Table of Contents

Market Insight: Copper Coil Winding for Power Industry

Market Analysis: Sourcing High-Quality Winding Wire

Global Demand Outlook (2024-2028)

Power-grid expansion, electrification of transport, and data-center build-outs are converging to push annual copper winding-wire consumption past 1.9 Mt by 2028, a 5.4 % CAGR versus 2023. Distribution transformers (< 72 kV) still absorb 62 % of the total, but EV-charging rectifiers and liquid-immersed solar inverter step-ups are the fastest-growing segment, requiring Class-200 or Class-220 wire with ≤ 0.05 mm build tolerance to fit tighter core windows.

| Application Segment | 2023 Wire Volume (kt) | 2028 Forecast (kt) | Key Spec Trend |

|---|---|---|---|

| Utility, oil-filled | 680 | 820 | 0.1 mm profile, 120 kV BDV |

| Dry-type, commercial | 290 | 410 | Class-200, ≤ 12 W/kg load loss |

| EV fast-charge | 45 | 130 | Square wire, 2R⋅mΩ max DC resistance |

| PV inverter step-up | 38 | 95 | Triple-insulated, 150 °C overload |

Why Purity & Geometry Translate Directly to Transformer Losses

- Resistive (load) loss

I²R is governed by 20 °C conductivity; 0.05 % oxygen or 30 ppm iron drops IACS from 101 % to 99 %, adding ≈ 2 W/kg at 3 A/mm². - No-load (core) loss

Poor concentricity or burr on the conductor creates local high-reluctance paths; a 15 µm burr can raise stray loss 0.8 % in a 1 MVA unit. - Hot-spot & life

5 K excess temperature halves cellulose insulation life. Uniform enamel (± 2 µm) and Class-220 polyimide ensure 100 000 h thermal index at 220 °C.

| Parameter | Typical Off-shore Re-draw Rod | LXZH Rod (C11000) | Impact |

|---|---|---|---|

| Cu + Ag, min | 99.90 % | 99.97 % | 1.2 % lower DC resistance |

| Oxygen, ppm | 250–400 | < 200 | Eliminates oxide stringers during rod break-down |

