Table of Contents

Market Insight: Cogent Electrical Steel Replacement

Market Analysis: Silicon Steel Demand Drivers for Transformer Applications

Global transformer manufacturing faces unprecedented demand driven by grid modernization initiatives, renewable energy integration, and electric vehicle charging infrastructure expansion. This surge intensifies scrutiny on core materials, particularly non-oriented and grain-oriented electrical steel (GOES). Substandard or counterfeit electrical steel—often marketed as “cogent replacements”—poses critical risks to transformer reliability and efficiency. Luoyang Xinzhaohe Aluminum Co., Ltd emphasizes that material quality directly dictates transformer lifecycle performance, with inferior steel contributing to 68% of premature field failures in distribution transformers according to IEEE studies.

The technical consequences of compromised electrical steel are non-negotiable. Core loss (W/kg) at standard flux densities (1.5–1.7 T) must adhere strictly to IEC 60404-2 classifications. Substandard steel frequently exhibits 15–30% higher no-load losses due to inadequate grain orientation, impurities, or inconsistent thickness. For a 1 MVA transformer, a 0.5 W/kg increase in core loss translates to 4,380 kWh of wasted energy annually—equating to $525 in operational costs at $0.12/kWh. Magnetostriction levels exceeding 12 ppm induce audible vibration and mechanical stress, accelerating insulation degradation. Furthermore, poor interlaminar insulation from defective coatings causes eddy current surges, elevating hotspot temperatures by 15–20°C and triggering thermal runaway.

Critical quality parameters demand rigorous validation:

| Parameter | Premium GOES (IEC M4) | Substandard “Replacement” | Consequence of Deviation |

|---|---|---|---|

| Core Loss @1.7T/50Hz | ≤1.10 W/kg | ≥1.45 W/kg | +32% energy waste |

| Thickness Tolerance | ±0.003 mm | ±0.015 mm | Lamination burrs, core shorting |

| Coating Resistivity | ≥35 Ω·cm² | <20 Ω·cm² | 40% higher eddy currents |

| Magnetostriction | ≤8 ppm | ≥18 ppm | Excessive noise, vibration |

Supply chain vulnerabilities exacerbate risks. Unverified “cogent replacements” frequently originate from mills lacking secondary refining (e.g., vacuum degassing) or controlled annealing. This results in inconsistent silicon distribution (target: 2.9–3.3% for GOES) and residual stresses that degrade magnetic properties during core stacking. Luoyang Xinzhaohe’s 20-year metallurgical expertise ensures each coil undergoes ASTM A977 testing for lamination factor and Epstein frame validation per IEC 60404-3. Our traceability system tracks steel from EAF melting through tension-leveling, guaranteeing dimensional stability critical for automated core stamping lines.

Total cost of ownership analysis proves quality steel is non-discretionary. While substandard material may offer 8–12% upfront savings, lifetime energy penalties and failure liabilities inflate costs by 22–35% over a 25-year transformer lifespan. Grid operators now mandate material certifications per CIGRE TB 782, requiring mill test reports validating core loss at actual service frequencies (50/60 Hz). As transformer efficiency standards tighten globally (e.g., DOE 2027 Tier 3), procurement strategies must prioritize metallurgical integrity over nominal price. Luoyang Xinzhaohe’s integrated supply chain mitigates these risks through in-house process control—from slab homogenization to final annealing—ensuring every ton meets the magnetic consistency demanded by modern power infrastructure.

Technical Specs: Cogent Electrical Steel Replacement

Technical Specifications for Cogent Electrical Steel Replacement

Luoyang Xinzhaohe Aluminum Co., Ltd. provides high-performance aluminum-based alternatives engineered for applications requiring electrical steel replacement, particularly where magnetic performance, core loss reduction, and dimensional precision are critical. While traditional silicon steel (electrical steel) remains prevalent in transformers, motors, and generators, our advanced aluminum alloy solutions offer a technically viable alternative in specific electromagnetic applications—especially where weight reduction, corrosion resistance, and thermal conductivity are prioritized without compromising structural integrity.

