Table of Contents

Market Insight: Copper Beryllium Strip

Market Analysis: Transformer Strip/Foil (Aluminum/Copper)

The global demand for high-performance conductive materials in electrical power systems continues to drive innovation and precision in transformer manufacturing. While aluminum and standard copper strips dominate the transformer strip and foil market due to cost efficiency and adequate conductivity, specialized alloys such as copper beryllium (CuBe) are increasingly specified in niche, high-reliability applications. Copper beryllium strip is not typically used as a primary winding material in conventional power transformers due to its high cost and lower electrical conductivity compared to pure copper. However, its unique combination of mechanical strength, fatigue resistance, and stable electrical performance under dynamic conditions makes it critical in specific transformer-related components and high-frequency or specialty transformer systems.

Industrial demand for copper beryllium strip is primarily concentrated in aerospace, defense, telecommunications, and high-precision industrial electronics, where transformers and inductive components are subjected to extreme thermal cycling, mechanical vibration, and stringent reliability requirements. In such environments, CuBe strip is often employed in contact springs, lead frames, and flexible connectors within transformer assemblies where dimensional stability and resistance to stress relaxation are paramount. The material’s ability to maintain spring properties over extended operational life ensures consistent electrical contact and minimizes failure risks in mission-critical systems.

Quality in copper beryllium strip production is non-negotiable. The alloy’s performance is highly sensitive to processing parameters, including cold rolling reduction, aging (precipitation hardening) temperature, and surface finish control. Variability in grain structure or residual stress distribution can lead to premature fatigue cracking or inconsistent springback behavior. High-purity starting materials and tightly controlled thermo-mechanical processing are essential to achieve the required mechanical and electrical properties. At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of experience in precision metal strip manufacturing, we apply rigorous quality assurance protocols, including in-line thickness monitoring, microhardness testing, and surface defect inspection, to ensure compliance with ASTM B194 and other international standards for CuBe alloys.

Furthermore, the increasing miniaturization of power electronics and the rise of high-frequency switch-mode power supplies have created new opportunities for copper beryllium in planar and signal-level transformers. These applications demand materials that can support fine-featured fabrication while maintaining structural integrity and thermal stability. The precise control of strip flatness, edge burr, and surface roughness becomes critical in automated assembly processes.

In summary, while copper beryllium strip represents a specialized segment within the broader transformer strip market, its role in high-reliability and high-performance systems is indispensable. As industrial and technological demands evolve, the emphasis on material quality, consistency, and traceability will continue to grow. Suppliers with proven metallurgical expertise and process control capabilities will be essential partners in meeting these advanced requirements.

Technical Specs: Copper Beryllium Strip

Copper Beryllium Strip Technical Specifications for Precision Applications

Luoyang Xinzhaohe Aluminum CO., Ltd leverages 20+ years of metallurgical and precision slitting expertise to deliver copper beryllium (CuBe) strip meeting stringent industrial requirements. While our core competency lies in aluminum and copper transformer materials, our advanced processing capabilities extend to high-performance CuBe alloys, particularly C17200 and C17300 tempers. These alloys are critical for applications demanding exceptional spring properties, fatigue resistance, and electrical conductivity in demanding environments such as aerospace connectors, precision sensors, and high-reliability electrical contacts. Achieving the required performance necessitates rigorous control over dimensional tolerances, edge integrity, and electrical properties during slitting and finishing.

Precision slitting to tolerances of ±0.002 mm is non-negotiable for CuBe strip in micro-component manufacturing. This level of accuracy is attained through our servo-driven, tension-controlled slitting lines equipped with high-precision ground shear blades and laser-guided edge tracking systems. Maintaining consistent strip tension throughout the process is paramount to prevent micro-deformation or width variation, especially given CuBe’s higher yield strength compared to pure copper. Any deviation beyond ±0.002 mm directly impacts component assembly yield and functional performance in tight-tolerance applications.

