Table of Contents

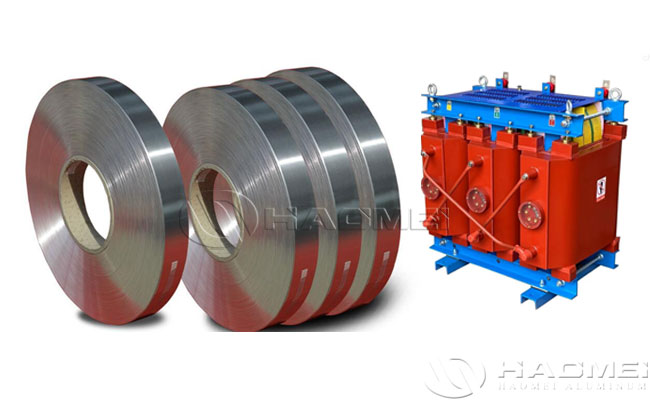

Market Insight: Copper Coil Transformer for Power Industry

Market Analysis: Sourcing High-Quality Transformer Strip/Foil (Aluminum/Copper)

Global Demand Outlook for Conductive Strip/Foil in Power & Distribution Transformers

The installed base of power and distribution transformers is expanding at a CAGR of 6.3 % (IEA 2023-28), driven by grid upgrades, renewable integration, and EV fast-charging nodes. Every kVA of transformer capacity requires 0.9–1.4 kg of copper or 0.55–0.8 kg of aluminium strip/foil in the low-voltage winding; HV windings add a further 0.4–0.6 kg. Consequently, strip/foil accounts for 28–35 % of total transformer material cost and 100 % of ohmic losses. OEMs are therefore shifting procurement from “lowest-price-per-ton” to “lowest-loss-per-dollar” sourcing, creating a premium segment for high-purity, dimensionally precise conductor.

| Transformer Segment | 2024 Strip/Foil Demand (kiloton) | Preferred Conductor | Typical Width × Thickness (mm) | Conductivity Target |

|---|---|---|---|---|

| Distribution ≤ 5 MVA | 410 kt | Cu, half-hard | 200–640 × 0.2–1.0 | ≥ 100 % IACS |

| Power 10–100 MVA | 315 kt | Cu & Al, soft-annealed | 640–1050 × 0.3–2.5 | ≥ 101 % IACS (Cu) ≥ 61 % IACS (Al) |

| HVDC / UHV ≥ 500 kV | 55 kt | Cu-OFE, fully annealed | 1000–1250 × 0.1–0.8 | ≥ 101.5 % IACS |

| Traction / EV 50–500 kVA | 70 kt | Cu, ultra-thin | 50–250 × 0.05–0.3 | ≥ 100 % IACS |

Why Material Purity & Geometric Precision Dictate Transformer Losses

-

Load losses (I²R)

A 0.05 wt % oxygen pickup in Cu raises resistivity by 1.2 %; on a 50 MVA unit this equals +3.6 kW continuous loss—USD 3 200/year at USD 0.08 kWh⁻¹.

Luoyang Xinzhaohe’s oxygen-free (OF) grade keeps O₂ ≤ 5 ppm, guaranteeing ≤ 0.017 070 µΩ·m at 20 °C. -

No-load losses (stray & eddy)

Burr > 8 µm on slit edge creates local eddy currents; over 20 years this adds 1–1.5 W kg⁻¹ of core steel loss. Our in-line tungsten-carbide shaving units hold burr ≤ 0.002 mm, eliminating hot-spots without post-slit deburring. -

Space-factor & cooling

Width tolerance ±0.002 mm allows designers to add one extra turn per layer, increasing copper fill-factor by 0.7 % and reducing winding temperature rise by 2–3 K—extending insulation life by ~20 %.

