Table of Contents

Market Insight: Copper Coil Winding

Market Analysis: Winding Wire – Copper Coil Windings in Transformer Applications

The industrial demand for copper coil winding in transformer manufacturing remains robust and continues to grow in parallel with global energy infrastructure development, renewable energy integration, and industrial electrification. Copper winding wire is a critical component in both power and distribution transformers, where it serves as the conductive medium for electromagnetic energy transfer. The performance, efficiency, and longevity of transformers are directly influenced by the quality and consistency of the copper winding material used.

Transformers operate under continuous electrical and thermal stress, requiring winding conductors that exhibit high electrical conductivity, excellent thermal stability, and mechanical durability. Copper, with its superior conductivity (approximately 100% IACS), remains the preferred material over aluminum in high-efficiency and high-reliability transformer designs. The demand is particularly strong in sectors such as utility power transmission, rail traction systems, industrial motor drives, and renewable energy inverters, where even marginal improvements in efficiency translate into significant operational cost savings and reduced carbon emissions over the asset lifecycle.

Quality in copper winding wire is not merely a manufacturing specification—it is a performance determinant. Variations in dimensional tolerances, surface finish, tensile strength, and elongation can lead to winding defects, increased eddy current losses, hot spot formation, and ultimately, premature transformer failure. Impurities or inconsistencies in the copper microstructure can compromise dielectric integrity and accelerate insulation degradation, especially under repeated thermal cycling. Therefore, premium-grade electrolytic tough pitch (ETP) copper, drawn to precise tolerances and annealed under controlled conditions, is essential for reliable transformer operation.

At Luoyang Xinzhaohe Aluminum CO., Ltd, with over two decades of metallurgical and wire processing expertise, we apply stringent quality control protocols to ensure our copper winding wire meets international standards such as IEC 60317 and ASTM B3. Our production process includes continuous oxygen-controlled annealing, laser-based diameter monitoring, and surface defect inspection systems to deliver wire with uniform electrical properties and smooth, oxide-free surfaces. This precision enables seamless high-speed winding operations and ensures optimal coil packing density, directly contributing to transformer efficiency and thermal management.

The global shift toward smart grids and energy-efficient appliances further intensifies the demand for high-performance winding solutions. As regulatory standards such as IE4 and IE5 for motor efficiency become more widespread, the need for low-loss, high-conductivity copper windings will continue to rise. In this evolving landscape, sourcing from a technically capable and quality-focused supplier is paramount. Consistent material properties, traceability, and process reliability are not optional—they are foundational to transformer design integrity and long-term field performance.

In summary, the industrial demand for copper coil winding in transformers is driven by the need for energy efficiency, reliability, and compliance with evolving technical standards. The selection of high-quality copper winding wire directly impacts the operational effectiveness and service life of transformers, making material quality a critical factor in the supply chain for power and industrial equipment manufacturers.

Technical Specs: Copper Coil Winding

Technical Specifications for Copper Coil Winding Wire

Luoyang Xinzhaohe Aluminum Co., Ltd leverages 20+ years of metallurgical and wire manufacturing expertise to deliver precision copper winding wire meeting stringent global electrical standards. While specializing in aluminum solutions, our copper winding wire production adheres to IEC 60317 and ASTM B3 specifications, ensuring optimal performance in motor, transformer, and inductor applications. Critical parameters include insulation integrity, mechanical ductility, and thermal resilience, which directly impact coil longevity and operational safety.

Insulation breakdown voltage is non-negotiable for dielectric reliability. Our polyurethane, polyester, or polyamide-imide insulated wires undergo rigorous testing per IEC 60317-0-1, with minimum breakdown thresholds exceeding 3.0 kV RMS at 50 Hz for 0.5 mm diameter wire. This exceeds baseline industry requirements, mitigating risks of short circuits under voltage surges. Elongation, measured per ASTM B3 on a 25 mm gauge length, is maintained between 15% and 35% to ensure crack-free winding during high-speed coil processing. Values below 15% risk insulation damage during tight-radius bends, while excessive elongation (>35%) compromises dimensional stability.

Thermal classification dictates operational limits in demanding environments. We supply wires rated from Class B (130°C) to Class C (220°C), validated via thermal endurance testing per IEC 60172. Class B (130°C) uses polyester-imide insulation for cost-sensitive applications, while Class H (180°C) and Class C (200–220°C) employ advanced polyamide-imide or ceramic-polymer hybrids for aerospace and EV traction motors. Continuous operation beyond the rated class accelerates insulation degradation, reducing service life by 50% per 10°C exceedance per the Arrhenius model.

