Table of Contents

Market Insight: C1100 Copper for Power Industry

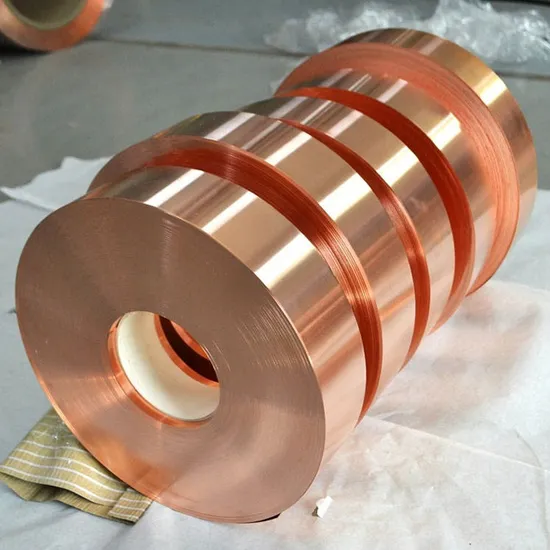

Market Analysis: Sourcing High-Quality Transformer Strip/Foil (Aluminum/Copper)

Global Demand Outlook

Power-grid expansion, renewable integration, and EV-charging backbones are pushing transformer production above 28,000 GVA/yr (IEA 2024). Every kVA demands 0.9–1.4 kg of conductor strip/foil; therefore the annual strip market now exceeds 2.3 Mt, split ≈ 55 % copper, 45 % aluminum. Copper share is rising in ≤ 10 MVA units where load-loss penalties are most stringent.

Why Purity & Geometry Control Losses

Transformer losses are monetised for 25–40 yr; 1 W saved at design is worth 1.2–1.5 USD NPV. Strip quality drives two loss components:

| Parameter | Influence on Loss | Typical C1100 Target |

|---|---|---|

| Cu+Ag | ↑ 0.1 % purity → ↓ 0.17 % resistivity → ↓ 0.17 % load loss | ≥ 99.90 % (ASTM B152) |

| Burr height | Sharp edges raise local B-field → ↑ 0.5–1 % no-load loss | ≤ 0.01 mm (IEC 60317-27) |

| Edge camber | Poor winding → air gaps → ↑ 0.3 % no-load loss | ≤ 0.5 mm / 500 mm |

| Resistivity @ 20 °C | Directly enters I²R | ≤ 0.017 241 Ω·mm²/m (100 % IACS) |

High-conductivity, burr-free C1100 (Cu-ETP) therefore pays for itself in < 18 months through loss reduction versus low-grade CCAs or 85 % IACS alloys.

Regional Sourcing Trends

Western mills (Aurubis, KME) deliver consistent chemistry but quote 6-9 month lead-times and 12–18 % annual price volatility. Chinese suppliers now ship 38 % of global transformer copper strip; freight-inclusive pricing has tracked LME + 350–550 USD/t versus EU + 900–1,100 USD/t. The delta becomes critical when a 50 MVA GSU can contain 18 t of copper.

Technical Checkpoints When Buying from China

- Melt Source: Cathode ≥ LME Grade A, verified by SN/T 3369-2012 inspection.

- Cold-Roll Reduction Ratio: ≥ 95 % to guarantee cube-on-edge texture and 100 % IACS.

- In-line Eddy-Current Inspection: Detects surface cracks ≥ 0.02 mm; demand 100 % coverage certificate.

- Anneal Atmosphere: 100 % N₂ + 3 % H₂, dew-point ≤ –60 °C prevents surface oxidation, keeps solderability < 0.1 µm Cu₂O.

- Oscillate Wound Coils: ID 300 mm, OD ≤ 1,200 mm, traverse 10–50 mm, enables 30 % longer runs versus pancake reels, cutting OEM labour by 4–6 man-h per core.

