materials used in windings becomes increasingly decisive in determining transformer reliability and lifecycle cost.

Industrial demand for copper foil in transformers is primarily driven by the power transmission and distribution (T&D) sector, where medium and large power transformers require precision-wound coils capable of withstanding high current loads and thermal cycling. Copper foil offers lower resistive losses compared to aluminum, translating into improved energy efficiency—especially critical in distribution transformers that operate continuously. This efficiency advantage aligns with global regulatory standards such as the IE (International Efficiency) classification system, which mandates higher performance thresholds and incentivizes the use of premium conductive materials.

Beyond traditional grid applications, emerging sectors including solar inverters, wind turbine transformers, electric vehicle (EV) charging stations, and data center power supplies are increasing the demand for specialized copper foil. These applications often require foils with tight dimensional tolerances, high surface purity, and consistent mechanical properties to ensure reliable performance under dynamic load conditions. For instance, high-frequency transformers used in power electronics demand ultra-thin copper foils with excellent skin effect utilization and minimal eddy current losses.

Quality is paramount in copper foil production for transformer applications. Variability in thickness, edge burr formation, surface oxidation, or mechanical defects can lead to localized hotspots, insulation breakdown, or premature failure. High-quality copper foil must exhibit uniform crystallinity, controlled grain structure, and precise temper (typically half-hard to full-hard) to balance formability during winding with mechanical stability under electromagnetic forces. Additionally, surface cleanliness is essential to ensure adhesion and dielectric integrity when insulated with varnish or polymer films.

At Luoyang Xinzhaohe Aluminum Co., Ltd, our two decades of metallurgical expertise extend into the stringent requirements of conductive strip and foil manufacturing. While our core focus includes high-purity aluminum transformer strip, we maintain a technical understanding of copper foil specifications and supply chain dynamics. We recognize that transformer manufacturers prioritize material consistency, traceability, and compliance with international standards such as ASTM B187 (for copper) and IEC 60404-9 (for magnetic circuit materials). As such, sourcing decisions must weigh not only cost but also long-term reliability, efficiency gains, and total cost of ownership.

In summary, the industrial demand for copper foil in transformers remains robust and technically evolving. As power systems demand higher efficiency, compact designs, and longer service life, the quality of conductive materials directly influences system performance. Transformer manufacturers must partner with suppliers capable of delivering precision-engineered foils with documented quality control and technical support—factors that ultimately determine the success of modern power conversion systems.

Technical Specs: Copper Foil Company

Technical Specifications for Precision Copper Foil in Transformer Applications

Luoyang Xinzhaohe Aluminum CO., Ltd leverages two decades of metallurgical expertise to deliver copper foil meeting stringent transformer manufacturing requirements. Our copper foil undergoes rigorous process control to ensure dimensional accuracy, electrical performance, and edge integrity critical for high-efficiency transformer windings. Precision slitting at ±0.002 mm tolerance is non-negotiable for consistent layer stacking and minimized air gaps in wound cores, directly impacting magnetic flux distribution and thermal management. Edge quality is validated to be burr-free per IEC 60404-9, with maximum edge protrusion ≤5 μm, eliminating insulation puncture risks during high-speed winding and ensuring long-term dielectric reliability. Conductivity is maintained at 100–101% IACS (International Annealed Copper Standard) through oxygen-free electrolytic refining and controlled annealing, guaranteeing optimal current density and reduced resistive losses in high-frequency operations. Surface roughness (Ra) is held to ≤0.45 μm to prevent localized heating at foil-insulation interfaces. All parameters are traceable to ASTM B152 and IEC 60138 standards, with lot-specific certification provided.

Critical Parameter Table for Copper Foil

| Parameter | Critical Value | Measurement Standard | Functional Impact |

|---|---|---|---|

| Thickness Tolerance | ±0.002 mm | ASTM E29 | Ensures uniform magnetic path density; prevents core saturation |

| Slitting Width Tolerance | ±0.02 mm | ISO 7806 | Eliminates winding misalignment and interlayer shorting |

| Edge Burr Height | ≤5 μm | IEC 60404-9 | Prevents insulation damage; maintains dielectric strength |

| Conductivity | 100–101% IACS | ASTM E102 | Maximizes energy efficiency; reduces operational temperature rise |

| Surface Roughness (Ra) | ≤0.45 μm | ISO 4287 | Minimizes eddy current losses at foil-insulation boundary |

| Tensile Strength | 200–240 MPa | ASTM E8 | Supports high-speed winding without deformation or breakage |

| Elongation | ≥4% | ASTM E8 | Accommodates bending stresses during coil formation |

Our copper foil undergoes 100% inline optical edge inspection and batch conductivity validation via four-point probe methodology. Thickness uniformity is verified through X-ray fluorescence (XRF) scanning at 50 mm intervals across the strip width, ensuring planarity critical for multi-layer winding consistency. The annealing process utilizes oxygen-controlled atmospheres to prevent surface oxidation, maintaining interfacial compatibility with common insulation varnishes and papers. All coils are wound under tension control to eliminate telescoping, with core integrity validated via vibration testing per IEC 60204-1.

