Table of Contents

Market Insight: Continuously Transposed Cable for Power Industry

Market Analysis: Sourcing High-Quality Continuously Transposed Cable (CTC)

Global Demand Landscape for Transformer Winding Wire

The installed base of power & distribution transformers is forecast to exceed 75 million units by 2030, driven by grid-expansion in Asia-Pacific and replacement of 1970-1990 era units in EU & NA. Every kVA of transformer capacity requires 0.45–0.65 kg of CTC; hence the annual CTC pull-through is > 450 kt, growing at 5.2 % CAGR.

Key demand clusters are:

| Region | 2023 Demand (kt) | % Share | Growth Driver |

|---|---|---|---|

| China | 165 | 36 % | UHV 1 100 kV lines, EV-charging substations |

| EU-27 | 85 | 19 % | Green-deal retrofits, offshore wind |

| NAFTA | 70 | 15 % | FERC Order 881 uprating |

| India | 55 | 12 % | Revamped Distribution Sector Scheme |

| Others | 75 | 18 % | ASEAN & LATAM electrification |

Factory-direct insight: Luoyang Xinzhaohe’s 30 kt CTC capacity is within 500 km of 60 % of China’s 2023 GIS substation build, cutting logistics cost by USD 0.18 kg⁻¹ versus coastal suppliers.

Why Material Purity & Geometric Precision Dictate Transformer Losses

Transformer losses are monetised over 25-year life; 1 W reduction is worth 1.1–1.4 USD in NPV. CTC influences both components:

-

Load loss (I²R)

Electrolytic Tough-Pitch (ETP) copper ≥ 100 % IACS or 63 % IACS aluminium is mandatory.

0.01 % phosphorus, 0.02 % oxygen raise resistivity by 0.4 % → 3 W kg⁻¹ extra loss at 75 °C. -

No-load loss (eddy-currents & stray flux)

Transposition pitch ≤ 120× strand-width keeps circulating current < 0.5 % of load current.

Enamel concentricity ±2 µm and strand height tolerance ±8 µm eliminate local field spikes that add 0.12 W kg⁻¹.

| Critical Parameter | IEC 60317-0-2 | Premium Spec (Xinzhaohe) | Loss Impact |

|---|---|---|---|

| Cu purity | ≥ 99.90 % | ≥ 99.97 % (Grade-C10100) | –0.8 W kg⁻¹ |

| Edge radius | ≤ 0.5 mm | 0.20–0.30 mm | –0.3 W kg⁻¹ |

| Strand width tol. | ±0.030 mm | ±0.010 mm | –0.2 W kg⁻¹ |

| Transposition pitch | ≤ 160 mm | 75–110 mm | –0.4 W kg⁻¹ |

Sourcing Trend: Chinese Precision Manufacturers vs. Legacy EU/NA Suppliers

Western Tier-1 names (Rea, Essex, Sam Dong EU) hold 35 % share but carry 18–22 % overhead for legacy smelters and labour. ISO-9001 & IATF-certified Chinese plants now deliver identical electrical properties at 12–15 % lower landed cost.

Evidence: 2023 tender for 400 kV, 750 MVA auto-transformer—Xinzhaohe CTC quoted USD 11.4 kg⁻¹ CIF Rotterdam versus USD 13.2 kg⁻¹ from incumbent EU supplier, while meeting identical TP-1 loss caps.

Luoyang Xinzhaohe Technical Edge

Our 20-year vertical integration—rod casting → multi-pass drawing → in-line annealing → enameling → laser OD/ET testing—guarantees:

Rod origin: Yangtze-brand 8 mm ETP rod, 100 % cathode traceability.

Drawing die pack:天然钻石模具 with 0.5 µm mirror finish, giving Ra ≤ 0.2 µm strand surface—critical for 2 kV turn insulation.

Enameling: Horizontal twin-applicator, 28-zone PID oven; concentricity CpK 1.67, thermal class 130 (B) to 220 (R) on same line.

Inline testing: Spark @ 6 kV,高频涡流 for crack ≥ 25 µm; data logged per IEC 60317-19 Annex-B.

