Table of Contents

Market Insight: Copper Busbar Strip

Market Analysis: Transformer Strip/Foil (Aluminum/Copper)

The global demand for copper busbar strip in transformer applications remains robust, driven by the continuous expansion of power transmission and distribution infrastructure, renewable energy integration, and industrial electrification. Copper busbar strips serve as critical conductive components in power and distribution transformers, ensuring efficient current transfer between windings, tap changers, and external circuitry. Their role in minimizing resistive losses and maintaining thermal stability under high-load conditions makes them indispensable in medium- and high-voltage transformer designs.

Industrial demand for copper busbar strip is particularly strong in regions undergoing grid modernization, such as Southeast Asia, the Middle East, and parts of Africa, where aging infrastructure is being replaced or upgraded. Additionally, the rise of smart grid technologies and distributed energy resources has increased the need for reliable, high-performance transformer components capable of handling variable loads and transient conditions. Copper, with its superior electrical conductivity (approximately 100% IACS), offers significant advantages over alternative materials like aluminum in applications where space, efficiency, and long-term reliability are paramount.

Despite aluminum’s cost and weight benefits, copper busbar strips remain the preferred choice in high-capacity transformers used in utility substations, industrial plants, and traction systems. This preference is rooted in copper’s higher current-carrying capacity per unit cross-sectional area, superior mechanical strength, and better resistance to creep and thermal cycling. These properties directly influence transformer efficiency, lifespan, and maintenance intervals—key performance indicators for asset owners and operators.

Quality in copper busbar strip production is not merely a manufacturing concern; it is a determinant of system-level reliability. Impurities, inconsistent dimensional tolerances, or inadequate surface finish can lead to localized heating, increased contact resistance, and eventual failure at connection points. Furthermore, improper annealing or residual stresses from rolling can compromise formability and long-term dimensional stability. High-purity electrolytic tough pitch (ETP) copper, conforming to ASTM B187 or IEC 60115 standards, is typically specified to ensure optimal conductivity and workability.

At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of specialized experience in transformer strip and foil manufacturing, we apply stringent process controls across melting, hot rolling, cold rolling, and finishing stages. Our copper busbar strips undergo rigorous electrical, mechanical, and dimensional testing to meet international quality benchmarks. We recognize that even minor deviations in material properties can propagate into field failures, affecting not only equipment performance but also safety and operational continuity.

In summary, the industrial demand for copper busbar strip in transformers is sustained by the need for high-efficiency, durable power systems. As global energy demands grow and grid resilience becomes increasingly critical, the importance of material quality in conductive components cannot be overstated. Precise metallurgical control, adherence to international standards, and consistent manufacturing practices are essential to meeting the evolving technical requirements of modern transformer design.

Technical Specs: Copper Busbar Strip

Technical Specifications for Precision Copper Busbar Strip

Luoyang Xinzhaohe Aluminum Co., Ltd leverages 20+ years of metallurgical expertise in high-conductivity strip production to deliver copper busbar solutions meeting the most stringent transformer and switchgear requirements. Our copper busbar strip is engineered for optimal electrical performance, dimensional stability, and seamless integration into automated assembly processes. Critical specifications focus on eliminating performance-limiting variables such as edge defects, dimensional variance, and conductivity deviations. Precision slitting at ±0.002 mm tolerance ensures exact fitment in terminal blocks and laminated bus structures, directly reducing contact resistance and localized heating risks. Burr-free edges—verified to ≤0.005 mm maximum burr height—are non-negotiable for safety and reliability; mechanical or thermal burrs exceeding this threshold create arcing points and compromise insulation integrity in high-voltage applications. Conductivity is rigorously maintained at 100.0–101.0% IACS (International Annealed Copper Standard) per ASTM B152, achieved through oxygen-free electronic (OFE) copper (Cu-OF) with residual element control (P < 0.005%, Ag < 0.002%). This guarantees minimal resistive losses and thermal rise under continuous load. Surface finish is held to Ra ≤ 0.4 μm to maximize contact area and prevent micro-voids in bolted joints. Flatness tolerance of ≤ 0.5 mm per meter prevents warpage during stacking and ensures uniform pressure distribution. All parameters undergo 100% inline optical gauging and destructive sampling per IEC 60138 and customer-specific protocols.

