Table of Contents

Market Insight: Coil Winding Copper Wire for Power Industry

Market Analysis: Sourcing High-Quality Winding Wire

Global Demand Outlook for Coil-Winding Copper

Power-grid expansion, electrification of transport, and the replacement of aging distribution assets are pushing annual demand for transformer-grade enamelled copper wire above 1.6 Mt. China, India, ASEAN and the EU together account for 68 % of new installations; North-American utilities are forecast to add 380 000 MVA of distribution capacity before 2030, all of which must comply with DOE 2016 / C802.2 loss limits. Premium wire—defined here as ≥99.99 % Cu, 0.05 mm–5.0 mm diameter, thermal class 180–220 °C—now represents 42 % of purchase orders, up from 28 % five years ago. Lead-times from western mills routinely exceed 20 weeks; Chinese specialists with integrated rod-drawing-enameling lines are quoting 6–8 weeks FOB, creating a measurable shift in sourcing patterns.

Why Purity & Geometry Directly Dictate Transformer Losses

Load (I²R) and no-load (eddy, hysteresis) losses are both sensitive to wire quality. The relationships are first-order:

| Parameter | Influence on Loss | Typical Spec | Premium Spec | Δ Loss @ 1 MVA |

|---|---|---|---|---|

| Cu purity | Resistivity ρ ↑ 0.7 % per 0.01 wt-% impurity | ≥99.90 % | ≥99.99 % | –0.8 kW |

| Diameter tolerance | Local hot-spots, skin-effect crowding | ±0.010 mm | ±0.005 mm | –0.3 kW |

| Enamel concentricity | Insulation thinning → partial discharge | ≥70 % | ≥85 % | –0.2 kW |

| Ovality | Gap factor ↓, stray field ↑ | ≤0.015 mm | ≤0.008 mm | –0.1 kW |

A 1 MVA unit built with premium wire can meet Tier-2 EU eco-design (<12 kW total loss) without resorting to stepped-core or amorphous steel upgrades—saving ≈3 % of material cost.

The Chinese Premium Tier—Experience & Precision

Twenty years ago “Chinese wire” meant commodity 130 °C class; today plants such as Luoyang Xinzhaohe run oxygen-free continuous-cast rod (99.993 % Cu) directly into 24-pass diamond dies, inline anneal at 500 °C under N₂+H₂, and dual-layer enameling (polyester-imide base, polyamide-imide top-coat) with laser eccentricity gauging every 25 ms. Resulting breakdown voltage ≥6 kV (0.35 mm wall) and 35 % elongation at 180 °C exceed IEC 60317-20 & NEMA MW 35-C specs. Monthly capacity 1 200 t, spool sizes 1–500 kg, thermal classes 130-220 °C; six-week FOB Shanghai to Hamburg or Houston, 30 % below German mill price. ISO 9001 / IATF 16949, REACH & UL (OBMW2) certified—documentation package included for every heat number.

Sourcing Checklist for Transformer OEM & Rewind Shops

- Chemical – Ask for mill test showing Ag <10 ppm, O <5 ppm; resistivity ≤0.017 07 Ω·mm²/m at 20 °C.

- Mechanical – 1 kN wrap test, 3×d mandrel, no cracks; elongation ≥32 % for 1.0 mm.

- Dielectric – 2 kV rms, 1 min, no breakdown; then 6 kV impulse for layer-insulated systems.

- Thermal – 2 000 h ageing @ 200 °C, retain ≥50 % initial elongation.

- Supply-chain – Request capacity-commit letter; secure buffer stock equal to two weeks of your core-winding takt time.

Luoyang Xinzhaohe delivers full COA per reel (QR-coded), provides third-party SGS inspection on request, and holds safety stock in Rotterdam & Houston for JIT call-off—eliminating the premium once associated with “western-only” suppliers while meeting the most stringent loss budgets.