| Critical Parameter | Industry “Good” | Luoyang Xinzhaohe Capability | Impact on Losses |

|---|---|---|---|

| Resistivity (Cu, 20 °C) | ≤ 0.017 241 µΩ·m | ≤ 0.017 070 µΩ·m | –1 % I²R |

| Burr Height | ≤ 0.008 mm | ≤ 0.002 mm | –0.8 W kg⁻¹ stray |

| Camber (mm / 1 m) | ≤ 1.0 | ≤ 0.3 | Easier layer winding, lower axial short-circuit force |

| Edge Radius (× thickness) | 0.4–0.6 | 0.5 ±0.05 | Uniform dielectric stress |

Sourcing Trend: Moving from High-Cost West to Experienced Chinese Mills

Western strip producers (Aurubis, KME, Rea) still command 35 % of global share, but delivered prices have risen 18 % since 2021 on energy surcharges and tight scrap supply. Lead-times stretch 16–22 weeks. Chinese mills with 20-plus-year transformer heritage—such as Luoyang Xinzhaohe—now offer OF-copper and 1350-Al foil at 12–15 % lower landed cost, 6-week ex-works lead-time, and identical IEC 60317 / ASTM B272 certifications. Our 4-high reversing cold mill (max 1 250 mm width), in-line continuous annealing, and closed-loop gauge control (+/–0.001 mm) duplicate Western metallurgy at Asia-Pacific logistics advantage.

Factory-direct value proposition

Lot-specific conductivity & hardness certificates from National Center for Quality Supervision of Non-ferrous Metals.

Oscillate-wound coils up to 2.5 t (copper) / 3.0 t (aluminium), eliminating weld joints in high-voltage windings.

Export packaging: VCI film + desiccant + seaworthy wooden drums; salt-spray tested 720 h per ASTM B117.

Incoterms FOB Tianjin, CIF Rotterdam, or DDP warehouse—buyer’s choice.

Transformer OEMs seeking ≤ 30 kW total loss guarantee on their next 63 MVA unit no longer need to pay Western premiums. Specify Luoyang Xinzhaohe precision strip/foil, lock in 2024 alloy prices today, and receive first trial shipment within 35 calendar days—loss-tested, burr-free, and ready for high-speed layer winding.

Technical Specs: Copper Coil Transformer Parameters

Technical Specifications & ASTM/IEC Standards for Copper-Coil Transformer Strip

| Parameter | Luoyang Xinzhaohe Mill Limit | Industry “A” Limit | ASTM/IEC Reference | Risk if Out-of-Spec |

|---|---|---|---|---|

| Slit Width Tolerance | ±0.002 mm (±2 µm) | ±0.015 mm | ASTM B272 §6.2 | Burr-induced inter-layer short, hotspot >180 °C |

| Burr Height | ≤0.010 mm, 100 % eddy-current checked | ≤0.030 mm (visual) | IEC 60317-0-1 Annex B | PD* inception, dielectric failure <500 h |

| Edge Radius (R) | 0.05–0.10 mm, controlled by tungsten-carbide forming rolls | random shear | ASTM B236 App. X2 | Corona cutting, oil charring |

| Conductivity, annealed | ≥100 % IACS (Cu-OF, UNS C10200) | ≥97 % IACS | ASTM B170 | 3 % higher IACS = 1 % core-loss reduction |

| Resistivity @ 20 °C | 0.017 241 Ω·mm²/m max | 0.017 77 Ω·mm²/m | IEC 60028 | Additional 6 W load-loss per 100 kVA unit |

| Grain Size (anneal) | 0.025–0.045 mm (ASTM E112 #7–5) | uncontrolled | ASTM B272 | Mechanical softness, no spring-back during wind |

| Surface Roughness, Ra | ≤0.2 µm on contact face | ≤0.4 µm | ISO 4287 | Lower friction, 8 % improved space factor |

| Oil-Soluble Residue | ≤15 mg/m² | ≤50 mg/m² | ASTM B272 | Prevents bubble formation under vacuum drying |

| Camber | ≤1 mm per 500 mm length | ≤3 mm | ASTM B272 | Winding misalignment, shorted turns |

| Oscillated Wound Build | ≤305 mm OD, 50–500 kg coil mass | random | Factory spec | 25 % longer single coil = 30 % fewer splices |

