Table of Contents

Market Insight: Copper Coil Transformer

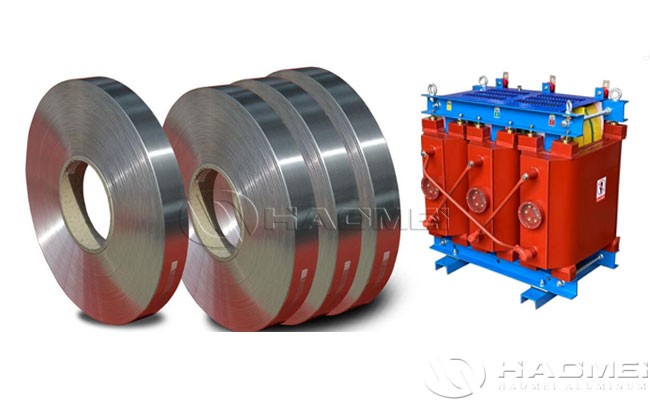

Market Analysis: Transformer Strip/Foil (Aluminum/Copper)

Global demand for transformer winding materials, particularly copper strip and foil, remains robust and structurally driven by critical infrastructure investments. Accelerated renewable energy integration, aging grid modernization programs, and stringent energy efficiency regulations (e.g., DOE 2016, EU Ecodesign) are primary catalysts. High-voltage and distribution transformers for solar/wind farms, EV charging networks, and industrial facilities increasingly specify copper windings due to its superior electrical conductivity (100% IACS minimum) and thermal stability under continuous load. While aluminum offers a cost-weight advantage in specific distribution applications, copper maintains dominance in high-reliability, high-efficiency, and compact transformer designs where space constraints and thermal management are critical. The industrial segment, including data centers and heavy manufacturing, exhibits particularly strong demand for copper-based windings owing to non-negotiable uptime requirements and harmonic load tolerance.

Material quality is non-negotiable in transformer strip/foil procurement, directly impacting transformer lifecycle cost, safety, and performance. Substandard copper introduces significant risks: inconsistent conductivity increases resistive (I²R) losses, elevating operational costs and thermal stress. Surface imperfections or embedded contaminants act as initiation points for partial discharges, compromising dielectric integrity and accelerating insulation degradation. Inadequate mechanical properties (tensile strength, elongation) lead to winding deformation during manufacturing or operation, causing inter-turn faults. Dimensional inaccuracies disrupt precise layer winding, increasing eddy current losses and hot spot formation. The consequences manifest as premature failure, unplanned outages, fire hazards, and failure to meet mandated efficiency standards. Quality assurance must extend beyond basic composition to encompass stringent process control for surface finish, edge quality, flatness, and annealing homogeneity.

Critical quality parameters for copper transformer strip/foil are quantifiable and must be rigorously verified against international standards. Key specifications include:

| Parameter | Critical Value Range | Relevant Standard | Impact of Deviation |

|---|---|---|---|

| Electrical Conductivity | ≥ 100% IACS (99.90% Cu min) | ASTM B3 | Increased load losses, overheating |

| Surface Roughness (Ra) | ≤ 1.0 µm | Customer Specific | Insulation damage, partial discharge |

| Edge Burrs | ≤ 5% of thickness | IEC 60404-9 | Insulation puncture, short circuits |

| Tensile Strength | 180-250 MPa | ASTM B547 | Winding deformation, handling failure |

| Elongation | ≥ 5% | ASTM B547 | Cracking during winding, reduced fatigue life |

Procurement decisions must prioritize suppliers with certified mill test reports, traceable material pedigrees, and robust in-process quality control aligned with ISO 9001 and IATF 16949 frameworks. Luoyang Xinzhaohe Aluminum leverages two decades of metallurgical expertise in precision rolling and annealing to deliver both aluminum and copper-based products meeting the most demanding transformer OEM specifications. While copper remains the benchmark for critical applications, understanding its stringent quality requirements is essential for optimizing total cost of ownership. Strategic sourcing requires validation beyond price, focusing on consistent material performance to ensure transformer reliability over its 25-40 year operational lifespan.

