Table of Contents

Market Insight: Copper Annealed Coil

Market Analysis: Transformer Strip/Foil (Aluminum/Copper) – Copper Annealed Coil Demand and Quality Imperatives

Global demand for copper annealed coil in transformer manufacturing remains robust, driven by fundamental electrical properties and stringent performance requirements. Copper’s superior electrical conductivity (approximately 100% IACS for annealed OFE grades) compared to aluminum makes it the material of choice for critical applications where space constraints, high efficiency targets, or specific thermal management needs dominate design parameters. This is particularly evident in distribution transformers serving urban infrastructure, high-efficiency premium transformers meeting DOE 2016/2018 standards, and specialized units for renewable energy integration and data center power systems. Rising global electricity consumption, coupled with aging grid infrastructure replacement programs worldwide and the accelerating deployment of distributed generation, sustains consistent industrial demand. While aluminum offers a cost and weight advantage in certain bulk transmission applications, copper annealed coil maintains irreplaceable dominance in segments demanding maximum conductivity density and long-term reliability under cyclic loading.

The criticality of copper annealed coil quality cannot be overstated, as it directly governs transformer performance, lifespan, and safety. Key quality parameters include precise control of electrical conductivity, stringent limits on interstitial impurities (oxygen, sulfur, lead), and optimal microstructural homogeneity achieved through controlled recrystallization annealing. Conductivity must consistently exceed 98% IACS; deviations of even 1-2% significantly increase I²R losses over the transformer’s operational life, directly impacting energy efficiency compliance and lifecycle costs. Impurity levels, especially oxygen forming Cu₂O precipitates, act as electron scattering sites reducing conductivity and, more critically, initiating grain boundary weakness. This compromises mechanical integrity during the demanding coil winding process, increasing the risk of conductor fracture or deformation under electromagnetic forces during fault conditions. Surface quality is equally vital; microscopic scratches, pits, or residual oxides from improper annealing or handling become nucleation points for partial discharges within the solid insulation system, leading to premature insulation degradation and catastrophic failure.

Consequences of substandard copper annealed coil manifest as reduced transformer efficiency, shortened operational lifespan, and elevated failure rates in the field. Inefficient conductors generate excessive heat, accelerating insulation aging (per Arrhenius law) and potentially triggering thermal runaway. Microstructural inconsistencies or surface defects introduce weak points prone to fatigue under continuous electromagnetic vibration, risking internal short circuits. The financial impact extends far beyond the initial material cost, encompassing warranty claims, costly field replacements, grid downtime penalties, and reputational damage for the transformer manufacturer. Rigorous quality assurance protocols are therefore non-negotiable. Leading suppliers implement multi-stage verification, including certified conductivity testing (ASTM E1004), spectrographic chemical analysis (ASTM E1086), metallographic grain structure evaluation (ASTM E3/E112), and advanced surface profilometry. Luoyang Xinzhaohe Aluminum leverages two decades of metallurgical expertise across both aluminum and copper conductor supply chains to emphasize that sourcing decisions must prioritize certified material traceability and demonstrable process control, not merely nominal price, to ensure the transformer’s core function as a reliable, efficient, and durable grid asset. The integrity of the annealed copper strip is foundational to the entire unit’s value proposition.

Technical Specs: Copper Annealed Coil

Copper Annealed Coil Technical Specifications

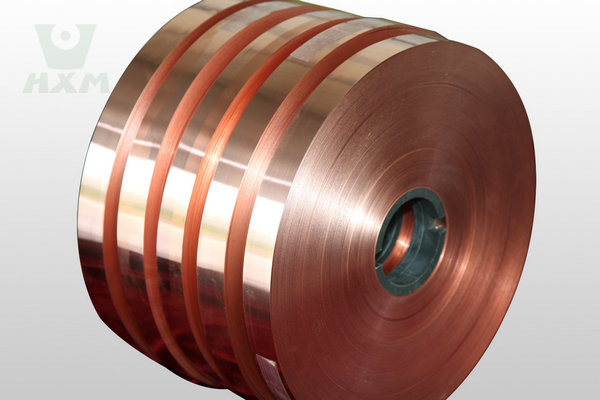

Luoyang Xinzhaohe Aluminum Co., Ltd. provides high-purity copper annealed coils engineered for precision applications in the transformer, electrical, and power distribution industries. Our manufacturing process integrates controlled atmosphere annealing, high-tolerance rolling, and precision slitting to ensure consistent material performance and dimensional accuracy. These coils are specifically designed to meet the stringent demands of electrical conductivity, edge quality, and flatness required in advanced winding and strip applications.