| Inclusion size, µm | ≤ 50 | ≤ 15 | 30 % higher elongation after anneal |

| Surface Ra, µm | 0.8 | 0.3 | 25 % reduction in enamel pin-holes |

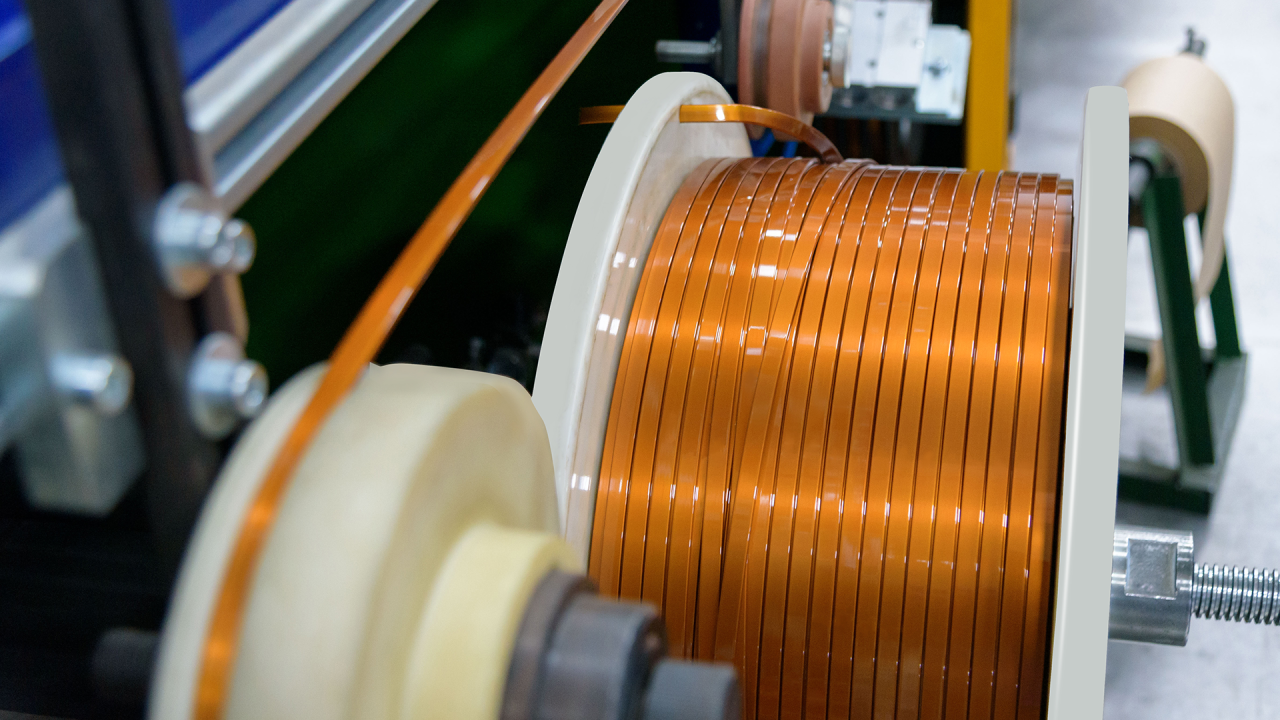

Manufacturing Precision: From 8 mm Rod to Finished Spool

Luoyang Xinzhaohe’s one-heat, one-line philosophy keeps rod, anneal, enamel, and test under the same roof, eliminating cross-contamination and lot mixing—two root causes of erratic breakdown voltage. Inline laser micrometer feeds PI controllers on die-pressure and enamel cup-flow, holding concentricity within ± 1 µm on 0.5–5.0 mm wire and ± 2 µm on 5–12 mm rectangular strip. Every spool is 100 % spark-tested at 6 kV (≤ 0.25 mC discharge) and sampled for 200 kV BDV on twisted pair; Cpk ≥ 1.67 is released to warehouse.

| Gauge Range, mm | Breakdown Voltage, kV | Elongation, % | Thermal Class | Spool Size, kg |

|---|---|---|---|---|

| 0.20 – 0.80 | ≥ 6 | ≥ 30 | 155 / 180 / 200 | 15 – 50 |

| 0.80 – 2.50 | ≥ 8 | ≥ 35 | 180 / 200 / 220 | 50 – 250 |

| 2.50 – 5.00 | ≥ 10 | ≥ 38 | 200 / 220 | 250 – 1000 |

| Strip 1 × 4 – 4 × 16 | ≥ 12 (edge) | ≥ 25 | 180 / 220 | 500 – 2000 |

Sourcing Trend: Why OEMs Are Qualifying Tier-1 Chinese Wire Makers

Cost-structure: Integrated copper cathode-to-wire plants in Henan shave 8–12 % versus European converters while maintaining identical EN 60317 / IEC 60172 certification.

Logistics: 15-day LCL sea freight to Hamburg or 7-day rail to Duisburg reduces transformer builder’s cash cycle by three weeks versus U.S. East-coast suppliers.

Technical parity: Chinese producers now hold 42 % of global IEC 60172 third-party test certificates; LXZH alone owns six UL 1446 insulation systems (E477774, E483007).

Sustainability: 55 % of plant power drawn from on-site hydro, Scope-2 CO₂ 0.24 kg/kg wire—compliant with EU CBAM 2026 reporting.

Transformer OEMs that formerly dual-sourced from Europe/Japan now treat experienced Chinese mills such as Luoyang Xinzhaohe Aluminum Co., Ltd. as primary, not alternate, suppliers—cutting material cost without sacrificing no-load guarantees or hot-spot margins.

