Table of Contents

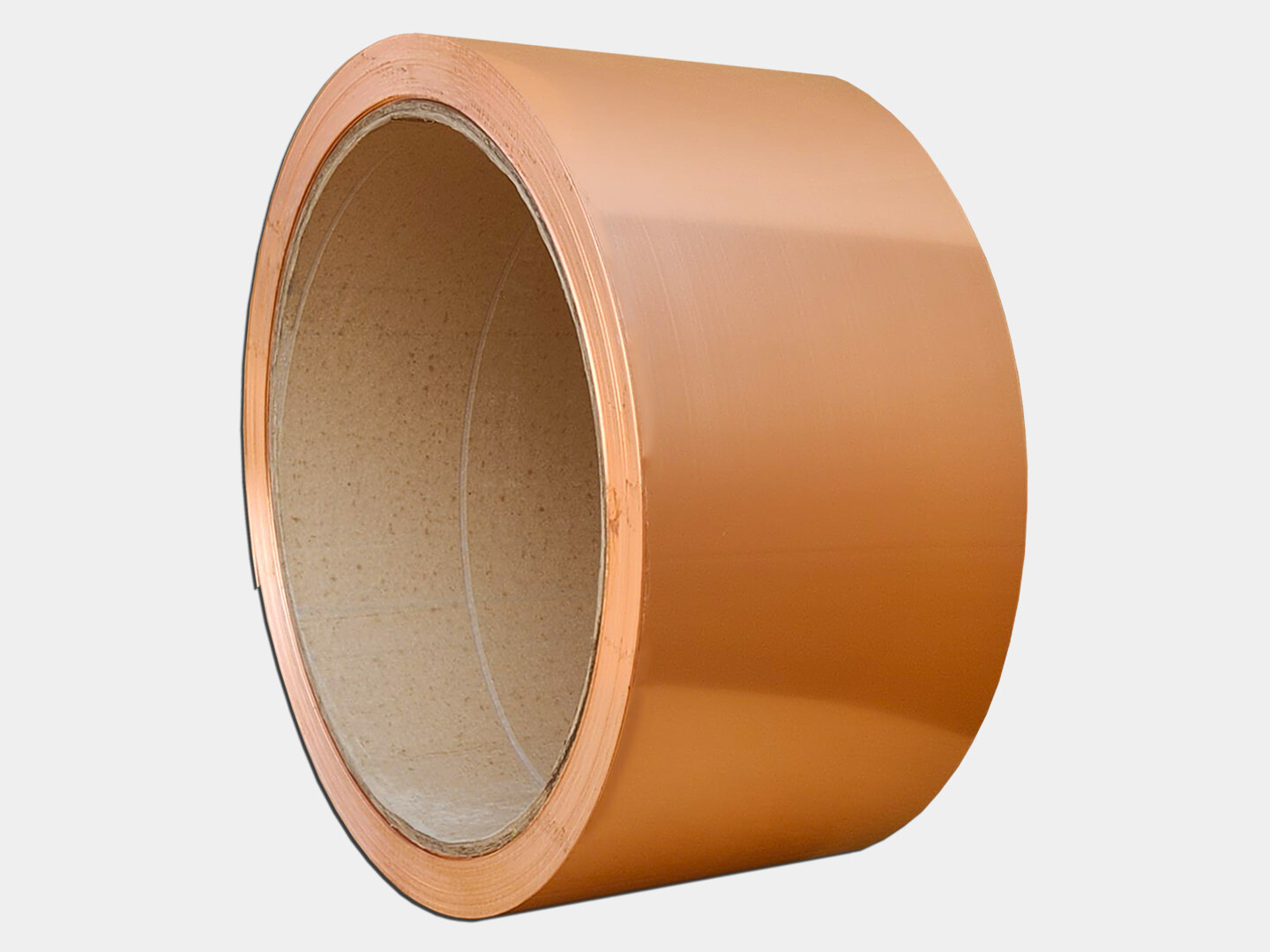

Market Insight: Copper Coils

Market Analysis: Transformer Strip/Foil (Aluminum/Copper)