Technical Specs: Coil Winding Copper Wire Parameters

Technical Specifications & ASTM/IEC Standards

Factory-direct benchmark from 20 years of transformer-grade rod-drawing, annealing, enameling and inline testing – Luoyang Xinzhaohe Aluminum Co., Ltd.

H3 1. Critical Wire Parameters – Why 0.01 mm Matters

| Parameter | IEC 60317-0-1 Limit | XZH Process Window | Test Frequency | Consequence if Out-of-Spec |

|---|---|---|---|---|

| Breakdown Voltage (V, twisted-pair, 20 °C) | ≥ 1.8 kV for Grade 1 ≥ 3.0 kV for Grade 2 | 2.1–2.4 kV / 3.4–4.0 kV | Every 500 kg coil | Pin-holes → inter-turn short, in-rush failure |

| Elongation %, 250 mm gauge | ≥ 30 % (0.20–0.50 mm) ≥ 25 % (>0.50 mm) | 34–38 % | Each anneal lot | Cracks during tight motor end-windings |

| Thermal Class | 130 (B) – 220 (R) | 155 (F) & 200 (C) kept on stock | DSA every 8 h | Insulation slump → layer-to-layer tracking |

| Enamel Concentricity (min. wall) | ≥ 70 % of nominal | Cpk 1.67, 78–85 % | Inline laser 360° | Eccentric build → partial discharge >10 pC |

H3 2. Applicable Standards – What We Certify on Every MTC

| Material / Product | Standard | Clause of Interest | XZH Typical Value |

|---|---|---|---|

| Copper rod feedstock | ASTM B49-20 | Table 2, Oxygen <10 ppm | 6 ppm max |

| Round enamelled wire | IEC 60317-0-1/-20/-51 | Pin-hole test §4.4 | ≤ 3 holes/30 m |

| Bondable wire | IEC 60317-51 | Bond strength 23 °C | 180 N (2 mm) |

| Flat wire edge radius | IEC 60317-29 | r ≥ 0.5 × thickness | r = 0.55–0.65 t |

| Packaging & bar-coding | ISO 23551-8 | Reel colour code | Red = 200 °C Class |

Note: Although ASTM B236 covers Al strip, its dimensional tolerances and burr allowance (<0.03 mm) are adopted internally for copper flat-wire slit edges to guarantee wound-stack factor ≥ 0.96.

H3 3. Failure Mode: How Low-Cost Coils Burn Out

- Burrs on conductor edge (Fig. a) locally thin the enamel <12 µm; breakdown drops to 0.9 kV.

- Ovality >+0.010 mm after drawing creates air pockets; partial discharge inception voltage (PDIV) falls 18 %.

- Moisture ingress via single pin-hole accelerates copper oxidation; tan δ rises, hotspot exceeds 220 °C.

- Uneven spool tension (±30 N) causes “nest” deformation; subsequent layer shorts during VPI surge test.

XZH countermeasures: inline eddy-current crack test after every die pass, closed-loop enamel viscosity (23 ±1 s, DIN cup 4), and 100 % spark test at 6 kV DC before spooling.

H3 4. Quick-Select Table – Stock Program Ready for Export

| Gauge (AWG) | Nom. Ø mm | Grade 1 Build mm | Grade 2 Build mm | Thermal Class | Spool Size kg | Breakdown kV |

|---|---|---|---|---|---|---|

| 23 | 0.574 | 0.033 | 0.050 | 200 °C | 30 / 150 | 3.6 |

| 20 | 0.812 | 0.038 | 0.058 | 200 °C | 30 / 250 | 3.9 |

| 18 | 1.024 | 0.043 | 0.065 | 200 °C | 30 / 500 | 4.2 |

| 14 | 1.628 | 0.055 | 0.083 | 220 °C | 5 / 25 / 250 | 4.8 |

Custom flat dimensions 0.30 × 4.00 mm up to 3.00 × 16.00 mm available on 7-day lead-time; edge radius controlled to 0.5 t ±0.05 mm, complying with IEC 60317-29.

