Table of Contents

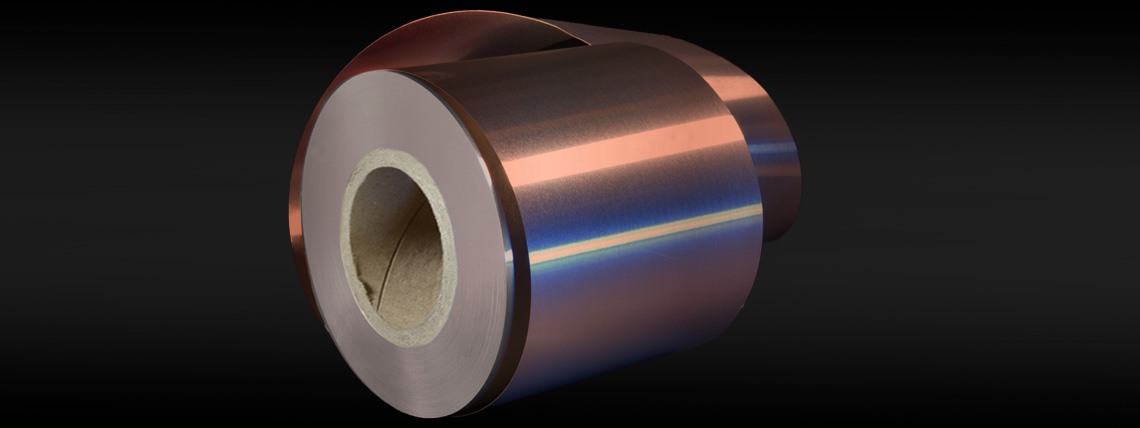

Market Insight: Copper Coated Coil

Market Analysis: Transformer Strip/Foil (Aluminum/Copper)

Global demand for copper coated aluminum coil in power and distribution transformers continues robust growth, driven by escalating energy infrastructure investments and renewable energy integration. This segment leverages the electrical conductivity of copper with the weight and cost advantages of aluminum, creating a critical material solution for modern transformer manufacturing. Key demand drivers include grid modernization programs across Asia Pacific and Europe, the expansion of solar and wind farm substations requiring compact, efficient transformers, and the persistent need for cost optimization without compromising core electrical performance. Copper coated coil specifically addresses the industry’s push for lighter transformers with reduced material costs compared to solid copper windings, while maintaining sufficient conductivity for medium-voltage applications. This balance positions it as a strategic material for manufacturers targeting competitive pricing in high-volume distribution transformer markets.

Quality parameters for copper coated coil are non-negotiable determinants of transformer reliability and longevity. Substandard coating adhesion or inconsistent thickness directly impacts electrical performance and thermal management. Poor interfacial bonding between the copper layer and aluminum substrate leads to increased contact resistance at the interface, accelerating localized heating under operational load. This manifests as elevated eddy current losses and potential hot spot formation, significantly degrading transformer efficiency and shortening operational lifespan. Industry standards such as IEC 60404-1 and ASTM B562 mandate stringent tolerances on coating thickness uniformity; deviations exceeding ±5% cause uneven current distribution across the conductor cross-section. Surface defects like pinholes, scratches, or oxide inclusions act as nucleation points for partial discharges within the winding insulation system, a primary precursor to catastrophic insulation failure. Furthermore, inadequate coating ductility results in micro-cracking during the rigorous coil winding process, compromising the integrity of the conductive path and creating internal short-circuit risks.

The consequences of quality lapses extend far beyond the coil itself, cascading through the transformer supply chain. Field failures stemming from inferior copper coated material trigger costly warranty claims, unplanned grid outages, and severe reputational damage for both transformer OEMs and utilities. Procurement decisions must therefore prioritize suppliers with demonstrable process control in key areas: continuous electroplating line stability for micron-level coating precision, rigorous in-line eddy current testing for defect detection, and comprehensive adhesion validation via peel tests per ASTM B571. Luoyang Xinzhaohe Aluminum CO., Ltd leverages its 20+ years of specialized metallurgical expertise to deliver copper coated coil meeting the most demanding global specifications. Our integrated quality management system ensures traceability from raw material certification through final product validation, directly mitigating the operational and financial risks associated with subpar conductive materials in critical power infrastructure. Transformer manufacturers require this level of assured quality to meet escalating efficiency regulations and deliver reliable assets with a 30+ year service life.