Each copper annealed coil is produced from oxygen-free electrolytic tough pitch (ETP) copper, ensuring minimal oxide inclusion and optimal electrical performance. The annealing process is conducted in a continuous hydrogen-nitrogen atmosphere furnace, which eliminates residual stresses, enhances ductility, and achieves full soft temper (C11000 or C10100 equivalent). This results in a material with superior formability and low springback, critical for high-speed winding operations and tight-radius bending without microcracking.

Dimensional control is maintained through laser-guided precision slitting technology, achieving a slit width tolerance of ±0.002 mm. This level of accuracy ensures uniform strip dimensions across the coil length, minimizing variation in winding tension and layer alignment in transformer cores and coils. Edge quality is rigorously controlled to deliver burr-free, smooth-cut edges, reducing the risk of die wear during stamping and preventing insulation damage in magnet wire applications.

Surface finish is optimized for adhesion and conductivity, with a typical roughness (Ra) range of 0.3–0.6 μm. Coils are supplied with protective film or paper interleave to prevent surface oxidation and mechanical damage during transit and storage. All coils undergo 100% eddy current testing and visual inspection to detect surface defects, inclusions, or edge irregularities.

The following table outlines the key technical parameters for our copper annealed coil product line:

| Parameter | Specification |

|---|---|

| Material Grade | C11000 (ETP Copper), C10100 (OFC) available |

| Temper | Annealed (Soft), ASTM B3 |

| Thickness Range | 0.10 mm – 3.00 mm |

| Width Range | 10 mm – 500 mm |

| Slitting Tolerance | ±0.002 mm |

| Edge Quality | Burr-free, deburred and edge-rolled |

| Electrical Conductivity | ≥100% IACS (min), typical 101–102% IACS |

| Tensile Strength | 200–240 MPa |

| Elongation (min) | 45% |

| Surface Roughness (Ra) | 0.3–0.6 μm |

| Coil Inner Diameter (ID) | 200 mm, 300 mm, 508 mm (customizable) |

| Coil Outer Diameter (OD) | Up to 1200 mm |

| Maximum Coil Weight | 3,000 kg |

| Packaging | Waterproof wrapping, wooden pallet, edge protectors |

All copper annealed coils are traceable to certified mill test reports (MTRs) and comply with ASTM B3, GB/T 5584, and IEC 60183 standards. Custom slit widths, special packaging, and extended conductivity testing (up to 102% IACS) are available upon request. Luoyang Xinzhaohe Aluminum Co., Ltd. ensures that every coil meets the highest benchmarks in electrical performance and dimensional precision for critical transformer and power electronics applications.

Factory Tour: Manufacturing

Manufacturing Process for Copper Annealed Coil: Precision Engineering for Transformer Applications

Luoyang Xinzhaohe Aluminum CO., Ltd leverages over two decades of specialized metallurgical expertise in non-ferrous strip production to deliver high-performance copper annealed coil meeting stringent transformer industry demands. Our process rigorously transforms raw copper into dimensionally precise, defect-free strip through controlled cold rolling, precision slitting, and critical edge conditioning, underpinned by comprehensive quality control at every stage.

The process commences with cold rolling of annealed copper substrate. Utilizing high-precision 4-high or 6-high rolling mills equipped with advanced automatic gauge control (AGC) systems, we achieve exceptional thickness uniformity across the coil width and length. Critical parameters including reduction ratio, rolling speed, tension control, and coolant application are meticulously managed to ensure optimal surface finish, minimize residual stresses, and attain the required mechanical properties without inducing surface defects such as scratches or roller marks. This stage establishes the fundamental dimensional accuracy and metallurgical structure essential for subsequent processing and final application performance.

