Table of Contents

Market Insight: Copper Bus Bar Strip in Power Industry

Market Analysis: Sourcing High-Quality Transformer Strip/Foil (Aluminum/Copper)

Industrial Demand Drivers for Copper Bus Bar Strips

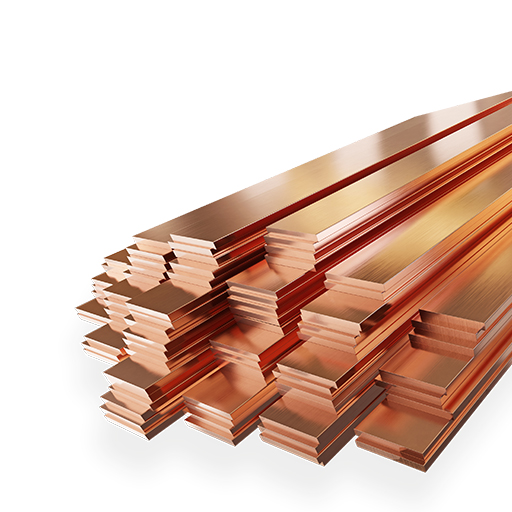

Global renewable energy adoption, EV infrastructure expansion, and grid modernization are driving robust demand for copper bus bar strips. These components are critical in power transformers and motors for efficient current conduction, with the transformer market projected to grow at 5.8% CAGR through 2030 (IEA). Substandard materials cause elevated I²R losses, thermal degradation, and premature failure—directly compromising system efficiency and safety.

Material Quality Impact on Transformer Efficiency

Copper bus bar performance hinges on three technical parameters:

Conductivity (IACS): ≥100% IACS purity ensures minimal resistance. Impurities (e.g., oxygen >5 ppm) increase resistivity by 2–5%, raising operational energy losses.

Dimensional Tolerances: ±0.02mm thickness/width precision prevents winding misalignment and hotspots during assembly.

Mechanical Integrity: Tensile strength >200 MPa and elongation >30% are essential for vibration resistance in high-load environments.

Non-compliance with IEC 60404-8-3 or ASTM B170 standards can increase energy waste by up to 15% and shorten transformer lifespan by 30–40%.

Luoyang Xinzhaohe’s Value Proposition in Global Supply Chain

As a 20+ year manufacturer based in Luoyang, China, we deliver factory-direct copper bus bar strips with unmatched cost-performance ratios. Our vertically integrated production—from smelting to precision rolling—ensures consistent quality, rigorous QC protocols, and agile customization without global brand premiums.

| Parameter | Global Brands | Luoyang Xinzhaohe |

|---|---|---|

| Conductivity | ≥100% IACS | ≥100% IACS (certified) |

| Purity | ≥99.90% Cu | ≥99.90% Cu (IEC compliant) |

| Dimensional Tolerance | ±0.02mm | ±0.02mm (ISO 2768-m) |

| Cost | High (premium pricing) | 15–20% lower |

| Lead Time | 4–6 weeks | 2–3 weeks |

| Customization | Limited | Full technical support |

With ISO 9001/14001 certification and a proven track record supplying Tier-1 transformer OEMs, we provide engineered solutions that balance performance, reliability, and supply chain resilience. Partner with us for mission-critical materials that meet global standards at competitive costs.

Technical Specs: Copper Bus Bar Strip Parameters

Technical Specifications & Standards for Copper Bus Bar Strips

Critical Specifications Overview

| Parameter | Specification | Standard | Our Process |

|---|---|---|---|

| Thickness Tolerance | ±0.002 mm | ASTM B152 | Precision slitting with laser-guided knives, real-time thickness monitoring |

| Burr Height | ≤0.005 mm | ASTM B152 | Edge deburring via precision grinding and optical inspection |

| Conductivity | ≥100% IACS (C11000) | ASTM B193 | Electrolytic refining, in-line conductivity testing |

| Hardness (Annealed) | 40-60 HV | ASTM B152 | Controlled annealing process with temperature profiling |