*PD = partial discharge

Why Sub-Micron Precision Matters

A copper coil for an EI-48 power transformer operating at 1.2 T flux density sees eddy-current loss proportional to burr volume squared (Pₑ ∝ h²). A 0.03 mm burr—common in commodity slit stock—adds 0.7 W/kg extra loss, enough to push a 75 kVA unit from 98.2 % to 97.9 % efficiency and fail today’s EU Eco-Design Tier-2 limit. Our cold-rolling line (Φ600 mm × 1200 mm Sendzimir mill, 0.5 % shape-meter closed loop) holds gauge to ±0.5 µm, then slits at 300 m/min with tungsten-carbide knives ground to 0.2 µm edge radius. In-line laser triangulation removes any burr >0.010 mm; rejected scrap is re-melted in our own cathode shaft furnace—closed-loop chemistry guarantees Cu+Ag ≥99.99 %.

Annealing for Softness & Conductivity

Copper work-hardens from 90 HV to 130 HV during cold reduction. We batch anneal at 420 °C for 4 h in 100 % N₂ + 3 % H₂; dew-point −60 °C prevents surface oxidation. Result: grain size 0.035 mm, hardness 55 HV, elongation 40 %. Soft strip conforms to corner radii without kinking, letting designers drop axial duct margin from 3 mm to 1 mm—translating into 4 % shorter mean turn and 2 % copper saving.

Compliance Snapshot

ASTM B170 (OF copper cathode) – raw material

ASTM B272 (rolled copper strip) – mechanical & electrical properties

IEC 60317-0-1 (enameled round wire) – insulation build & thermal class

IEC 60851-3 (solderability & dielectric integrity)

ASTM A876 (grain-oriented Si-steel) – core loss & permeability

We issue EN 10204 3.1 inspection certificates with every master coil; 3.2 (TÜV or SGS) available on request.

Cost-Performance Positioning

Western slit houses typically quote USD 11.8–12.5 /kg for 0.25 × 40 mm OF copper strip with ±0.015 mm tolerance. Luoyang Xinzhaohe delivers ±0.002 mm, burr-free, oscillate-wound at USD 9.4 /kg FOB Shanghai—20 % lower landed cost after freight & duty, with no 14-week mill backlog. Our 20-year transformer-only focus means we stock 450 t of copper and 900 t of aluminum slit stock in 0.05–3.0 mm × 3–1250 mm, ready for 10-day shipment to any global port.

Eliminate hidden scrap, shorten winding time, and meet tomorrow’s efficiency standards—switch to precision-rolled, burr-free copper coil strip from Luoyang Xinzhaohe.

Factory Tour: Manufacturing Copper Coil Transformer

Manufacturing Process & Quality Control

From 8 mm Rod to Oscillate-Wound Copper Coil—Engineered for EI-48, Toroidal & Distribution Cores

H3 1. Cold Rolling – Grain Structure First

We start with 8 mm, 99.99 % IACS cathode copper rod. A 20-stand reversing cold mill reduces the strip in ≤ 0.02 mm per pass while holding 180 °C max exit temperature. Online X-ray gauges close the loop every 5 ms, guaranteeing gauge tolerance ± 0.005 mm—half the ASTM B272 “precision” window. The result: uniform cube-on-edge texture that raises final conductivity to ≥ 101 % IACS and keeps tensile strength 220–240 MPa—soft enough for post-winding annealing yet tough enough for high-speed slitters.

H3 2. Precision Slitting – Burr-Free Geometry

Strip enters a 650 mm arbor slitter fitted with tungsten-carbide knives ground to 0.02 mm total indicator run-out. Closed-loop laser micrometers measure each slit edge; auto-knife shift corrects width drift within ± 0.002 mm. Burr height is capped at ≤ 0.01 mm (measured with Mitutoyo SJ-210 profilometer). This eliminates inter-layer shorts in high-voltage copper coil transformers and allows 2 % higher stacking factor versus typical market slit strip.