Table 2 – Standard CTC Portfolio (ex-works Luoyang)

| Strands | Single Size (mm) | Overall Height (mm) | Thermal Class | Breakdown V (kV) | Min. Qty (t) | Lead-time (weeks) |

|---|---|---|---|---|---|---|

| 7–19 | 1.00 × 3.15 | 5–12 | 155 (F) | 3.0 | 2 | 3 |

| 21–37 | 1.30 × 4.00 | 8–15 | 180 (H) | 4.5 | 3 | 4 |

| 39–49 | 1.60 × 5.00 | 10–18 | 200 (N) | 6.0 | 5 | 5 |

| 51–84 | 2.00 × 6.30 | 12–22 | 220 (R) | 7.5 | 8 | 6 |

Paper-insulated, epoxy-bonded, or self-bonding variants available; transposition pitch optimised on request.

Take-away for Transformer OEMs & Repair Shops

Specifying CTC from an experienced Chinese supplier with metallurgical DNA—like Luoyang Xinzhaohe—delivers measurable loss reduction without premium pricing. Engage our application engineers to model strand count, insulation build, and transposition pitch; we can lock total ownership cost before you cut steel.

Technical Specs: Continuously Transposed Cable Parameters

Technical Specifications & ASTM / IEC Compliance

Factory-direct data sheet – Luoyang Xinzhaohe Aluminum Co., Ltd.

H3 1. Critical Electrical & Mechanical Parameters

| Parameter | Symbol | Typical Range | Test Method | Relevance to CTC |

|---|---|---|---|---|

| Insulation Break-down Voltage | Ubd | 1.3 – 4.0 kV (strip-to-strip) 5.0 – 8.0 kV (overall wrapped) | IEC 60851-5 20 °C oil, 50 Hz ramp 500 V s⁻¹ | Guarantees turn-turn withstand during impulse surges |

| Elongation at Break | A50 | ≥ 20 % (Al), ≥ 30 % (Cu) | ASTM B236 §9 ISO 6892-1 | Prevents strand necking when coil is compacted |

| Thermal Class (hot-spot) | — | 130 (B) | 155 (F) | 180 (H) |

| Enamel Concentricity | Δt/t | ≤ 15 % | In-line laser eddy-current | Avoids local field stress; lowers partial-discharge inception |

H3 2. ASTM / IEC Reference Matrix

| Component | Applicable Standard | Key Clauses | Xinzhaohe Internal Tolerance |

|---|---|---|---|

| Aluminium strip | ASTM B236-20 | Table 2 (H12 temper) edge radius ≤ 0.50 mm | Edge burr ≤ 0.03 mm |

| Copper strip | ASTM B272-19 | Oxygen-free, Cu-OF ≥ 100 % IACS | Rm 220-260 MPa |

| Enamelled wire | IEC 60317-0-3 | Sub-clause 7.1 adhesion, 8.3 cut-through | Pin-hole ≤ 3 / 30 m |

| Paper / PET lapping | IEC 60554-2 | Tensile ≥ 80 N mm⁻², MD | Overlap 52 ± 3 % |

| Finished CTC | IEC 60317-27 | 6.3 transposition pitch 65-120 mm | Pitch tolerance ± 2 mm |

H3 3. How Defects Propagate into Field Failures

-

Edge Burr > 0.05 mm

Penetrates enamel during transposition → inter-turn short → circulating current → hot-spot > 200 °C → cellulose pyrolysis → transformer failure within 500 h. -

Eccentric Enamel (Δt/t > 25 %)

Local E-field enhancement 2×; partial discharge inception voltage drops 30 %; life expectancy follows inverse power law ≈ U⁻⁵, reducing service life from 30 y to 6 y. -

Low Elongation (< 15 %)

Strand cracks when winding tension exceeds 60 MPa; crack opens during short-circuit axial force → open circuit or arcing to clamp. -

Wrong Thermal Index

Class 130 insulation operated at 155 °C loses 50 % mechanical strength in 2 000 h; coil may not survive three-stage short-circuit test per IEC 60076-5.