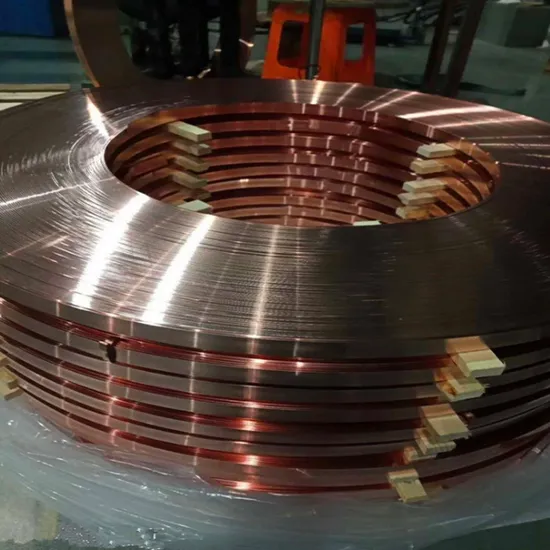

Following cold rolling, precision slitting transforms the master coil into the required narrow strip widths. Our state-of-the-art slitting lines employ hardened tungsten carbide knives with micron-level concentricity control, coupled with precise tension management systems across multiple payoffs and winders. This ensures consistent slit width tolerances typically held within ±0.05 mm, critical for transformer winding consistency. Continuous monitoring of edge tracking and strip tension prevents edge waviness, camber, or width variation, directly impacting the coil’s suitability for high-speed automatic winding equipment in transformer manufacturing.

Edge conditioning represents a vital step specific to transformer foil/strip applications. Immediately post-slitting, the strip edges undergo proprietary deburring and edge rounding processes. This eliminates microscopic burrs and sharp edges generated during slitting, which could otherwise damage delicate interlayer insulation during transformer winding, leading to catastrophic electrical failures. Our controlled mechanical brushing and edge profiling techniques produce a smooth, radius-defined edge contour, significantly enhancing product safety and reliability in the end-use application.

Rigorous quality control is integrated throughout the production sequence. Key verification points include in-process thickness monitoring via laser micrometers during rolling, 100% width inspection post-slitting, and mandatory edge profile validation. Final coil inspection encompasses comprehensive dimensional verification, mechanical property testing, and full surface examination. The table below summarizes critical QC parameters and methodologies.

| Quality Parameter | Test Method | Acceptance Criteria | Frequency |

|---|---|---|---|

| Thickness Tolerance | Laser Micrometer / Micrometer | ±0.01 mm to ±0.03 mm (per spec) | Continuous / 100% |

| Width Tolerance | Precision Width Gauge | ±0.05 mm | Continuous / 100% |

| Tensile Strength | ASTM E8 Tensile Testing | 200-250 MPa (Typical Annealed Cu) | Per Batch |

| Elongation | ASTM E8 Tensile Testing | ≥40% | Per Batch |

| Surface Defects | Visual Inspection (100x Magnification) | Zero pinholes, scratches, inclusions | 100% |

| Edge Burr / Profile | Optical Profilometry / Microscope | Max Burr Height < 5μm; Defined Radius | Per Coil |

This integrated manufacturing and QC approach, refined over 20+ years, guarantees copper annealed coil that meets the exacting dimensional, mechanical, and surface integrity requirements essential for high-efficiency, reliable transformer construction. Luoyang Xinzhaohe Aluminum CO., Ltd delivers consistent material performance critical for our global transformer manufacturing partners.

Packaging & Logistics

Export Packaging for Copper Annealed Coil: Ensuring Integrity During Sea Freight

At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of specialized experience in the production and international distribution of transformer-grade strip and foil materials, we recognize that packaging is not merely a logistical necessity but a critical component in preserving material integrity. For copper annealed coil shipments intended for export, particularly those transported via sea freight, our packaging protocols are engineered to mitigate environmental and mechanical risks inherent in long-distance maritime logistics.

All copper annealed coils are mounted on robust wooden pallets constructed from high-density, kiln-dried hardwood. These pallets are designed to support the substantial weight of tightly wound copper coils, which can range from several hundred kilograms to multiple metric tons per shipment. The structural rigidity of the pallet ensures dimensional stability during lifting, stacking, and transit, preventing coil deformation or core collapse. Each pallet is treated to ISPM 15 standards, ensuring compliance with international phytosanitary regulations for cross-border movement of wood-based packaging materials.

Immediately following palletization, the coil is wrapped in multi-layer moisture-proof composite film. This film consists of aluminum foil laminates bonded with polyethylene layers, providing a high-barrier shield against humidity, salt-laden air, and condensation—common challenges during ocean transport, especially in tropical and coastal regions. The wrapping process is executed under controlled ambient conditions to prevent the entrapment of moisture between the coil layers prior to sealing. The film is heat-sealed at all seams and secured with polymer strapping to maintain a hermetic enclosure throughout the shipping cycle.