The following table summarizes core technical parameters for our copper winding wire:

| Parameter | Standard Value | Test Method | Critical Tolerance |

|---|---|---|---|

| Conductor Purity | ≥ 99.95% Cu (OFE grade) | ASTM B133 | ±0.02% |

| Breakdown Voltage | 3.0–8.0 kV RMS (diameter-dependent) | IEC 60317-0-1 | +0.5 kV / -0 kV |

| Elongation | 15–35% | ASTM B3 | ±2% |

| Thermal Class | B (130°C) to C (220°C) | IEC 60172 | ±5°C |

| Tensile Strength | 200–350 MPa | ASTM E8 | ±15 MPa |

| Dimensional Tolerance | ±0.003 mm (diameter) | IEC 60122-1 | ±0.001 mm |

All wires utilize oxygen-free electrolytic (OFE) copper with grain structure optimized for uniform drawing and adhesion. Insulation thickness follows IEC 60317 diameter bands, with ±5% tolerance to balance space factor and dielectric strength. Our production integrates real-time在线 monitoring for voltage withstand and dimensional consistency, ensuring 100% compliance before shipment. For high-reliability sectors like renewable energy or industrial automation, we recommend Class F (155°C) or higher with dual-layer insulation to withstand thermal cycling and partial discharge. Partner with Xinzhaohe for technically validated copper winding wire where electrical integrity and process efficiency are non-negotiable.