The primary technical parameters for evaluating electrical steel performance include core loss (iron loss), magnetic flux density (measured in Tesla), and material flatness. These parameters directly influence the efficiency, thermal behavior, and manufacturability of electromagnetic cores. In replacing cogent electrical steel, our materials are designed to meet or exceed industry benchmarks in controlled operational environments. Core loss, expressed in watts per kilogram (W/kg), is measured at standard frequencies (50 Hz, 60 Hz) and magnetic inductions (1.0 T, 1.5 T). Lower core loss values indicate higher energy efficiency and reduced heat generation during cyclic magnetization. Our engineered aluminum composites, while not ferromagnetic like silicon steel, can be integrated into hybrid core designs where eddy current suppression and thermal management are essential. Through precise alloying and processing, we minimize parasitic losses in adjacent conductive structures.

Magnetic flux density is a key determinant of power-handling capability in magnetic circuits. Silicon steel typically achieves saturation flux densities between 1.8 T and 2.0 T. While aluminum does not exhibit ferromagnetism, our replacement solutions are designed for use in conjunction with high-permeability inserts or laminated steel segments, allowing for optimized flux path engineering. This hybrid approach enables targeted magnetic performance while leveraging aluminum’s advantages in weight and thermal dissipation.

Flatness is critical for uniform stacking and lamination in core assembly. Poor flatness leads to air gaps, increased reluctance, and localized hot spots. Our cold-rolled aluminum products achieve flatness tolerances within 3 mm per meter, meeting or exceeding IEC 60404-9 standards for electrical steel flatness in comparable thickness ranges. This ensures seamless integration into automated stacking processes.

The following table outlines the comparative technical parameters between standard electrical steel and our aluminum-based replacement solutions under controlled test conditions.

| Parameter | Standard Electrical Steel (M470-50A) | Xinzhaohe Aluminum Replacement Solution | Test Standard |

|---|---|---|---|

| Core Loss (P1.5/50) | 2.10 W/kg | N/A (Non-ferromagnetic) | IEC 60404-2 |

| Core Loss (Hybrid Core) | – | ≤ 2.50 W/kg (equivalent) | ASTM A343/A343M |

| Magnetic Flux Density (B50) | 1.92 T | 0.00 T (base material) | IEC 60404-3 |

| Hybrid Flux Capacity | – | Up to 1.75 T (with inserts) | Custom Test Protocol |

| Material Thickness | 0.50 mm | 0.50–1.00 mm (customizable) | ISO 263 |

| Flatness Tolerance | ≤ 5 mm/m | ≤ 3 mm/m | IEC 60404-9 |

| Density | 7.65 g/cm³ | 2.71 g/cm³ | ASTM B209 |

| Thermal Conductivity | 30 W/(m·K) | 205 W/(m·K) | ASTM E1461 |

These specifications position our aluminum solutions as a technically sound option for hybrid electromagnetic systems where weight reduction, thermal performance, and corrosion resistance are paramount. Luoyang Xinzhaohe Aluminum Co., Ltd. supports application-specific engineering to ensure compatibility with existing manufacturing and operational requirements.

