Table of Contents

Market Insight: Copper Bus Bar Strip

Market Analysis: Transformer Strip/Foil (Aluminum/Copper)

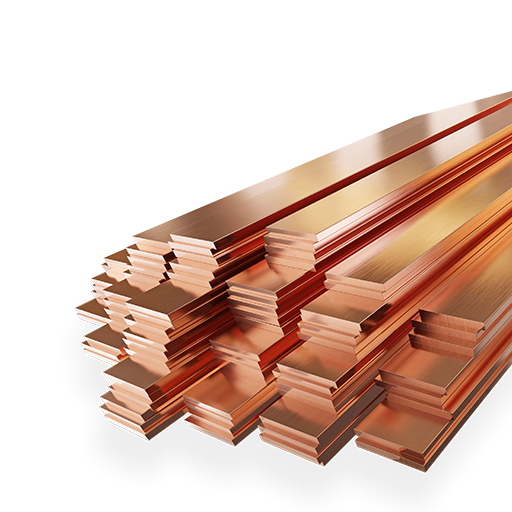

Global demand for copper bus bar strip within the transformer sector remains robust, driven by continuous expansion and modernization of electrical infrastructure. The worldwide transformer market, projected to grow at a compound annual rate exceeding 5.5% through 2030, directly fuels requirements for high-purity copper conductors. Key demand catalysts include the rapid deployment of renewable energy integration systems, urban grid upgrades necessitating higher efficiency distribution transformers, and stringent global energy efficiency regulations (e.g., DOE 2016, EU EcoDesign). Copper bus bars are indispensable in critical applications such as power distribution transformers (11kV-33kV), traction transformers for rail, and large power transformers (100+ MVA), where they serve as the primary current-carrying interface between windings and external connections. Unlike aluminum alternatives, copper’s superior conductivity and mechanical stability make it the mandated material for high-reliability, high-fault-current scenarios, particularly in compact or mission-critical installations where space constraints and thermal management are paramount.

Quality assurance for copper bus bar strip is non-negotiable in transformer manufacturing due to direct implications on operational safety, efficiency, and lifespan. Substandard material introduces systemic risks that compromise the entire unit. Metallurgical purity is foundational; oxygen-free electronic (OFE) copper (C10100/C10200) with minimum 99.99% Cu content is essential to prevent hydrogen embrittlement during vacuum pressure impregnation (VPI) and ensure long-term structural integrity. Impurities exceeding 50 ppm—particularly iron, sulfur, or oxygen—degrade electrical conductivity below the critical 97% IACS threshold, directly increasing resistive losses (I²R) and localized heating. Mechanical properties require precise control: tensile strength must range 200–250 MPa with minimum 40% elongation to withstand bus bar bending, clamping forces, and electromagnetic stresses during short-circuit events without cracking or permanent deformation. Surface finish demands meticulous attention; roughness averages below 1.6 μm Ra prevent corona discharge and minimize contact resistance at bolted joints, which if elevated, accelerate oxidation and thermal runaway. Dimensional tolerances are equally critical, with thickness deviations held to ±0.05 mm to ensure uniform current distribution and prevent eddy current hotspots.

Failure to adhere to these specifications manifests in catastrophic field failures. Inadequate conductivity elevates operating temperatures, accelerating insulation degradation per Arrhenius aging principles. Poor mechanical properties lead to bus bar fracture during seismic events or fault currents, causing immediate transformer outage. Surface defects initiate arcing, potentially triggering internal faults requiring costly rewinds. Luoyang Xinzhaohe Aluminum Co., Ltd leverages two decades of metallurgical expertise to enforce rigorous in-process controls, including real-time conductivity monitoring via eddy current testing, laser profilometry for surface validation, and destructive testing per ASTM B193 and IEC 60164 standards. This precision engineering ensures copper bus bar strip meets the uncompromising demands of modern transformer design, where material quality directly dictates asset reliability and total cost of ownership.

Technical Specs: Copper Bus Bar Strip

Technical Specifications for Copper Bus Bar Strip

Luoyang Xinzhaohe Aluminum Co., Ltd. manufactures high-precision copper bus bar strips designed for critical electrical applications, particularly within power transformers, switchgear, and high-current distribution systems. Our copper bus bar strips are engineered to meet stringent international standards, ensuring optimal electrical performance, mechanical stability, and long-term reliability. Each product undergoes rigorous quality control throughout the production cycle, from raw material selection to final inspection, to guarantee consistency and compliance with customer specifications.