Factory Tour: Manufacturing

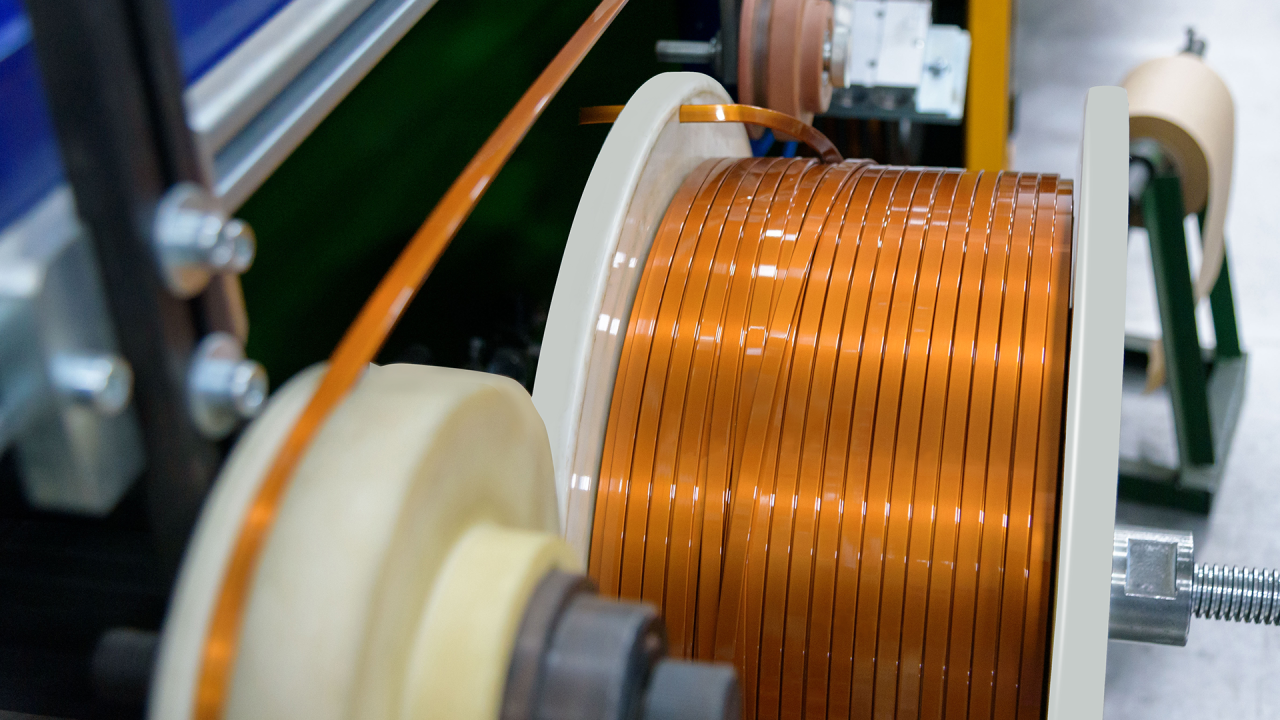

Manufacturing Process for Copper Coil Winding Wire

The production of high-performance copper coil winding wire at Luoyang Xinzhaohe Aluminum Co., Ltd follows a rigorously controlled sequence designed to ensure mechanical integrity, electrical conductivity, and thermal endurance. With over two decades of metallurgical and process engineering expertise, our manufacturing line integrates precision equipment and real-time quality monitoring across four core stages: Rod Drawing, Annealing, Enameling, and Inline Testing.

The process begins with high-purity electrolytic tough pitch (ETP) copper rod, meeting ASTM B3 and IACS conductivity standards of at least 100%. The rod undergoes multi-pass drawing through diamond or tungsten carbide dies to achieve the target wire diameter, with tolerances maintained within ±0.005 mm. Drawing is performed under controlled tension and lubrication conditions to minimize work hardening and surface defects. Each drawing pass is followed by intermediate cleaning to remove residual drawing compounds and oxide particles, ensuring a contaminant-free surface prior to subsequent processing.

Following cold drawing, the wire enters a continuous inert-atmosphere annealing furnace. This stage restores ductility and eliminates internal stresses induced during drawing. The annealing profile is precisely regulated, with temperature zones ranging from 450°C to 600°C depending on wire gauge and final application requirements. A nitrogen-hydrogen atmosphere prevents surface oxidation and ensures a bright, oxide-free finish essential for uniform enamel adhesion.

The annealed wire then proceeds to the enameling section, where multiple layers of polymer insulation are applied via precision die coating. Depending on the insulation class (e.g., 130°C, 155°C, 180°C, or 200°C), materials such as polyurethane (PU), polyester (PE), polyester-imide (PEI), or polyamide-imide (PAI) are used in single or dual-layer configurations. Each coat is immediately cured in a series of high-efficiency ovens with zoned temperature control, ensuring complete cross-linking and optimal dielectric strength. Film thickness is maintained within ±5% of nominal values, verified through laser micrometry.

Throughout the production line, inline testing systems provide continuous quality assurance. High-voltage breakdown testing is conducted at 3 kV to 12 kV depending on wire size and insulation class, with 100% coverage. Pinhole defect detection, diameter profiling via laser gauges, and tensile strength monitoring are integrated at critical control points. All data are logged in real time for traceability and statistical process control.

Final quality checks include thermal shock testing, softening resistance, and dielectric breakdown per IEC 60317 and GB/T 6109 standards. Every production lot is accompanied by a certified test report, including conductivity, elongation, winding integrity, and insulation adhesion. This comprehensive approach ensures that each spool of winding wire meets the stringent demands of motors, transformers, and electromagnetic devices in industrial and automotive applications.

Packaging & Logistics

Export Packaging Standards for Copper Coil Winding Wire

Luoyang Xinzhaohe Aluminum Co., Ltd. implements rigorously engineered export packaging protocols for copper coil winding wire, specifically designed to mitigate maritime transit hazards. With over two decades of metallurgical and supply chain expertise, our methodology prioritizes dimensional stability, corrosion prevention, and structural integrity during extended ocean voyages. All packaging adheres to ISO 11607 and ISPM-15 international standards, ensuring global customs compliance and cargo safety.

Wooden pallets form the foundational structural element of our export system. We utilize kiln-dried, heat-treated softwood pallets certified to ISPM-15 specifications, eliminating phytosanitary risks. Pallet dimensions are standardized at 1200mm × 1000mm × 150mm (L×W×H), engineered to support static loads exceeding 2,500 kg without deflection. Critical reinforcement includes triple-layer cross-blocking and 60mm × 80mm stringers, preventing coil deformation during container stacking. Each pallet undergoes moisture content verification (≤18% per EN 13226), reducing wood-related humidity ingress. Coils are secured via steel strapping (minimum 16 mm width, 15 kN tensile strength) tensioned to 30% of breaking load, with edge protectors preventing strap-induced damage.

Moisture control constitutes the most critical technical safeguard for copper winding wire. Our multi-barrier system integrates three sequential protective layers:

First, coils are sealed in 0.1 mm thick moisture-vapor transmission rate (MVTR) film (ASTM F1249 ≤0.5 g/m²/day), composed of ethylene-vinyl acetate copolymer laminates. This primary wrap is vacuum-shrunk to eliminate air pockets.