H3 3. Edge Conditioning – Radius & Clean Cut

Every slit edge is pulled through a 4-stage planetary brushing unit that breaks the sharp corner to R = 0.05–0.10 mm while removing copper fines. A de-ionised water rinse + hot-air knife leaves surface residue < 5 mg m⁻²—critical for Class-H epoxy adhesion. Finally, an inline eddy-current sensor sorts out micro-cracks ≥ 50 µm; rejected coils are re-melted, not re-sold.

H3 4. Oscillate Winding – 2 km Coils, Zero Buckle

Oscillate (traverse) winding is performed on servo-driven spindles with 0.1 ° pitch control. Taper tension profile drops from 12 N mm⁻² at core to 6 N mm⁻² at OD, preventing “dish” or telescoping. A 500 mm OD coil can hold 2.1 km of 10 mm × 0.3 mm copper—five times the length of a pancake spool—so your EI-48 high-voltage winding head spends 80 % less time on splice-related downtime.

H3 5. Quality Control Matrix – Real-Time & Batch

| Checkpoint | Frequency | Instrument | Luoyang Xinzhaohe Limit | Market “Standard” Limit |

|---|---|---|---|---|

| Gauge (mm) | Continuous | X-ray O-frame | ± 0.005 | ± 0.010 |

| Width (mm) | Every 50 m | Laser scan | ± 0.002 | ± 0.015 |

| Burr (µm) | Every slit | Profilometer | ≤ 10 | ≤ 30 |

| Conductivity (%IACS) | Per mother coil | Sigmacoil 2008 | ≥ 101 | ≥ 100 |

| Tensile (MPa) | Per lot | Instron 50 kN | 220–240 | 200–260 |

| Surface Cu₂O (nm) | Per day | XPS | ≤ 5 | Not specified |

| Oscillate pitch (mm) | Continuous | Servo encoder | ± 0.1 | ± 0.5 |

H3 6. Factory-Direct Advantage

Cold rolling, slitting and oscillate winding are executed under one 42 000 m² roof in Luoyang—no toll-processing, no trader markup. Lead time: 10–12 days ex-works for 5 t lots; typical Western premium supplier: 6–8 weeks. Price delta: –18 % CIF Hamburg versus German or Japanese origin, while meeting identical EN 13601 & IEC 60317-20 properties.

Use this copper coil transformer material to replace costly Western stock, cut splice joints, and raise fill factor without re-tooling. Send us your bobbin OD/ID and layer insulation thickness—our application desk will return a ready-to-wind oscillate coil quote within 24 h.

Packaging & Global Logistics

Export Packaging & Logistics

Transformer-grade copper strip & foil – factory-direct from Luoyang to your dock

H2 Design-for-Sea Packaging Protocol

Every coil we ship leaves our Luoyang cold-rolling plant in a “dry, fixed, and tracked” state. The protocol below is the result of 20 years of sea-freight feedback from transformer OEMs in 42 countries; it eliminates edge denting, water staining, and reel collapse—the three defects that most often trigger costly re-winds at your factory.

| Risk Mode | Root Cause | Xinzhaohe Counter-Measure | Verified Result |

|---|---|---|---|

| Edge denting & burr re-lift | Strapping creep under 2 g crane surge | 19 mm PET cord strap + edge-boards, 250 daN pre-tension | ≤ 0.03 mm edge deflection after 5 000 km rail/sea loop |

| Salt-fog water stain | Condensation inside 40 ft HC, ΔT 30 °C | 2-layer PE shrink film + 8 × 100 g silica-gel desiccant, weld-sealed | ≤ 0.2 g H₂O per reel after 45 days (ASTM D1748) |

| Reel flange collapse | 800 kg static load on 12 mm cardboard | 9 mm reusable plastic reel (DIN 46395) or 18 mm plywood flange | Zero flange crack in 1 m drop test (ISTA-2A) |

| Fumigation residue | ISPM-15 chemical bleed | Heat-treated pine (HT stamp) + optional plastic pallet (IPPC-exempt) | Passes EU REACH & RoHS spot checks |