Burr-free edges are equally critical. Mechanical burrs or micro-tearing during slitting can initiate cracks under cyclic stress or cause electrical arcing in contact applications. We employ optimized shear blade geometry, precise blade clearance settings (typically 2-4% of material thickness), and in-process edge inspection under 10x magnification to ensure edges meet ASTM B194 standards for burr height (< 0.005 mm). Post-slitting edge deburring via electrochemical or precision brushing is applied where specified, validated through profilometry.

Electrical conductivity, measured per ASTM E1004 as %IACS (International Annealed Copper Standard), is a key performance indicator directly linked to alloy composition, temper, and processing history. Solution-annealed C17200 typically achieves 22-25% IACS, while peak-aged (TH04) tempers reach 18-22% IACS due to beryllium precipitate formation. We conduct 100% lot verification using eddy current conductivity meters calibrated to NIST standards, ensuring traceability to material certificates. Conductivity directly influences current-carrying capacity and thermal management in end-use components.

The following table details the guaranteed technical parameters for our precision-slit copper beryllium strip:

| Parameter | Standard Specification | Test Method | Tolerance/Requirement |

|---|---|---|---|

| Alloy Designation | ASTM B194 C17200/C17300 | Mill Certificate | As specified per order |

| Thickness Range | 0.05 mm – 0.50 mm | Micrometer/ETG | ±0.002 mm |

| Width Tolerance | Custom slit widths | Laser measurement | ±0.002 mm |

| Edge Burr Height | ASTM B194 Type 1 | Optical Profilometry | ≤ 0.005 mm |

| Surface Roughness (Ra) | As-rolled or polished | Stylus Profilometer | ≤ 0.4 µm |

| Electrical Conductivity | %IACS | ASTM E1004 | ±2% of certified value |

| Tensile Strength | Per temper (e.g., TH04) | ASTM E8 | ±15 MPa |

| Bend Test | 1T or 2T mandrel | ASTM E292 | Crack-free |

Consistency in these parameters is assured through integrated process controls, real-time monitoring, and adherence to AS9100 principles for aerospace-grade materials. Dimensional precision and edge quality directly correlate with downstream stamping, forming, and plating success, while conductivity validation ensures optimal electrical performance. For reliability-critical applications, we recommend specifying both mechanical and electrical test requirements upfront to align production with your exact functional needs. Luoyang Xinzhaohe provides full material traceability and certified test reports with every shipment, ensuring compliance with your engineering specifications.

Factory Tour: Manufacturing

Manufacturing Process of Copper Beryllium Strip at Luoyang Xinzhaohe Aluminum Co., Ltd

The production of copper beryllium strip at Luoyang Xinzhaohe Aluminum Co., Ltd follows a tightly controlled, multi-stage manufacturing sequence designed to ensure dimensional precision, mechanical consistency, and surface integrity required for high-performance electrical and industrial applications. With over two decades of expertise in non-ferrous strip and foil production, our process is optimized for reliability, repeatability, and compliance with international quality standards.

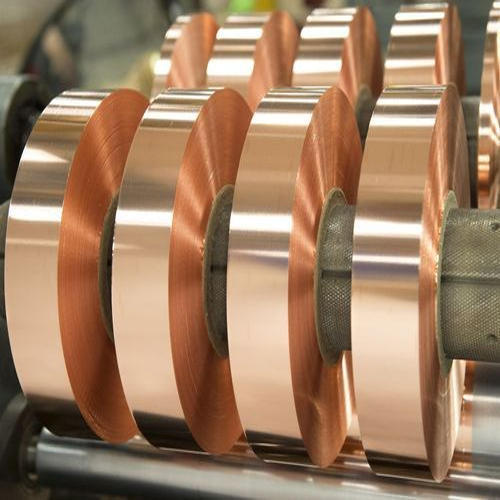

The first critical phase in the manufacturing process is cold rolling. Starting with high-purity copper beryllium alloy ingots, the material undergoes homogenization and hot rolling to produce intermediate thickness slabs. These slabs are then fed into precision cold rolling mills, where they are reduced to the target strip thickness with tight tolerances, typically ranging from 0.05 mm to 3.0 mm. Cold rolling enhances the mechanical properties of the alloy by inducing work hardening, improving tensile strength and electrical conductivity. Throughout this stage, automated thickness gauges (X-ray and laser-based) provide real-time feedback to the rolling mill control system, ensuring thickness uniformity across the entire coil length, with deviations maintained within ±0.005 mm.