Industrial demand for copper coils in power and distribution transformers remains robust despite aluminum’s growing adoption in specific applications. Global grid modernization initiatives, renewable energy integration, and electric vehicle infrastructure expansion are primary growth drivers. Copper’s superior electrical conductivity (100% IACS minimum per ASTM B3) ensures minimal resistive losses, critical for high-efficiency transformers mandated by standards like DOE 2016 and EU Ecodesign. While aluminum offers weight and cost advantages in distribution transformers, copper dominates in high-reliability applications such as traction transformers for rail systems, industrial furnace units, and critical grid infrastructure where thermal stability and current density are non-negotiable. Current market data indicates copper coil demand for transformers will grow at 4.2% CAGR through 2028, heavily influenced by Asia-Pacific grid investments and data center proliferation requiring ultra-low-loss designs.

Quality parameters for copper transformer coils are directly tied to transformer longevity and safety. Impurities exceeding 50 ppm oxygen or trace elements like sulfur degrade conductivity and accelerate thermal aging. Dimensional precision—particularly thickness tolerance (±0.005 mm for foil, ±0.01 mm for strip) and edge straightness—is essential to prevent interlayer short circuits during winding. Surface integrity, including absence of micro-scratches or oxide inclusions, mitigates partial discharge risks that initiate insulation breakdown. Substandard coils introduce hotspots through uneven current distribution, reducing transformer lifespan by up to 40% and increasing failure rates during thermal cycling. Industry studies correlate coil defects with 68% of premature transformer failures in the 10–50 MVA range, underscoring that material quality directly impacts total cost of ownership.

At Luoyang Xinzhaohe Aluminum CO., Ltd., our 20-year metallurgical expertise extends to rigorous copper coil validation despite our aluminum specialization. We enforce triple-stage quality control:

1. Raw Material Certification: Direct-sourced cathode copper with 99.99%+ purity, verified via OES spectroscopy against IEC 60138.

2. Process Control: Cold-rolling under inert atmosphere to prevent hydrogen embrittlement; tension leveling for residual stress elimination.

3. Final Inspection: Automated eddy current testing for subsurface flaws, coupled with ASTM B3 conductivity validation at 56.0–58.0 MS/m.

The cost of non-conformance far exceeds material premiums. A single 132 kV transformer failure due to coil defects incurs average downtime costs of $1.2M and replacement expenses exceeding $500k. Sourcing partners must demonstrate traceability to smelter lots and adherence to IEC 60404-29 mechanical property benchmarks. As grid resilience becomes paramount, copper coil quality transitions from a technical specification to a strategic risk mitigation factor. Luoyang Xinzhaohe applies aluminum foil production discipline to copper coil verification, ensuring seamless integration into mission-critical transformer manufacturing.

Technical Specs: Copper Coils

Technical Specifications for Copper Coils – Precision Sourcing Guide

Luoyang Xinzhaohe Aluminum Co., Ltd. provides high-performance copper coils tailored for critical applications in power transformers, electrical systems, and industrial equipment. With over two decades of metallurgical and precision processing expertise, our copper coil manufacturing adheres to stringent international standards, ensuring dimensional accuracy, electrical efficiency, and mechanical integrity. This section outlines the key technical parameters essential for sourcing high-quality copper coils, particularly for transformer strip and foil applications.

Dimensional precision is paramount in copper coil performance, especially in slitting processes where edge conformity directly impacts winding efficiency and core losses. Our precision slitting capability maintains a tolerance of ±0.002 mm across coil widths ranging from 10 mm to 500 mm. This tight tolerance ensures uniform layer stacking in transformer windings, minimizing air gaps and reducing hot-spot formation. The slit edges are processed using advanced rotary shear technology with wear-compensated tooling, achieving a burr level consistently below 2% of material thickness. Burr-free edges are critical to prevent dielectric breakdown in insulation systems and to ensure smooth handling during high-speed winding operations.

