Table of Contents

Market Insight: Continuously Transposed Conductor

Market Analysis: Transformer Strip/Foil (Aluminum/Copper)

The global demand for continuously transposed conductors (CTC) is intrinsically linked to the expansion and modernization of power transmission and distribution infrastructure. CTCs are a critical component in large power and traction transformers, particularly in high-capacity applications where efficiency, thermal management, and electromagnetic performance are paramount. These conductors are constructed from multiple rectangular wires—typically aluminum or copper—insulated and transposed in a continuous pattern to minimize eddy current losses and ensure uniform current distribution across parallel strands. This design is essential in mitigating hotspots and enhancing the operational longevity of transformers under dynamic load conditions.

Industrial demand for CTCs has been driven by several macro-level factors. Increasing urbanization, rising electricity consumption, and the integration of renewable energy sources into the grid have necessitated the deployment of high-efficiency transformers capable of handling variable loads and maintaining grid stability. In particular, high-voltage direct current (HVDC) transmission systems, offshore wind farm substations, and railway traction networks represent key growth segments requiring advanced CTC solutions. Additionally, regulatory standards such as IEC 60076 and IEEE C57.12.00 are increasingly emphasizing energy efficiency and reliability, further elevating the technical requirements for transformer components, including strip and foil materials used in CTC fabrication.

Aluminum and copper transformer strip/foil serve as the foundational raw materials for CTC production, each offering distinct advantages. Copper provides superior electrical conductivity and mechanical strength, making it ideal for compact, high-performance transformers. However, aluminum offers a favorable conductivity-to-weight ratio and cost efficiency, making it the preferred choice for large-scale, weight-sensitive applications such as generator step-up (GSU) transformers and mobile traction units. The selection between aluminum and copper is often dictated by application-specific constraints, including current density requirements, cooling methods, and lifecycle cost considerations.

Quality in transformer strip and foil is non-negotiable. Dimensional precision, surface integrity, metallurgical homogeneity, and consistent mechanical properties directly influence the performance and reliability of the final CTC. Even minor deviations in thickness tolerance or surface defects can lead to insulation breakdown, uneven current sharing, or localized overheating. At Luoyang Xinzhaohe Aluminum CO., Ltd, with over two decades of specialized manufacturing experience, we enforce stringent process controls across rolling, annealing, and slitting operations to ensure our aluminum strips meet the exacting standards required for CTC applications. Our in-house testing capabilities, including eddy current inspection and mechanical property validation, ensure batch-to-batch consistency and compliance with international specifications.

As transformer manufacturers strive to meet evolving performance benchmarks, the role of high-quality strip and foil in enabling efficient, reliable, and durable CTCs becomes increasingly critical. The supply chain must therefore prioritize material excellence, traceability, and technical collaboration to support the next generation of power infrastructure.

Technical Specs: Continuously Transposed Conductor

Technical Specifications for Continuously Transposed Conductors (CTC)

Luoyang Xinzhaohe Aluminum CO., Ltd leverages 20+ years of specialized expertise in transformer conductor manufacturing to deliver Continuously Transposed Conductors meeting the most stringent global transformer OEM requirements. Our CTC products, fabricated from high-purity aluminum alloy strip or foil, are engineered to minimize eddy current losses and ensure uniform current distribution within high-voltage and power transformer windings. Precision in dimensional control and material properties is non-negotiable for reliability and efficiency. We emphasize three critical technical parameters: dimensional accuracy, edge integrity, and electrical conductivity. These parameters are rigorously controlled through our ISO 9001-certified production processes, featuring advanced tension leveling, laser-guided slitting, and in-line metrology.

Dimensional precision is paramount for consistent transposition geometry and core fit. Our slitting process achieves a width tolerance of ±0.002 mm across the entire strip length. This extreme accuracy ensures uniform strand positioning within the transposition assembly, preventing localized heating and mechanical stress points during transformer operation. Achieving this requires proprietary tension control systems and real-time laser micrometer feedback during cold rolling and slitting. Edge quality directly impacts winding integrity and insulation system longevity. All slit edges are guaranteed burr-free, with maximum micro-burr height consistently held below 5 µm. This is verified using high-magnification optical profilometry and tactile measurement. Burr-free edges prevent puncture of inter-strand insulation paper or film during the transposition and winding processes, eliminating a critical failure vector in transformer insulation systems. Electrical performance is defined by conductivity, measured per ASTM B193. Our high-purity aluminum alloys (typically 1350 or equivalent) achieve a minimum conductivity of 61.0% IACS (International Annealed Copper Standard), with standard production consistently reaching 61.5% IACS. This high conductivity minimizes resistive (I²R) losses, directly contributing to transformer energy efficiency and thermal management. Conductivity is validated through four-point probe testing on samples taken from both ends and the center of each production coil.