The dimensional accuracy of our copper bus bar strips is maintained through advanced precision slitting technology, capable of achieving a width tolerance of ±0.002 mm. This level of precision ensures uniform current distribution and facilitates seamless integration into automated assembly processes, reducing fit-up errors and minimizing contact resistance at connection points. The slit edges are processed using optimized tooling and tension control systems to eliminate burrs, resulting in smooth, clean edges that meet industry requirements for safety and performance. Burr-free edges are essential in high-density electrical systems to prevent localized heating, insulation damage, and potential arcing.

Electrical conductivity is a core performance metric for copper bus bar applications. Our strips are produced from high-purity electrolytic tough pitch (ETP) copper (Cu-ETP1, UNS C11000), achieving a minimum conductivity of 98% IACS at 20°C. This high conductivity ensures minimal resistive losses and superior thermal management under continuous load conditions. All batches are tested using calibrated eddy current and four-point probe systems to verify conductivity compliance.

Mechanical properties are tailored to balance formability and structural integrity. Typical tensile strength ranges from 200–240 MPa with an elongation of ≥5% in 50 mm, supporting both straight-run installations and moderate bending operations without cracking. Surface finish is controlled to less than 1.6 µm Ra, minimizing interfacial resistance in bolted or clamped joints.

All copper bus bar strips are supplied in straight lengths or coil form, depending on customer requirements, and are protected with anti-tarnish coating and moisture-resistant packaging to prevent oxidation during transit and storage.

| Parameter | Specification |

|---|---|

| Material | Cu-ETP1 (UNS C11000) |

| Conductivity | ≥98% IACS at 20°C |

| Width Tolerance | ±0.002 mm |

| Thickness Range | 0.1 mm – 6.0 mm |

| Edge Quality | Burr-free, slit with high-precision tooling |

| Tensile Strength | 200–240 MPa |

| Elongation (50 mm) | ≥5% |

| Surface Roughness (Ra) | ≤1.6 µm |

| Coil ID / Straight Length | 200 mm, 300 mm, or custom cut-to-length |

| Packaging | Anti-tarnish film, moisture-resistant wrapping |

These specifications reflect our commitment to delivering copper bus bar strips that meet the demanding requirements of modern power transmission and distribution infrastructure. Custom profiles, tempers, and testing documentation (including mill test certificates) are available upon request.

Factory Tour: Manufacturing

Manufacturing Process for Copper Bus Bar Strip

Luoyang Xinzhaohe Aluminum CO.,Ltd applies two decades of metallurgical expertise to produce copper bus bar strip for critical power transmission applications. Our process prioritizes dimensional stability, surface integrity, and electrical performance through a rigorously controlled sequence: cold rolling, precision slitting, and edge conditioning. This methodology ensures compliance with IEC 61439 and ASTM B187 standards while minimizing resistive losses in transformer and switchgear systems.

Cold rolling forms the foundational stage, where electrolytic tough pitch (ETP) copper ingots undergo homogenization annealing followed by multi-stand reduction. We maintain strict temperature control below 150°C to prevent recrystallization, achieving precise thickness tolerances of ±0.02 mm for strips ranging from 0.5 mm to 6.0 mm. Roll force and tension are dynamically adjusted via closed-loop systems to eliminate centerline waviness and ensure uniform grain structure. This stage critically influences conductivity, with post-rolling conductivity consistently exceeding 98% IACS through optimized dislocation density management.

Precision slitting transforms master coils into customer-specified widths using servo-driven rotary shear lines with micron-level positional accuracy. Our slitters employ tungsten carbide knives ground to 0.005 mm edge tolerance, minimizing burr formation and width deviation to ±0.1 mm. Real-time laser width monitoring triggers automatic knife position correction, while tension-controlled payoff and take-up reels prevent edge distortion. Each slit coil undergoes inline eddy current testing to detect subsurface inclusions or conductivity anomalies exceeding 0.5% IACS deviation.