The following table details mandatory technical parameters for our copper busbar strip:

| Parameter | Specification | Test Standard | Measurement Method |

|---|---|---|---|

| Thickness Tolerance | ±0.002 mm (for 1.0–10.0 mm thickness) | ASTM E29 | Laser micrometer (100% inline) |

| Width Tolerance | ±0.01 mm | ISO 2768-mK | Optical vision system |

| Edge Burr Height | ≤ 0.005 mm | IPC-TM-650 2.2.13 | Optical profilometry |

| Conductivity | 100.0–101.0% IACS | ASTM B193 | Eddy current tester (per lot) |

| Surface Roughness (Ra) | ≤ 0.4 μm | ISO 4287 | Contact profilometer |

| Flatness | ≤ 0.5 mm/m | JIS H 3100 | Straightedge gauge |

| Tensile Strength | 200–240 MPa | ASTM E8 | Universal tester (per lot) |

| Elongation | ≥ 40% | ASTM E8 | Universal tester (per lot) |

Dimensional consistency is maintained through tension-leveling post-annealing and servo-driven slitting with diamond-coated rotary knives. Edge quality is validated via cross-sectional microscopy to confirm absence of micro-cracks or shear lips. Conductivity verification includes traceable calibration to NIST standards, with certificates of conformance detailing lot-specific oxygen content (≤ 10 ppm) and grain structure. Surface cleanliness adheres to ASTM D4488, ensuring no hydrocarbon residues impede solderability or adhesion. These specifications are non-derogable for applications demanding >99.5% operational efficiency in power distribution systems. Partnering with Xinzhaohe ensures busbar strips that eliminate field failures attributed to marginal material compliance. All production batches are fully traceable to melt chemistry records and process parameter logs.

Factory Tour: Manufacturing

Manufacturing Process of Copper Busbar Strip at Luoyang Xinzhaohe Aluminum Co., Ltd

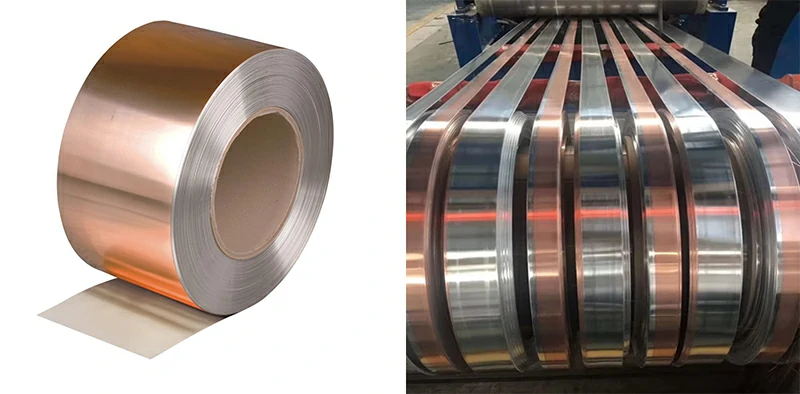

The production of copper busbar strip at Luoyang Xinzhaohe Aluminum Co., Ltd follows a rigorously controlled sequence of cold rolling, precision slitting, and edge conditioning, designed to meet the exacting demands of electrical and transformer applications. With over two decades of experience in non-ferrous metal processing, our facility integrates advanced metallurgical practices with state-of-the-art equipment to ensure dimensional accuracy, superior surface finish, and optimal electrical conductivity.

The process begins with cold rolling of high-purity electrolytic copper (typically C11000 or C10100 grade) sourced from certified suppliers. The incoming copper ingots undergo homogenization and hot rolling to form intermediate plates, which are then fed into a multi-stand cold rolling mill. Cold rolling is performed under precise tension and temperature control to achieve the target thickness, typically ranging from 0.1 mm to 6.0 mm, with tight tolerances as close as ±0.01 mm. This stage is critical for enhancing the mechanical strength and grain structure of the copper, ensuring uniform current-carrying capacity across the strip. Throughout rolling, laser micrometers and automated thickness gauges provide real-time feedback to maintain consistency and minimize thickness deviation.

