Table of Contents

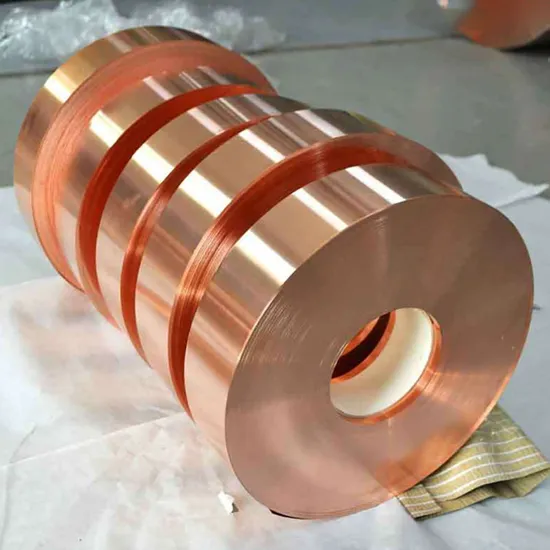

Market Insight: Copper Earthing Strip

Market Analysis: Transformer Strip/Foil (Aluminum/Copper)

The global demand for copper earthing strip within the transformer manufacturing sector continues to grow, driven by increasing investments in power infrastructure, renewable energy integration, and grid modernization. Copper earthing strips serve a critical function in power and distribution transformers by providing a low-resistance path for fault currents, ensuring equipment safety, personnel protection, and system reliability. As electrical networks expand and operating voltages rise, the performance of grounding components—particularly copper earthing strip—has become a focal point in transformer design and compliance.

Copper is the preferred material for earthing applications due to its superior electrical conductivity, thermal stability, and corrosion resistance. In transformer construction, copper earthing strips are typically installed to bond the core, tank, and other metallic components to the grounding system. This ensures equipotential bonding, minimizes touch potential during faults, and facilitates rapid operation of protective relays. The use of high-purity, oxygen-free copper with consistent mechanical and electrical properties is essential to maintain performance under dynamic electrical and thermal loads.

Industrial demand for copper earthing strip is closely tied to transformer production volumes, particularly in emerging markets across Asia, the Middle East, and Africa, where grid expansion projects are accelerating. Additionally, developed regions are replacing aging transformer fleets with more efficient and reliable units, further supporting demand. The trend toward smart grids and high-efficiency transformers also necessitates precise grounding solutions, reinforcing the need for high-quality copper components.

Quality is paramount in the selection of copper earthing strip. Substandard materials—such as recycled copper with impurities or inconsistent cross-sectional dimensions—can lead to increased resistance, localized heating, and failure during fault conditions. Poor surface finish or inadequate mechanical strength may compromise connection integrity, especially in environments with vibration or thermal cycling. Moreover, non-compliance with international standards such as IEC 60464, ASTM B187, or IS 12393 can result in rejection during quality audits or, worse, field failures with significant safety and financial consequences.

Luoyang Xinzhaohe Aluminum Co., Ltd brings over two decades of experience in the production and supply of high-performance transformer strips and foils, including precision-engineered copper earthing solutions. Our manufacturing processes adhere to stringent quality control protocols, ensuring dimensional accuracy, optimal conductivity, and long-term durability. Each batch undergoes rigorous testing for resistivity, tensile strength, and surface integrity, guaranteeing compliance with global technical specifications.

As the electrical industry advances toward higher reliability and sustainability, the role of quality copper earthing strip in transformer safety and performance cannot be overstated. Manufacturers and procurement teams must prioritize material integrity, traceability, and supplier expertise when sourcing these critical components. Partnering with an established supplier ensures not only compliance but also operational resilience across the transformer lifecycle.

Technical Specs: Copper Earthing Strip

Technical Specifications for Copper Earthing Strip

Luoyang Xinzhaohe Aluminum Co., Ltd leverages 20+ years of precision strip manufacturing expertise to deliver copper earthing strips meeting the most stringent electrical safety and performance requirements. Our copper earthing strips are engineered for critical applications in power distribution, substations, and industrial grounding systems where dimensional accuracy, edge integrity, and electrical conductivity are non-negotiable. We utilize high-purity electrolytic tough pitch (ETP) copper (C11000) or oxygen-free electronic (OFE) copper (C10100) sourced from certified mills, ensuring consistent material properties and traceability. All production adheres to ISO 9001 quality management systems, with rigorous in-process and final inspections validating conformance to international standards including IEC 62561-2, ASTM B115, and BS EN 50164-2.