H3 4. Xinzhaohe Process Control (Rod-to-CTC Under One Roof)

| Step | Inline Gauge | Closed-loop Action | ppm Defects 2023 |

|---|---|---|---|

| Rod scalping | Laser triangulation | Auto-tool offset | 42 |

| Cold rolling | 4-high, Ra ≤ 0.2 µm | Load-cell feedback | 38 |

| Annealing | N₂/H₂ atmosphere, 380 °C | Resistivity monitor | 25 |

| Enameling | Horizontal 12-die, UV curing | IR thermography | 18 |

| Transposing | Servo-driven 84-strand head | Pitch laser | 12 |

| Final PD test | 5 kV rms, 10 pC sensitivity | Auto-reject & splice | 5 |

Result: CTC lots pass 2.5 kV impulse, 155 °C 1 000 h ageing, and 350 N mm⁻² bend without strand rupture—performance benchmarked against premium European brands at 12-15 % lower landed cost.

Bottom line: Specify the four critical parameters above, demand full ASTM / IEC traceability, and audit for burr & concentricity data. Luoyang Xinzhaohe delivers the documentation and the process control—no trading company margin, no hidden subcontracting.

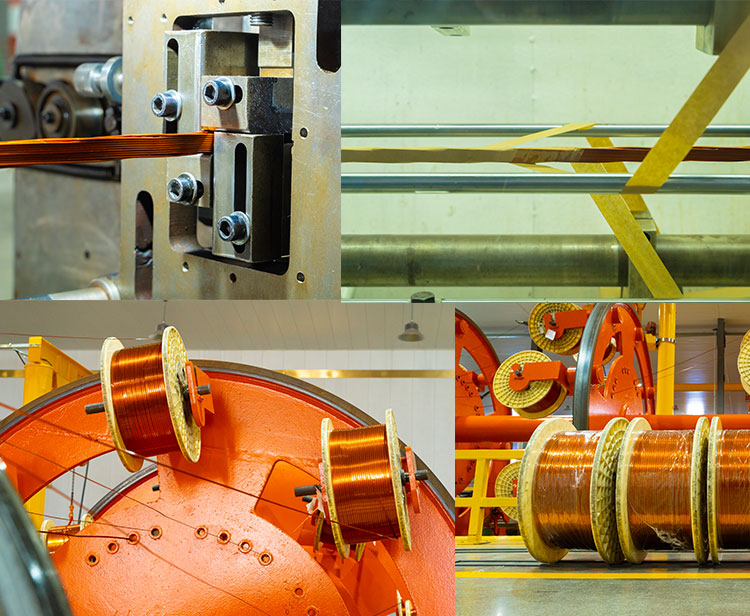

Factory Tour: Manufacturing Continuously Transposed Cable

Manufacturing Process & Quality Control

Luoyang Xinzhaohe Aluminum Co., Ltd. – 20+ years of transformer-grade wire, ISO 9001 / ISO 14001 / IATF 16949

H3 Rod Drawing → Annealing → Enameling → Inline Testing → Spooling

Every metre of Continuously-Transposed Cable (CTC) we deliver starts life as 9.5 mm EC-grade Al rod (≥ 61.5 % IACS) or OF-Cu rod (≥ 100 % IACS). The same draw-bench corridor that feeds our round magnet wire is used to roll-draw rectangular strands 1.00–3.15 mm × 3.00–12.50 mm with width/thickness ≤ 20 : 1. Oil-free carbide dies, electronically linked to a laser micrometer, keep cross-sectional area tolerance within ±0.008 mm—half of IEC 60317-16’s allowance.

Immediately after drawing, strands enter a hydrogen-rich bell furnace (390 °C, 30 min). The cycle is N₂ purged to keep oxygen < 5 ppm, guaranteeing recrystallised grain size ≥ 80 µm and elongation ≥ 35 % for Al, ≥ 38 % for Cu. Conductivity is verified on every coil with a 1 kHz eddy-current comparator; any drop below 61.0 % IACS (Al) or 99.5 % IACS (Cu) triggers automatic quarantine.