Technical Specs: Copper Coated Coil

Technical Specifications: Copper Coated Aluminum Coil for Transformer Applications

Luoyang Xinzhaohe Aluminum Co., Ltd. delivers high-performance copper coated aluminum coil engineered specifically for advanced transformer strip and foil applications. With over two decades of metallurgical expertise, our manufacturing process ensures strict adherence to dimensional tolerances, electrical performance, and surface integrity required in high-reliability power systems. The copper coating, applied via advanced electroplating or cladding techniques, enhances surface conductivity while preserving the lightweight and cost-efficiency advantages of aluminum substrates.

Precision slitting is a critical parameter in the production of transformer-grade coil material. Our slitting process maintains a dimensional tolerance of ±0.002 mm, ensuring uniform strip width across the entire coil length. This level of precision is essential for consistent winding tension, reduced interlayer stress, and minimized eddy current losses in transformer cores. Each coil undergoes real-time laser measurement during slitting to verify width consistency and detect deviations, enabling immediate process correction and ensuring end-product reliability.

Edge quality is paramount in transformer windings to prevent dielectric breakdown and mechanical damage during coiling. Our production line incorporates precision-tuned rotary shear slitters and edge smoothing technology to produce burr-free edges. Post-slitting inspection using high-magnification optical profilometry confirms the absence of micro-tears, protrusions, or edge deformation. Burr height is consistently maintained below 1% of material thickness, meeting the stringent requirements of high-voltage and high-frequency transformer designs.

Electrical conductivity is optimized through controlled alloy selection and thermal processing. The aluminum core (typically 1060, 1070, or 1350 series) achieves a base conductivity of ≥61% IACS. Following copper coating—typically 0.5% to 3% by weight depending on application—the effective surface conductivity approaches that of pure copper, significantly improving current carrying capacity at the conductor surface where skin effect dominates at higher frequencies. The metallurgical bond between copper and aluminum is diffusion-controlled to prevent delamination under thermal cycling.

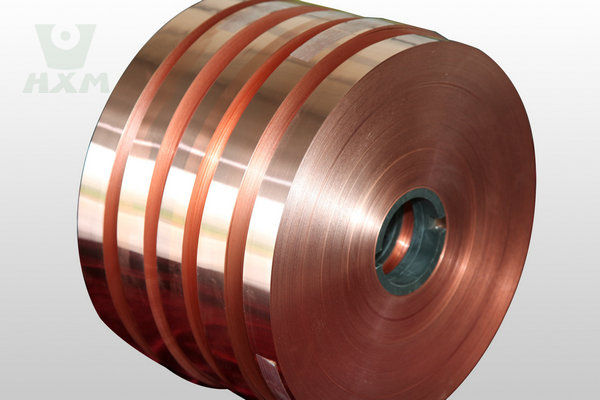

All coils are wound under controlled tension to prevent coil set and edge wave, and are supplied with protective interleafing to avoid surface scratching. Core diameters, outer diameters, and packaging are customizable to meet customer handling and processing requirements.

| Parameter | Specification |

|---|---|

| Material Core | 1060, 1070, or 1350 Aluminum (99.6% min Al) |

| Copper Coating Thickness | 0.5% – 3.0% by weight (adjustable) |

| Strip Width Tolerance | ±0.002 mm |

| Thickness Range | 0.10 mm – 3.0 mm |

| Edge Burr Height | <1% of material thickness |

| Conductivity (Al Core) | ≥61% IACS |

| Surface Finish | Clean, oxidation-controlled, no delamination |

| Coating Adhesion | Passed tape test and thermal cycling (200°C) |

| Coil ID | 200 mm, 300 mm, 509 mm (customizable) |

| Max Coil OD | Up to 1200 mm |

| Packaging | Waterproof, wooden pallet, interleaf paper |

Factory Tour: Manufacturing

Manufacturing Process for Copper Coated Aluminum Transformer Coil

Luoyang Xinzhaohe Aluminum Co., Ltd leverages over two decades of specialized metallurgical expertise to produce high-performance copper coated aluminum coil for critical transformer applications. Our integrated manufacturing sequence ensures stringent dimensional control, surface integrity, and electrical properties essential for efficient transformer operation. The core process chain comprises Cold Rolling, Precision Slitting, and Edge Conditioning, each stage incorporating rigorous quality verification.