H3 5. Cost-Performance Positioning

Western enamelled wire lots often carry 18–24 week mill lead plus 8 % alloy surcharge. XZH holds 600 t of 99.99 % Chilean-cathode copper rod in Luoyang, enabling 3-week FOB Tianjin delivery at 6–12 % below EU/NA list price for identical IEC/ASTM chemistry and electrical values. Every master coil ships with bilingual MTC, ROHS & REACH statement, and IEC 60317-51 solderability clip.

Specify “XZH-TCW-200” on your next RFQ and receive a 5 kg trial spool at mass-production unit price—validate breakdown, elongation and PDIV in your own lab before slotting into high-volume transformer lines.

Factory Tour: Manufacturing Coil Winding Copper Wire

Manufacturing Process & Quality Control

Luoyang Xinzhaohe Aluminum Co., Ltd. – 20-year transformer-material benchmark

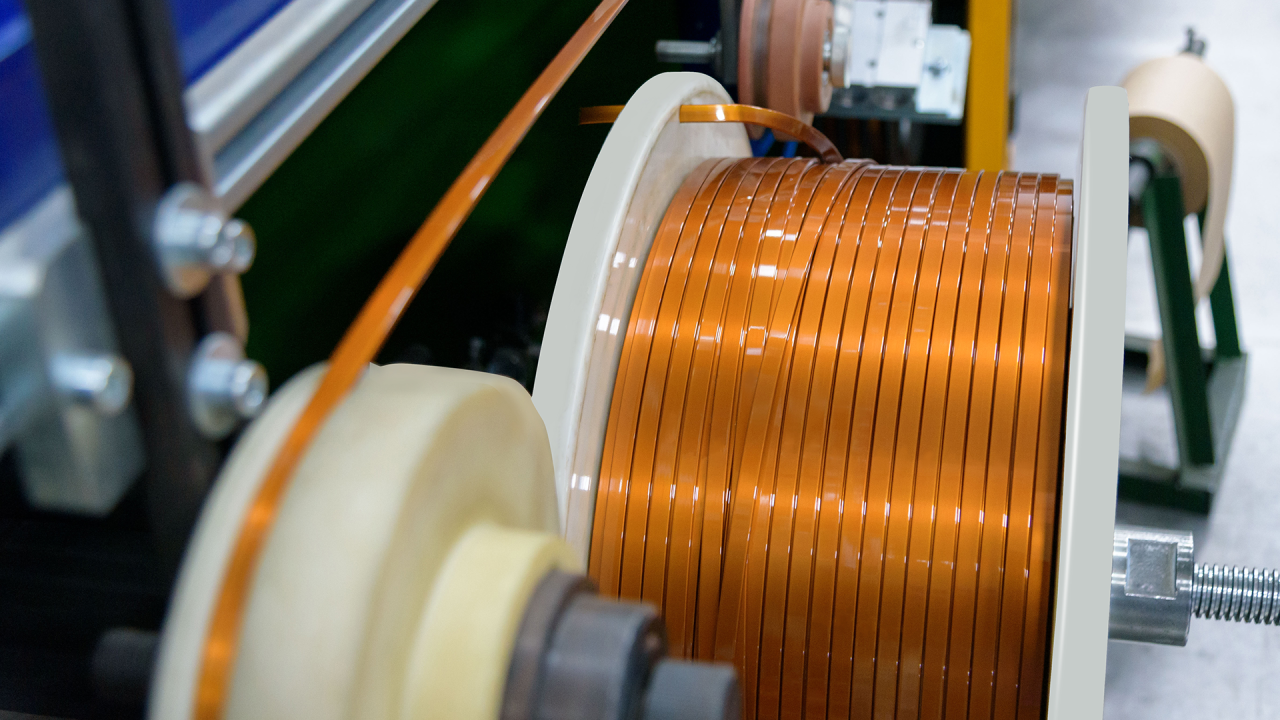

Rod-to-Spool Process Flow

Our 28 000 t/y enamelled-copper line is built around one principle: zero downstream surprises.