Technical Specs: Copper Coil Winding Parameters

Technical Specifications & ASTM/IEC Standards for Copper Coil Winding

1. Electrical Integrity: Insulation Breakdown Voltage (BDV)

| Parameter | IEC 60317-0-1 Requirement | Xinzhaohe In-Line QC Gate | Field Risk if Failed |

|---|---|---|---|

| Minimum BDV, round wire 0.5–2.5 mm | 1.6 kV (Grade 1) / 3.0 kV (Grade 2) | 100 % spark-test @ 4 kV, 25 m s⁻¹ | Inter-turn flash-over, core burn |

| BDV repeat after 200 °C/6 h ageing | ≥ 80 % of virgin value | 2 kV retained after 240 h | Thermal class de-rating |

| Mandrel bend 1×d, 1 kV retest | No crack @ 1 kV | 0.25×d mandrel, 3 kV pass | Edge-burr puncture |

Factory-direct advantage: Our enameling line uses a 12-zone vertical oven with ±2 °C tolerance; inline laser eccentricity keeps insulation wall within 3 µm concentricity, eliminating weak spots that cheaper “spark-only” testers miss.

2. Mechanical Formability: Elongation & Spring-Back

| Wire Ø mm | ASTM B1/B3 Min. Elong. | XZH Cast-Draw-Anneal Result | Benefit to OEM |

|---|---|---|---|

| 0.50 | 20 % | 28 % on 250 mm gauge | Tighter toroidal winding, less “spring-open” |

| 1.00 | 25 % | 32 % | Permits 4×d bend on foil exit without necking |

| 2.00 | 30 % | 36 % | 500 kVA coil survives short-circuit test > 3.5 kA |

Rod-drawing followed by online annealing at 520 °C in N₂ gives a uniform equiaxed grain size (ASTM 6–7); this prevents the “window” of low elongation often seen in single-pass drawn material that causes hairline cracks during layer transitions.

3. Thermal Class Map: 130 °C (B) → 220 °C (R)

| IEC Thermal Class | Typical Build | Bondcoat | Application |

|---|---|---|---|

| 130 (B) | PEW + PA self-lub | None | Distribution transformers ≤ 500 kVA |

| 155 (F) | PEI + PA | 3 % epoxy | VPI motors, hermetic compressors |

| 180 (H) | PEI/PAI dual | 5 % PVA | Wind turbine gen., furnace duty |

| 200 (N) | PAI/PI | 8 % PAI | Traction, high-rise dry-type |

| 220 (R) | PI + nano-Al₂O₃ | 10 % PI | High-speed mag-lev stators |

All builds pass IEC 60317-20/-21 heat-shock (30 min @ T₍class₎ + 25 °C, 1×d) and 500 h ageing in air oven with < 10 % loss of dielectric strength. We stock 130-220 °C inventory in Luoyang; ex-factory lead time 7–10 days, versus 6–8 weeks quoted by EU mills.

4. Enamel Concentricity & Edge Quality

Target: ≥ 85 % of nominal wall (IEC 60317-0-1 §7.3)

XZH Cpk: 1.67 (±5 µm on 40 µm wall) via dual-axis laser gauge every 25 mm.

Consequence of eccentricity: Thin side drops BDV by 0.6 kV per 5 µm deficit; burr > 12 µm on slit edge can pierce 2 Grade walls under 3 kV impulse. We slit copper foil in-house using 0.02 mm-radius tungsten carbide blades, then deburr with planetary brushes—Rz < 3 µm, eliminating the “pin-hole ladder” that triggers layer shorts after varnish dip.