Cold Rolling Stage

High-purity aluminum substrate (typically 1060, 1070, or 1350 alloys per ASTM B209) undergoes multi-stand cold rolling to achieve the precise final gauge required for transformer windings, commonly ranging from 0.10 mm to 0.80 mm. This stage utilizes computer-controlled tension management and precision roll grinding to maintain tight thickness tolerances of ±0.005 mm across the strip width. Critical parameters monitored include roll force, interstand tension, and exit speed to ensure uniform microstructure and mechanical properties. Immediate post-rolling inline surface inspection via high-resolution optical systems detects defects such as scratches, roll marks, or residual oxides. Verified material proceeds to annealing if required for specific temper (e.g., H14, H18), followed by thorough cleaning to remove rolling oils prior to coating.

Copper Coating Application

The cleaned aluminum strip enters an electroless copper plating line. This chemical deposition process applies a uniform, pore-free copper layer (typically 0.5 μm to 3.0 μm thick) without external current, ensuring consistent coverage even on complex geometries. Bath chemistry, temperature, and pH are continuously monitored and adjusted to maintain coating adhesion, conductivity, and solderability per ASTM B317 requirements. Real-time thickness verification employs non-contact X-ray fluorescence (XRF) gauges. Post-coating, the strip undergoes multi-stage rinsing and drying under controlled humidity to prevent oxidation before winding.

Precision Slitting and Edge Conditioning

The coated coil is processed through high-precision slitting lines equipped with servo-driven knife positioning systems. Slitting achieves width tolerances within ±0.10 mm, critical for minimizing winding gaps in transformer cores. Immediately following slitting, the strip edges undergo dedicated conditioning. This involves either mechanical deburring to remove micro-burrs or controlled edge rounding to a specified radius (typically 0.05 mm to 0.15 mm). Edge conditioning is paramount; it prevents insulation damage during winding, reduces partial discharge risks, and enhances long-term reliability in high-voltage applications. Conditioned edges are verified using automated edge profile scanners.

Integrated Quality Control Framework

Quality assurance is embedded throughout production. Key QC checkpoints include:

Incoming aluminum coil certification (chemical composition, mechanical properties)

Continuous thickness monitoring via laser micrometers during rolling and slitting

Coating thickness and adhesion testing (tape test per ASTM D3359) at defined intervals

Surface roughness measurement (Ra ≤ 0.4 μm target) using profilometry

Final coil inspection for edge quality, surface defects, and dimensional conformance

The following table summarizes critical final product verification parameters:

| Parameter | Test Method | Standard Requirement | Frequency |

|---|---|---|---|

| Thickness | Laser Micrometer | ±0.005 mm | Continuous |

| Coating Thickness | XRF | ±0.1 μm | Per ASTM B317 |

| Edge Radius | Optical Profiler | 0.05 – 0.15 mm | Hourly |

| Tensile Strength | ASTM E8 | As Specified | Per Lot (5 coils) |

| Surface Roughness | ISO 4287 | Ra ≤ 0.4 μm | Per Lot (5 coils) |

All coils undergo 100% surface and edge inspection prior to shipment, with full traceability from raw material to finished product maintained under our ISO 9001 certified quality management system. This disciplined process control guarantees the copper coated aluminum coil meets the demanding electrical, mechanical, and reliability standards required for modern power and distribution transformers.

Packaging & Logistics

Export Packaging Standards for Copper Coated Coil – Luoyang Xinzhaohe Aluminum CO., Ltd

At Luoyang Xinzhaohe Aluminum CO., Ltd, with over two decades of specialized experience in the production and international supply of transformer strip and foil—spanning aluminum, copper, and advanced composite materials—we maintain rigorous export packaging protocols to ensure product integrity during global logistics. For copper coated coil shipments, our packaging system is engineered to withstand the demanding conditions of sea freight, which remains the dominant mode of transport for bulk industrial metal products.

All copper coated coils are mounted on high-strength wooden pallets constructed from kiln-dried, ISPM 15-compliant hardwood. These pallets are designed to support the full mechanical load of the coil, typically ranging from 500 kg to over 3,000 kg, without deformation or structural failure. The wood is treated to prevent pest infestation and decay, meeting international phytosanitary standards essential for customs clearance across major markets including the EU, North America, and Southeast Asia. Each pallet is reinforced with steel strapping at multiple anchor points to secure the coil base and prevent lateral displacement during vessel movement or port handling.

Immediately following coil placement on the pallet, a multi-layer moisture-proof wrapping system is applied. This consists of an inner layer of anti-corrosion paper (VCI—Vapor Corrosion Inhibitor treated), followed by two wraps of high-density polyethylene (HDPE) film with a minimum thickness of 120 microns. The film is heat-sealed at all seams to form a hermetic barrier against humidity, salt spray, and condensation—common risks in marine environments. An additional external layer of UV-resistant polypropylene (PP) woven cloth is often added for mechanical protection against abrasion and minor impacts during loading and unloading.