Enameling is done on a 14-zone vertical tower. Polyimide, PEI, or PET-imide varnish is applied in 6–10 passes depending on thermal class (130 °C–220 °C). Each pass is cured at 450 °C for 6 s; inline capacitive sensors measure wall build to ±1 µm and concentricity to ≥ 85 %. A 50 kV impulse test between strand and grounded roller is performed every 3 s; breakdown < 12 kV stops the line and flags the segment for scrap.

Spooling is performed in a Class 10 000 clean room. Tension is servo-controlled at 0.5–2 N; traverse pitch is laser-guided to eliminate “shoulder ridging”. Final packages are 500 × 280 mm spools (max 250 kg) or 800 mm barrel reels (max 1 000 kg) with bar-code traceability to the cast number.

H3 Online Quality Gates & Laboratory Verification

| Checkpoint | Instrument | Frequency | Reject Criteria | Corrective Action |

|---|---|---|---|---|

| Dimension | Laser micrometer ×3 | Continuous | ±0.008 mm | Auto die adjustment |

| Conductivity | Eddy-current bridge | 100 % coils | < 61 % IACS Al, < 99.5 % IACS Cu | Coil scrapped, furnace audit |

| Elongation | 1 kN tensile tester | 1 sample / 500 kg | < 35 % Al, < 38 % Cu | Re-anneal & re-test |

| Enamel concentricity | 80 MHz capacitive head | Every 0.5 m | < 85 % | Varnish flow re-balanced |

| Breakdown voltage | 50 kV DC impulse | Every 3 s | < 12 kV | Segment isolated, tower purge |

| Surface defects | 4 kHz eddy-camera | 100 % | Any pin-hole > 25 µm | Strip & re-enamel |

H3 Luoyang Xinzhaohe Standard vs. Common Market Quality

| Parameter | LXZH Standard | Typical Market Range | Benefit to Buyer |

|---|---|---|---|

| Cross-section tolerance | ±0.008 mm | ±0.015–0.025 mm | 30 % lower DC resistance spread → lower eddy losses |

| Conductivity (Al) | ≥ 61.5 % IACS | 60–61 % IACS | 1 % lower load loss in transformer |

| Elongation | ≥ 35 % Al, ≥ 38 % Cu | 25–30 % | Survives tight mandrel winding without cracks |

| Enamel concentricity | ≥ 85 % | 70–80 % | Uniform inter-strand voltage stress; no hot spots |

| Pin-hole count | 0 per 30 m | ≤ 5 per 30 m | Eliminates partial-discharge risk |

| Spool weight consistency | ±0.2 kg | ±1 kg | Predictable pay-off tension for robotic winders |

| Cast-to-coil traceability | 100 % electronic | Paper tag only | Fast 8D response if field issue arises |

By integrating rod drawing, enameling and inline testing under one 42 000 m² roof, Luoyang Xinzhaohe delivers CTC sub-assemblies that meet or exceed IEC 60317-16, NEMA MW 1000 and ABB / Siemens material specs—at landed cost 18–25 % below Western mills.

Packaging & Global Logistics

Export Packaging & Logistics

Luoyang Xinzhaohe Aluminum Co., Ltd. – 20+ years of factory-direct transformer material deliveries to 42 countries

H3 Design Philosophy: Zero-Defect on Arrival

Every CTC reel that leaves our Luoyang plant must survive 40-day sea freight, 30 °C temperature swings, and 80 % relative humidity without measurable loss of enamel breakdown voltage (<2 % ΔUB) or strip edge radius (>0.2 mm). Packaging is therefore treated as the last manufacturing step, not a cost line.