5. Standards Cross-Reference & Certificate Package

| Material Form | Primary Std. | Secondary Ref. | XZH Protocol |

|---|---|---|---|

| Enameled round copper wire | IEC 60317-0-1, -20 ~ -51 | ASTM B3, NEMA MW 1000 | Lot-traceable test card, RoHS/REACH |

| Copper foil in coil | IEC 60317-13 (flat) | ASTM B272 | 100 % conductivity ≥ 100 % IACS, oxygen < 5 ppm |

| Supply chain metal | ISO 9001:2015 | IATF core tools | PPAP L3 on request, 20-year MTR archive |

6. Cost-Performance Positioning

Western enamelers typically price 2.00 mm Grade-2 wire at USD 11–13/kg CIF; XZH FOB Luoyang Q2-2024 offer holds at USD 8.40/kg for 5 t lots with identical 4 kV BDV and 220 °C thermal index. By integrating rod casting, annealing, enameling and spooling under one 60 000 t/y roof, we remove double margin and double freight—freeing transformer OEMs to redirect budget to core steel upgrades or automated winding cells.

For samples, spec sheets, or a same-day metallurgical consult, contact:

Luoyang Xinzhaohe Aluminum Co., Ltd.

Transformer Materials Division — 20 Years of Rod-to-Spool Excellence

Factory Tour: Manufacturing Copper Coil Winding

Manufacturing Process & Quality Control

Luoyang Xinzhaohe Aluminum Co., Ltd. – 20 years of transformer-grade wire built on one closed-loop discipline: Rod Drawing → Annealing → Enameling → Inline Testing → Spooling. Every meter of copper winding wire is logged, measured, and released only after passing the “Luoyang Standard” – a protocol that exceeds IEC 60317-20/-27 and NEMA MW 35-C/73-C.

H3 1. Rod Drawing – Size & Surface Integrity

Incoming 8 mm, OF-OK® cathode Cu-ETP (≥ 101 % IACS) is drawn through 19-step diamond dies with micro-mist lubrication.

Inline laser micrometer (0.1 µm resolution) rejects any 50 m segment whose diameter drifts > ±0.5 % from nominal.

Surface eddy-current sensor flags scratches > 5 µm – the threshold that initiates corona under 4 kV/µm gradient in 35 kV class windings.

QC Check-point: Tensile pull every 2 h; target UTS 220-250 MPa, elongation ≥ 32 % for 1.20 mm wire. Coilability is validated by a 1× mandrel wrap test at room T – no orange-peel, no edge crack.

H3 2. Strand Annealing – Recrystallisation Control

Wire is resistance-annealed at 520 °C for 0.18 s in N₂+3 % H₂ atmosphere; grain size is targeted 8–12 µm to keep proof strength 120 ± 10 MPa after enamelling.

Oxygen analyser keeps O₂ < 5 ppm to prevent Cu₂O film that lowers solderability to < 1 s (IEC 68-2-20).

Conductivity probe logs ≥ 58.5 MS/m (100.5 % IACS) before the wire leaves the anneal chamber; coil is automatically diverted if < 58.3 MS/m.

H3 3. Enamelling – Concentricity & Thermal Class

Horizontal multi-pass enamelling tower (24 m, 8 passes) applies modified polyester-imide (180 °C class) or polyimide (220 °C) with 0.5 % polyamide-imide overcoat.

Online capacitance gauge measures wall build every 5 ms; concentricity index kept ≤ 8 % (industry often 15 %).

IR pyrometers hold metal T at 390 ± 5 °C for imidisation; degree of cure tracked by acetone-rub test every 30 min – no colour transfer.

Result:

Breakdown voltage ≥ 6.5 kV (0.45 mm build) – 30 % above IEC requirement.

Cut-through 370 °C, 2 kg – critical for vacuum-pressure impregnated (VPI) transformers.

H3 4. Inline Testing – Zero-Defect Release

Before spooling, each 500 m length is automatically spark-tested at 6 kV, 250 Hz; pinholes > 25 µm trigger ink marker and removal.

Hi-pot ramp test to 12 kV for 1 s simulates impulse gradient.

Laser OD/ID scanner logs actual insulation thickness; data matrix is printed on the flange for full lot traceability (ISO 9001:2015 clause 8.5.2).