Coils are further secured using steel or PET straps tensioned to industrial specifications, ensuring no axial or radial movement occurs during transit. All strapping is anchored to the pallet and passes over the coil flanges at a minimum of four equidistant points. Edge protectors made of laminated cardboard or steel are applied at critical contact zones to prevent damage to the coil’s outer wraps and edges.

Labeling is executed in compliance with international shipping standards. Each package carries a durable, weather-resistant tag indicating product specifications (alloy, temper, dimensions, weight), batch number, production date, and handling instructions (e.g., “Do Not Roll,” “This Side Up”). Hazard communication, where applicable, follows GHS guidelines.

Our packaging methodology has been validated through long-term sea voyages, including trans-Pacific and trans-Atlantic routes, with zero reported incidents of moisture ingress or structural failure. This reliability is integral to our commitment to delivering copper coated coil products in as-manufactured condition, preserving surface quality and electrical performance upon arrival. For global partners, this translates into reduced inspection time, minimized claims, and seamless integration into downstream transformer manufacturing processes.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe: Your Precision Copper Coated Coil Manufacturer

Luoyang Xinzhaohe Aluminum Co., Ltd leverages over two decades of specialized metallurgical expertise and vertical integration to deliver copper coated aluminum coil solutions meeting the stringent demands of modern transformer and inductor manufacturing. Our core strength lies in the precise control of both the aluminum substrate and the electroplated copper layer, ensuring optimal electrical performance, mechanical reliability, and long-term stability in critical electromagnetic applications. We understand that dimensional accuracy, coating adhesion, and consistent conductivity are non-negotiable for your core lamination and winding processes.

Our integrated production facility houses advanced casting, cold rolling, and continuous electroplating lines under one roof. This vertical control enables rigorous management of the aluminum alloy composition (primarily 1060, 1070, and 1100 series), grain structure, and surface preparation – foundational elements for achieving superior copper adhesion and minimizing interfacial resistance. Our proprietary electroplating process delivers uniform copper coatings with exceptional thickness control and purity, critical for maintaining high electrical conductivity while leveraging aluminum’s weight and cost advantages. We maintain strict process parameters to prevent hydrogen embrittlement and ensure the metallurgical integrity of the bond between the aluminum core and copper layer.

Production capabilities are engineered for transformer-grade precision. We consistently achieve tight dimensional tolerances essential for high-efficiency core stacking and automated winding operations. Our standard production parameters are detailed below.

| Parameter | Capability Range | Typical Tolerance |

|---|---|---|

| Aluminum Thickness | 0.10 mm – 1.50 mm | ±0.005 mm |

| Copper Coating Thickness | 0.01 mm – 0.10 mm | ±0.003 mm |

| Total Thickness | 0.11 mm – 1.60 mm | ±0.008 mm |

| Width | 50 mm – 1250 mm | ±0.5 mm |

| Tensile Strength | 80 MPa – 120 MPa (Al core) | ±5 MPa |

| Elongation | ≥ 25% | ±3% |

| Conductivity (IACS) | ≥ 58% (Coated product) | ±1% |

Quality assurance is embedded at every stage, from raw material certification through final inspection. We implement comprehensive in-process monitoring, including continuous thickness gauging, adhesion testing per ASTM B571, surface resistivity mapping, and rigorous mechanical property validation via tensile and bend testing. Our ISO 9001 certified quality management system ensures traceability and adherence to international standards such as IEC 60140 and customer-specific technical specifications. This systematic approach minimizes process variation and guarantees the batch-to-batch consistency your production lines require.

Partnering with Luoyang Xinzhaohe provides direct access to deep metallurgical knowledge, responsive engineering support, and a reliable supply chain optimized for the transformer industry. We collaborate closely with customers during the design phase to tailor material properties, ensuring compatibility with your specific lamination, annealing, and winding processes. Our logistics network ensures on-time delivery of coils meeting precise winding requirements, reducing your inventory risk and production downtime.

Initiate a technical consultation to discuss how our copper coated aluminum coil can enhance the performance and cost-efficiency of your transformer cores. Contact our Chief Technical Officer, Cathy Zhang, directly at cathy@transformerstrip.com to specify your requirements and receive a detailed capability assessment.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing copper coated coil directly from China.