Electrical conductivity is a defining characteristic of electrolytic tough pitch (ETP) copper used in our coils. All copper material meets or exceeds 100% IACS (International Annealed Copper Standard) at 20°C, ensuring optimal current-carrying capacity and minimal resistive losses. Conductivity is verified through four-point probe resistivity testing across multiple coil sections to ensure homogeneity. Trace element analysis confirms oxygen content between 180–400 ppm, balancing conductivity with weldability and thermal stability.

Mechanical properties are controlled through precise annealing profiles in oxygen-free nitrogen atmospheres, preventing surface oxidation and maintaining ductility. Typical tensile strength ranges from 200–240 MPa with elongation exceeding 40%, enabling cold forming and tight-radius bending without cracking. Surface finish is maintained at Ra ≤ 0.4 µm to support uniform insulation coating adhesion and reduce partial discharge risks.

All coils are supplied in master rolls with inner diameters of 508 mm (20″) or 610 mm (24″), with maximum outer diameters of 1800 mm. Standard coil weights range from 1,500 to 3,500 kg, depending on width and thickness. Material traceability is ensured through batch-specific mill test certificates (MTCs) compliant with ISO 9001 and IATF 16949 standards.

The following table summarizes the critical technical parameters for copper coils supplied by Luoyang Xinzhaohe Aluminum Co., Ltd.

| Parameter | Specification |

|---|---|

| Material Grade | ASTM B3, C11000 (ETP Copper) |

| Thickness Range | 0.05 mm – 3.0 mm |

| Width Range | 10 mm – 500 mm |

| Slitting Tolerance | ±0.002 mm |

| Edge Burr | ≤ 2% of material thickness |

| Conductivity | ≥ 100% IACS at 20°C |

| Tensile Strength | 200–240 MPa |

| Elongation | ≥ 40% (ASTM E8) |

| Surface Roughness (Ra) | ≤ 0.4 µm |

| Inner Diameter (ID) | 508 mm or 610 mm |

| Outer Diameter (OD) | Up to 1800 mm |

| Annealing Atmosphere | Oxygen-free Nitrogen |

| Packaging | Waterproof core sealing, steel strapping |

These specifications reflect our commitment to delivering copper coils that meet the exacting demands of modern transformer and electrical component manufacturing.

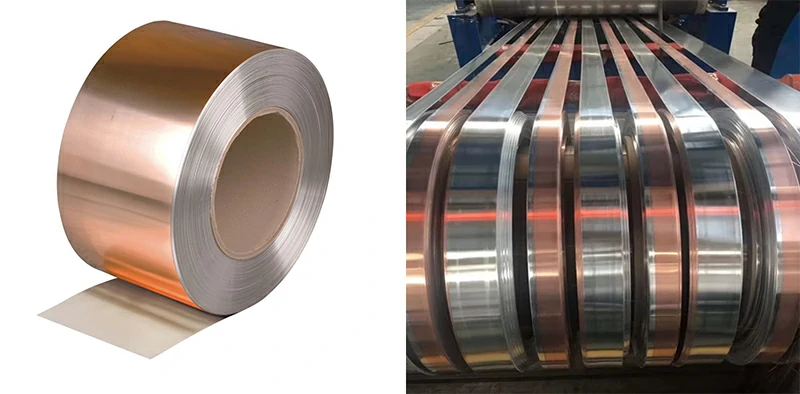

Factory Tour: Manufacturing

Manufacturing Process for High-Purity Copper Coils: Precision Engineering for Transformer Applications

As a specialized producer of critical transformer conductive materials with over two decades of metallurgical expertise, Luoyang Xinzhaohe Aluminum Co., Ltd. applies rigorous, industry-proven methodologies to copper coil production. Our process ensures dimensional stability, surface integrity, and mechanical properties essential for high-efficiency transformer windings. The core sequence involves Cold Rolling, Precision Slitting, and Edge Conditioning, each stage incorporating stringent quality control protocols.