Dimensional Precision

Width tolerance is maintained at ±0.002 mm through our advanced servo-controlled slitting lines, calibrated daily using laser micrometers traceable to NIST standards. This precision ensures seamless integration into busbar systems and minimizes contact resistance at connection points. Thickness tolerance is held to ±0.005 mm for strips below 0.5 mm and ±0.01 mm for thicker gauges, verified via non-contact eddy current gauging across the entire coil length. Flatness is controlled to ≤ 0.5 mm/m deviation, preventing warping during installation under mechanical stress.

Edge Quality and Surface Integrity

Burr-free edges are achieved through a proprietary dual-stage slitting and edge conditioning process. Maximum edge burr height is strictly limited to ≤ 0.005 mm, measured per ISO 1302 using optical profilometry. This eliminates sharp protrusions that could compromise insulation integrity or cause arcing in high-fault-current scenarios. Surface roughness (Ra) is maintained below 0.4 μm, ensuring optimal contact pressure and minimizing oxidation points. Each strip undergoes 100% visual and automated edge inspection via machine vision systems before shipment.

Electrical Conductivity

Minimum conductivity of 100% IACS (International Annealed Copper Standard) at 20°C is guaranteed for ETP copper, with typical batch averages exceeding 101% IACS. OFE copper variants achieve 101–102% IACS. Conductivity is validated using a four-point probe method per ASTM E1004, with results documented in material test reports. Resistivity remains ≤ 0.017241 μΩ·m, critical for low-impedance fault current paths. All strips are supplied in H02 (1/2 hard) temper unless specified otherwise, balancing formability with mechanical stability.

Key Parameter Compliance

| Parameter | Standard Requirement | Xinzhaohe Specification | Test Method |

|---|---|---|---|

| Width Tolerance | ±0.01 mm | ±0.002 mm | ISO 7438 |

| Thickness Tolerance | ±0.02 mm | ±0.005 mm (≤0.5 mm) | ASTM E29 |

| Edge Burr Height | ≤ 0.02 mm | ≤ 0.005 mm | ISO 1302 |

| Electrical Conductivity | ≥ 100% IACS | 100–102% IACS | ASTM E1004 |

| Surface Roughness (Ra) | ≤ 1.0 μm | ≤ 0.4 μm | ISO 4287 |

These specifications directly address failure modes in earthing systems, including thermal runaway at imperfect joints and reduced fault current carrying capacity. Our slitting precision ensures uniform current distribution across parallel strips, while burr elimination prevents localized heating at clamping interfaces. All strips are packaged in anti-tarnish VCI paper with humidity-controlled desiccants to maintain surface integrity during transit. Technical data sheets with lot-specific test results accompany every shipment, supporting full compliance auditing for critical infrastructure projects.

Factory Tour: Manufacturing

Manufacturing Process of Copper Earthing Strip at Luoyang Xinzhaohe Aluminum Co., Ltd

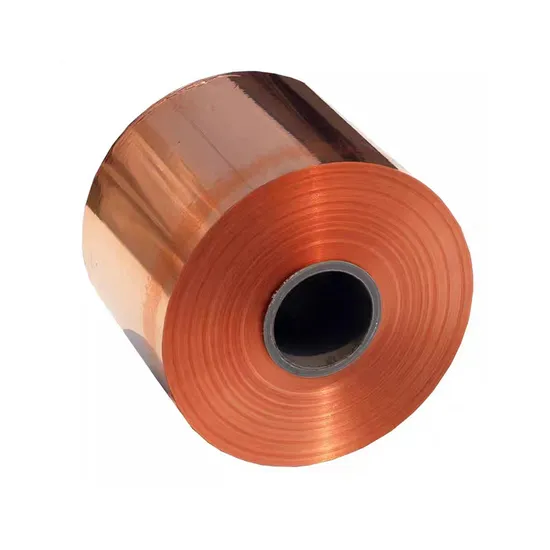

The production of high-performance copper earthing strip at Luoyang Xinzhaohe Aluminum Co., Ltd follows a tightly controlled, multi-stage manufacturing process designed to ensure dimensional accuracy, mechanical integrity, and optimal electrical conductivity. With over two decades of specialization in transformer-grade metallic strips, our facility integrates advanced cold rolling technology with precision slitting and edge conditioning to deliver copper earthing products that meet stringent international standards for grounding and bonding applications.

