Table of Contents

Market Insight: Conductivity Of Aluminum Foil

Market Analysis: Transformer Strip/Foil (Aluminum/Copper) – Conductivity Imperatives

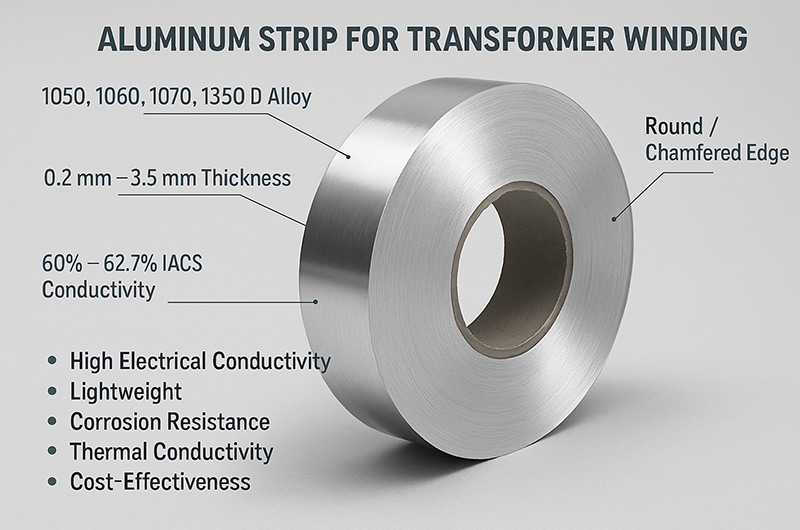

The electrical conductivity of aluminum foil represents a non-negotiable performance parameter within transformer manufacturing, directly dictating core efficiency, thermal management, and long-term operational reliability. As global energy efficiency standards tighten (e.g., DOE 2016, EU Ecodesign), transformer designers increasingly specify aluminum strip/foil with minimum conductivity thresholds, typically ≥61.0% IACS (International Annealed Copper Standard) for high-efficiency units. This demand stems from the fundamental physics of resistive (I²R) losses; a mere 1.0% deviation below target conductivity can elevate winding losses by 1.6-2.0%, accumulating significant wasted energy and heat generation over a transformer’s 30+ year lifespan. Aluminum’s inherent advantage over copper lies in its superior conductivity-to-weight ratio (approximately double that of copper by weight), enabling lighter, more cost-effective windings without compromising current-carrying capacity per cross-sectional area. However, this advantage is critically dependent on achieving and maintaining high-purity metallurgical structures.

Conductivity degradation in aluminum transformer foil primarily originates from trace metallic impurities and suboptimal microstructural conditions. Elements such as iron (Fe) and silicon (Si), even at concentrations below 0.15%, form intermetallic compounds (e.g., Al₃Fe, AlFeSi) that act as electron scattering sites. Manganese (Mn) additions, while beneficial for strength, must be precisely controlled as excess Mn also reduces conductivity. Furthermore, inadequate homogenization during casting or improper annealing during rolling can leave residual stresses or inhomogeneous grain structures, further impeding electron flow. The consequences of insufficient conductivity manifest as elevated operating temperatures, accelerated insulation aging, reduced overload capacity, and potential premature field failures – risks that far outweigh minor initial material cost savings.

Luoyang Xinzhaohe Aluminum leverages two decades of specialized process control to consistently deliver transformer foil meeting stringent conductivity requirements. Our integrated production chain begins with high-purity 1xxx-series ingot casting under rigorously controlled atmospheres, minimizing oxide and hydrogen pickup. Advanced melt purification techniques, including multi-stage filtration and optimized degassing, reduce Fe and Si to ≤0.12% and ≤0.08% respectively. Precision hot and cold rolling schedules, coupled with computer-controlled continuous annealing lines, ensure complete recrystallization and uniform grain structure without over-aging. Every coil undergoes 100% conductivity verification via eddy-current testing calibrated to ASTM E1004 standards, with traceable certification.