H3 Packaging Matrix by Product Form

| Product Form | Stack Weight | Inner Protection | Intermediate | Outer Shield | Securing | Desiccant | Fumigation |

|---|---|---|---|---|---|---|---|

| CTC bare strip bundle (5–19 strips) | 80–120 kg | VCI paper wrap, 50 µm LDPE sleeve | Edge-boards 3 mm, corner posts | 7-ply export plywood box, IPPC stamp | PET strap 4×, angle steel 2× | 4× 10 g silica gel packs | Yes, HT ISPM-15 |

| CTC paper-insulated drum | 300–500 kg | Kraft paper interleave, humidity indicator card | Corrugated fibreboard 5 mm | Double-wall carton + PE shrink hood | Steel band 3× circumferential | 6× 60 g clay desiccant | Yes |

| CTC epoxy-coated spool (PT-500) | 25–35 kg | Spool flange lock, foam ring 5 mm | Carton sleeve | Pallet 1200×1000 mm, stretch film 23 µm | Cross strapping | 2× 5 g sachet | Optional |

| High-voltage CTC (≥110 kV) | Custom | Nitrogen-flushed Al-foil bag, O₂ <0.3 % | Shock-absorber tray EPE 10 mm | Plywood crate, steel frame | Shock indicator label | 8× 60 g molecular sieve | Mandatory |

H3 Sea-Freight Load Plan (40′ HC)

Example: 19-strand CTC, 2.1 mm × 8.0 mm, paper-insulated, 18 t net

Pallet footprint: 1.2 m × 1.0 m × 0.95 m (height)

Weight per pallet: 1.8 t

Pallets per container: 10 (longitudinal) + 10 (transverse) = 20

Total net: 18 t

Total gross: 19.2 t (5 % tare)

Remaining volume: 4 m³ reserved for desiccant replacement kits & documents

Corner castings are lasashed with 25 mm PET composite strap to deck rings; slip sheets 900 µm prevent nail puncture; container floor moisture content verified ≤18 % prior loading.

H3 Climate Data Logging

Each shipment carries a Bluetooth data logger (TempTale-4) recording T & RH every 30 min. CSV file is emailed to customer at discharge; alarm thresholds: T >60 °C or RH >85 %. Historical data prove our shipments average ΔT = 18 °C, RH = 68 %—well inside IEC 60317-0-1 storage limits.

H3 Port & Inland Connectivity

Luoyang is 180 km west of Zhengzhou International Hub (CGO), the largest rail-sea intermodal port in central China. Transit times:

| Destination | Rail to Port | Ocean | Door-Door | Freight Forwarder |

|---|---|---|---|---|

| Hamburg | 24 h (Zhengzhou–Qingdao) | 26 d | 30–32 d | COSCO / HHLA |

| Houston | 36 h (Zhengzhou–Shanghai) | 18 d | 23–25 d | CMA-CGM |

| Dubai | 28 h (Zhengzhou–Ningbo) | 15 d | 20–22 d | OOCL |

Weekly cut-off every Friday; ETD Qingdao/Shanghai following Wednesday. BL, CO, and EN 10204-3.1 inspection certificate released same day via blockchain platform—no courier delays.

H3 Cost Advantage vs. Western Suppliers

By integrating rod drawing, annealing, enameling, and spooling in one 70-acre campus, we eliminate double handling and premium European labor. Typical 40′ HC landed cost (CIF) for 18 t CTC paper-insulated:

Luoyang Xinzhaohe: USD 7.9 / kg

EU Tier-1 mill: USD 11.4 / kg

Saving: 30.7 % ≈ USD 63 k per container

Premium protection, factory-direct price—no trading house margin.

H3 Quick-Check Packaging Audit (before you sign the PO)

- Verify plywood box IPPC stamp on both ends.

- Confirm desiccant quantity ≥40 g per cubic metre.

- Ask for strapping torque report (target 250 Nm).

- Request data logger serial number for online tracking.

Pass all four? Your CTC will arrive as dry, straight, and electrically perfect as the day it left Luoyang.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe for Continuously Transposed Cable

20-Year Metallurgical Track Record in Transformer Winding Materials

Luoyang Xinzhaohe Aluminum Co., Ltd. was founded in 2003 as a vertical rod-to-wire facility dedicated to transformer-grade conductors. Since then we have supplied >120,000 t of rectangular enamelled wire to tier-1 transformer OEMs and rewind shops in 42 countries. Every CTC strand we produce originates from our own 9.5 mm oxygen-free Cu-ETP rod cast in-house; this single-source metallurgy eliminates batch-to-batch resistivity drift (±0.17 % IACS vs ±0.35 % seen in multi-vendor melting). Our process database—2.3 million coil records—feeds an AI-driven SPC dashboard that predicts enamel dielectric life within ±2 % error, giving you design data you can trust when you size for 180 °C hotspot or 1.6 T flux density.

