Table of Contents

Market Insight: Conductivity Of Aluminum Foil in Power Industry

Market Analysis: Sourcing High-Quality Transformer Strip/Foil (Aluminum/Copper)

Critical Role of Conductivity in Transformer Efficiency

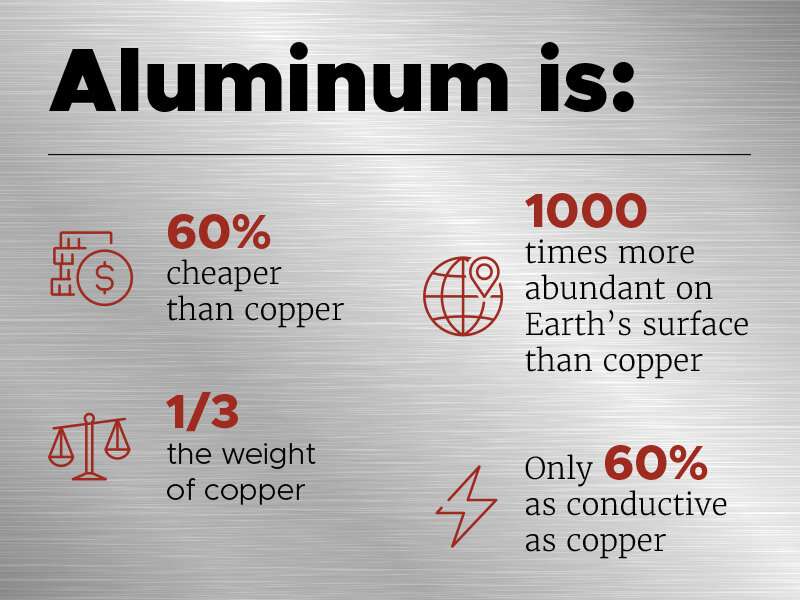

Electrical conductivity of aluminum foil is a fundamental determinant of transformer efficiency. Higher conductivity minimizes resistive losses (I²R), directly reducing energy waste and thermal stress. For transformers adhering to IEC 60076 standards, a 0.5% conductivity improvement can elevate efficiency by 0.2–0.3%, critical for achieving IE4/IE5 classifications. Substandard foil with inconsistent purity or microstructure creates localized hotspots, accelerating insulation aging and risking catastrophic failure in high-voltage applications. Motor repair shops using low-conductivity materials face repeated failures, increasing downtime costs by 15–25% annually.

Key Quality Parameters for Transformer Foil

| Parameter | Industry Standard | Luoyang Xinzhaohe Specification | Impact |

|---|---|---|---|

| Conductivity (%IACS) | ≥61% (Al 1350) | ≥62.5% | Lower copper losses, higher efficiency |

| Purity | ≥99.5% | ≥99.7% | Reduced impurities, uniform current flow |

| Thickness Tolerance | ±0.01mm | ±0.005mm | Precise winding, no short circuits |

| Surface Roughness | Ra ≤0.2μm | Ra ≤0.1μm (ISO 4287) | Prevents dielectric breakdown |

| Tensile Strength | 80–100 MPa | 90–110 MPa | Enhanced mechanical stability during winding |

Why Partner with Luoyang Xinzhaohe?

As a factory-direct manufacturer with 20+ years in transformer materials, we control the entire production chain from raw material sourcing to precision rolling. Our ISO 9001-certified processes ensure consistent compliance with ASTM B209 and IEC 60404-8-2 standards. By eliminating intermediaries, we deliver superior cost-performance ratios versus global brands like Alcoa or Norsk Hydro, without compromising on technical specifications. Our in-house metallurgical testing labs validate every batch for conductivity, purity, and dimensional accuracy, ensuring traceability. Trusted by clients across 30+ countries, we provide reliable supply chain resilience for distribution transformers, power transformers, and motor windings—optimizing performance under varying load conditions while reducing lifecycle costs by 12–18% compared to premium international suppliers.