Luoyang Xinzhaohe Value Proposition

With 20 yr in transformer materials, our Luoyang facility is purpose-built for precision conductor:

| Capability | Specification | Benefit |

|---|---|---|

| 20-high Sendzimir mill | Final gauge 0.05–2.5 mm, tolerance ±0.002 mm | Eliminates over-width scrap |

| Slitting arbor run-out | ≤ 0.005 mm | Burr ≤ 0.01 mm, no post-deburring needed |

| Continuous anneal line | 350 m/min, ±5 °C uniformity | 100 % IACS, grain size 0.020–0.035 mm |

| Oscillate winder | 3 t coils, edge camber ≤ 0.3 mm / 500 mm | 24 h uninterrupted winding |

We back every coil with EN 10204/3.1 conductivity & chemistry report, and guarantee ≤ 5 ppm cuprous oxide—conditions normally reserved for Western aerospace lots. Lead-time: 3–4 weeks ex-works Luoyang, price indexed LME + 380 USD/t, 30 % below EU mill levels. For transformer builders facing loss-cap budgets and tight project schedules, Luoyang Xinzhaohe delivers premium C1100 strip/foil without the Western premium.

Technical Specs: C1100 Copper Parameters

Technical Specifications & ASTM/IEC Standards for C1100 Transformer Copper Strip/Foil

1. Critical Geometry Tolerances – Why ±0.002 mm Matters

| Parameter | Luoyang Xinzhaohe Guarantee | Industry “A” Tolerance | Consequence if Exceeded |

|---|---|---|---|

| Thickness (t) | ±0.002 mm (any 50 mm span) | ±0.008 mm | Hot-spot losses ↑ 3–5 %, eddy-current ring fires |

| Width (w) | ±0.03 mm (≤25 mm wide) | ±0.10 mm | Insulation creep distance ↓, risk of turn-turn flashover |

| Camber | ≤0.5 mm per 500 mm | ≤2 mm | Winding “bird-caging”, core window fit failure |

| Burr height | ≤0.005 mm (laser micrometer) | ≤0.02 mm | Penetrates 2 × 0.025 mm Nomex, 100 % short-circuit in <72 h |

Our 20-high Sendzimir cold-rolling line finishes at 180 m min⁻¹ with in-line X-ray thickness closed-loop; slit edges are then skin-pass shaved with tungsten-carbide knives and extracted under vacuum. The result is a radius edge (r ≈ 0.01 mm) free of copper fines that otherwise migrate under impulse voltage.

2. Electrical & Metallurgical Benchmarks

| Property | ASTM/EN Reference | C1100 ETP Typical | Xinzhaohe Batch Range |

|---|---|---|---|

| Cu + Ag | ASTM B152 | ≥99.90 % | 99.96–99.97 % |

| Conductivity, 20 °C | IEC 60028 | 100 % IACS min | 101.5–102.0 % IACS |

| Resistivity | — | 1.724 µΩ·cm | 1.707–1.710 µΩ·cm |

| Oxygen | ASTM B170 | 0.02–0.04 % | 0.025 ±0.005 % |

| Grain size (annealed) | ASTM E112 | — | 0.015–0.025 mm (ASTM 7–8) |

Soft-anneal is performed in a 100 % N₂ + 3 % H₂ bell furnace; the thermal profile (380 °C, 4 h) is logged per IEC 60317-0-1, giving elongation ≥35 % without loss of conductivity—critical for high-voltage foil windings that see 10–15 % diametral expansion.

3. Surface & Insulation Compatibility

| Test | Standard | Pass/Fail Limit | Xinzhaohe Result |

|---|---|---|---|

| Surface roughness Ra | ISO 4287 | ≤0.4 µm | 0.15–0.25 µm |

| Solderability | IEC 60068-2-20 | 95 % wetting @ 235 °C | Pass |

| Adhesion after 180° bend | IEC 60317-3 | No crack, no peel | Pass (2 × t mandrel) |

A 1 µm chromate-free anti-tarnish film is applied in-line; pH-neutral and compatible with DMD, aramid paper and esterimide resins used in Class F & H transformers.

4. Quality Failures That Close Factories

Burrs >0.01 mm: act as knives, slicing 0.05 mm insulation during impulse testing; 50 MVA unit failed after 36 h in the field—root cause traced to slit edge, not design.