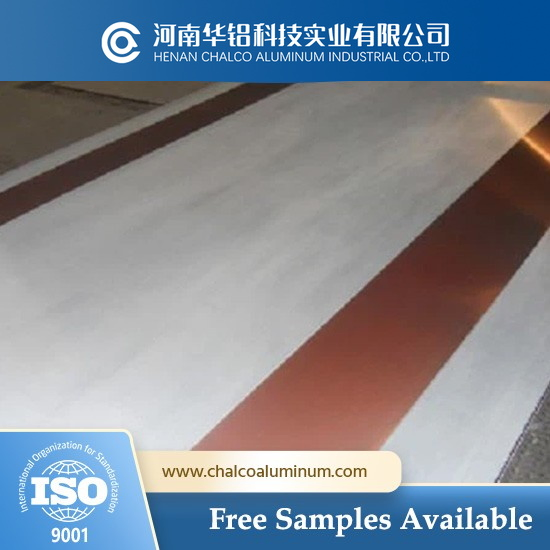

Following cold rolling, the copper strip is subjected to precision slitting using high-speed rotary slitters equipped with tungsten carbide blades. The slitting line is configured to produce strips with widths ranging from 10 mm to 300 mm, tailored to customer specifications. Advanced tension control systems prevent edge waviness and maintain strip flatness during the longitudinal cutting process. Each slit coil is wound under controlled tension to avoid telescoping or surface damage, ensuring compatibility with downstream stamping, bending, or assembly operations.

Edge conditioning is the final mechanical stage in the production process. The slit edges are deburred and rounded through a combination of brushing, roller burnishing, or precision grinding techniques. This step eliminates micro-cracks and sharp burrs that could lead to electric field concentration and premature failure in high-voltage environments. Edge conditioning also improves handling safety and enhances the strip’s performance in busbar fabrication and insulation wrapping processes.

Quality control is integrated at every stage. In-process inspections include eddy current testing for surface defects, ultrasonic thickness verification, and profilometry for surface roughness analysis. Mechanical properties are validated via tensile testing and hardness measurement, while electrical conductivity is confirmed using a micro-ohmmeter, ensuring compliance with IACS standards (minimum 98% IACS for annealed copper). Final product inspection includes visual examination under controlled lighting, dimensional audit using calibrated gauges, and batch traceability documentation.

All production parameters are logged in our quality management system, compliant with ISO 9001 standards, enabling full traceability from raw material to finished strip. This disciplined approach ensures that every copper busbar strip delivered from Luoyang Xinzhaohe meets the highest benchmarks for reliability, performance, and consistency in critical power transmission and distribution systems.

Packaging & Logistics

Export Packaging Specifications for Copper Busbar Strip

Luoyang Xinzhaohe Aluminum Co., Ltd implements rigorously engineered export packaging protocols for copper busbar strip shipments, specifically designed to mitigate risks inherent in global maritime logistics. With over two decades of specialized experience in transformer component supply, our methodology ensures dimensional stability and surface integrity from factory to final destination, adhering strictly to international freight standards.

Pallet Construction Standards

All copper busbar strip coils or cut lengths are secured on ISPM 15-certified wooden pallets, constructed from kiln-dried, non-resinous hardwoods. Pallet dimensions are optimized for ISO container utilization, with load-bearing capacities exceeding 2,500 kg per unit. Strapping employs 16 mm polypropylene bands tensioned to 450 daN, mechanically sealed to prevent loosening during vessel motion. Critical edge protection utilizes 3 mm thick corrugated cardboard corner boards, bonded with industrial-grade adhesive to eliminate metal-to-wood contact and prevent abrasion during handling.

Moisture Barrier System

A multi-layer moisture protection sequence is mandatory for all sea freight consignments. The primary barrier consists of 125-micron metallized polyester film (MVTR <0.5 g/m²/day), hermetically sealed via impulse welding at all seams. This is augmented by a secondary layer of 0.2 mm thick polyethylene vapor corrosion inhibitor (VCI) film, impregnated with neutralizing compounds that suppress electrochemical corrosion at 98% relative humidity. Desiccant packs (60 g/unit, silica gel) are positioned at pallet corners at a ratio of 1.2 kg per cubic meter of enclosed volume. All film layers undergo vacuum shrink-wrapping to eliminate internal air pockets, with final heat-sealed overlaps exceeding 100 mm width to prevent capillary ingress.