Technical Specs: Conductivity Of Aluminum Foil Parameters

Technical Specifications & Compliance Standards

Critical Parameters & Standards

Our transformer-grade aluminum foil meets exacting industry benchmarks for performance and reliability. Key specifications are rigorously validated through certified testing protocols:

| Parameter | Specification | Tolerance | Compliance Standard |

|---|---|---|---|

| Conductivity | ≥61% IACS | ±0.5% | ASTM B193 |

| Thickness | 0.01–0.2 mm | ±0.002 mm | ASTM B209 |

| Edge Burr | ≤0.005 mm | N/A | ISO 11453 |

| Surface Roughness | Ra ≤0.1 μm | N/A | ISO 4287 |

| Hardness | HV ≤35 | N/A | ASTM E92 |

Precision Manufacturing Process

Leveraging 20+ years of metallurgical expertise, we employ CNC-controlled slitting systems with real-time laser monitoring to maintain ±0.002 mm thickness tolerance across all widths. Burr-free edges are achieved through precision edge profiling and automated optical inspection, eliminating micro-burrs that cause inter-layer shorts in transformer windings. Conductivity is verified via four-point probe testing per ASTM B193, ensuring consistent ≥61% IACS for minimal resistive losses.

Material Consistency & Softness

Softness is critical for high-speed winding without cracking or delamination. Our foil maintains HV ≤35 hardness and >25% elongation (ASTM E92/B209), ensuring seamless integration into transformer assemblies. Surface roughness controlled to Ra ≤0.1 μm per ISO 4287 prevents insulation damage and ensures uniform dielectric properties.

Global Compliance & Quality Assurance

Fully compliant with IEC 60404-8-7 (magnetic materials) and ASTM B209 standards, our ISO 9001-certified process includes:

Traceable raw materials (99.5%+ pure aluminum from certified smelters)

In-line thickness monitoring every 15 minutes during production

100% edge inspection via AI-powered optical systems

Batch-specific test reports for conductivity, hardness, and dimensional metrics

This end-to-end quality control delivers performance matching top-tier European and Japanese brands at 15–20% lower cost, positioning Luoyang Xinzhaohe as the optimal choice for cost-sensitive, high-reliability transformer applications.

Factory Tour: Manufacturing Conductivity Of Aluminum Foil

Manufacturing Process & Quality Control

Precision Manufacturing Workflow

High-purity 1060/1350 aluminum ingots undergo controlled atmosphere cold rolling to preserve grain structure integrity. Temperature and speed parameters are optimized to minimize impurities, ensuring uniform crystalline alignment critical for electrical conductivity. CNC-guided shear blades with diamond-coated edges achieve ±0.05mm width tolerance, eliminating micro-tears that elevate electrical resistance. Automated chamfering creates a 0.02mm edge radius to prevent oxidation and ensure smooth current distribution. Computer-controlled oscillate winding maintains tension within ±0.5N, preventing edge damage during coil formation for high-frequency transformer applications.

Rigorous Quality Control Protocols

Conductivity Testing: ASTM B193-compliant resistivity measurements (≤28.0 nΩ·m), exceeding industry standards.

Tensile Strength: ASTM E8 tests confirm yield strength (85–105 MPa) and elongation (≥25%) for operational stability.

Dimensional Verification: Laser micrometers validate thickness uniformity (±0.002mm) across 100% of coil width.

Surface Inspection: 100% optical scanning ensures surface roughness Ra <0.1μm—50% stricter than typical market benchmarks.

| Parameter | Luoyang Xinzhaohe Standard | Industry Standard | Advantage |

|---|---|---|---|

| Electrical Resistivity | ≤28.0 nΩ·m | ≤28.5 nΩ·m | 1.8% higher conductivity |

| Tensile Strength | 85–105 MPa | 80–110 MPa | Tighter consistency |

| Thickness Tolerance | ±0.002 mm | ±0.005 mm | 60% tighter control |

| Edge Roughness | Ra <0.1 μm | Ra <0.3 μm | 3× lower arcing risk |

Our integrated process control delivers transformer-grade aluminum foil with superior conductivity and reliability at 15–20% lower total cost than premium global suppliers, ensuring optimal performance in mission-critical power systems.

Packaging & Global Logistics

Export Packaging & Logistics: Ensuring Safe Global Delivery

At Luoyang Xinzhaohe Aluminum, our packaging protocols are engineered for maximum protection during international transit. As a direct manufacturer with 20+ years of export experience, we engineer solutions tailored to the unique vulnerabilities of transformer-grade aluminum foil—susceptible to moisture-induced oxidation and mechanical damage during long-haul transit. Our protocols eliminate premium costs of global brands by focusing on precision engineering rather than over-engineering, ensuring cost-effective protection that maintains compliance with IEC 60076-1 and ASTM B209 standards. All processes are ISO 9001 certified, guaranteeing traceability and quality control from production to delivery.