The following table details the core technical specifications for our standard CTC aluminum strip/foil offerings:

| Parameter | Specification Value | Test Standard | Critical Impact |

|---|---|---|---|

| Width Tolerance | ±0.002 mm | In-house Laser Metrology | Ensures precise strand alignment in transposition, preventing uneven current distribution |

| Edge Burr Height | ≤ 5 µm (Max) | ISO 1302 / Optical Profilometry | Prevents insulation damage during winding, critical for long-term dielectric integrity |

| Electrical Conductivity | ≥ 61.0% IACS (Min) | ASTM B193 | Minimizes resistive losses, directly impacts transformer efficiency and operating temperature |

| 61.5% IACS (Typical) | |||

| Thickness Range | 0.80 mm – 4.00 mm | ASTM E29 | Supports diverse core designs and MVA ratings |

| Surface Roughness (Ra) | ≤ 0.8 µm | ISO 4287 | Facilitates smooth winding and optimal impregnation of insulation fluids |

| Tensile Strength | 85 – 110 MPa | ASTM E8 | Balances formability during transposition with mechanical stability in service |

| Elongation | ≥ 25% | ASTM E8 | Ensures ductility for complex transposition without cracking |

These specifications represent the baseline for our premium CTC material. Luoyang Xinzhaohe Aluminum maintains full traceability from molten metal to finished coil, utilizing state-of-the-art continuous casting and cold rolling lines. Our metallurgical control ensures consistent grain structure and absence of detrimental intermetallic phases, directly supporting the achievement of these tight tolerances and high conductivity. Partnering with us guarantees CTC material that meets the exacting demands of modern, high-efficiency transformer design and manufacturing.

Factory Tour: Manufacturing

Manufacturing Process of Continuously Transposed Conductors at Luoyang Xinzhaoanghe Aluminum Co., Ltd

The production of continuously transposed conductors (CTC) at Luoyang Xinzhaohe Aluminum Co., Ltd follows a tightly controlled, multi-stage manufacturing sequence designed to ensure dimensional precision, mechanical integrity, and electrical performance. With over two decades of specialized experience in aluminum and copper transformer strip and foil production, our facility integrates advanced cold rolling, precision slitting, and edge conditioning technologies to meet the rigorous demands of high-efficiency transformer manufacturing.

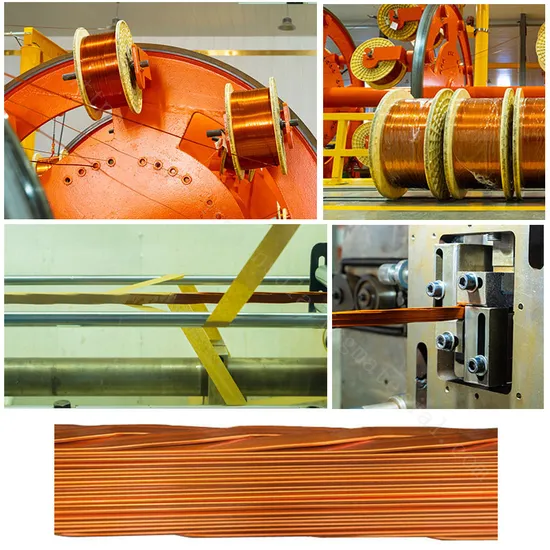

The process begins with cold rolling, where high-purity aluminum or copper ingots are first homogenized and hot-rolled into intermediate gauge stock. This material is then processed through a series of precision cold rolling mills under controlled temperature and tension conditions. Cold rolling achieves the target final thickness with tight tolerances, typically ranging from 0.8 mm to 4.0 mm, depending on application requirements. The rolling schedule is optimized to produce a uniform microstructure with enhanced electrical conductivity and mechanical strength. Throughout this stage,在线 thickness gauges (X-ray or laser-based) continuously monitor strip profile and crown, enabling real-time roll gap adjustments to maintain ±0.01 mm thickness consistency across the coil width.