The process begins with cold rolling, where high-purity electrolytic copper (typically C11000 or C10100) in the form of hot-rolled coils is fed into a reversing cold rolling mill. This stage reduces the material thickness to the specified gauge with exceptional uniformity, typically ranging from 0.1 mm to 3.0 mm, depending on customer requirements. Cold rolling enhances the material’s tensile strength and surface finish while maintaining tight thickness tolerances (±0.02 mm or better). The rolling parameters—roll pressure, speed, and interstand tension—are continuously monitored via automated process control systems to ensure consistency across batches.

Following cold rolling, the copper strip undergoes precision slitting to achieve the final required width. Utilizing high-precision rotary shear slitters with computer-controlled knife positioning, the master coils are longitudinally cut into narrower strips with width tolerances held within ±0.1 mm. This stage is critical for applications requiring exact fitment in busbar systems or transformer grounding assemblies. Slitting is performed under tension control to prevent edge wave or camber, ensuring flatness and dimensional stability.

Edge conditioning is the subsequent critical phase, particularly for earthing strips that interface with sensitive electrical equipment. The slit edges are processed through a deburring and edge rounding system to eliminate sharp burrs and micro-cracks that could act as stress concentration points or initiate corrosion. This conditioning improves safety during handling and enhances long-term reliability in service. The degree of edge radius is controlled per customer specification, typically achieving a smooth, uniform edge profile with Ra < 2.0 µm.

Throughout the manufacturing sequence, comprehensive quality control measures are enforced. In-process inspections include continuous monitoring of thickness via laser gauges, eddy current testing for surface defects, and periodic tensile and conductivity testing. Final quality verification involves dimensional checks, visual inspection under controlled lighting, and batch certification for electrical resistivity (typically ≤ 0.01724 Ω·mm²/m at 20°C). All production data is documented and traceable to ensure compliance with ISO 9001 and IEC 61439 standards.

This integrated approach to copper earthing strip manufacturing ensures that every product shipped from Luoyang Xinzhaohe Aluminum Co., Ltd meets the highest benchmarks for performance, safety, and consistency in critical power system applications.

Packaging & Logistics

Export Packaging Specifications for Copper Earthing Strip

Luoyang Xinzhaohe Aluminum Co., Ltd implements rigorously engineered export packaging protocols for copper earthing strip shipments, specifically designed to mitigate marine transit hazards over extended sea freight durations. Our 20+ years of metallurgical expertise in conductor materials dictates that packaging must prevent physical deformation, electrochemical corrosion, and moisture ingress—critical factors directly impacting the strip’s electrical conductivity and mechanical integrity upon delivery.

All copper earthing strip coils or cut lengths are secured to kiln-dried, ISPM 15-certified wooden pallets. These pallets undergo thermal treatment to eliminate biological contaminants and reduce moisture content to ≤20%, preventing fungal growth and structural weakening during voyages exceeding 30 days. Pallet dimensions are standardized at 1200 × 1000 mm or 1100 × 1100 mm, engineered to withstand stack loads of 2,500 kg without deflection. Strips are tension-wound onto robust cardboard cores (minimum 150 mm inner diameter), then strapped to the pallet base using galvanized steel bands (width: 19 mm; tensile strength: 900 MPa) at intervals ≤300 mm. This configuration eliminates coil shifting and edge damage during vessel acceleration or port handling.