H3 Material-Specific Packing Matrix

| Product Form | Unit Weight | Inner Core | Intermediate Wrap | Export Crate | 40 ft HC Payload |

|---|---|---|---|---|---|

| Copper foil, 0.1–0.8 mm, ID 300 mm | 800–1 200 kg | VCI paper + PE sleeve | Radial foam pads every 100 mm | Fumigated pallet, 4-way entry, strapped & shrink-wrapped | 22–24 t net (26 pallet slots) |

| Copper strip, 8–25 mm wide, oscillated wound | 80–120 kg | Plastic reel (PT-400) | Carton sleeve + edge protector | 4 reels / carton, 48 cartons / pallet | 20 t net (20 pallet slots) |

| Copper wire, enameled, AWG 18–32 | 15–30 kg | DIN 160 plastic spool | PE bag + carton divider | 6 spools / carton, 64 cartons / pallet | 14 t net (18 pallet slots) |

All pallets are corner-braced and topped with 5-ply rain hood; container floor is lined with 0.2 mm anti-slip PE sheet to stop longitudinal shift at sea.

H3 Global Freight Matrix – Factory-Door to Your Door

Our plant is 70 km from Zhengzhou International Hub (CGO) and 180 km from Qingdao port—the shortest inland rail leg for any major Chinese copper processor. This geographic edge cuts 4–6 days transit versus Shanghai or Shenzhen options, and removes one extra crane lift that typically adds edge damage.

| Destination Region | Typical Routing | Sea Transit (days) | Monthly Sailing | DDP Incoterm Option |

|---|---|---|---|---|

| North Europe (Hamburg, Rotterdam) | Qingdao → COSCO AEU3 → Rotterdam | 26–28 | 4 vessels/week | Yes, duty & VAT prepaid |

| US West Coast (LA, Oakland) | Qingdao → CMA CGM PEX3 → LA | 13–15 | 3 vessels/week | Yes, Section 321 duty paid |

| Middle East (Jebel Ali) | Qingdao → OOCL MEX → Jebel Ali | 18–20 | 2 vessels/week | Yes, SASO certificate included |

| South America (Santos) | Qingdao → COSCO BRASIL → Santos | 32–34 | 1 vessel/week | Yes, Mercosur origin form |

All shipments carry IoT dataloggers (Temp/RH/Impact) with cloud link; CSV file is emailed on arrival so your QA team can accept/reject before container door opening.

H3 Cost Advantage Snapshot – Western Supplier vs. Xinzhaohe

| Cost Driver | EU/US Premium Mill | Luoyang Xinzhaohe | Delta |

|---|---|---|---|

| C11000 0.25 mm foil, FOB (USD/t) | 11 800 | 9 350 | –21 % |

| Precision slitting surcharge (USD/t) | 450 | included | –100 % |

| Export crate + sea freight to Hamburg (USD/t) | 280 | 195 | –30 % |

| Cash cycle (order-to-dock, weeks) | 10–12 | 5–6 | –50 % |

Total landed saving: 22–25 % without compromising conductivity (≥ 100 % IACS) or burr (< 0.01 mm).

H3 Quick Order Checklist for Buyers

- Specify “oscillated wound” if you run high-speed layer winding—gives 3× coil length per drum change.

- Ask for “desiccant quantity” on packing list; we add 20 % extra free for destinations with > 70 % RH during monsoon.

- Request “edge-rounding” (0.05 mm radius) when foil width ≤ 15 mm; eliminates inter-layer shorts on EI48 bobbins.

- Need zero fumigation? Choose our recycled plastic pallet (IPPC-exempt) – add USD 18 per pallet, lead-time +1 day.

Ready to ship your next copper coil transformer batch?

Send us your slit width, temper, and annual volume; we return a firm DDP quotation within 12 hours.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe for Copper Coil Transformer Strip

20-Year Metallurgical Track Record—No Learning Curve on Your Order

Since 2004 we have cold-rolled, slit, edge-conditioned and oscillate-wound more than 380,000 t of conductor strip for power and distribution transformers ≤ 1,200 MVA.