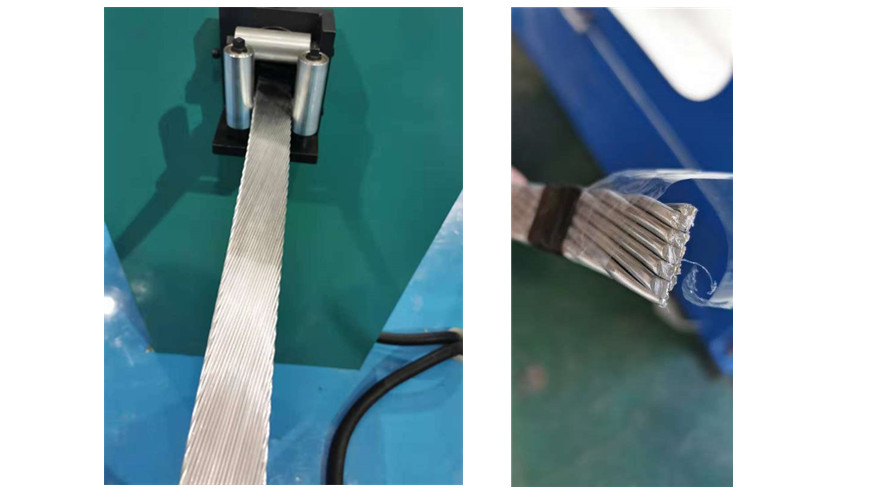

Following cold rolling, the strip undergoes precision slitting to produce multiple narrow conductor elements required for transposition. Utilizing high-precision rotary shear slitters with computer-controlled alignment, the master coil is divided into individual strips with widths as narrow as 2.5 mm and tolerances held within ±0.05 mm. The slitting line is equipped with edge guiding systems and tension dancers to prevent edge wave or center buckle, ensuring flatness and consistent edge geometry. Each slit strip is wound onto precision arbors with controlled tension to avoid coil defects such as telescoping or edge damage.

Edge conditioning is a critical downstream operation that directly influences winding performance and insulation integrity. Each slit strip passes through a dedicated edge rounding and deburring module, where mechanical or abrasive tools uniformly condition the longitudinal edges. This process removes micro-burrs and sharp asperities generated during slitting, producing a controlled edge radius typically between 0.05 mm and 0.15 mm. Proper edge conditioning minimizes the risk of dielectric breakdown in transformer windings and reduces localized stress on insulating paper or films.

Quality control is embedded at every stage of production. In-process inspections include hourly sampling for dimensional verification, surface defect mapping via automated optical inspection (AOI), and mechanical testing for yield strength, elongation, and conductivity. Final coils are subjected to eddy current testing to detect subsurface flaws and undergo strict visual and profilometric examination of edge quality. All material is traceable through batch records, with full certification provided per customer specifications, including ASTM B233 or IEC 60101 standards.

This integrated manufacturing approach ensures that Luoyang Xinzhaohe’s continuously transposed conductors deliver superior performance in high-voltage and high-current transformer applications.

Packaging & Logistics

Export Packaging Specifications for Continuously Transposed Conductors

Luoyang Xinzhaohe Aluminum Co., Ltd leverages over two decades of metallurgical and supply chain expertise to ensure the secure global delivery of continuously transposed conductors (CTC), whether aluminum or copper based. Our export packaging system is engineered specifically to mitigate the significant risks inherent in ocean freight, prioritizing product integrity from factory gate to transformer winding facility. This system is not merely a container but a critical component of the conductor’s quality assurance, designed to withstand prolonged exposure to high humidity, salt air, temperature fluctuations, and mechanical stresses encountered during sea transport.

Wooden pallets form the foundational structural element of our export packaging. Constructed exclusively from ISPM 15 compliant, kiln-dried hardwood, these pallets provide the necessary rigidity and load-bearing capacity to support the substantial weight of wound conductor reels without deformation. Critical dimensions and load ratings are strictly adhered to, ensuring compatibility with global containerization standards and automated handling equipment. The pallet design incorporates robust blocking and bracing elements to prevent reel movement during transit, eliminating the risk of edge damage or core collapse under dynamic cargo shifting forces. All wooden components undergo mandatory heat treatment certification to meet stringent international phytosanitary regulations, preventing customs delays.