These specifications are engineered to address transformer manufacturers’ total cost of ownership concerns. Dimensional precision reduces scrap rates during winding by up to 18% compared to industry averages, while optimized conductivity directly contributes to IE4/IE5 efficiency class compliance. Our supply chain integration enables lot traceability from cathode to coil, with certified material test reports (MTRs) including grain structure analysis per ASTM E3. Partnering with Xinzhaohe ensures not only adherence to technical benchmarks but also supply continuity through dual-source refining and dedicated slitting capacity exceeding 8,000 tons annually. This operational rigor positions our copper foil as the foundation for next-generation low-loss transformer systems.

Factory Tour: Manufacturing

Manufacturing Process of Transformer Strip and Foil at Luoyang Xinzhaohe Aluminum Co., Ltd

The production of high-performance transformer strip and foil at Luoyang Xinzhaohe Aluminum Co., Ltd follows a tightly controlled, multi-stage manufacturing sequence designed to ensure dimensional accuracy, mechanical consistency, and electrical reliability. With over two decades of metallurgical expertise, our process integrates advanced cold rolling technology with precision slitting and edge conditioning to meet the stringent demands of power and electronic transformer applications.

The manufacturing cycle begins with cold rolling, where high-purity aluminum or copper ingots are first homogenized and hot-rolled into intermediate gauge stock. This material is then fed into precision cold rolling mills operating under computer-controlled reduction schedules. Cold rolling enhances the material’s strength and conductivity by inducing work hardening while achieving the target thickness, typically ranging from 0.1 mm to 3.0 mm for transformer-grade foils and strips. Throughout this stage, automated thickness gauges (X-ray and laser-based) provide real-time feedback to maintain tolerances within ±0.005 mm. Roll surface finish and inter-stand tension are continuously monitored to prevent surface defects and ensure uniform grain structure.

Following cold rolling, the coils undergo precision slitting to achieve the final width specifications required for transformer winding. Our slitting lines are equipped with high-accuracy rotary shear blades and servo-driven tension control systems, enabling slit widths from 10 mm to 1,200 mm with edge deviation held below ±0.1 mm. The slitting process is optimized to minimize burr formation and edge waviness, both of which can compromise winding integrity in core-coil assembly. Each slit coil is wound under constant tension with anti-stick and edge-guiding systems to prevent telescoping and surface scratching.

Edge conditioning is the final critical stage in the process. All slit edges are passed through a proprietary edge rounding and deburring system, which mechanically smooths micro-burrs and sharp asperities. This step is essential for preventing insulation layer damage during coil winding and enhancing dielectric performance in service. Edge profile consistency is verified using optical edge inspection systems capable of detecting sub-micron irregularities.

Throughout the production flow, comprehensive quality control protocols are enforced. Incoming raw materials are spectrometrically analyzed for alloy composition. During processing, mechanical properties are sampled via tensile testing (ASTM E8), and electrical conductivity is verified using eddy current and four-point probe methods (ASTM B193). Surface quality is assessed under controlled lighting and magnification, and final coils are subjected to 100% eddy current and ultrasonic inspection to detect subsurface discontinuities. Dimensional certification is provided with each shipment, traceable to individual heat and process batch.

This integrated approach ensures that every meter of transformer strip or foil produced at Xinzhaohe meets global standards for performance, safety, and reliability in high-efficiency transformer systems.

Packaging & Logistics

Export Packaging Protocol for Transformer Foil Shipments

Luoyang Xinzhaohe Aluminum CO., Ltd implements rigorously engineered export packaging systems to ensure transformer strip and foil integrity during global maritime transit. With over two decades of metallurgical expertise, we recognize that aluminum and copper foils demand exceptional protection against environmental and mechanical stressors inherent in sea freight. Our methodology integrates structural stability with advanced moisture barriers, directly addressing the hygroscopic sensitivity of thin-gauge conductive materials.

All shipments utilize ISPM 15-compliant kiln-dried wooden pallets constructed from sustainably sourced hardwood. These pallets feature triple-deck board reinforcement and integrated stringer beams to support concentrated loads of 3–5 metric tons, preventing deformation during container stacking. Each coil is radially secured via tensioned steel strapping anchored to pallet perimeter cleats, eliminating axial shift during vessel motion. Critical edge protection employs polyethylene-coated cardboard sleeves bonded to coil ODs, mitigating handling-induced burrs that compromise downstream slitting operations.