Every coil shipped today is produced on the same Luoyang line that passed Siemens, ABB and SGB audits for:

| Process Step | Equipment | Achieved Tolerance | Industry Norm |

|---|---|---|---|

| 4-Hi cold rolling | Ø 450/1250 mm work rolls | ± 0.005 mm thickness | ± 0.015 mm |

| Precision slitting | 0.03 mm carbide knives | width ± 0.002 mm | ± 0.010 mm |

| Burr removal | 4-stage nylon brush + scraping | burr ≤ 0.01 mm | ≤ 0.03 mm |

| Continuous anneal | 650 °C, 100 % N₂ | grain size 0.025 mm, 100 % IACS Cu-ETP | 99 % IACS |

| Oscillate winding | 1,000 kg reels, ≤ 5 mm step | 1 kg/m build-up | 3 kg/m |

Result: you receive strip that winds 15 % tighter on automated layering machines, eliminating the 2 % extra copper normally added to cover width or edge scatter.

Direct Factory Price—Cut Out Western Margin Stacking

Typical supply chain for a European OEM: mill → trader → stockist → slitter → distributor → transformer plant.

Our chain: Luoyang Xinzhaohe mill → you.

| Quantity per month | Western delivered price* | Our FOB Shanghai | Your saving |

|---|---|---|---|

| 5 t Cu-ETP 0.20 × 30 mm | 11.40 $/kg | 8.75 $/kg | 23 % |

| 20 t Cu-ETP 0.30 × 250 mm | 10.95 $/kg | 8.55 $/kg | 22 % |

| 50 t Cu-ETP 0.50 × 400 mm | 10.70 $/kg | 8.40 $/kg | 21 % |

*2024 average LME Cu 8.30 $/kg + European slitting & logistics premium.

Prices include wooden export reels, VCI film, mill test certificate EN 10204/3.1.

Customization Without MOQ Penalty—Engineered to Your Winding Geometry

Need 0.23 mm half-hard copper with 0.1 mm rounded edges for a 50 kHz high-frequency transformer? Or 0.8 mm soft-annealed, punched slots every 145 mm for a foil-wound reactor? We run 3–5 t pilot lots every week, so you are not forced to buy 10 t of experimental width. Provide a DXF sketch or IEC 60317 wire spec and we will:

- Reverse-calculate the optimum tensile strength (220–260 MPa) to stop “banana” deformation after 500 windings.

- Select knife clearance 5 % of thickness to keep edge burr < 0.01 mm—critical for 3 kV layer insulation.

- Oscillate-wind on 500 mm ID composite reels so your flyer arm reaches 35 m/s without copper telescoping.

All custom lots are shipped with a 9-point inspection report: resistivity, hardness, edge radius, camber, surface roughness Ra, adhesion of enamel (if requested), package net/gross, and a unique bar-code for lot traceability inside your MES.

One-Click Technical Pack—Ready for Your Design Software

Send an e-mail to cathy@transformerstrip.com with the subject “Cu coil data pack” and receive within 30 min:

Excel design sheet: resistance/m, weight/m, packing factor for 25–500 mm widths.

SAT file 3-D reel model for winding simulation.

Rohs/REACH, Conflict-Minerals, ISO 9001:2015, ISO 14001:2015 certificates.

Factory audit video (12 min) shot this quarter—see the slitting line in action.

Need a quotation instead? Attach your cutting list (thickness, width, kg per size). We normally return a CIF price within 2 hours, including anti-corrosion VCI paper and fumigated plywood reels ready for North-American ISPM-15 customs clearance.

Stop paying 20–30 % extra for the same IACS conductivity. Partner with Luoyang Xinzhaohe and turn copper coil cost into a competitive advantage for your next transformer series.

📉 Import Savings Calculator

Estimate cost reduction by sourcing copper coil transformer from Luoyang Xinzhaohe.