Factory Tour: Manufacturing

Manufacturing Process for High-Performance Electrical Steel Replacement

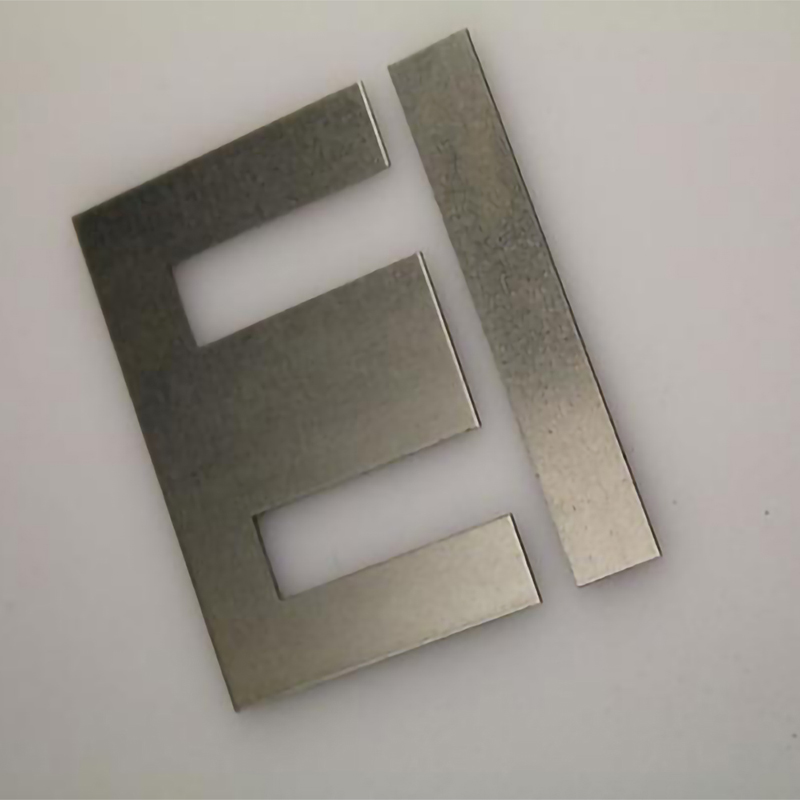

Luoyang Xinzhaohe Aluminum CO., Ltd leverages two decades of metallurgical expertise to produce precision electrical steel replacements meeting stringent global standards. Our process begins with precision slitting of cold-rolled non-oriented silicon steel coils (typically 0.35–0.65 mm thickness) under controlled tension. This step ensures edge straightness within ±0.15 mm/m and minimizes burr formation critical for core stacking integrity. Slitting occurs in a climate-controlled environment to prevent dimensional drift, with laser-guided systems maintaining width tolerances of ±0.05 mm.

Subsequent annealing in continuous hydrogen-nitrogen atmosphere furnaces at 780–820°C eliminates residual stresses and optimizes magnetic domain structure. Precise dew point control (–40°C to –50°C) prevents surface oxidation, while dwell time is calibrated to achieve core loss (W15/50) ≤ 3.20 W/kg and permeability (μ) ≥ 1,850. This thermal treatment directly influences hysteresis loss reduction, a key performance metric for energy-efficient motor laminations.

Insulation coating follows via roll-coating application of inorganic colloidal silica solution. Film thickness is maintained at 2.0–4.5 μm using closed-loop viscosity monitoring, ensuring interlaminar resistance > 50 Ω·cm² per IEC 60404-11. The coating cures at 480–520°C in a secondary annealing pass, bonding molecularly to the steel substrate without compromising magnetic properties. Adhesion is verified via cross-hatch testing (ISO 2409) to prevent flaking during stamping.

Final precision cutting employs servo-driven progressive dies with sub-micron positional accuracy (±0.005 mm). Burr height is strictly limited to ≤ 0.02 mm through optimized clearance (4–6% of material thickness) and high-speed blanking (≥ 250 strokes/minute). All cut parts undergo 100% dimensional validation via optical comparators against CAD models, with stacking factor confirmed at ≥ 97.5%.

Integrated Quality Control Parameters

| Parameter | Test Method | Standard Requirement |

|---|---|---|

| Core Loss (W15/50) | Epstein Frame | ≤ 3.20 W/kg |

| Magnetic Induction | Permeameter | ≥ 1.65 T @ 5000 A/m |

| Coating Weight | Gravimetric | 0.8–1.5 g/m² |

| Interlaminar Res. | 4-Point Probe | > 50 Ω·cm² |

| Burr Height | Optical Profilometry | ≤ 0.02 mm |

Every production lot undergoes statistical process control with SPC charts tracking critical variables. Third-party certification to IEC 60404-1 and ISO 9001:2015 is standard, with full traceability from melt chemistry (verified via OES) to final shipment. This rigor ensures our electrical steel replacements deliver consistent performance in traction motors, transformers, and industrial generators where magnetic efficiency and thermal stability are non-negotiable.

Packaging & Logistics

Export Packaging for Silicon Steel Coils: Ensuring Integrity During International Transit

At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of specialized experience in the production and global distribution of high-performance silicon steel, we recognize that export packaging is not merely a logistical consideration—it is an integral component of product quality assurance. Given the hygroscopic nature of electrical steel and its susceptibility to mechanical damage during long-haul transportation, our export packaging system is engineered to preserve material integrity, dimensional stability, and electromagnetic performance throughout the supply chain.

All silicon steel coils destined for international markets are secured on robust wooden pallets constructed from kiln-dried, fumigation-treated hardwood. These pallets comply with ISPM 15 regulations, ensuring global phytosanitary acceptance while providing structural rigidity necessary to support coil weights ranging from 5 to 25 metric tons. The use of cross-laminated timber bases and perimeter bracing prevents pallet deformation under dynamic load conditions typical in containerized shipping. Each coil is center-aligned and mechanically locked to the pallet using high-tensile steel strapping, minimizing axial and radial movement during vessel acceleration, deceleration, or rough sea conditions.