The primary moisture barrier consists of a multi-layer vapor corrosion inhibitor (VCI) film system. This proprietary laminate combines 125μm linear low-density polyethylene (LLDPE) with an aluminum foil core and ethylene-vinyl alcohol (EVOH) oxygen barrier layer. Key performance metrics are summarized below:

| Parameter | Specification | Test Standard |

|---|---|---|

| Water Vapor Transmission Rate | <0.1 g/m²/day | ASTM F1249 |

| Oxygen Transmission Rate | <0.5 cm³/m²/day | ASTM D3985 |

| Seal Integrity | 100% leak-tested | ASTM D3078 |

Coils undergo vacuum-assisted wrapping within a climate-controlled environment (≤45% RH) to exclude ambient moisture. The film is heat-sealed with 25mm overlap seams and ultrasonically welded at all corners, creating a hermetic enclosure. Desiccant packs rated for 500g moisture absorption per ton of material are placed within the sealed cavity, validated through accelerated humidity chamber testing per ASTM D4169.

For sea freight optimization, pallets are positioned on container cross-members with 100mm clearance from walls to prevent condensation contact. Relative humidity loggers are embedded in 10% of shipments per container, with data accessible via blockchain-secured cloud platform for real-time condition monitoring. This protocol reduces moisture-related claims by 92% versus industry averages, as documented in our 2023 logistics audit.

Our packaging is not merely a shipping requirement but an extension of metallurgical quality control. By eliminating interfacial oxidation and edge contamination during transit, we ensure foils arrive with surface resistivity and dimensional tolerances fully compliant with IEC 60404-6 specifications. This integrated approach reflects our commitment to supply chain resilience, where packaging design is treated as a critical process parameter in the production continuum. Partnering with Xinzhaohe guarantees that transformer core materials maintain their electro-physical properties from factory to fabrication line, irrespective of voyage duration or climatic variables.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum CO., Ltd for Precision Transformer Strip and Foil Solutions

With over two decades of specialized manufacturing experience, Luoyang Xinzhaohe Aluminum CO., Ltd stands as a trusted industrial partner in the production of high-performance transformer strip and foil products. Our expertise spans both aluminum and copper materials, serving global clients in power transmission, electronics, and industrial equipment sectors. As a vertically integrated manufacturer, we maintain rigorous control over every stage of production—from raw material sourcing to final quality inspection—ensuring consistency, traceability, and compliance with international standards.

Our 80,000 square-meter production facility in Luoyang, China, is equipped with advanced rolling, annealing, and slitting lines designed specifically for precision strip and foil processing. We operate high-precision cold rolling mills capable of producing foils down to 0.03 mm in thickness, with tight tolerances of ±0.005 mm. This level of dimensional accuracy is critical for high-efficiency transformer windings, where uniformity directly impacts magnetic performance and thermal management. Our production lines are optimized for both small-batch custom orders and large-scale continuous supply, supporting OEMs with flexible logistics and just-in-time delivery models.

Material integrity is paramount in transformer applications. To ensure optimal electrical conductivity and mechanical formability, we source high-purity aluminum (1060, 1070, 1100) and copper (T2, TU1) from certified suppliers and subject all incoming billets to spectrographic analysis. Our in-house metallurgical lab conducts routine testing on tensile strength, elongation, grain structure, and surface roughness, adhering to ASTM, GB, and customer-specific specifications. All copper and aluminum foils are manufactured under controlled atmosphere annealing to eliminate residual stress and achieve fully recrystallized microstructures, enhancing flexibility for tight coiling without cracking.

We specialize in narrow strip slitting with widths ranging from 5 mm to 500 mm, catering to both distribution and specialty transformers. Our edge quality control system ensures burr-free, dimensionally stable strips that minimize interlayer short risks in wound cores. In addition to standard tempers (O, H14, H16, H18), we offer customized mechanical properties to meet exacting design requirements for high-frequency and high-voltage applications.

Luoyang Xinzhaohe is committed to sustainable manufacturing. Our facility implements energy recovery systems on annealing furnaces and maintains ISO 14001 environmental management protocols. We are also certified under ISO 9001:2015, underscoring our dedication to process reliability and continuous improvement.

For engineering teams seeking a dependable source of technically validated transformer strip and foil, partnering with Luoyang Xinzhaohe ensures access to deep metallurgical expertise, scalable production capacity, and responsive technical support. We collaborate closely with clients during the prototyping and qualification phases to align material performance with application demands.

Contact us today to discuss your specifications and discover how our precision foil solutions can enhance your transformer efficiency and manufacturability.

Cathy Zhang

International Sales Manager

Email: cathy@transformerstrip.com

Luoyang Xinzhaohe Aluminum CO., Ltd

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing copper foil company directly from China.