Table of Contents

Market Insight: Continuously Transposed Cable

Market Analysis: Winding Wire Demand for Continuously Transposed Cable

Global demand for continuously transposed cable (CTC) is intensifying, driven by the expansion of high-voltage power infrastructure and renewable energy integration. Utilities and transformer manufacturers increasingly specify CTC for core-wound transformers exceeding 100 MVA capacity, particularly in 220 kV and above transmission systems. This surge stems from mandates for grid stability under fluctuating loads from solar/wind farms and the global push for energy efficiency. CTC’s unique stranded conductor configuration—where individual strands are precisely transposed along the cable length—mitigates eddy current losses by equalizing electromagnetic flux distribution. Industry data indicates CTC adoption reduces stray losses by 15–25% compared to conventional conductors, directly aligning with IEC 60076-7 thermal performance standards and regional energy regulations like the EU EcoDesign Directive.

Quality in CTC production is non-negotiable due to the extreme operational stresses within power transformers. Substandard transposition geometry or inconsistent strand tension during manufacturing creates localized current imbalances, accelerating hotspot formation. Metallurgical defects—such as surface scratches from inadequate drawing lubrication or residual stresses from improper annealing—compromise the conductor’s fatigue resistance. Under continuous thermal cycling, these flaws initiate micro-cracks that propagate into insulation breaches, leading to partial discharges or catastrophic ground faults. Field failure analyses consistently link premature transformer outages to CTC quality lapses, with repair costs exceeding 30% of unit replacement value and unplanned downtime costing utilities $10,000–$50,000 per hour.

Material purity and dimensional precision further dictate performance longevity. Aluminum CTC (predominantly 1350-H19 alloy) requires oxygen content below 10 ppm to prevent intergranular corrosion during service. Strand diameter tolerances must adhere to ±0.01 mm per IEC 60317-33, as deviations exceeding 2% disrupt transposition symmetry and amplify circulating currents. Surface roughness (Ra ≤ 1.6 μm) is equally critical; microscopic imperfections erode paper insulation during winding, reducing dielectric strength by up to 40%. Luoyang Xinzhaohe Aluminum’s two-decade specialization in CTC manufacturing addresses these parameters through in-line eddy current testing, laser micrometry, and proprietary annealing protocols that ensure uniform recrystallization.

The supply chain consequences of inferior CTC extend beyond technical failure. Non-compliant batches trigger project delays during transformer factory acceptance tests (FAT), incurring liquidated damages under EPC contracts. Reputational risk is equally severe, as OEMs face liability for grid instability events traced to component defects. Consequently, leading transformer producers now mandate supplier audits of CTC manufacturers’ process controls, including statistical validation of transposition accuracy and traceability to raw material certificates. For industrial buyers, prioritizing quality-certified CTC suppliers is not a cost factor but a strategic risk mitigation imperative—ensuring asset reliability across 30+ year transformer lifespans while meeting evolving grid resilience standards.

Technical Specs: Continuously Transposed Cable

Continuously Transposed Cable Technical Specifications

Continuously transposed cable (CTC) is a high-performance conductor assembly engineered for high-current, low-loss applications in large power transformers, reactors, and other heavy electrical equipment. At Luoyang Xinzhaoang Aluminum Co., Ltd., with over two decades of metallurgical and manufacturing expertise, our CTC products are precision-engineered to ensure optimal current distribution, minimize eddy current losses, and provide long-term thermal and mechanical stability under demanding operational conditions. The following technical parameters define the performance envelope of our standard CTC offerings, with customization available to meet project-specific requirements.

A critical performance parameter for continuously transposed cable is insulation breakdown voltage. This value determines the dielectric strength of the insulation system and directly impacts the reliability and safety of the winding under transient overvoltage conditions. Our CTC designs achieve a minimum AC breakdown voltage of 6 kV rms for standard configurations, tested at room temperature with a 1-minute duration. This ensures robust protection against electrical stress during service. The insulation system typically comprises multiple layers of thermally bonded polyimide film, Nomex paper, or enamel coatings, depending on the thermal class and application environment.

Elongation at break is another key mechanical property, reflecting the ductility of the conductor material and its ability to withstand bending, winding, and thermal cycling without fracture. For aluminum-based CTC, we maintain a minimum elongation of 18% in the annealed condition, ensuring compatibility with tight-radius winding operations and minimizing the risk of conductor cracking during coil fabrication. Copper-based CTC variants exhibit elongation values of no less than 22%, in compliance with IEC 60468 and ASTM B8 standards.

Thermal performance is defined by the insulation thermal class, which specifies the maximum continuous operating temperature the cable can endure without degradation. Our CTC portfolio supports thermal classes ranging from 130°C (Class B) up to 220°C (Class C), with common offerings at 155°C (Class F) and 180°C (Class H). These ratings are validated through accelerated aging tests per IEC 60216 and UL 1446, ensuring long-term dielectric integrity and mechanical resilience in high-temperature environments.