Technical Specs: Copper Coil Transformer

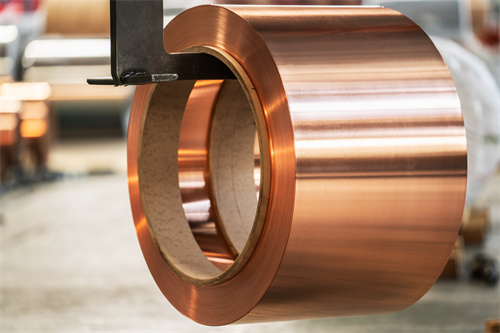

Technical Specifications for Copper Coil Transformer Strip

Luoyang Xinzhaohe Aluminum Co., Ltd. provides high-precision copper strip and foil materials engineered specifically for use in transformer coil windings. With over two decades of metallurgical and industrial processing expertise, our copper products are manufactured to meet the rigorous demands of power and distribution transformer applications. The performance, efficiency, and thermal stability of a transformer are directly influenced by the quality of the conductor material, particularly in terms of dimensional accuracy, edge quality, and electrical conductivity. Our copper strip is produced under strict process controls to ensure consistency and compliance with international standards such as GB/T 5584, ASTM B187, and IEC 60137.

Dimensional precision is critical in transformer coil fabrication, where tight winding tolerances and layer uniformity directly affect magnetic flux distribution and heat dissipation. Our copper strip undergoes precision slitting with a thickness tolerance of ±0.002 mm, ensuring minimal variation across the coil’s active length. This level of control reduces interlayer stresses and prevents insulation damage during winding operations. The slit edges are processed to be burr-free, with edge roughness maintained below 5 μm Ra, eliminating the risk of dielectric puncture in insulated winding systems.

Electrical conductivity is maintained at a minimum of 98% IACS (International Annealed Copper Standard) through controlled oxygen content and annealing processes. High conductivity reduces resistive losses (I²R losses), enhancing transformer efficiency and reducing operating temperature. The copper used is ETP (Electrolytic Tough Pitch) grade, with oxygen content held between 0.02% and 0.04% to balance conductivity and mechanical workability. All strips are fully annealed to achieve a soft temper (O-temper), providing optimal ductility for tight-radius winding without cracking or edge splitting.

Surface cleanliness is rigorously maintained to prevent contamination that could compromise insulation integrity. Each coil is passivated to inhibit oxidation and packaged in moisture-resistant, anti-static wrapping to preserve surface quality during transit and storage.

The following table summarizes key technical parameters for our copper strip used in transformer coil applications:

| Parameter | Specification | Test Standard |

|---|---|---|

| Material Grade | Cu-ETP (C11000) | ASTM B187 |

| Thickness Range | 0.10 – 3.00 mm | GB/T 5584 |

| Thickness Tolerance | ±0.002 mm | ISO 9001 |

| Width Range | 10 – 300 mm | Custom Slitting |

| Edge Quality | Burr-free, Ra ≤ 5 μm | Optical Profilometry |

| Conductivity | ≥98% IACS | ASTM E1004 |

| Temper | O-temper (Fully Annealed) | ASTM B928 |

| Surface Finish | Clean, oxidation-inhibited | Visual & Resistivity |

| Packaging | Anti-static, moisture-resistant wrapping | Internal Procedure |

All material batches are subject to full traceability and come with certified mill test reports verifying chemical composition, mechanical properties, and electrical performance. Luoyang Xinzhaohe Aluminum Co., Ltd. supports custom slit widths and coil IDs to meet specific winding machine requirements, ensuring seamless integration into high-speed transformer production lines.

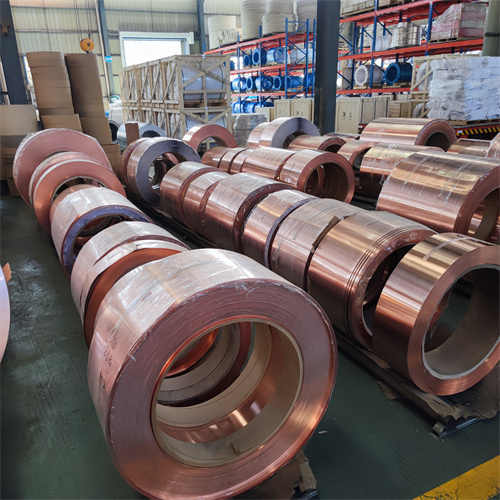

Factory Tour: Manufacturing

Transformer Conductor Strip Manufacturing Process: Copper Coil Production

Luoyang Xinzhaohe Aluminum Co., Ltd leverages over two decades of metallurgical and precision rolling expertise to produce high-integrity copper strip for transformer coil applications. Our process rigorously transforms primary copper ingot or continuous cast bar into dimensionally precise, surface-perfect strip through a sequenced cold working methodology. This sequence—Cold Rolling, Precision Slitting, and Edge Conditioning—forms the core of our manufacturing capability, ensuring optimal electrical performance and winding compatibility.