Moisture intrusion represents the paramount threat to CTC integrity during sea voyages. Xinzhaohe employs a multi-layer, hermetically sealed moisture barrier system. The conductor reel is first tightly wrapped with industrial-grade, metallized moisture-proof film possessing a minimum thickness of 125 microns and a water vapor transmission rate (WVTR) below 0.5 g/m²/24hr. This primary barrier is meticulously sealed using heat-welded seams, creating an impermeable envelope. A secondary layer of heavy-duty polyethylene film provides additional puncture resistance and redundancy. Desiccant packs, precisely calculated based on reel volume and expected voyage duration, are strategically placed within the sealed cavity to actively absorb any residual or infiltrated moisture, maintaining an internal relative humidity below 40% throughout transit. This dual-film approach is essential to prevent hygroscopic degradation of insulation paper and electrochemical corrosion of conductor surfaces.

Securing the wrapped reel to the pallet is achieved through tension-controlled steel or polyester strapping applied at calibrated tension levels (typically 2500-3500 N for standard reels). A minimum of six straps, configured in a cross-pattern over top and bottom edges, distribute load evenly and prevent reel rotation or lateral displacement. Edge protectors are utilized to prevent strap-induced damage to the film barrier. All strapping components feature corrosion-resistant coatings suitable for marine environments.

The efficacy of this integrated packaging system is validated through rigorous internal testing simulating 60+ days of open-ocean conditions, including salt spray exposure, cyclic humidity chambers, and vibration profiles matching ISO 13355 standards. This commitment ensures that Xinzhaohe CTC arrives at destination ports globally in pristine, ready-to-wind condition, safeguarding your transformer manufacturing schedule and eliminating costly moisture-related failures or rework. Our packaging is a direct extension of our metallurgical quality control, guaranteeing the conductor’s electrical and mechanical properties remain uncompromised.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum CO., Ltd – Your Trusted Source for Continuously Transposed Conductors

With over two decades of specialized manufacturing experience, Luoyang Xinzhaohe Aluminum CO., Ltd has established itself as a leading supplier of high-precision aluminum and copper transformer strip and foil products. Our expertise in the production of continuously transposed conductors (CTC) is rooted in a deep understanding of electromagnetic performance, thermal stability, and mechanical reliability required in modern power and distribution transformers. As a vertically integrated manufacturer, we control every stage of the production process—from raw material selection to final inspection—ensuring consistent product quality and performance that meets international standards including IEC 60317-0-7 and GB/T 20088.

Our production facility is equipped with advanced rolling mills, precision annealing lines, and state-of-the-art transposition equipment designed specifically for CTC manufacturing. This enables us to produce aluminum and copper conductors with tight dimensional tolerances, excellent surface finish, and uniform mechanical properties. We offer custom configurations in cross-sectional dimensions, transposition pitch, and insulation types—including polyimide films, DMD, and Nomex—tailored to meet specific design requirements for low-loss, high-efficiency transformers. Our quality assurance system is certified under ISO 9001:2015, and we conduct rigorous in-process and final testing, including electrical resistivity measurement, tensile strength evaluation, and transposition integrity verification.

Luoyang Xinzhaohe maintains a robust supply chain for high-purity aluminum (1350, 1070) and electrolytic tough pitch (ETP) copper, ensuring material consistency and traceability. Our in-house metallurgical laboratory performs chemical composition analysis and microstructure evaluation to guarantee material homogeneity and performance under long-term operational stress. With an annual production capacity exceeding 15,000 metric tons of transformer strip and foil, we are well-positioned to support large-scale projects and long-term supply agreements across global markets.

We serve a diverse client base, including transformer OEMs, winding pack suppliers, and energy infrastructure developers across Asia, Europe, and North America. Our engineering team works closely with clients during the design and prototyping phases to optimize conductor geometry, minimize eddy current losses, and enhance overall transformer efficiency. This collaborative approach has led to successful integration of our CTC products in high-voltage power transformers, traction transformers, and renewable energy applications.

For sourcing professionals and technical procurement teams seeking a reliable, technically capable partner in continuously transposed conductor supply, Luoyang Xinzhaohe offers a compelling combination of manufacturing excellence, material expertise, and responsive customer support. We invite you to contact us directly to discuss your project requirements and explore how our capabilities can support your transformer manufacturing goals.

Contact us at: cathy@transformerstrip.com

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing continuously transposed conductor directly from China.