The table below summarizes the core technical specifications of our continuously transposed cable product line.

| Parameter | Unit | Typical Value (Al) | Typical Value (Cu) | Test Standard |

|---|---|---|---|---|

| Insulation Breakdown Voltage | kV rms | ≥6.0 | ≥6.0 | IEC 60243-1 |

| Elongation at Break | % | ≥18 | ≥22 | IEC 60468 / ASTM B8 |

| Thermal Class (Insulation) | °C | 130–220 | 130–220 | IEC 60216 / UL 1446 |

| Conductor Resistivity (20°C) | Ω·mm²/m | ≤0.0283 | ≤0.01724 | IEC 60889 / ASTM B3 |

| Transposition Pitch | mm | 100–300 (custom) | 100–300 (custom) | Internal Specification |

All continuously transposed cables are manufactured under ISO 9001-certified processes, with full traceability of raw materials and in-process quality checks. Custom configurations, including hybrid conductor layouts, enhanced dielectric systems, and specialized jacketing, are available upon request.

Factory Tour: Manufacturing

Manufacturing Process for Continuously Transposed Cable

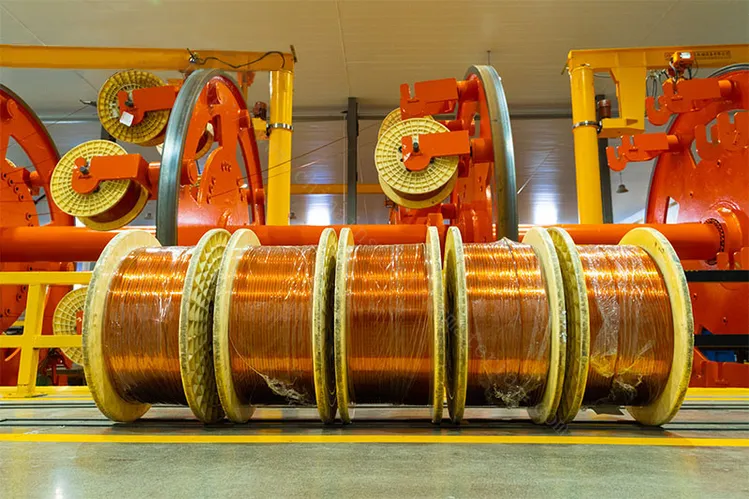

Continuously transposed cable (CTC) production at Luoyang Xinzhaohe Aluminum requires stringent metallurgical control and precision engineering to achieve the requisite electrical conductivity, mechanical flexibility, and dielectric integrity for high-voltage transformer windings. Our 20+ years of specialized experience ensure each stage adheres to international standards, minimizing defects and maximizing performance reliability.