To further enhance protection, desiccant packets are strategically placed within the sealed film envelope to absorb any residual moisture and buffer against internal dew point fluctuations. Additionally, edge protectors made from corrugated fiberboard or plastic are applied to the lateral faces of the coil to prevent mechanical damage during handling and to preserve the precision edge geometry critical for downstream slitting and winding operations.

All packaged units are labeled with durable, weather-resistant tags indicating product specifications, batch numbers, weight, handling instructions, and orientation markers (e.g., “This Side Up”). These identifiers ensure traceability and proper handling protocols are maintained throughout the supply chain.

Our packaging system has been validated through accelerated climatic testing and real-world shipment monitoring across major trade lanes, including trans-Pacific and trans-Indian Ocean routes. This rigorous approach ensures that copper annealed coils arrive at their destination with unaltered metallurgical properties, surface cleanliness, and dimensional accuracy—essential for high-performance applications in transformers, electrical machinery, and power distribution systems.

By integrating material science expertise with industrial logistics, Luoyang Xinzhaohe Aluminum Co., Ltd delivers copper annealed coil products in packaging engineered for global reliability and compliance.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe for Precision Copper Annealed Coil

Luoyang Xinzhaohe Aluminum CO.,LTD leverages over two decades of specialized metallurgical expertise to deliver mission-critical copper annealed coil for demanding transformer and electrical applications. Our vertically integrated manufacturing platform, purpose-built for high-purity electrical conductors, ensures consistent material performance meeting stringent global specifications. We transcend basic supplier status by embedding deep process knowledge into every coil produced, directly addressing the thermal stability, formability, and conductivity requirements essential for efficient power conversion systems.

Our production infrastructure centers on advanced twin-stand cold rolling mills coupled with proprietary continuous annealing lines. These systems enable precise control over grain structure refinement and recrystallization kinetics, critical for achieving the target mechanical properties and surface integrity demanded in transformer strip. We process high-conductivity electrolytic tough pitch (ETP) copper cathode, strictly adhering to chemical purity thresholds (Cu+Ag ≥ 99.90%, O: 0.02-0.04%) to minimize resistivity. Each annealing cycle undergoes rigorous thermal profile validation, ensuring uniform softness (typically 60-80 MPa tensile strength) and optimal bendability without surface oxidation or scaling. This metallurgical precision translates directly to reduced winding defects and enhanced transformer efficiency in your final assembly.

Quality assurance is non-negotiable within our ISO 9001-certified facility. Comprehensive in-process testing monitors dimensional tolerances (thickness ±0.005mm, width ±0.5mm), surface roughness (Ra ≤ 0.4µm), and electrical conductivity (≥ 100% IACS). Final inspection protocols include 100% eddy current testing for subsurface flaws and destructive verification of mechanical properties per batch. Our adherence to international and regional standards is absolute, as evidenced by the following key compliance benchmarks:

| Standard | Specification Scope | Xinzhaohe Implementation |

|---|---|---|

| ASTM B3 | Soft Copper Strip | Exceeds dimensional & conductivity requirements |

| GB/T 11091 | Copper and Copper Alloy Strip for Electrical Purposes | Full conformance with Grade T2 annealed properties |

| IEC 60138 | Specifications for Winding Wires | Material properties aligned with Class 1 requirements |

Supply chain resilience is engineered into our operations. We maintain strategic raw material buffers and operate dedicated annealing lines with 24-hour production capability, ensuring on-time delivery for volumes ranging from pilot batches to multi-tonnage contracts. Our logistics network integrates seamlessly with major global ports, utilizing climate-controlled container solutions to prevent transit-induced moisture damage or mechanical handling defects. This operational discipline minimizes your production line interruptions and inventory risk.

Partnering with Luoyang Xinzhaohe means securing a metallurgical ally committed to the technical success of your transformer projects. We provide not just material, but documented process validation, responsive engineering support, and unwavering consistency. Contact our Technical Sourcing Team today to discuss your specific copper annealed coil requirements and receive a detailed capability statement. Reach Cathy directly at cathy@transformerstrip.com for immediate technical consultation and quotation.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing copper annealed coil directly from China.