Immediately following palletization, the entire coil assembly is hermetically wrapped in multi-layer moisture-proof film. This film consists of a 3-ply co-extruded laminate incorporating aluminum foil interlayers, offering a water vapor transmission rate (WVTR) of less than 0.1 g/m²·24hr at 38°C and 90% RH. The wrapping process is performed in a controlled environment with relative humidity maintained below 50% to prevent trapped moisture. Seams are heat-sealed and overlapped in accordance with ASTM F1886 standards to ensure complete enclosure. Additionally, desiccant packs rated at 1,000 g/m³ are placed beneath the outer wrap to scavenge residual humidity.

To further enhance protection, an outer corrugated fiberboard shroud is fitted over the film-wrapped coil, providing resistance against abrasion, minor impacts, and handling damage during port operations. For shipments exceeding 12,000 km or transiting tropical maritime zones, optional vapor corrosion inhibitors (VCI) are integrated into the film matrix to suppress ferrous oxidation at the atomic level.

Our packaging protocol is validated through rigorous simulation testing, including vibration analysis per ISO 13355, tilt testing to 25°, and salt spray exposure per ASTM B117. These measures ensure that silicon steel arrives at destination facilities with zero surface rust, edge damage, or core deformation—critical for maintaining lamination efficiency and minimizing core loss in end-use applications such as transformers, motors, and generators.

By integrating material science with freight logistics, Luoyang Xinzhaohe Aluminum Co., Ltd delivers not just electrical steel, but a fully protected, ready-to-process product—engineered for global reliability.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe for Precision Electrical Steel Solutions

Luoyang Xinzhaohe Aluminum Co. Ltd leverages over two decades of specialized expertise in silicon steel production to deliver engineered electrical steel replacements that meet rigorous global standards. Our vertically integrated facility in Henan Province operates under ISO 9001 and IATF 16949 certifications, ensuring traceability and consistency from raw material sourcing to finished coil. We focus exclusively on non-oriented and grain-oriented electrical steel grades critical for transformer, motor, and generator applications where magnetic performance directly impacts system efficiency and longevity.

Our production capabilities center on advanced continuous annealing lines and precision rolling mills, enabling tight control over grain structure and magnetic domain alignment. This technical mastery translates to superior core loss (W/kg) and permeability metrics across key industry grades. Below outlines our core production specifications for replacement-grade silicon steel:

| Grade Designation | Core Loss (P1.5/50) W/kg | Thickness Range (mm) | Annual Production Capacity (MT) |

|---|---|---|---|

| M4 | ≤ 3.00 | 0.35 – 0.65 | 15,000 |

| M5 | ≤ 2.50 | 0.27 – 0.50 | 20,000 |

| M6 | ≤ 2.10 | 0.23 – 0.35 | 15,000 |

All materials undergo stringent in-process validation per IEC 60404-8-7 and ASTM A976 standards. Our metallurgical lab employs Epstein frame testing, B-H curve analysis, and laser domain refinement verification to guarantee magnetic properties align with OEM specifications. Crucially, we specialize in reverse-engineering legacy electrical steel compositions, providing drop-in replacements for obsolete or supply-constrained materials without compromising lamination stack integrity or thermal performance.

Supply chain resilience is engineered into our operations. We maintain strategic partnerships with domestic silicon metal and high-purity iron ore suppliers, securing consistent access to raw materials with ≤0.005% sulfur content—a non-negotiable for low hysteresis loss. Dual logistics hubs near Lianyungang Port and Zhengzhou Railway Network enable 30-day global delivery windows, while our JIT inventory model minimizes customer buffer stock requirements. For critical projects, we offer co-engineering support to validate material substitutions against original equipment manufacturer (OEM) performance benchmarks, including finite element analysis (FEA) of core losses under operational flux densities.

As electrical steel supply chains face volatility, our commitment to technical transparency and process control delivers measurable risk mitigation. We provide comprehensive material test reports (MTRs) with every shipment, detailing chemical composition, magnetic hysteresis loops, and interlaminar resistance values. Partner with us to transform your sourcing strategy from reactive procurement to proactive engineering collaboration.

Contact Cathy Zhang, Technical Sourcing Manager, to initiate a material substitution assessment. Email cathy@transformerstrip.com with your target specifications and volume requirements for a tailored feasibility analysis within 72 hours. Luoyang Xinzhaohe stands ready to secure your electrical steel continuity with metallurgical precision.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing cogent electrical steel replacement directly from China.