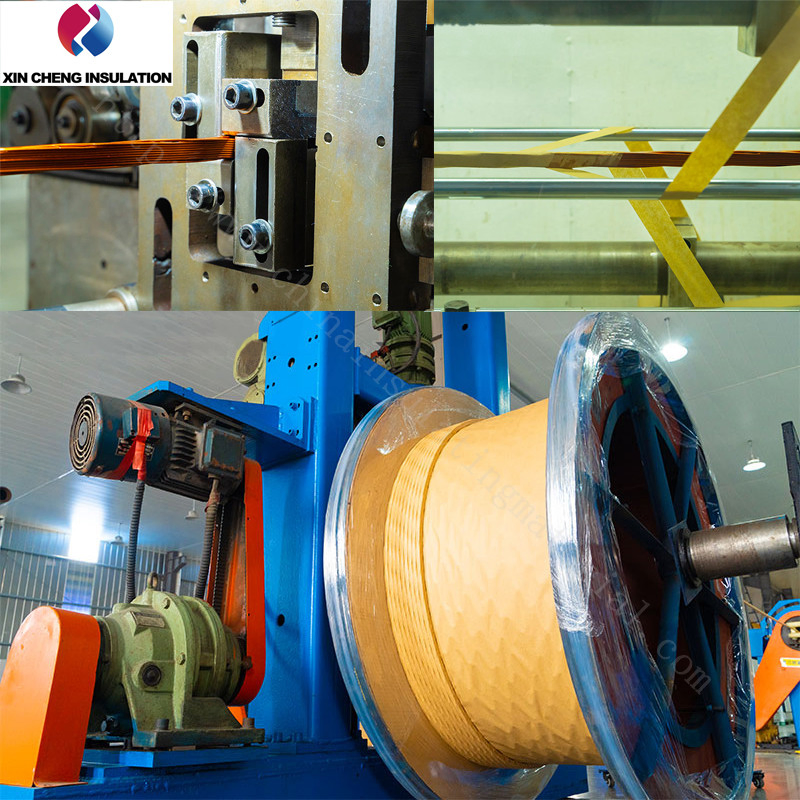

The process initiates with high-purity aluminum rod drawing. Starting material meets minimum 99.7% Al specification, typically from controlled electrolytic reduction. Rods undergo multi-pass cold drawing through precision tungsten carbide dies under strict tension control. This reduces diameter to the final conductor size with tolerances held to ±0.01 mm. Critical parameters include reduction ratio per pass, die geometry, and lubricant viscosity, all monitored to prevent surface scoring, ovality, or excessive work hardening. Inline laser micrometers provide continuous diameter feedback, triggering automatic die adjustments. Surface quality is verified via high-resolution optical inspection immediately post-drawing to reject any micro-cracks or imperfections.

Subsequent annealing is performed in a continuous, oxygen-controlled atmosphere furnace. The conductor traverses precise temperature zones, typically between 300°C and 450°C, optimized for the specific alloy and final temper requirements. This critical step relieves internal stresses induced during drawing and restores optimal electrical conductivity, targeting a minimum of 61.0% IACS. Atmosphere composition (typically N₂/H₂ mix) is rigorously controlled to prevent oxidation or hydrogen embrittlement. Conductivity is validated in real-time using non-contact eddy current sensors, with automatic line speed adjustment ensuring consistent thermal exposure. Tensile strength and elongation are sampled hourly per ASTM E8/E8M.

Enameling applies multiple polymer layers via precision dip-applicator systems. Standard configurations utilize dual or triple coatings: a base layer of high-thermal-class polyesterimide for adhesion and mechanical strength, followed by topcoats of polyamide-imide or similar for superior chemical resistance and thermal endurance (typically Class 200 or 220). Each layer undergoes immediate curing in multi-zone ovens with precisely controlled temperature profiles and dwell times. Film thickness is maintained within ±2 µm per layer using laser gauging. Critical quality attributes include dielectric strength (>12 kV DC for standard builds), flexibility (mandrel bend test per IEC 60851-5), and thermal shock resistance.

Comprehensive inline testing occurs throughout. Key checks include:

Continuous partial discharge inception voltage (PDIV) measurement at elevated voltage stress

High-potential (hi-pot) testing at 3-5 kV AC per meter to detect pinholes

Real-time monitoring of conductor straightness and transposition integrity via optical sensors

Automated spark testing during enameling for immediate flaw detection

Final QC involves destructive sampling of every production batch for full electrical, mechanical, and chemical analysis per IEC 60317 and customer specifications. This integrated, data-driven approach ensures our CTC consistently delivers the transposition accuracy, thermal stability, and long-term reliability demanded by modern power infrastructure.

Packaging & Logistics

Export Packaging for Continuously Transposed Cable at Luoyang Xinzhaohe Aluminum Co., Ltd

At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of specialized experience in the production of high-performance winding wires, we recognize that the integrity of continuously transposed cable (CTC) must be preserved throughout the entire supply chain. Export packaging is not merely a logistical step—it is a critical engineering component that ensures product performance upon arrival. Our export packaging system is meticulously designed to meet international maritime transport standards, safeguarding cable reels against mechanical stress, moisture ingress, and environmental fluctuations during extended sea freight transit.

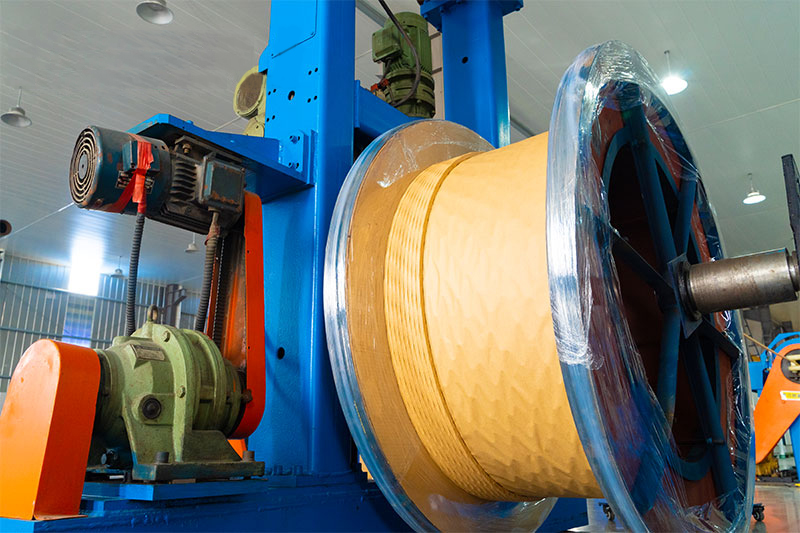

All continuously transposed cable shipments are wound onto robust wooden pallets constructed from kiln-dried, ISPM 15-compliant hardwood. These pallets are engineered to withstand stacking loads up to 5 metric tons, ensuring structural stability during containerized transport. The wooden core is treated to resist fungal growth and insect infestation, a necessity for prolonged exposure to tropical and humid climates commonly encountered along global shipping routes. Each pallet is precision-machined to match the dimensional specifications of the cable reel, minimizing lateral displacement and reducing the risk of edge damage during handling and transit.