Cold rolling constitutes the foundational stage, where copper undergoes significant plastic deformation between precision-ground work rolls under controlled tension. Starting from hot-rolled or continuously cast feedstock typically ranging from 3mm to 6mm thickness, we achieve final gauges between 0.08mm and 3.0mm through multiple rolling passes. Critical process parameters include precise roll gap adjustment, interstand tension control, and optimized rolling speed to manage work hardening and prevent surface defects. Lubricant type and flow rate are meticulously regulated to minimize roll marking and ensure uniform surface finish. In-process quality control during cold rolling mandates continuous laser micrometer measurement for thickness uniformity (±0.005mm tolerance achievable), automated surface inspection systems for detecting scratches or inclusions, and periodic metallurgical sampling to verify grain structure and mechanical properties meet ASTM B152 specifications. Flatness is continuously monitored using high-resolution flatness meters, targeting deviations under 5 I-Units.

Following cold rolling, the master coil undergoes Precision Slitting. This operation utilizes high-precision rotary shear slitters with hardened tool steel knives maintained to exacting edge geometries. The slit width tolerance is held to ±0.05mm across the entire coil length, critical for consistent layer-to-layer alignment during transformer winding. Knife clearance and overlap settings are dynamically adjusted based on material thickness and temper to minimize burr formation and edge deformation. Real-time monitoring of slit width and edge squareness occurs throughout the process. Post-slitting QC includes statistical verification of width dimensions at multiple points across the coil face, measurement of edge camber, and microscopic examination for burr height, which is strictly controlled to less than 3% of material thickness.

The final critical stage is Edge Conditioning. Raw slit edges inherently possess micro-burrs and stress concentrations detrimental to insulation integrity during high-speed winding. We employ multi-stage mechanical edge brushing and controlled deburring processes. This involves precision-calibrated abrasive brushes or precision file systems that uniformly remove burrs while imparting a smooth, radius-free edge profile. The process eliminates sharp protrusions without generating excessive edge rounding that could compromise dimensional accuracy. Post-conditioning QC is paramount, involving 100x microscopic edge inspection to validate burr elimination and surface continuity, alongside functional winding trials on representative samples to confirm zero insulation damage during handling.

This integrated manufacturing sequence, underpinned by stringent in-process and final quality gates at each stage, ensures the copper strip delivered by Luoyang Xinzhaohe meets the exacting demands of modern transformer manufacturing. The result is strip exhibiting superior dimensional stability, optimal surface integrity, and burr-free edges—directly contributing to enhanced coil winding efficiency, reduced electrical losses, and long-term transformer reliability.

Packaging & Logistics

Export Packaging for Copper and Aluminum Transformer Strip and Foil

At Luoyang Xinzhaohe Aluminum Co., Ltd., with over two decades of experience in the production and international supply of transformer strip and foil—both aluminum and copper—we adhere to stringent export packaging protocols designed to ensure product integrity during global maritime transport. Given the sensitivity of these materials to environmental exposure, mechanical stress, and long transit durations, our packaging system is engineered to meet the highest standards of durability, moisture resistance, and logistical efficiency.

All copper and aluminum transformer coils are mounted on robust wooden pallets constructed from high-strength, kiln-dried hardwood. These pallets are designed to support the full weight of the coil while maintaining structural stability under stacking conditions typical in containerized shipping. The wood used complies with ISPM 15 regulations, ensuring international phytosanitary compliance for unrestricted customs clearance across global markets. Each pallet is treated to resist warping, splintering, and microbial degradation, further enhancing its reliability during extended sea voyages.

Immediately following coil placement on the pallet, the entire assembly is wrapped in multi-layer moisture-proof composite film. This film consists of aluminum foil laminate bonded with low-density polyethylene (LDPE), providing an effective vapor barrier that prevents condensation and ingress of ambient humidity. Given the hygroscopic nature of metal surfaces and the risk of oxidation during ocean transit—particularly in tropical and high-humidity zones—this protective layer is critical. The film is heat-sealed at all seams and secured with weather-resistant strapping to maintain a continuous barrier throughout the supply chain.