The following table summarizes critical conductivity specifications versus typical industry impacts:

| Conductivity Level (% IACS) | Typical Purity/Process Condition | Impact on Transformer Performance |

|---|---|---|

| ≥62.0 | Ultra-high purity (Fe<0.08%) with optimized annealing | Minimal I²R losses, optimal thermal performance, extended insulation life |

| 61.0 – 61.9 | Standard high-purity grade (Fe<0.12%) | Meets Tier 2 efficiency standards; acceptable for most distribution transformers |

| 59.0 – 60.9 | Elevated impurities or suboptimal annealing | Increased losses (2-4% above spec), higher operating temperature, reduced lifespan |

| <59.0 | Significant impurity content or processing defects | Non-compliant with major efficiency standards; high field failure risk |

For B2B sourcing professionals, prioritizing certified conductivity data from metallurgically competent suppliers is paramount. Accepting marginal conductivity values incurs substantial lifetime operational costs through energy waste and reliability risks. Luoyang Xinzhaohe Aluminum’s process discipline ensures conductivity consistency, directly supporting transformer manufacturers in achieving design efficiency targets and mitigating total cost of ownership. Quality in aluminum foil conductivity is not an incremental specification – it is the foundation of transformer performance economics.

Technical Specs: Conductivity Of Aluminum Foil

Technical Specifications: Conductivity of Aluminum Foil for Transformer Applications

Luoyang Xinzhaohe Aluminum Co., Ltd. has over two decades of specialized expertise in the production and supply of high-purity aluminum strip and foil for critical electrical applications, including transformers, inductors, and power distribution systems. A fundamental performance parameter in such applications is electrical conductivity, which directly influences efficiency, thermal management, and overall system reliability. The conductivity of aluminum foil is intrinsically linked to alloy composition, temper, and manufacturing precision. Our standard product offering is based on 1060, 1070, and 8011 aluminum alloys, with primary emphasis on 1060 (Al ≥99.6%) for high-conductivity requirements. These alloys are processed under strict quality controls to achieve optimal grain structure and minimal impurity content, ensuring consistent electrical performance.

Electrical conductivity is measured in percent International Annealed Copper Standard (%IACS), which compares the material’s conductance relative to annealed copper. High-purity aluminum foils typically achieve conductivity levels between 59% and 62% IACS when fully annealed. At Luoyang Xinzhaohe, our aluminum transformer foils consistently meet or exceed 61% IACS, reflecting our stringent process controls and raw material selection. This level of conductivity is essential for minimizing resistive losses (I²R losses) in transformer windings, thereby improving energy efficiency and reducing operational temperature rise.

In addition to bulk conductivity, dimensional precision and edge quality are critical for reliable performance in automated winding and layer insulation processes. Our aluminum foils undergo precision slitting with a tolerance of ±0.002 mm, ensuring uniform width and consistent layer stacking. This tight tolerance minimizes edge misalignment and reduces the risk of dielectric breakdown in high-voltage applications. Furthermore, our proprietary slitting and edge-trimming technology produces burr-free edges, with burr height controlled to less than 3% of material thickness. This eliminates the risk of internal short circuits and enhances the dielectric integrity of the final component.

All foils are supplied in controlled environments to prevent oxidation and surface contamination, which can adversely affect contact resistance and long-term reliability. Surface resistivity is maintained through clean handling protocols and optional protective coatings upon request. The combination of high conductivity, precise dimensional control, and defect-free edges makes our aluminum foils ideal for high-efficiency transformers, including distribution, traction, and renewable energy system transformers.

The following table summarizes key technical parameters for our standard aluminum transformer foil product line:

| Parameter | Specification |

|---|---|

| Alloy | 1060, 1070, 8011 |

| Purity (Al) | ≥99.6% (1060) |

| Temper | O (Fully Annealed) |

| Conductivity (%IACS) | ≥61% |

| Thickness Range | 0.08 mm – 0.50 mm |

| Width Range | 20 mm – 600 mm |

| Slitting Tolerance | ±0.002 mm |

| Edge Burr Height | <3% of thickness |

| Surface Condition | Clean, oxide-controlled, no grease residue |

| Core ID | 76 mm, 152 mm (customizable) |

| Max Tensile Strength | 70–95 MPa |

| Elongation at Break | ≥25% |

These specifications are validated through in-house testing using eddy current conductivity meters, optical profilometry for edge analysis, and precision micrometry. All batches are accompanied by material test reports (MTRs) and are compliant with GB/T 3880 and IEC 60146 standards.