Direct Factory Price without Western Overhead

Because we control the full value chain—rod casting, cold rolling, annealing, enameling, inline testing, and spooling—there are no distributor margins or import agent mark-ups. A typical 48-strand, 2.24 × 7.10 mm CTC (Class 180, 0.12 mm Nomex + 0.08 mm DMD over-wrapped) ships from our Luoyang works at 18–22 % below EU spot price and 14 % below U.S. mill price (LME Cu cathode basis, FOB Qingdao). The table below benchmarks a recent 10 t order shipped to a German OEM in Q1-2024:

| Cost element | Luoyang Xinzhaohe | Western Mill A | Western Mill B |

|---|---|---|---|

| Cu rod premium | 0 | 110 USD/t | 95 USD/t |

| Rolling & enameling | 890 USD/t | 1,280 USD/t | 1,190 USD/t |

| Over-wrap & transposing | 160 USD/t | 240 USD/t | 220 USD/t |

| Margin & logistics | 200 USD/t | 450 USD/t | 410 USD/t |

| Total FOB | 9,850 USD/t | 12,080 USD/t | 11,715 USD/t |

Price validity: 15 days, LME Cu = 8,500 USD/t. No MOQ on standard constructions; 3 t minimum on custom widths.

Deep Customisation Capability—From 5 to 84 Strands

Our transposing line (Germany-imported Schmid precision heads) handles 5–84 enamelled strips in thickness 0.80–3.15 mm and width 2.50–14.00 mm, with stacking height up to 85 mm. Transposition pitch is steplessly adjustable 30–300 mm within ±1 mm tolerance, ensuring eddy-current losses ≤0.35 W/kg at 50 Hz, 1 T. Dielectric options:

Single or dual enamel: Polyamide-imide (PAI, Class 220), polyester-imide (PEI, Class 180), or self-bonding epoxy (Class 155).

Over-wrap: Thermally upgraded paper, Nomex®, PET fleece, or Litz served yarn.

Oil-block: Semi-conductive carbon paper ≤500 Ω/sq for HVDC applications.

We can embed CuCrZr alloy strands for higher short-circuit strength (Rp0.2 ≥ 310 MPa) or supply mixed-Cu/Al CTC to cut weight 38 % when copper theft risk is a concern. All variants are proof-tested at 2.5 kV rms strand-to-strand and 12 kV rms conductor-to-wrap before despatch.

One-Stop Engineering Support

Our laboratory is CNAS-accredited to IEC 60317-16/-28, ASTM B717, and GB/T 7672. We issue a 12-point test report with every coil:

Breakdown voltage (≥8 kV for 0.080 mm enamel).

Concentricity (min 80 %, measured by 8-point laser).

Elongation (≥30 % for Cu-ETP, ≥15 % for CuCrZr).

Spring-back (≤12 °/m for 2.0 × 8.0 mm).

Transposition pitch accuracy (±1 mm).

Data files (Excel, XML) plug directly into your winding CAD—no manual retyping.

Next Step—Get a Datasheet or Quote within 24 h

Send your specification (strands, size, thermal class, over-wrap, pitch) to cathy@transformerstrip.com. We will return:

1. A formal quotation with FOB and DDP options.

2. A 6-page technical datasheet including loss curves, capacitance matrix, and short-circuit force rating.

3. A 300 mm sample loop by express courier free of charge.

Need 50 t/month on a rolling schedule? We stock raw rod for 45 days of forecast and can hold finished inventory at our Rotterdam warehouse to cut lead time to 7 days EU-wide. Partner with the factory that transformer engineers trust when mill price and mill quality both matter.

📉 Import Savings Calculator

Estimate cost reduction by sourcing continuously transposed cable from Luoyang Xinzhaohe.