Cold Rolling forms the foundational step where continuously cast or extruded copper billets undergo significant reduction at ambient temperature. This process critically enhances mechanical strength through work hardening while achieving precise thickness tolerances down to ±0.005 mm. Controlled interstand tension and precise roll gap adjustments are paramount to prevent centerline defects and ensure uniform elongation across the coil width. Surface finish is meticulously monitored to eliminate scratches or roll marks that could initiate insulation damage during winding. In-process thickness gauges and surface scanners provide real-time feedback, with samples subjected to immediate metallurgical analysis for grain structure verification and hardness uniformity checks per ASTM E384 standards.

Following cold rolling, Precision Slitting segments the master coil into customer-specified widths with exceptional accuracy. Advanced tension leveling systems maintain consistent strip flatness throughout the operation, minimizing edge wave or center buckle. High-precision shear or razor slitting knives, maintained to exacting geometries, achieve width tolerances of ±0.05 mm. Critical parameters include controlled knife overlap, optimal strip tension, and precise side clearance to prevent edge burring or dimensional drift. Every slit coil undergoes immediate width verification using laser micrometers at multiple points along the length, with flatness measured via precision straightness testers to ensure compliance with IEC 60404-9 specifications for transformer strip.

Edge Conditioning represents a decisive stage for transformer reliability. Imperative to eliminate micro-burrs generated during slitting, our process employs controlled abrasive brushing or precision edge rolling. This treatment ensures burr heights remain consistently below 0.01 mm, preventing puncture of insulating varnishes during high-speed coil winding. Surface roughness (Ra) is maintained within 0.2–0.8 µm to optimize adhesion of subsequent insulation coatings. Final edge quality is validated using high-magnification optical profilometry and tactile surface roughness testers, with 100% edge inspection conducted on critical transformer-grade orders.

Quality assurance is embedded at every phase, not merely as final checks. The integrated control framework ensures material traceability from melt to shipment. Key verification metrics are summarized below:

| Process Stage | Critical Parameter | Verification Method |

|---|---|---|

| Cold Rolling | Thickness Tolerance | Laser Micrometer + X-ray Gauging |

| Surface Defect Density | Automated Optical Inspection (AOI) | |

| Tensile Strength / Hardness | ASTM E8 Tensile Testing + Hardness Indentation | |

| Precision Slitting | Width Tolerance | Laser Micrometer (Continuous Monitoring) |

| Edge Wave / Center Buckle | Precision Straightness Tester | |

| Edge Conditioning | Burr Height | Optical Profilometry (100% Inspection) |

| Surface Roughness (Ra) | Tactile Profilometer |

This disciplined sequence, governed by ISO 9001-certified procedures and leveraging our deep metallurgical understanding of conductor behavior, delivers copper coils meeting the most demanding transformer manufacturing requirements. Consistent edge quality and dimensional precision directly translate to reduced winding defects, enhanced core efficiency, and extended transformer service life.

Packaging & Logistics

Export Packaging for Copper Coils: Ensuring Integrity in International Shipments

At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of specialized experience in the production and global distribution of transformer strip and foil—spanning both aluminum and copper alloys—packaging is recognized not merely as a logistical necessity, but as a critical component of product integrity. For copper coils destined for international markets, our export packaging system is engineered to withstand the rigorous demands of sea freight, ensuring material quality is preserved from factory to final destination.

All copper coils are systematically mounted on high-strength wooden pallets constructed from kiln-dried, ISPM 15-compliant hardwood. These pallets are designed to support the substantial weight and dimensional stability of tightly wound copper coils, typically ranging from 500 kg to 5,000 kg per unit. The structural integrity of the pallets prevents deformation during lifting, stacking, and long-haul transport. Reinforced baseboards and cross-beams distribute load evenly, minimizing the risk of coil collapse or edge damage during vessel motion or port handling.

Immediately following palletization, each coil is wrapped in multi-layer moisture-proof composite film, incorporating aluminum foil barriers and high-density polyethylene (HDPE) laminates. This vapor-resistant wrapping is heat-sealed at all seams to form a hermetic enclosure, protecting against salt-laden maritime atmospheres, condensation, and humidity fluctuations inherent in ocean container environments. The moisture barrier maintains dew point differentials, preventing oxidation, surface tarnishing, and the formation of cuprous oxide, which can compromise electrical conductivity and downstream processing performance.