Factory Tour: Manufacturing

Manufacturing Process for High-Conductivity Aluminum Transformer Foil

Luoyang Xinzhaohe Aluminum CO., Ltd leverages 20+ years of metallurgical expertise to produce aluminum transformer foil meeting stringent electrical conductivity requirements. Our process begins with high-purity aluminum ingot casting (99.7%+ Al), followed by homogenization annealing to eliminate segregation. The critical cold rolling phase employs computer-controlled tandem mills with precise interstand tension management. Reduction ratios are optimized between 85–92% to achieve target foil thicknesses of 0.08–0.30 mm while minimizing work hardening. In-process thermal profiling ensures controlled recrystallization, preserving electrical conductivity by preventing excessive dislocation density. Roll gap tolerances are maintained within ±2 µm, critical for uniform current distribution in transformer windings.

Precision slitting follows cold rolling, utilizing servo-driven rotary shear cutters with dual-axis laser alignment systems. This stage achieves edge straightness deviations of ≤0.05 mm over 1,000 mm lengths, essential for minimizing interlayer gaps during coil winding. Tension is dynamically regulated at 40–60 N/mm² to prevent edge waviness or width variations exceeding ±0.10 mm. All slitting tools undergo daily metrological verification per ISO 1302 surface roughness standards, ensuring Ra ≤ 0.4 µm to reduce dielectric losses.

Edge conditioning represents a non-negotiable safety step for transformer applications. Foil edges pass through an electrochemical deburring system operating at 12–15 V DC, removing micro-burrs to <3 µm height. This eliminates potential corona discharge points during high-voltage operation. Simultaneously, edge rounding is applied via precision roller burnishing, achieving a consistent 15–25 µm radius. Each foil reel undergoes 100% edge profile scanning using non-contact optical profilometry before release.

Quality control integrates real-time monitoring and batch validation. Conductivity is verified at 1-meter intervals via four-point probe testing (ASTM E1004), with minimum acceptance at 61.0% IACS (20°C). Mechanical properties are cross-checked through microhardness mapping (HV 25–35) and tensile testing (YS 35–50 MPa, UTS 65–85 MPa). Dimensional compliance is validated using laser micrometers recording thickness profiles across the foil width. Final certification includes traceability to melt chemistry reports (Fe ≤ 0.12%, Si ≤ 0.08%) and annealing cycle documentation. All test data is archived in our ERP system for full lot traceability, supporting customer audits per IEC 60204-1 standards.

This integrated process ensures our aluminum transformer foil delivers consistent 61.5–62.5% IACS conductivity with zero edge defects, directly enhancing transformer efficiency and thermal stability. Luoyang Xinzhaohe’s adherence to these protocols has established our foil as a preferred material for Tier-1 transformer manufacturers across 17 countries.

Packaging & Logistics

Export Packaging for Aluminum Foil – Ensuring Integrity in Global Shipments

At Luoyang Xinzhaohe Aluminum Co., Ltd., with over two decades of specialized manufacturing experience in transformer strip and foil products, we recognize that packaging is not merely a logistical necessity but a critical component in preserving material integrity throughout international distribution. Our export packaging protocols are engineered to meet the rigorous demands of sea freight, ensuring aluminum foil products arrive at their destination with uncompromised dimensional stability, surface quality, and electrical performance.

All aluminum foil coils designated for export are mounted on high-strength wooden pallets constructed from kiln-dried, ISPM 15-compliant hardwood. These pallets are designed to withstand dynamic loading conditions encountered during ocean transport, including vibration, compression, and lateral shifting. The structural integrity of the pallet is reinforced with steel strapping and corner protectors, minimizing the risk of coil deformation during handling and transit. Each pallet is rated for standard containerized shipping loads and conforms to international maritime safety standards.

To mitigate the risk of moisture-induced surface oxidation—a critical concern for conductivity-sensitive applications—each coil is hermetically sealed in multi-layer moisture-proof film. This packaging system consists of an inner layer of vapor barrier film, laminated with aluminum foil and high-density polyethylene, providing a water vapor transmission rate (WVTR) of less than 0.5 g/m²·24hr at 38°C and 90% relative humidity. The film is heat-sealed circumferentially and longitudinally to form a continuous protective envelope, effectively isolating the aluminum from ambient humidity and saline atmospheres typical in marine environments.