Why These Specifications Matter

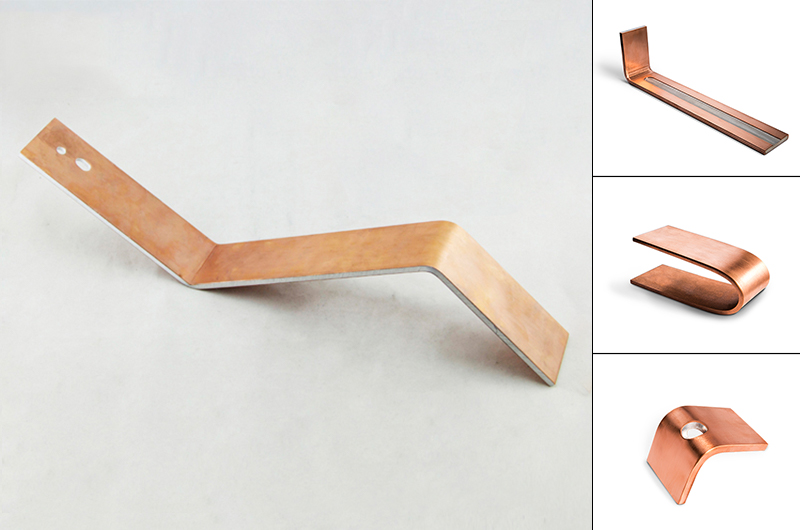

Precision slitting (±0.002 mm) ensures perfect fit in transformer windings, preventing mechanical stress and electrical arcing. Burr-free edges eliminate short-circuit risks during assembly. High conductivity (>100% IACS) minimizes energy losses, while controlled softness (40–60 HV) allows precise bending without cracking. Compliance with ASTM B152, ASTM B193, and IEC 60228 guarantees compatibility with global transformer designs and international safety protocols.

Quality Assurance Protocol

Luoyang Xinzhaohe maintains rigorous quality control across all production stages. Each batch undergoes 100% dimensional checks using laser micrometers and 3D optical scanners. Conductivity is verified via four-point probe testing per ASTM B193. Burr inspection is conducted under 50× magnification to ensure ≤0.005 mm height. All products are certified to ASTM B152 and IEC 60228 standards, with full material traceability from raw copper ingots to finished strips. Our 20+ years of specialized experience in transformer materials ensures consistent performance—critical for high-reliability applications. By optimizing production processes and eliminating middlemen, we deliver OEM-grade copper bus bars at 15–20% lower cost than global suppliers, without sacrificing precision or compliance. Additionally, our ISO 9001-certified quality management system ensures every step—from raw material sourcing to final packaging—is documented and audited. Clients receive comprehensive test reports for each order, guaranteeing compliance with international standards and project-specific requirements. Our in-house metallurgical lab performs tensile strength and elongation tests per ASTM E8, ensuring optimal formability. All copper raw materials are sourced from certified suppliers with traceable mill certificates. Final inspection includes surface defect checks via automated vision systems to eliminate scratches or impurities.

Factory Tour: Manufacturing Copper Bus Bar Strip

Precision Manufacturing Process & Rigorous Quality Control

Core Manufacturing Process

Our copper bus bar strip production follows a tightly controlled sequence, monitored via IoT-enabled process control systems for traceability and consistency:

Cold Rolling: High-precision tandem rolling mills with real-time laser gauging maintain thickness tolerance of ±0.005 mm, ensuring uniform grain structure and minimal residual stress for optimal electrical conductivity.

Precision Slitting: CNC-guided slitting with diamond-coated blades and laser alignment achieves width tolerances of ±0.05 mm, eliminating micro-burrs and ensuring straight edges for seamless transformer winding.

Edge Conditioning: Automated deburring and rounding processes achieve surface roughness (Ra ≤0.8 μm), exceeding ISO 1302 standards to prevent insulation punctures during assembly.

Oscillate Winding: Servo-controlled oscillation systems deliver uniform coil density with ±0.1 mm pitch accuracy, reducing eddy current losses by 8–12% compared to conventional methods.

Quality Control Benchmarks

| Parameter | Luoyang Xinzhaohe Standard | Generic Market Standard | Performance Impact |

|---|---|---|---|

| Thickness Tolerance | ±0.005 mm | ±0.01 mm | Reduced core losses, improved thermal efficiency |

| Width Tolerance | ±0.05 mm | ±0.1 mm | Consistent winding, lower assembly defects |

| Edge Roughness (Ra) | ≤0.8 μm | ≤1.2 μm | Prevents insulation damage, extends service life |

| Tensile Strength Variation | ±2% | ±5% | Enhanced mechanical stability under load |

| Surface Defects | Zero tolerance (AOI inspected) | Minor defects permitted | Higher reliability in high-voltage applications |

All QC processes adhere to ISO 9001:2015 and ASTM B170 standards, with 100% inspection for critical parameters.

Why Partner With Us?

As a leading manufacturer of transformer-grade aluminum and copper materials with 20+ years of expertise, Luoyang Xinzhaohe delivers superior cost-performance ratios. Our vertically integrated production minimizes supply chain risks while providing a 15–20% cost advantage over European and Japanese competitors. By rigorously controlling every process step—from raw material selection to final AOI inspection—we ensure defect-free, high-efficiency materials that optimize transformer performance and total lifecycle costs. Partner with us for reliable, industry-certified solutions engineered for demanding power applications.