Additional protective measures include the application of desiccant packs within the sealed film envelope and the use of edge protectors made from corrugated fiberboard or plastic to guard against mechanical abrasion. Coils are further secured with steel or PET strapping across the pallet to prevent axial shift during transit. Each packaged unit is labeled with UV-resistant, barcoded identification tags indicating alloy type, temper, dimensions, batch number, and handling instructions compliant with IMDG and IATA maritime regulations.

Our packaging protocols are validated through accelerated climate chamber testing simulating 45-day sea voyages under tropical and temperate conditions. This quality assurance process ensures that copper coils arrive at overseas facilities—whether in Southeast Asia, the Middle East, or South America—with zero degradation in surface finish or metallurgical properties.

By integrating robust wooden palletization with advanced moisture-resistant encapsulation, Luoyang Xinzhaohe Aluminum Co., Ltd guarantees that every exported copper coil meets the highest standards for safe, reliable, and contamination-free maritime transportation. This commitment underscores our role as a trusted technical partner in the global transformer and electrical manufacturing supply chain.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe for Precision Copper Coil Sourcing

Luoyang Xinzhaohe Aluminum Co., Ltd leverages over two decades of specialized metallurgical engineering to deliver transformer-grade copper coils meeting the most stringent industrial specifications. While our core heritage lies in aluminum transformer strip and foil, our vertically integrated facility applies identical precision manufacturing protocols to copper coil production, ensuring material consistency critical for high-efficiency transformer windings. Our technical expertise spans the full production lifecycle—from raw material purity verification to final temper control—guaranteeing coils that optimize electrical conductivity, thermal stability, and mechanical formability during coil winding operations.

Our 45,000m² manufacturing campus houses dedicated copper processing lines featuring twin-stand cold rolling mills with automatic gauge control (AGC) systems, achieving thickness tolerances of ±0.005mm for coils up to 1,250mm width. All copper undergoes rigorous melt refining to 99.99% minimum purity (C10100/C11000 standards), followed by controlled annealing in oxygen-free atmospheres to eliminate hydrogen embrittlement risks. This process delivers uniform O50 (½ hard) to O60 (full hard) tempers with precise grain structure refinement, directly impacting transformer no-load loss performance. In-house metallurgical labs conduct daily spectrographic analysis, tensile testing, and eddy current flaw detection, ensuring compliance with ASTM B3, IEC 60138, and customer-specific material certifications.

Supply chain resilience is engineered into our operations through strategic partnerships with LME-approved copper cathode suppliers and dual-source billet casting capabilities. This mitigates raw material volatility while maintaining traceability from smelter to finished coil. Our just-in-sequence (JIS) logistics system integrates with global transformer OEM production schedules, supporting JIT deliveries to ports worldwide with 99.2% on-time shipment accuracy. All processes adhere to a certified quality management framework, validated through third-party audits:

| Certification | Standard | Scope Coverage |

|---|---|---|

| ISO 9001 | 2015 | Copper coil design & production |

| ISO 14001 | 2015 | Environmental management |

| IATF 16949 | 2016 | Automotive-grade materials |

| SGS Mill Test Reports | ASTM/IEC | Full batch traceability |

Partnering with Luoyang Xinzhaohe eliminates supply chain fragmentation by consolidating engineering consultation, precision rolling, and global logistics under one technical authority. Our engineers collaborate directly with transformer designers to resolve material compatibility issues—such as mitigating interfacial oxidation during aluminum-copper hybrid winding assembly—and provide metallurgical data packages for regulatory submissions. For projects demanding consistent conductivity ≥100% IACS with edge burr control under 0.02mm, our process capability indices (Cp/Cpk >1.67) deliver measurable reductions in winding scrap rates.

Contact Cathy Zhang at cathy@transformerstrip.com to request copper coil technical datasheets or schedule a metallurgical review of your transformer material requirements. We provide sample coils within 72 hours for performance validation against your core loss and mechanical winding specifications.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing copper coils directly from China.