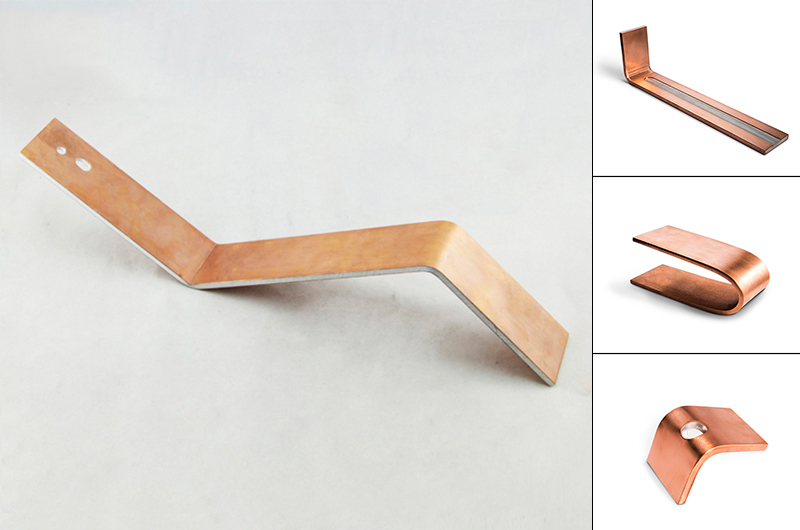

Edge conditioning is non-negotiable for high-voltage safety and connection reliability. Strips pass through dual-stage deburring units where rotating abrasive brushes and precision milling cutters remove micro-burrs to <0.01 mm height. Simultaneously, edge radiusing tools apply controlled 0.1–0.3 mm fillets to prevent corona discharge at sharp corners. This process eliminates particle shedding during installation and ensures optimal contact pressure in bolted joints, directly enhancing current-carrying capacity.

Quality control integrates at three critical junctures. Post-rolling, samples undergo tensile testing (yield strength 60–120 MPa), microstructure analysis per ASTM E3, and surface profilometry verifying Ra < 0.8 µm. After slitting, 100% coils receive automated edge inspection via machine vision systems detecting burrs >0.015 mm. Final validation includes conductivity spot checks, dimensional reconfirmation, and visual inspection under 500 lux lighting per ISO 2859-1 sampling plans. All data logs are traceable to melt chemistry certificates, providing full material pedigree for utility-grade applications.

This integrated approach delivers copper bus bar strip with exceptional flatness (<2 mm/m), edge perfection, and conductivity consistency. By mastering these sequential processes with industrial-grade precision, Luoyang Xinzhaohe Aluminum CO.,Ltd guarantees bus bars that support uninterrupted power transmission in mission-critical infrastructure.

Packaging & Logistics

Export Packaging for Copper Bus Bar Strip: Ensuring Integrity During Sea Freight

At Luoyang Xinzhaohе Aluminum Co., Ltd, with over two decades of specialized manufacturing experience in transformer-grade aluminum and copper strip products, we recognize that reliable export packaging is critical to maintaining material integrity, especially under the demanding conditions of international sea freight. Our copper bus bar strip is engineered to meet stringent electrical and mechanical performance standards, and our packaging protocols are designed to preserve these qualities from production through final delivery.

All copper bus bar strip shipments destined for export are systematically prepared using industrial-grade wooden pallets constructed from high-strength, kiln-dried hardwood. These pallets are engineered to ISO 15283 compliance standards, ensuring compatibility with global handling equipment and resistance to structural deformation under load. Each pallet is treated to ISPM 15 phytosanitary requirements, eliminating the risk of pest infestation and ensuring unrestricted customs clearance in all major international markets. The bus bar strips are uniformly stacked and secured to the pallet using steel strapping and edge protectors to prevent lateral movement, edge damage, or coil deformation during extended transit.

To mitigate the risks associated with high-humidity marine environments, every palletized load is hermetically wrapped in multi-layer moisture-proof composite film. This film consists of an aluminum foil interlayer sandwiched between high-density polyethylene (HDPE) sheets, providing a vapor transmission rate of less than 0.5 g/m²·24h at 38°C and 90% relative humidity. The sealing process employs heat-welded seams to ensure a continuous barrier against salt-laden air, condensation, and atmospheric corrosion. Additionally, desiccant packs are strategically placed within the wrapped package to absorb any residual moisture and maintain an internal dew point below ambient conditions throughout the voyage.