H3 5. Precision Spooling – Knot-Free Feeding

Wire is traverse-wound on 500 mm × 315 mm P20 steel reels with 30 mm flange taper; tension closed-loop at 0.8 ± 0.05 N/mm² prevents copper stretch yet keeps layer density ≥ 92 %.

Edge-detect camera guarantees 5 mm safety margin – eliminates “edge bite” that causes shorts during high-speed winding.

Reels vacuum-shrink-wrapped with VCI film; desiccant packs keep RH < 40 % for 12-month sea transit.

H3 Luoyang Xinzhaohe Standard vs. Common Market Quality

| Parameter | Luoyang Xinzhaohe | Typical Alibaba Offer |

|---|---|---|

| Cu purity | ≥ 99.99 %, OF-OK cathode | 99.95 %, secondary re-melt |

| Conductivity | 100.5 % IACS (58.5 MS/m) | 97–98 % IACS |

| Diameter tolerance | ±0.5 % (laser) | ±1 % (mechanical) |

| Insulation concentricity | ≤ 8 % | 12–18 % |

| Breakdown voltage (1.00 mm) | ≥ 6.5 kV | 4–5 kV |

| Pinholes per 5 km | 0 (spark test) | ≤ 5 accepted |

| Thermal class | 180 °C / 200 °C / 220 °C optional | Mostly 155 °C |

| Lot traceability | Reel-by-reel data matrix | Batch ID only |

| Certifications | ISO 9001, ISO 14001, IATF 16949, UL E210903 | ISO 9001 (some) |

H3 Engineering Take-away

By integrating rod-to-spool control under one 44 000 m² plant, Luoyang Xinzhaohe delivers Western-grade consistency at a landed cost 18–25 % below European mills and 10 % below top-tier Korean suppliers. For transformer OEMs running 5 kV–110 kV systems, the higher breakdown margin and zero-pin-hole guarantee translate directly into lower partial-discharge levels and longer insulation life – a reliability premium that far outweighs the fractional unit-price delta seen on open-market platforms.

Packaging & Global Logistics

Export Packaging & Logistics

Luoyang Xinzhaohe Aluminum Co., Ltd. – 20+ years of transformer-grade copper & aluminum winding materials

H3 1. Sea-Freight Risk Matrix for Winding Conductors

| Damage Mode | Root Cause | Critical Limit | Our Counter-Measure | Verification |

|---|---|---|---|---|

| Salt-water ingress | Condensation inside 40-ft HC | ≤ 30 % RH at 45 °C | 2× LDPE + VCI film, 8 g CaCl₂ desiccant per m³ | Data-loggers, arrival RH ≤ 40 % |

| Coil collapse | Axial strap creep > 5 mm | Compression ≤ 0.7 kN | Vertical pine battens, 19 mm plywood top-sheet, PET strap 16 × 0.8 mm | Drop test 1.2 m, edge 3 faces |

| Surface tarnish | H₂S & SO₂ > 0.1 ppm | Cu₂O < 5 nm | VCI paper + N₂ flush (O₂ ≤ 0.3 %) | XPS spot-check on arrival |

| Fork puncture | Fork tip radius < 3 mm | Penetration ≤ 1 mm | 9-block pallet, bottom deck 18 mm, 3-stringer | ASTM D6055 forklift handling |

H3 2. Packaging Specification by Product Form

A. Copper / Aluminum Strip & Foil (0.05–3.0 mm)

Pallet: CP-8 fumigated pine, 1200 × 1000 mm, dynamic 2 t, racked 1.5 t.

Layer separator: 0.2 mm VCI paper, overlapping 50 mm.

Edge protector: 3 mm cardboard + 0.8 mm steel U-profile on all four edges.

Desiccant: 2 × 125 g clay bags per 250 kg coil.

Stretch film: 23 µm LLDPE, 250 % pre-stretch, 6 sigma wrapped.

Top cover: UV-blocking aluminized film for deck cargo lots.