The primary defense against salt-laden marine atmospheres is our multi-layer moisture barrier system. Strips are first wrapped in vapor corrosion inhibitor (VCI) polyethylene film (thickness: 0.10 mm), which releases non-toxic organic compounds to form a molecular shield on copper surfaces. This is followed by a secondary layer of metallized polyester moisture-proof film (MVTR: ≤0.5 g/m²/24hr) to block humidity penetration. The entire assembly is then hermetically sealed within a third layer of high-density polyethylene (HDPE) shrink film (thickness: 0.12 mm), heat-shrunk to eliminate air pockets. This triple-barrier approach ensures internal relative humidity remains below 40% RH for 120+ days, even in tropical shipping corridors.

Packaging Performance Metrics

| Parameter | Standard Configuration | Enhanced Configuration |

|————————–|————————|————————|

| Pallet Load Capacity | 2,500 kg | 3,500 kg |

| Moisture Barrier Layers | 3 | 5 (includes desiccant) |

| Humidity Protection | 90 days | 180 days |

| Salt Spray Resistance | 500 hours | 1,000 hours |

Sea freight safety is further assured through ISO 11607-compliant edge protectors made from recycled polypropylene, preventing film puncture during container stacking. Each pallet receives a weatherproof label displaying batch traceability codes, copper alloy grade (e.g., C11000), and moisture-sensitive device (MSD) indicators. Our packaging has achieved zero corrosion-related claims across 1,200+ ocean shipments since 2018, validated by third-party logistics audits. This system aligns with IEC 62561-2 requirements for earthing component preservation, ensuring strips arrive with surface oxidation levels <0.5 μm—essential for maintaining low-resistance grounding performance. Partnering with certified freight forwarders, we monitor container humidity in real-time via IoT sensors for critical orders, providing clients with verifiable transit environmental data.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum CO., Ltd for High-Performance Copper Earthing Strip Solutions

With over two decades of specialized manufacturing experience, Luoyang Xinzhaohe Aluminum CO., Ltd stands as a trusted leader in the production of precision transformer strips and foils, including high-conductivity copper earthing strips essential for electrical safety and grounding systems. Our facility integrates advanced metallurgical engineering with stringent quality control protocols to deliver copper earthing strips that meet international standards such as IEC 62305, BS EN 50164, and ASTM B187, ensuring reliable performance in power distribution, industrial infrastructure, and renewable energy applications.

Our production capabilities are anchored in a fully integrated rolling and finishing line designed specifically for flat-rolled copper products. Utilizing high-purity electrolytic tough pitch (ETP) copper (Cu ≥ 99.90%), we produce earthing strips with precise dimensional tolerances, uniform cross-sectional geometry, and superior surface finish. Standard thicknesses range from 1.0 mm to 6.0 mm, with widths from 10 mm to 60 mm, available in both soft (annealed) and hard (as-rolled) tempers to meet diverse installation and conductivity requirements. Each batch undergoes rigorous mechanical and electrical testing, including tensile strength, elongation, and DC resistivity verification, to guarantee long-term stability under continuous load and fault current conditions.

The factory operates under ISO 9001:2015 quality management certification, with in-house metallurgical laboratories equipped for chemical composition analysis (via OES spectrometry), microstructure evaluation, and adhesion testing for tinned variants. This technical depth enables us to customize material properties for specific environmental conditions, including enhanced corrosion resistance for coastal or high-humidity installations. Additionally, our cold-rolling technology ensures minimal thickness deviation—maintaining tight tolerances within ±0.05 mm—critical for consistent contact pressure and low-impedance grounding paths.

As a vertically integrated supplier, Luoyang Xinzhaohe controls the entire value chain from raw material sourcing to final packaging, enabling stable lead times and cost efficiency without compromising quality. We serve OEMs, transformer manufacturers, and electrical contractors across Asia, the Middle East, and Africa, with export-ready packaging that includes moisture-resistant wrapping and wooden palletization for sea freight durability.

Our engineering team supports clients with technical documentation, material test reports (MTRs), and sample provisioning to facilitate qualification and integration into existing grounding system designs. Whether you require standard C11000 strips or custom solutions with tin plating or adhesive backing, our R&D department collaborates closely to meet project-specific performance criteria.

For reliable supply of high-purity copper earthing strips backed by 20+ years of metallurgical expertise, partner with Luoyang Xinzhaohe Aluminum CO., Ltd. Contact us today at cathy@transformerstrip.com to discuss your technical requirements and receive a detailed quotation.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing copper earthing strip directly from China.