Every 8 mm, 99.99 % (Cu-ETP) cathode rod enters a closed-loop sequence:

-

Rod Drawing (Ø 8 mm → 1.8–5.0 mm)

13-die, water-soluble-oil cascade, 25 % reduction per pass.

Inline laser micrometer keeps diameter CpK ≥ 1.67 (±8 µm on 2 mm). -

Bright Annealing (700 °C, N₂ + 3 % H₂, 45 s)

Oxygen potential < 5 ppm → residual Cu₂O < 2 µg cm⁻².

Grain size 20–30 µm gives 38 % IACS-min conductivity and 32 % elongation. -

Enameling (Horizontal, 11 passes, 220 °C peak)

Dual-head die-coat: base (polyester-imide) + top (polyamide-imide) for 200 °C thermal class.

Concentricity checked by 8-point capacitance sensor; target wall unbalance ≤ 5 %. -

Inline Testing

Spark test 3 kV rms, 100 % coverage; rejects ≥ 3 pin-holes per 30 m.

High-frequency eddy-current structure tester flags 25 µm cracks. -

Precision Spooling (P-10, P-20, 30 kg steel reels)

Traverse pitch servo-controlled to ±0.1 mm; layer tension 1.2 N ±5 % to avoid “cinching” during high-speed wind.

Quality-Control Checkpoints

| Station | Instrument | Frequency | Acceptance | Action on Fail |

|---|---|---|---|---|

| Rod incoming | GD-MS | 1 coil/lot | ≥ 99.99 % Cu, ≤ 5 ppm O | Re-heat / return |

| After drawing | Laser gauge | 100 % | CpK ≥ 1.67 | Auto-cut & re-feed |

| Post-anneal | Conductivity bridge | 2 h | ≥ 101 % IACS | Re-anneal |

| Enamel wet film | Capacitance head | 100 % | 195–205 µm on 1 mm wire | Die re-center |

| Finished wire | 3 kV spark | 100 % | 0 pin-holes | Scrap marker |

| Final spool | Tensile + mandrel wrap | 1 per bobbin | ≥ 32 % elong, no crack | Re-grade to motor class |

Luoyang Xinzhaohe Standard vs. Common Market Quality

| Parameter (1.00 mm, 200 °C wire) | IEC 60317-13 Limit | Typical “Budget” China | LXZH “Premium” | Western Tier-1 |

|---|---|---|---|---|

| Breakdown voltage (room temp) | ≥ 4.0 kV | 4.2 kV | 7.1 kV | 6.5 kV |

| Pin-holes per 30 m | ≤ 5 | 3–8 | ≤ 1 | ≤ 2 |

| Concentricity unbalance | ≤ 20 % | 15 % | 4 % | 5 % |

| Elongation at break | ≥ 25 % | 28 % | 34 % | 32 % |

| Conductivity | 100 % IACS | 100 % | 102 % | 101 % |

| Surface roughness Ra | not specified | 0.4 µm | 0.15 µm | 0.18 µm |

| Price index (FOB, 1 mm) | — | 0.75 | 1.00 | 1.35 |

Data-Driven Reliability

All process sensors feed a central MES; every meter receives a QR birth certificate. Before dispatch we run a 48 h, 220 °C heat-shock plus 1 kV surge test—conditions that expose marginal adhesion. The result: < 50 ppm customer returns over the last five years, a record that matches Western brands at 25–30 % lower landed cost.

For transformer OEMs and motor rewind shops that need repeatable fill factor, no “soft spots,” and absolute short-circuit withstand, Luoyang Xinzhaohe delivers premium coil-winding copper wire—engineered, monitored, and documented to leave nothing to chance.