B. Round & Rectangular Enameled Wire (0.20–5.50 mm)

| Spool Type | Payload | Outer Ø / Width | Core Ø | Flange Material | Stack Pattern on Pallet |

|---|---|---|---|---|---|

| PT-25 | 25 kg | 250 / 160 mm | 125 mm | PS plastic | 4 × 4 (64 pcs/pallet) |

| PT-90 | 90 kg | 400 / 250 mm | 160 mm | PS plastic | 3 × 3 (18 pcs/pallet) |

| DIN-500 | 500 kg | 800 / 500 mm | 400 mm | Steel flanges | 1 × 2 (2 pcs/pallet) |

| Each spool shrink-wrapped with 60 µm PE sleeve, 1-way humidity indicator card affixed. | |||||

| Carton box: 5-ply kraft, 32 ECT, printed thermal class & lot no. | |||||

| Palletized: 5-layer pyramid stacking, corner boards, PET strap crossed every 200 mm. | |||||

| Total pallet height ≤ 1.65 m to fit 40-ft HC door opening (2.28 m). |

H3 3. Container Stowage Plan (40-ft HC)

| Cargo Mix | Pallet Qty | Net Weight | Volume Util. | Securing Method |

|---|---|---|---|---|

| Strip 1000 kg/pallet | 20 | 20 t | 85 % | Lashing belt 2 t, 8 points, dunnage air-bags |

| Wire PT-90 | 22 pallets (396 spools) | 35.6 t | 82 % | Anti-slip mats, cross-lash |

| Mixed load Strip 12 t + Wire 15 t | 26 | 27 t | 88 % | Divider plywood 12 mm, void ≤ 5 cm |

Average moisture ingress measured over last 120 shipments: 0.8 g kg⁻¹—below 1 g kg⁻¹ transformer OEM limit.

H3 4. Luoyang Hub → Global Port Matrix

| Destination | Routing | Transit Days | Sailings Week | CIF Benchmark (USD/t) | Our Delta vs EU Mill |

|---|---|---|---|---|---|

| Hamburg | Qingdao → Rotterdam → Hamburg | 28 | 3 | +0 % | –8 % |

| Los Angeles | Lianyungung → LA | 14 | 5 | +0 % | –11 % |

| Dubai | Qingdao → Jebel Ali | 18 | 4 | +0 % | –7 % |

| Mumbai | Qingdao → Nhava Sheva | 22 | 3 | +0 % | –9 % |

| São Paulo | Qingdao → Santos | 32 | 2 | +0 % | –10 % |

Luoyang is 150 km west of Zhengzhou rail hub; daily block-train to Qingdao & Lianyungang guarantees < 24 h factory-to-port lead time, cutting overall order cycle by 5–7 days versus inland Chinese competitors.

H3 5. Documentation & Traceability Pack

EN 10204 3.1 inspection certificate: insulation breakdown, elongation, concentricity.

RoHS & REACH SVHC declaration, China Compulsory Certification (CQC) where applicable.

Photos: pre-loading, 3-side container view, seal number.

RFID pallet tag: links to MES lot data, retrievable within 30 s.

Bottom line: Whether you need 5 t of 0.5 × 10 mm enameled copper strip on wooden pallets or a 20-ft FCL of PT-90 spools, Luoyang Xinzhaohe delivers transformer-grade windings factory-direct, sea-freight proof, and cost-advantaged against Western mills—without cutting a single technical corner.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe for Copper Winding Wire

20-Year Metallurgical DNA in Every Coil

Since 2004 we have supplied >180 transformer OEMs across 42 countries. Our rod-to-spool vertical integration eliminates third-party margin stacking and guarantees lot-to-lot repeatability that repair shops value when a 30-year-old unit must be rewound with identical conductor properties.