Second, a desiccant layer comprising silica gel packets (50g/m³ capacity) and humidity indicator cards (calibrated 10–60% RH range) is positioned between the coil and secondary barrier.

Third, an outer layer of metallized polyester film (aluminum-coated, 12 μm thickness) provides electromagnetic shielding and reflects radiant heat. All seams are heat-sealed with 25 mm overlap, validated via helium leak testing (detection limit 5×10⁻⁶ mbar·L/s).

This integrated approach directly addresses sea freight vulnerabilities. Salt-laden air, temperature cycling (−25°C to +60°C), and relative humidity fluctuations (30–95% RH) are neutralized through hermetic sealing and vapor barriers. Accelerated corrosion testing (ASTM B117, 5% NaCl fog, 1,000 hours) confirms zero pitting or oxidation on packaged copper samples. Containerized shipments further incorporate humidity-absorbing pallet collars (calcium chloride-based, 300g capacity) and shock loggers (recording 3-axis impacts >5g).

Our packaging efficacy is quantified through real-world logistics performance. Over the past five years, 98.7% of copper coil shipments arrived with zero moisture-related claims, and 99.8% maintained dimensional tolerances within ±0.05 mm. Documentation includes certified packing lists, humidity logs, and third-party inspection reports (SGS/BV). For clients, this translates to reduced insurance premiums, elimination of post-arrival rework, and guaranteed wire surface integrity for precision winding applications. Luoyang Xinzhaohe’s packaging is not merely containment—it is a calibrated extension of our metallurgical quality control, engineered for the harsh realities of global supply chains.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe for Precision Copper Coil Winding Solutions

Luoyang Xinzhaohe Aluminum Co., Ltd brings over two decades of specialized expertise in the design and production of high-performance winding wires, positioning itself as a trusted partner for global manufacturers in the transformer, motor, and inductor sectors. While our core competency lies in aluminum strip and foil processing, our technical expansion into copper coil winding solutions reflects our commitment to delivering integrated, precision-engineered conductive materials tailored to the evolving demands of the electrical and electronic industries.

Our manufacturing infrastructure is engineered for consistency, scalability, and adherence to international quality benchmarks. Spanning over 50,000 square meters, our production facility integrates advanced drawing, annealing, and winding lines capable of processing copper conductors with diameters ranging from 0.05 mm to 5.0 mm. This range supports applications from fine-wire micro-coils to heavy-duty power transformer windings. All processes are monitored under ISO 9001-certified quality management protocols, ensuring dimensional accuracy, uniform tensile strength, and optimal elongation properties critical for high-reliability winding performance.

A key differentiator at Luoyang Xinzhaohe is our in-house metallurgical laboratory, equipped with state-of-the-art testing instrumentation including tensile strength analyzers, micro-ohmmeters, and surface profilometers. Every batch of copper winding wire undergoes rigorous evaluation for conductivity (minimum 98% IACS), surface cleanliness, and oxide layer control, minimizing the risk of inter-turn insulation failure and ensuring compatibility with varnish impregnation and encapsulation processes. Our strict raw material sourcing policy mandates the use of high-purity electrolytic tough pitch (ETP) copper, traceable to certified suppliers, further enhancing product reliability.

We specialize in custom coil configurations, including pancake, helical, and orthocyclic winding patterns, with precise layer insulation and termination options. Our engineering team collaborates directly with clients to optimize coil geometry, fill factor, and thermal performance based on application-specific electrical and mechanical constraints. Whether supporting prototyping or high-volume production, our agile manufacturing model allows for rapid tooling setup and batch traceability, reducing lead times without compromising quality.

With a logistics network spanning Asia, Europe, and North America, we ensure timely delivery through strategic partnerships with certified freight operators, offering both FOB and CIF shipping terms. Our export experience includes compliance with REACH, RoHS, and IEC 60317 standards, enabling seamless integration into international supply chains.

For OEMs and tier-level suppliers demanding precision, consistency, and technical partnership in copper coil winding, Luoyang Xinzhaohe Aluminum Co., Ltd offers a proven manufacturing foundation backed by deep metallurgical insight and customer-centric engineering support.

Contact us at cathy@transformerstrip.com to discuss your winding wire specifications and discover how we can enhance the performance and reliability of your electromagnetic components.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing copper coil winding directly from China.