Additional protective measures include desiccant packs placed within the sealed cavity to absorb residual moisture, and anti-corrosion paper interleafing between coil wraps where applicable. Labels affixed to the exterior of the package are printed with UV-resistant ink and include product specifications, batch traceability codes, handling instructions, and orientation markers to ensure correct unloading and processing at the destination facility.

Our packaging methodology is validated through accelerated climatic testing simulating 45-day sea voyages across tropical and temperate zones. These tests confirm the efficacy of the moisture barrier under sustained high-humidity and temperature-fluctuation conditions. Furthermore, all packaging materials are selected to comply with REACH, RoHS, and IMSBC Code requirements, ensuring regulatory acceptance across global markets.

For transformer-grade aluminum foil, where surface purity directly influences electrical conductivity and insulation compatibility, these packaging standards are non-negotiable. Luoyang Xinzhaohe’s integrated approach—combining robust mechanical support with advanced moisture protection—ensures that every shipment meets the exacting performance expectations of our international clients. This commitment underscores our role not only as a supplier but as a technically accountable partner in the global power transmission and electronics supply chain.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe: Precision Aluminum Foil for Critical Transformer Applications

Luoyang Xinzhaohe Aluminum CO., Ltd leverages 20+ years of specialized metallurgical expertise to deliver aluminum transformer foil meeting the most stringent conductivity and dimensional requirements. Our vertically integrated production ecosystem, from raw material sourcing to finished foil, ensures unparalleled control over the critical properties defining electrical performance. As a dedicated supplier to the global transformer industry, we understand that conductivity consistency directly impacts core loss, thermal management, and transformer efficiency. Our facility operates under ISO 9001 and ISO 14001 certified quality management systems, with dedicated in-house laboratories conducting real-time metallurgical analysis to guarantee compliance with IEC 60138 and ASTM B209 standards.

Our continuous casting-rolling production lines are engineered specifically for high-purity aluminum electrical conductor grades. We utilize 99.70%+ Al9970 and 99.80%+ Al9980 ingot, processed through controlled homogenization and multi-stage cold rolling. The defining step occurs in our oxygen-free annealing furnaces, where precise temperature profiling (±3°C tolerance) and atmosphere control eliminate intermetallic precipitation and optimize recrystallization. This proprietary thermal treatment achieves stable electrical conductivity values consistently within 61.0% to 62.5% IACS for fully annealed foil, exceeding the minimum 61.0% IACS required by major transformer OEMs. Thickness tolerances are maintained at ±2.5% for gauges ranging from 0.20mm to 0.80mm, critical for minimizing eddy current losses in wound cores.

Key performance metrics are rigorously validated through our quality assurance protocols

| Parameter | Specification Range | Testing Frequency | Method |

|---|---|---|---|

| Conductivity (IACS) | 61.0% – 62.5% | Per melt batch | IEC 60468 |

| Thickness Tolerance | ±2.5% (0.20-0.80mm) | Continuous inline | Laser micrometer |

| Surface Roughness | Ra ≤ 0.35 µm | Hourly | Profilometer |

| Tensile Strength | 40-60 MPa | Per coil | ASTM E8 |

Supply chain resilience is engineered into our operational model. With an annual production capacity exceeding 20,000 metric tons of transformer-grade aluminum strip and foil, we maintain strategic inventory buffers of critical alloys to mitigate upstream volatility. Our logistics network integrates with major global ports and offers JIT delivery scheduling tailored to transformer manufacturing cycles, supported by digital shipment tracking and full material traceability from ingot lot to finished coil. This ensures zero disruption to your production lines while meeting the tight delivery windows demanded by the power infrastructure sector.

Partnering with Luoyang Xinzhaohe means accessing engineered material solutions backed by metallurgical rigor and supply chain certainty. We collaborate with transformer designers to optimize foil specifications for your core architecture, providing comprehensive material test reports and technical documentation for audit compliance. Request conductivity validation data or discuss your specific transformer foil requirements to ensure your next production run achieves maximum electrical efficiency. Contact Cathy directly at cathy@transformerstrip.com to initiate a technical consultation and receive sample specifications for immediate evaluation.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing conductivity of aluminum foil directly from China.