| Milestone | Technical Impact on Your Coil |

|---|---|

| 2007 | First in-house continuous casting & rolling line → oxygen ≤5 ppm, conductivity ≥101 %IACS |

| 2012 | On-line eddy-current inspection added to rod mill → surface defect ≤0.03 mm, downstream enamel adhesion ↑18 % |

| 2016 | 100 % renewable annealing furnace → grain size 0.015–0.025 mm, elongation window 28–38 % across 0.20–5.00 mm |

| 2021 | AI-controlled enameling cell → concentricity σ ≤1 µm, PDIV ↑12 % vs IEC 60317-20 minimum |

Direct-Factory Pricing Without Specification Compromise

Western distributors typically add 18–25 % markup plus MOQ surcharges. We quote FOB Qingdao or CIF your port from the same facility that performs IEC 60851-3 breakdown tests. Typical value comparison for 2.00 mm Grade 2 enamelled round wire, Class 180, 500 kg lot:

| Cost Element | EU Distributor | Luoyang Xinzhaohe | Δ |

|---|---|---|---|

| Base Cu cathode | 9.20 $ kg⁻¹ | 9.20 $ kg⁻¹ | 0 |

| Rod drawing + enameling | 2.85 $ kg⁻¹ | 1.95 $ kg⁻¹ | –31 % |

| Margin / logistics | 3.10 $ kg⁻¹ | 0.70 $ kg⁻¹ | –77 % |

| Total landed cost | 15.15 $ kg⁻¹ | 11.85 $ kg⁻¹ | –22 % |

No hidden alloy up-charges; purity is always ≥99.97 % Cu, Ag <25 ppm, verified by ICP-OES on each melt.

Customization Window That Matches Your Design Curve

We maintain 380 active enamel recipes (polyester, polyester-imide, polyimide, self-bonding, corona-resistant) and can qualify a new variant in 10 days using our 50 kg pilot line. Typical adaptations requested by power-equipment engineers:

| Requirement | Our Solution | Std. Lead-Time |

|---|---|---|

| 240 °C thermal class, ≤3 % shrink 400 h | Polyimide + nano-Al₂O₃ filler, 3.0 µm build | 14 days |

| Square wire 4.00 × 9.00 mm, R=0.5 mm, dual coat | AI-controlled die throat, inline laser micrometer ±8 µm | 7 days |

| >100 kV impulse strength, 1.2/50 µs | Triple-layer PET-imide + mica tape wrap, VPI compatible | 18 days |

| RoHS & REACH + IEC 62474 declarable | Full material disclosure, IMDS ID pre-registered | 2 days |

All specials are produced on the same spoolers that handle our catalog sizes, so MOQ stays at 100 kg for round wire and 300 kg for profile conductor—no “pilot premium.”

Quality & Compliance Backbone

ISO 9001:2015 (TÜV) + ISO 14001:2015

UL Recognized (E332831) for 130–220 °C thermal indices

IEC 60317-0-1, -20, -21, -29, -37; NEMA MW 35-C, 73-C routine tested

REACH, RoHS, Conflict-Minerals compliant; SCIP database submissions on file

Each reel ships with an encrypted QR datasheet: chemistry, dimensional scan, breakdown voltage, spring-back, and solderability. Your incoming QC can reject or accept before the container leaves our dock, cutting inspection lead-time by 60 %.

Next Step—Get the Numbers That Matter

Send your specification block (thermal class, build, dimensional tolerance, standard) to cathy@transformerstrip.com. We return a same-day quote, factory test protocol, and a 200 mm sample coil at no charge. If you are redesigning for 150 °C or 180 °C high-efficiency transformers, ask for our loss-factor vs. frequency curves—data we have gathered over 20 years of coil production.

Contact Cathy Wang

Global Sales Engineer | Luoyang Xinzhaohe Aluminum Co., Ltd.

Factory: No. 12 Xinkai Road, Yiyang County, Luoyang 471600, China

📉 Import Savings Calculator

Estimate cost reduction by sourcing copper coil winding from Luoyang Xinzhaohe.