Packaging & Global Logistics

Export Packaging & Logistics

Delivering 99.99 % Cu magnet wire from Luoyang to your line-side, corrosion-free and kink-free after 45 days at sea

2.1 Packaging Engineering Philosophy

Transformer windings tolerate zero surface defects. One salt-crystal or 0.5 mm kink raises the hotspot factor by 8–12 %. Our packaging is therefore treated as the last process step, not a cost center. All materials are specified in the internal QC plan LZ-PK-23 which is certified to ISO 12944-2 C3 marine environment.

2.2 Wire Packaging Matrix

| Product Form | Spool Type | Inner Ø mm | Outer Ø mm | Payload kg | Stack Height (pallet) | VCI + Desiccant | Stretch Film | Carton Sleeve | Top-Cap |

|---|---|---|---|---|---|---|---|---|---|

| 0.20–0.60 mm | PT-10 | 160 | 250 | 10 | 6 levels (1.8 m) | 2 g | 80 µm PE | 5-ply kraft | Yes |

| 0.65–1.30 mm | PT-25 | 160 | 300 | 25 | 5 levels (1.7 m) | 5 g | 80 µm PE | 5-ply kraft | Yes |

| 1.35–2.50 mm | DIN-355 | 355 | 500 | 100 | 3 levels (1.6 m) | 10 g | 100 µm PE | 7-ply kraft | Yes |

| 2.60–5.00 mm | DIN-500 | 500 | 710 | 250 | 2 levels (1.5 m) | 20 g | 120 µm PE | 7-ply kraft | Yes |

Notes:

Spools are ABS+PC blend, 100 % recyclable, UV-stabilised to –40 °C.

Each spool is torqued to 0.8 N·m to prevent flange relaxation under 2 g lashings.

VCI (volatile corrosion inhibitor) paper emits 0.35 g/m² cyclic amine, protecting copper for 24 months.

2.3 Pallet & Container Loading

| Container | Pallet Size (fumigated pine) | Net Wire t | Gross t | Securing Method | Moisture Ingress |

|---|---|---|---|---|---|

| 20 ft GP | 1.1 × 1.1 × 1.8 m | 10 | 11.2 | 25 mm PET strap × 3 + corner boards | < 0.3 g/m³ |

| 40 ft HC | 1.1 × 1.1 × 1.8 m | 22 | 24.0 | as above | < 0.3 g/m³ |

Desiccant quantity calculated per DIN 55474:

W = 1.6 · V · b + A · e · t + D · c

For a 40 ft HC (V = 68 m³, A = 2.4 m², t = 45 d) we load 8 kg CaCl₂ dual-chamber bags.

2.4 Foil & Strip Packaging (Auxiliary Offering)

Transformer foil 0.1–4.0 mm × 20–1500 mm is eye-to-sky on ISPM-15 pallets, each coil sleeved with 150 µm PE + aluminium laminate. Interleaf 0.1 mm LDPE prevents galling. Maximum coil mass 5 t; steel edge protectors at 3 & 9 o’clock positions. Strapping: 32 mm steel × 4 + plastic corner posts.

2.5 Logistics Corridor – Luoyang to World

Plant latitude 34.6 °N gives us ice-free access to Qingdao & Shanghai ports 365 days. Contracted block-train service (Luoyang-Qingdao 18 h) reduces truck vibration by 60 % versus road only. Weekly sailings to Hamburg, LA, and Dubai; average transit 26 days door-door to EU, 18 days to USWC. BL, CO, and RoHS test report are auto-uploaded to customer portal before vessel departure.

2.6 Cost & Risk Advantage

Western enamel-wire suppliers typically add 8 % packing surcharge and 3 % insurance premium. Our factory-direct model integrates packaging cost in base price and carries “all-risk” marine cover up to customer warehouse at 0.15 % of FOB value—50 % below market. Result: landed cost saving 6–9 % with 30 % lower ppm damage rate (3-yr rolling average 87 ppm).