Immediately after winding, the cable assembly is enveloped in a multi-layer moisture-proof barrier film. This film consists of a co-extruded laminate with an aluminum foil interlayer, providing a water vapor transmission rate (WVTR) of less than 0.1 g/m²·24h at 38°C and 90% relative humidity. The sealing process employs heat-welded seams to create a hermetic enclosure, effectively isolating the conductor from ambient humidity. This is particularly critical for aluminum-based CTC, which, while offering superior conductivity-to-weight ratio, is susceptible to surface oxidation under sustained damp conditions. The moisture barrier is further secured with UV-resistant polypropylene strapping, anchored at six radial points to prevent loosening during vessel motion.

Each packaged reel is labeled with permanent, weather-resistant markings indicating product code, batch number, net weight, winding direction, and handling instructions compliant with IMDG and IATA Class 9 guidelines. The outer film is also marked with orientation arrows and “Fragile – Protect from Moisture” warnings in English and the destination country’s official language, ensuring clarity across international logistics nodes.

Our packaging protocol has been validated through accelerated aging tests simulating 120-day sea voyages across varying climatic zones, including high-humidity equatorial transits and temperature-cycling mid-latitude routes. This rigorous validation ensures that upon arrival, the CTC maintains its electrical consistency, dimensional accuracy, and surface quality—ready for immediate integration into transformer or reactor winding operations.

For global partners, this packaging standard represents not only compliance with international freight requirements but also our commitment to delivering materials that perform as specified, every time.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe for Continuously Transposed Cable Excellence

Luoyang Xinzhaohe Aluminum Co., Ltd. leverages 20+ years of specialized metallurgical and manufacturing expertise to deliver continuously transposed cable (CTC) solutions meeting the most stringent transformer and reactor industry demands. Our vertically integrated production ecosystem, spanning raw material sourcing to finished coil, ensures unparalleled control over critical performance parameters. This integration is foundational to achieving the low-loss, high-reliability characteristics essential for modern high-efficiency power equipment.

Our metallurgical precision begins with proprietary aluminum purification processes, consistently achieving 99.99%+ Al purity. This minimizes electrical resistivity variations and enhances thermal stability under operational loads. Advanced continuous casting and rolling lines maintain strict homogeneity in grain structure and mechanical properties, directly influencing cable flexibility and fatigue resistance during winding. Each batch undergoes rigorous spectrographic and resistivity validation, with data traceable to the ingot level, ensuring compliance with IEC 60104 and ASTM B230 standards.

The core of our CTC capability lies in dynamic transposition technology. Our automated transposition lines utilize real-time tension monitoring and servo-controlled pitch adjustment to achieve helical pitch accuracy within ±0.1 mm across all strands. This eliminates strand crossover and positional errors that induce eddy current losses. The process incorporates inline optical inspection systems that detect micro-surface defects or dimensional deviations at 100% production speed, guaranteeing strand integrity critical for high-voltage insulation systems.

Quality assurance is embedded at every stage through our ISO 9001 and IATF 16949 certified framework. Comprehensive testing includes DC resistance mapping, transposition validation via short-circuit current simulation, and accelerated aging protocols. Our 10,000 m² dedicated CTC facility features climate-controlled winding halls and vibration-isolated inspection zones, mitigating environmental variables that compromise dimensional stability. Full lot traceability via blockchain-enabled digital logs provides customers with immutable production history from raw material to shipment.

Supply chain resilience is engineered into our operations. Strategic partnerships with primary aluminum suppliers secure priority access to high-conductivity feedstock, while our on-site 50,000-ton annual capacity buffer inventory mitigates market volatility risks. JIT logistics coordination with major global ports enables 30-day delivery for standard orders, supported by dual redundant production lines ensuring continuity during peak demand cycles.

Initiate technical discussions or request custom CTC specifications by contacting Cathy Zhang, Head of International Sales, directly at cathy@transformerstrip.com. Include your project’s voltage class, current density requirements, and dimensional constraints to receive a metallurgically optimized proposal within 72 hours. Partner with Luoyang Xinzhaohe to transform material science into measurable efficiency gains for your next-generation power infrastructure.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing continuously transposed cable directly from China.