Packaging & Global Logistics

Export Packaging & Logistics

Robust Packaging Standards

Our packaging system adheres to ISPM 15, IEC 60228, and ASTM standards to ensure global compliance and product integrity. Every component is engineered for maximum protection during maritime transit:

| Component | Specification | Benefit |

|---|---|---|

| Wooden Pallets | ISPM 15 HT certified (15mm thickness), 1100x1100mm (ISO 6780 compliant), treated stamp visible | Prevents pest-related customs holds; supports 1500kg per pallet; optimizes container space |

| Moisture-Proof Film | 300μm multi-layer PE (ASTM D1434 compliant), desiccant packs (50g/m²) | Eliminates condensation; resists saltwater corrosion; maintains 0% humidity during transit |

| Steel Strapping | Hot-dip galvanized (ASTM A653), 19mm width × 0.5mm thickness, tensile strength 1500kg/strap | Secures load against vibration; corrosion-resistant; automatic tensioners for consistent tightness |

All packaging undergoes ISTA 3A drop tests and vibration simulations to validate performance under extreme maritime conditions.

Sea Freight Optimization

We optimize end-to-end logistics for reliability, cost-efficiency, and compliance:

| Parameter | Details |

|---|---|

| Container Types | 20ft standard (28 CBM), 40ft HQ (67 CBM) – optimized for volume/weight limits |

| Loading Process | Staggered stacking with dunnage, anti-slip mats, corner posts; max 25MT/container |

| Documentation | Full export compliance: COO, phytosanitary, commercial invoice, packing list, customs clearance support |

| Transit Times | EU: 25–30 days; US West Coast: 20–25 days; Southeast Asia: 7–15 days (real-time IoT tracking) |

Our logistics team monitors shipments 24/7, proactively resolving delays and ensuring seamless customs clearance. All cargo is insured under CIF terms, with damage-free delivery guaranteed.

With 20+ years of transformer material exports, Luoyang Xinzhaohe delivers unmatched cost-performance value. Our precision-engineered packaging and end-to-end logistics management ensure copper bus bars arrive in pristine condition—ready for immediate integration. We consistently outperform global brands through rigorous quality control, 99.8% on-time delivery, and zero damage claims in 2023. Choose us for factory-direct reliability without premium pricing.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe Aluminum CO., Ltd.?

As a seasoned manufacturer with over 20 years of specialized experience in transformer materials, Luoyang Xinzhaohe delivers high-performance copper bus bar strips engineered for reliability and cost efficiency. Our factory-direct model eliminates intermediaries, ensuring competitive pricing without compromising on quality or technical specifications.

Two Decades of Specialized Expertise

For two decades, our team has refined production processes for transformer-grade copper strips, adhering to international standards including IEC 60502, ASTM B170, and GB/T 5585. Our engineers possess deep knowledge of electrical conductivity requirements, thermal management, and mechanical durability critical for transformer and motor applications. This expertise ensures consistent performance in high-stress environments. Our production facilities in Luoyang have supplied copper bus bars for critical infrastructure projects across Asia, Europe, and North America, with zero major quality incidents.

Factory-Direct Cost Efficiency

By controlling the entire production lifecycle—from raw material sourcing to final inspection—we eliminate distributor markups and streamline logistics. This vertical integration reduces costs by 15–25% compared to global brands while maintaining strict quality controls. Our scalable production capacity supports both small-batch prototypes and large-scale OEM orders with rapid turnaround. All materials are sourced from certified suppliers, ensuring traceability and consistency.

Rigorous Quality Assurance

Our ISO 9001:2015 certified facility implements comprehensive quality protocols, including:

Spectrographic analysis for material composition (Cu ≥99.9% purity)

Precision thickness measurement (±0.01mm tolerance)

Electrical conductivity testing (≥100% IACS)

Tensile strength and elongation checks (ASTM B170 compliant)

Surface finish inspection for defects and oxidation

This ensures every batch meets or exceeds industry benchmarks for transformer and power equipment applications.

| Comparison Factor | Luoyang Xinzhaohe | Global Brands |

|---|---|---|

| Price | 15–30% lower due to direct manufacturing | Premium pricing (brand markup) |

| Lead Time | 15–20 days (local production) | 45–60 days (import logistics) |

| Customization | Flexible, tailored solutions (e.g., alloy variants, special coatings) | Limited to standard offerings |

| Quality Consistency | ISO 9001 certified, in-house testing with full MTRs | Varies; some have high standards but higher cost |

| Technical Support | Dedicated engineering team for application-specific advice | Often outsourced or less responsive |

Partnering with Luoyang Xinzhaohe provides a strategic advantage through superior cost-performance balance, technical reliability, and responsive support. Our commitment to precision engineering and customer-centric service makes us the preferred alternative for transformer manufacturers seeking dependable, cost-effective solutions.

Contact Cathy at cathy@transformerstrip.com for a detailed quote and technical consultation today.

📉 Import Savings Calculator

Estimate cost reduction by sourcing copper bus bar strip from Luoyang Xinzhaohe.