Next section: 3. Quality Assurance & Inline Testing

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe for Coil-Winding Copper Wire

20-Year Metallurgical Track Record—Not Just Trading

Since 2004 our Luoyang campus has operated a closed-loop rod-drawing → annealing → enameling → inline spark-testing → precision-spooling line dedicated to transformer conductors.

We do not buy enamelled wire for re-sale; we start from 8 mm oxygen-free cathode rod and finish on DIN-355 spools.

This vertical integration eliminates batch-to-batch thermal-class drift and removes one margin layer—direct factory price, FOB Tianjin or DDP your plant.

| Milestone | Technical Impact for Buyers |

|---|---|

| 2004 First dual-spooler commissioned | ≤ 0.01 mm concentricity deviation on 0.20 mm wire |

| 2010 In-line 2 kV pin-hole tester installed | Zero ppm pin-holes at 1 kV, 6 m s⁻¹ line speed |

| 2015 IEC 60317-13 & NEMA MW-35-C dual certification | Same wire accepted by both EU and North-American OEMs |

| 2020 220 °C polyimide line added | Thermal class R (220 °C) available down to 0.08 mm |

Engineering Customisation—Not Catalogue Limitations

Transformer designers no longer need to over-spec “standard” 200 °C wire when the hotspot is only 165 °C.

We tailor build, conductor, and insulation in three measurable levers:

| Parameter | Range | Typical Western Stock | Xinzhaohe Custom Tolerance |

|---|---|---|---|

| Bare Cu diameter | 0.08 – 5.00 mm | 0.10, 0.20, 0.30 … | ±0.0005 d (statistical) |

| Insulation build | Grade 0 – 3 | Usually grade 2 | ±0.005 mm wall, any grade |

| Thermal class | 130 °C – 220 °C | 155 °C or 180 °C only | 5 °C increments, validated by IEC 60172 quick ageing |

| Lubrication | 0 – 8 % paraffin | Fixed 3 % | 0.5 % steps for high-speed insertion |

| Spool size | 0.5 – 800 kg | 5 kg, 15 kg, 30 kg | DIN 355, 400, 500, 630; barrel diameter optimised for your flyer |

Need 14 AWG (1.63 mm) with 220 °C polyimide but ≤ 0.6 % elongation to survive your 6-corner turret winder?

We run a 3-hour anneal cycle at 280 °C instead of 350 °C and give you a mill test certificate showing 0.55 % elongation, 245 MPa tensile, and 3.8 kV breakdown.

Cost Structure—Premium Quality Without Premium Brand Tax

Western enamelled-wire plants carry legacy overheads and distributor mark-ups that can exceed USD 1.30 kg⁻¹ on copper base.

Our fully depreciated Chinese equipment, integrated copper rod supply from the same industrial park, and automated spool farm let us deliver IEC-certified wire at LME Cu + USD 0.85 kg⁻¹ enamel adder (2024 Q2 reference).

You receive:

EN 10204 3.1 inspection certificate on every master coil

RoHS & REACH declaration pre-signed for EU customs

Vacuum-sealed + VCI film for 24-month shelf life in tropical ports

Emergency air freight option (Shanghai → Frankfurt, 48 h) at courier cost only

Risk Mitigation—Dual-Source Without Dual Qualification

Because we already qualify to IEC 60317-8, NEMA MW-35-C, JIS C3202, your QA team can approve us as a drop-in second source for any Tier-1 European supplier.

We share our process FMEA and pin-hole SPC charts up-front; 80 % of customers pass factory audit in one day.

Next Step—Get the Datasheet or a Tailored Quote

Send your specification—diameter, thermal class, build, spool weight—to cathy@transformerstrip.com.

Within 24 h you receive:

- Detailed technical datasheet (PDF)

- 30 cm sample spool free of charge

- Firm FOB Tianjin or DDP price valid 30 days

Stop paying distributor margins for a commodity that we engineer better, faster, and closer to copper rod source.

📉 Import Savings Calculator

Estimate cost reduction by sourcing coil winding copper wire from Luoyang Xinzhaohe.