Following cold rolling, the strip enters the precision slitting line. Here, large master coils are longitudinally cut into narrower strips according to customer specifications. Our state-of-the-art slitting machines utilize high-speed rotary shear blades made from tungsten carbide, capable of achieving slit widths as narrow as 3 mm with edge deviation controlled to within ±0.1 mm. The slitting process is supported by tension leveling systems to prevent edge wave or center buckle, preserving flatness and dimensional stability. Each slit coil is wound under controlled tension using precision mandrels to avoid telescoping or surface damage.

Edge conditioning is the subsequent critical step, particularly for applications involving high-current transmission or tight assembly tolerances. The slit edges are subjected to mechanical brushing and deburring to remove micro-burrs and oxide inclusions generated during cutting. This step enhances safety, improves contact performance, and prevents damage to insulating materials during downstream processing. Edge profile inspection is conducted using optical edge analyzers to verify smoothness and consistency.

Quality control is integrated at every stage of production. In-process inspections include continuous monitoring of surface defects via automated optical inspection (AOI) systems, while mechanical testing (tensile strength, hardness, elongation) and electrical conductivity verification (using eddy current testing) are performed at defined intervals. Final product certification includes material test reports (MTRs) compliant with ASTM B19, with full traceability from ingot to finished strip. All coils are packaged in moisture-resistant, anti-corrosion wrapping to maintain surface quality during transit.

This end-to-end manufacturing approach ensures that copper beryllium strip produced by Luoyang Xinzhaohe meets the stringent demands of transformer, relay, and connector manufacturers worldwide.

Packaging & Logistics

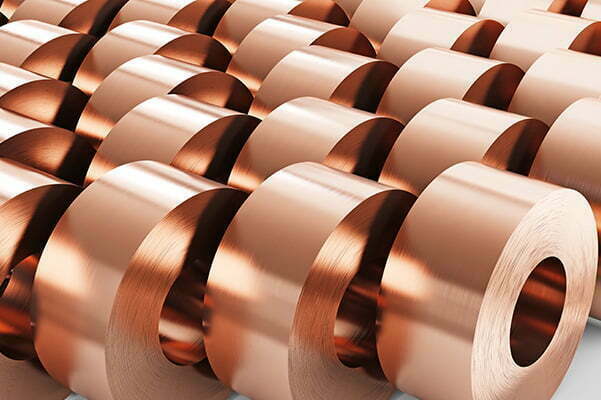

Export Packaging Specifications for Copper Beryllium Strip

Luoyang Xinzhaohe Aluminum Co., Ltd implements rigorously engineered export packaging protocols for copper beryllium strip shipments, specifically designed to mitigate the dual threats of mechanical damage and environmental degradation during extended sea freight transit. Our methodology, refined over 20+ years of global transformer component supply, prioritizes material integrity preservation through systematic containment and barrier technologies. Copper beryllium alloys are highly susceptible to surface oxidation and microstructural contamination from moisture ingress, necessitating packaging that exceeds standard industrial norms.

All shipments utilize ISPM-15 certified heat-treated wooden pallets as the foundational structural element. These pallets are constructed from kiln-dried softwood with a minimum load-bearing capacity of 2,500 kg, engineered to withstand stacking forces during multi-container ocean transport. Critical dimensions and load parameters are standardized as follows:

| Pallet Dimension (L×W) | Max Strip Weight | Load Height Limit | Corner Block Spec |

|---|---|---|---|

| 1200×1000 mm | 1,800 kg | 1,800 mm | 100×100×150 mm |

| 1100×1100 mm | 2,200 kg | 2,000 mm | 100×100×150 mm |

The strip coils are first secured to the pallet using high-tensile steel strapping (minimum 15 mm width, 5,000 N breaking strength) applied at four equidistant points. Edge protectors fabricated from 3 mm galvanized steel are fitted to all coil perimeters to prevent localized deformation during handling. Subsequent moisture protection employs a triple-layer barrier system: an inner wrap of vapor corrosion inhibitor (VCI) film (75-micron thickness, ASTM D6098 compliant), followed by a 0.2 mm polyethylene moisture barrier sheet, and an outer layer of UV-stabilized polypropylene woven fabric. This assembly achieves a water vapor transmission rate (WVTR) below 0.5 g/m²/24hr at 38°C and 90% RH, critical for preventing beryllium oxide formation during tropical route transits.