For containerized shipments, we recommend the use of 20-foot or 40-foot dry van containers with verified door seals and floor integrity. Our packaging design accounts for standard container dimensions and load distribution requirements, minimizing the risk of shifting during rail, road, or sea transport. Each package is labeled with durable, weather-resistant markings indicating product specifications, batch numbers, handling instructions, and orientation indicators to ensure proper storage and unloading.

Our packaging methodology has been validated through accelerated climatic testing and real-world logistics performance across key export corridors, including Southeast Asia, the Middle East, and South America. By integrating robust mechanical support with advanced moisture protection, Luoyang Xinzhaohe ensures that copper bus bar strip arrives at its destination in as-manufactured condition, ready for immediate processing and integration into high-reliability electrical systems.

This disciplined approach to export packaging reflects our commitment to product quality, supply chain resilience, and customer satisfaction in the global transformer and power distribution sectors.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe: Your Precision Copper Bus Bar Strip Source

Luoyang Xinzhaohe Aluminum Co., Ltd leverages over two decades of specialized metallurgical engineering and industrial manufacturing expertise to deliver copper bus bar strip meeting the most stringent global transformer and power distribution requirements. While our heritage includes significant aluminum transformer foil production, our dedicated copper processing division provides B2B partners with a critical advantage: deep domain knowledge applied specifically to high-conductivity copper alloys essential for efficient, reliable bus bar performance. We understand that bus bar integrity directly impacts system safety, energy loss, and operational lifespan, demanding uncompromising material consistency and dimensional precision.

Our core strength resides in rigorous metallurgical process control. We source only high-purity electrolytic tough pitch (ETP) copper cathodes, primarily C11000 and C10100 grades, ensuring baseline conductivity exceeding 100% IACS as per ASTM B152 standards. Advanced continuous casting and precision cold rolling lines operate under strict thermal and mechanical parameter regimes. This controlled environment minimizes residual stresses, optimizes grain structure for enhanced formability and fatigue resistance, and guarantees uniform electrical and thermal properties throughout the coil. Critical surface finish requirements for low contact resistance and clean insulation adhesion are consistently achieved through proprietary cleaning and passivation protocols.

Precision engineering defines our manufacturing output. We specialize in producing copper bus bar strip within exceptionally tight tolerances, critical for automated assembly and minimizing clearance issues in compact transformer designs. Typical capabilities include:

| Parameter | Standard Capability | Tight Tolerance Option |

|---|---|---|

| Thickness Range | 0.8 mm – 10.0 mm | 1.0 mm – 6.0 mm |

| Thickness Tolerance | ±0.05 mm | ±0.02 mm |

| Width Range | 20 mm – 300 mm | 30 mm – 200 mm |

| Width Tolerance | ±0.2 mm | ±0.1 mm |

| Edge Straightness | < 1.0 mm/m | < 0.5 mm/m |

Comprehensive quality assurance is non-negotiable. Every production lot undergoes rigorous in-process and final inspection. This includes 100% eddy current testing for subsurface defects, certified conductivity verification via direct current measurement, precise dimensional metrology using calibrated optical comparators and micrometers, and full mechanical property validation (tensile strength, yield strength, elongation) per ASTM E8. Material traceability from cathode to finished coil is fully implemented, supported by our ISO 9001 certified quality management system. Documentation packages include full material test reports (MTRs) compliant with customer specifications and international standards.

Our integrated supply chain model, refined over 20 years serving global transformer OEMs, ensures reliability and responsiveness. Strategic raw material partnerships mitigate volatility, while optimized production scheduling and dedicated logistics coordination guarantee on-time delivery for both bulk orders and critical just-in-time requirements. We function as a true engineering partner, offering technical consultation on alloy selection, formability analysis, and process optimization to reduce your total cost of ownership.

Elevate your copper bus bar strip sourcing with a manufacturer whose metallurgical precision and supply chain discipline directly enhance your end-product performance and reliability. Contact our technical sales team to discuss your specific requirements and receive a detailed capability statement. Reach Cathy directly at cathy@transformerstrip.com to initiate a partnership built on engineering excellence.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing copper bus bar strip directly from China.