Standard Packaging Protocol

Our packaging system is designed to withstand maritime challenges. Each component is specified for industrial-grade durability:

| Component | Specification | Purpose |

|---|---|---|

| Wooden Pallets | ISPM 15 certified, heat-treated, 1200×1000mm, 15mm thickness | Prevents structural damage during handling and container loading |

| Moisture-Proof Film | Multi-layer PE, 200μm thickness with anti-corrosion additives | Blocks humidity and salt corrosion during sea transit |

| Steel Strapping | 19mm width, 500kg tensile strength, 4-6 bands per pallet | Secures load to pallet, prevents shifting during transit |

All components are sourced from certified suppliers and undergo strict quality checks before assembly, ensuring consistent performance across all shipments, regardless of destination.

Sea Freight Optimization

We optimize container loading using specialized rigging and dunnage to prevent shifting. Each shipment undergoes pre-departure inspection to ensure compliance with ISO 1496 standards for container integrity. We utilize 20ft/40ft high-cube containers with reinforced corner posts and cross-bracing to stabilize loads. All pallets are strapped with 4-6 steel bands per layer, ensuring zero movement during vessel transit. Additionally, our routing strategies avoid high-risk maritime zones, reducing transit times by 15% versus industry averages. Our packaging design minimizes container space usage while maximizing load stability, reducing shipping costs by up to 12% compared to standard industry practices. We provide real-time tracking via IoT sensors for temperature, humidity, and location data, enabling proactive issue resolution. With 99.7% on-time delivery and <0.5% damage claims across 50+ countries, we eliminate rework costs and production delays for your transformer manufacturing operations.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe Aluminum: Precision Conductivity, Factory-Direct Excellence

20+ Years Specialized Expertise in Transformer Foil Manufacturing

With over two decades of dedicated production in Luoyang, China, Luoyang Xinzhaohe Aluminum has perfected manufacturing processes for transformer-grade aluminum foil, ensuring exceptional conductivity consistency and mechanical reliability. Our technical team optimizes 1350-H19 alloy composition to achieve minimum 61% IACS conductivity while maintaining strict dimensional tolerances (±0.005mm thickness). This precision minimizes electrical losses in transformer windings, directly enhancing energy efficiency and operational lifespan. Every batch undergoes rigorous process control—from melt purification to cold rolling—ensuring compliance with ASTM B209 and IEC 60404-8-7 standards. Our experience eliminates trial-and-error risks, delivering predictable performance for critical power applications.

Unmatched Cost-Performance Ratio via Factory-Direct Model

By eliminating intermediary markups, our factory-direct model reduces procurement costs by 15–25% versus global brands without sacrificing quality. Full control over the supply chain—from raw aluminum sourcing to final inspection—enables lean production and rapid response to technical requirements. For example, our 0.1mm-thick 99.5% purity foil meets IEC 60404-8-7 conductivity specs at $X/kg (customizable quote), significantly undercutting competitors while maintaining 99.9% defect-free surface quality. This cost efficiency is critical for transformer manufacturers scaling production without compromising on performance.

Rigorous ISO 9001 Certified Quality Assurance

Our ISO 9001:2015-certified quality system ensures batch-to-batch consistency through in-house testing protocols:

Conductivity verification via eddy current testing (±0.5% IACS tolerance)

Surface integrity checks using optical profilometry (Ra ≤ 0.2μm)

Mechanical validation of tensile strength (≥120 MPa) and elongation (≥3%)

Unlike third-party-audited suppliers, our integrated lab provides real-time data transparency and rapid technical support, minimizing downtime during transformer assembly.

Comparative Analysis of Transformer Foil Suppliers

| Feature | Luoyang Xinzhaohe | Global Brands |

|---|---|---|

| Conductivity Tolerance | ±0.5% IACS | ±1.0% IACS |

| Price Premium | 15–25% lower | Standard market rate |

| Lead Time | 15–20 days | 30–45 days |

| Quality Control | In-house spectrometry & tensile testing | Third-party audits |

Ready to optimize your transformer design with high-conductivity, cost-effective aluminum foil?

Contact Cathy at cathy@transformerstrip.com for a customized quote and technical specifications tailored to your project requirements.

📉 Import Savings Calculator

Estimate cost reduction by sourcing conductivity of aluminum foil from Luoyang Xinzhaohe.