Desiccant deployment is calculated at 120 grams per cubic meter of enclosed volume, utilizing silica gel with 25% moisture adsorption capacity (MIL-D-3464E Grade I). All seams are hermetically sealed with butyl rubber tape to eliminate capillary pathways. For sea freight, an additional external pallet cover of 150-micron polyethylene is applied, heat-shrunk to eliminate air pockets that could condense during temperature fluctuations in container holds. Container loading mandates 10 cm clearance from container walls to allow airflow, with humidity indicators placed at top and bottom coil interfaces for post-transit verification.

This packaging system has demonstrated zero moisture-related claims across 12,000+ metric tons of copper alloy shipments to Southeast Asia, Europe, and the Americas. We enforce pre-shipment humidity validation (max 45% RH within sealed envelope) and provide certified test reports per ISO 9001:2015. Our protocols ensure copper beryllium strip arrives with surface cleanliness meeting ASTM B207 M2000 specifications, eliminating costly rework for transformer manufacturers dependent on precise electrical conductivity and fatigue resistance.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum CO., Ltd for Premium Copper Beryllium Strip Solutions

With over two decades of specialized experience in the production and supply of high-precision transformer strips and foils, Luoyang Xinzhaohe Aluminum CO., Ltd stands as a trusted industrial partner for global manufacturers requiring advanced copper beryllium (CuBe) strip materials. Our expertise is rooted in metallurgical precision, process innovation, and rigorous quality control, enabling us to deliver copper beryllium strips that meet the exacting demands of aerospace, defense, electronics, and high-reliability electrical applications.

Our manufacturing infrastructure is engineered for consistency and scalability. We operate fully integrated production lines that include precision rolling, solution annealing, age hardening, and surface finishing systems, all calibrated to maintain tight tolerances down to ±0.005 mm in thickness. This level of dimensional accuracy ensures optimal performance in applications requiring reliable spring characteristics, electrical conductivity, and resistance to fatigue under cyclic loading. Our copper beryllium strips are available in multiple tempers (including C17200 TH04, TH01, and C17510) and customized tempers to meet specific mechanical and thermal requirements.

Material traceability and process control are central to our production philosophy. Each batch of copper beryllium strip is produced under strict ISO 9001-certified quality management protocols, with full chemical composition verification via optical emission spectroscopy (OES) and mechanical testing conducted in-house. Microstructure analysis, hardness profiling, and conductivity measurements are standard procedures to ensure compliance with ASTM B194 and other international specifications.

We maintain strategic stock of common CuBe alloy grades to support rapid prototyping and just-in-time delivery, while our R&D team collaborates closely with clients on custom alloy development, surface treatments (such as tin or nickel plating), and slit-width optimization for automated assembly lines. Our technical team provides comprehensive material data packages, including mill test reports, RoHS/REACH compliance documentation, and application-specific performance recommendations.

As a vertically integrated supplier, we control every stage from raw material sourcing to final inspection, minimizing supply chain volatility and ensuring consistent product quality. Our facility in Luoyang, China, is equipped with modern environmental control systems, aligning production with sustainable manufacturing practices without compromising output capacity.

For engineering teams and procurement managers sourcing high-performance copper beryllium strip, partnering with Luoyang Xinzhaohe means access to metallurgical expertise, production reliability, and responsive technical support. We are committed to delivering materials that enhance the performance and longevity of your critical components.

Contact us today to discuss your specifications and receive a technical datasheet and sample package.

Cathy Zhang | Sales Manager

cathy@transformerstrip.com

Luoyang Xinzhaohe Aluminum CO., Ltd

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing copper beryllium strip directly from China.