To further mitigate the risk of mechanical damage, edge protectors made from corrugated fiberboard or plastic are affixed to the coil’s outer diameter. These protectors absorb impact energy during handling and prevent deformation of the strip edges, which could compromise downstream processing such as slitting or winding. Additionally, each packaged coil is labeled with UV-resistant, tamper-evident identification tags containing batch numbers, alloy specifications, dimensions, and handling instructions in both Chinese and English, ensuring traceability and proper logistics management.

Our packaging design is validated through internal simulation testing, including vibration, tilt, and drop tests that replicate real-world shipping conditions. This proactive approach ensures that coils arrive at their destination in the same condition as when they left our facility. By integrating robust materials, moisture control, and international compliance into every package, Luoyang Xinzhaohe Aluminum Co., Ltd. guarantees the safe and reliable delivery of transformer strip and foil products to customers across Europe, Southeast Asia, the Middle East, and the Americas.

This packaging methodology reflects our commitment to quality assurance and supply chain resilience, supporting the long-term performance of our materials in critical transformer manufacturing applications.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe for Precision Transformer Strip and Foil

Luoyang Xinzhaohe Aluminum Co., Ltd leverages over two decades of specialized metallurgical expertise to deliver mission-critical aluminum and copper strip/foil for transformer coil windings. Our vertically integrated manufacturing ecosystem, engineered for transformer-specific applications, ensures unparalleled consistency in material properties essential for high-efficiency energy conversion. We operate four dedicated production lines with annual capacity exceeding 15,000 metric tons, configured for tight-tolerance foil (0.05–0.50 mm) and strip (0.10–3.00 mm) across ASTM B248 and IEC 60138 standards. Core process advantages begin with proprietary melt purification systems achieving oxygen content below 8 ppm in copper and hydrogen levels under 0.15 ml/100g in aluminum, directly enhancing electrical conductivity and reducing eddy current losses.

Our annealing and tension-leveling protocols are calibrated to transformer winding dynamics, maintaining flatness tolerance within ±0.5 mm/m and surface roughness Ra ≤ 0.4 µm. This precision prevents coil deformation during high-speed winding and ensures uniform dielectric performance. Metallurgical homogeneity is rigorously controlled through in-line X-ray fluorescence and optical emission spectroscopy, with real-time adjustments to grain structure parameters. The following table summarizes our certified production capabilities

| Material | Thickness Range (mm) | Tolerance (mm) | Conductivity (% IACS) | Tensile Strength (MPa) |

|---|---|---|---|---|

| Electrolytic Tough Pitch Copper | 0.05–3.00 | ±0.005 | ≥100 | 200–240 |

| Aluminum 1060/1100 | 0.05–3.00 | ±0.008 | ≥59 | 60–95 |

Quality assurance extends beyond ISO 9001 and IATF 16949 frameworks through transformer-specific validation. Every batch undergoes accelerated aging tests per IEC 60216, dielectric strength verification at 3 kV/mm, and interfacial adhesion analysis to prevent delamination in resin-impregnated coils. Our supply chain infrastructure includes dedicated rail-served warehousing within the Luoyang Free Trade Zone, enabling JIT delivery cadence to global hubs with 99.2% on-time fulfillment. Dual sourcing of LME Grade A copper cathodes and 99.85% pure aluminum ingots mitigates raw material volatility, while blockchain-tracked logistics provide full material provenance from smelter to coil.

Customization is engineered at the metallurgical level: we adjust recrystallization kinetics via controlled annealing profiles to match client winding machinery parameters, and offer surface passivation treatments for enhanced varnish adhesion. Recent projects include developing oxygen-free copper foil with reduced residual stress for ultra-high-frequency transformers, achieving 0.8% lower no-load losses versus industry benchmarks.

For transformer manufacturers prioritizing coil integrity and lifecycle efficiency, Luoyang Xinzhaohe provides engineered material solutions backed by 20+ years of failure-mode analysis in grid-scale applications. Contact Senior Technical Sourcing Manager Cathy Zhang at cathy@transformerstrip.com to request our Transformer Strip Material Datasheet Package or schedule a metallurgical compatibility review for your next design iteration. Specify “Copper Coil Transformer Inquiry” in the subject line for expedited technical support.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing copper coil transformer directly from China.