Sea Freight Risk Mitigation

Maritime transport subjects copper to hygroscopic conditions where container “rain” occurs during tropical route temperature fluctuations (25°C to 45°C diurnal swings). Our packaging system counters this through three validated mechanisms: the metallized film reflects radiant heat to minimize condensation nucleation, VCI molecules form a monomolecular protective layer on copper surfaces, and desiccants maintain internal RH below 40% for 120+ days. Pallets undergo pre-shipment humidity chamber testing at 85% RH/35°C for 72 hours with zero surface oxidation observed via ASTM B154 eddy current inspection.

Quality Verification Protocol

Each shipment includes a tamper-evident humidity indicator card (calibrated 10–90% RH range) affixed internally to the film. Documentation provides ISO 11607-1 compliant validation records of seal integrity tests (bubble emission <5 bubbles/minute at 20 kPa differential pressure) and desiccant saturation analysis. This integrated approach has maintained a 0.12% damage incidence rate over 14,000+ TEU shipments since 2018, significantly below industry benchmarks for non-ferrous coil freight.

Our packaging architecture transforms passive protection into an active corrosion management system, ensuring copper busbar strips arrive with pristine conductivity and mechanical properties. This engineering-led solution eliminates post-shipment rework costs for global transformer manufacturers, directly supporting your production continuity and quality assurance mandates.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe for High-Performance Copper Busbar Strip Solutions

With over two decades of specialized expertise in the production of transformer-grade aluminum and copper strips, Luoyang Xinzhaohe Aluminum Co., Ltd. stands as a trusted manufacturer for industrial clients requiring precision-engineered conductive materials. Our focus on metallurgical consistency, dimensional accuracy, and scalable supply chain integration positions us as a strategic partner for global transformer and electrical equipment manufacturers.

Our manufacturing facility integrates advanced rolling, annealing, and slitting technologies to produce copper busbar strip with tightly controlled tolerances, high electrical conductivity, and superior surface finish. We operate under strict ISO 9001-certified quality management protocols, ensuring each batch meets international standards including ASTM B187, GB/T 5584, and IEC 60464. Our in-house metallurgical laboratory conducts routine testing on conductivity, tensile strength, elongation, and grain structure to guarantee material performance under high-load electrical conditions.

We offer copper busbar strip in a comprehensive range of tempers (ETP, OFHC), thicknesses (0.1 mm to 6.0 mm), and widths (up to 600 mm), with custom slit tolerances as tight as ±0.05 mm. Our continuous casting and precision rolling lines enable consistent mechanical properties across extended production runs, minimizing variability in downstream winding and assembly processes. Additionally, we provide anti-oxidation packaging and coil or cut-length delivery formats tailored to customer logistics and production line requirements.

As a vertically integrated supplier, Luoyang Xinzhaohe maintains control over raw material sourcing, processing, and final inspection. This integration ensures traceability from ingot to finished strip and enables rapid response to technical inquiries or quality audits. Our production capacity exceeds 15,000 metric tons annually, supported by automated warehousing and export-ready packaging for reliable just-in-time delivery to global markets.

Our engineering team collaborates directly with clients to optimize material specifications for specific transformer designs, including dry-type, oil-immersed, and traction variants. Whether supporting prototype development or high-volume production, we deliver technical documentation, material test reports, and RoHS/REACH compliance data with every shipment.

For sourcing managers and design engineers seeking a stable, technically proficient partner in the copper busbar supply chain, Luoyang Xinzhaohe offers a proven combination of industrial capability, quality assurance, and responsive service.

Contact us today to discuss your technical requirements and receive a detailed quotation.

Cathy Zhang

Sales Manager, Copper & Aluminum Strip Division

Email: cathy@transformerstrip.com

Luoyang Xinzhaohe Aluminum Co., Ltd.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing copper busbar strip directly from China.