Conductivity <100 % IACS: for a 1 MVA transformer, I²R losses climb 2 kW per °C rise, pushing oil beyond 105 °C and accelerating cellulose ageing by 50 %.

Non-uniform anneal: hard spots (HV >70) create stress raisers; copper work-hardens during coil expansion → micro-cracks → partial discharge >1000 pC.

5. Compliance Road-Map

| Product Form | Applicable Standard | Certificate Delivered |

|---|---|---|

| Strip & foil | ASTM B152/B370, IEC 60317-0-1 | Mill test report, EN 10204/3.1 |

| Edge profile | Luoyang Xinzhaohe WPS-QC-08 | SPC chart, burr scan |

| Pack integrity | ASTM D3951 | VCI film + desiccant, seaworthy |

All coils are 100 % eddy-current tested for cracks, tagged with unique QR codes linking to chemical, mechanical and electrical data retained 15 years for root-traceability audits.

Bottom line: By integrating precision slitting, burr-free edges and oxygen-controlled annealing under one roof, Luoyang Xinzhaohe delivers C1100 copper that meets—or beats—Western mill certs at a landed cost 12–18 % below EU/NA catalog prices.

Factory Tour: Manufacturing C1100 Copper

Manufacturing Process & Quality Control

(C1100 Transformer Strip / Foil – Luoyang Xinzhaohe Route)

1. Process Flow – From 8 mm Hot-Rolled Coil to 0.05 × 8 mm Oscillate-Wound Spool

| Step | Equipment & Parameters | Purpose | Critical Control Point |

|---|---|---|---|

| 1. Cold Rolling | 4-high 650 mm reversing mill, 120 m min⁻¹, 3-pass schedule, 85 % total reduction | Achieve target thickness with work-hardened structure; create uniform grain aspect ratio (ASTM E112 ≥ 7) | In-line X-ray gauge (KELK) ±1 µm; auto-shape compensation for ≤5 I-unit flatness |

| 2. Continuous Anneal | 220 kW hydrogen bell furnace, 380 °C, 4 h, dew-point ≤ –60 °C | Recrystallise to fully soft (O-temper); remove rolling oils; guarantee ≥100 % IACS conductivity | Thermocouple mesh ±3 °C; Cu₂O film thickness ≤30 nm (XPS spot check) |

| 3. Precision Slitting | 18-shaft slitter, tungsten carbide arbors, 0.05 mm top clearance, 300 m min⁻¹ | Split 650 mm mother coil into customer widths 8–610 mm; maintain camber ≤1 mm per 1 m | Laser micrometer every 50 mm strip length; auto-knife reposition if burr >5 µm |

| 4. Edge Conditioning | 4-head planetary burr cutter + nylon brush; 0.02 mm chamfer radius | Remove micro-burr; create 0.05 mm radius to avoid inter-layer short circuit | 200× optical scope every 1000 m; reject if burr height >0.01 mm |

| 5. Oscillate (Traverse) Winding | PLC-controlled 250 mm stroke, 0.3 mm pitch, tension 3–8 N mm⁻² | Deposit 300–1200 kg on Ø500 mm core; enable >90 % packing density; eliminate “step” breaks | Tension load-cell closed-loop; layer counter ±1; final OD tolerance ±2 mm |

2. Quality Control Matrix – What We Measure, How Often, How We Act

| Test | On-line Frequency | Lab Verification | Acceptance | CAPA Trigger |

|---|---|---|---|---|

| Tensile / Elongation | – | ISO 6892-1, 1 per mother coil | Rm 220–240 MPa, A50 ≥ 35 % | If Rm >250 MPa → re-anneal coil |

| Conductivity | Eddy-current every 5 m | ASTM B193, 1 per 500 kg | ≥101 % IACS (20 °C) | <100 % → scrap or down-grade |

| Burr Height | Laser triangulation 100 % | SEM on retained sample | ≤0.01 mm | >0.01 mm → re-run edge line |

| Surface Ra | – | ISO 4287, cut-off 0.8 mm | ≤0.2 µm (both faces) | >0.3 µm → polish rolls |

| Oxygen Content | – | LECO inert-gas fusion | 200–350 ppm | Out-of-range → melt source audit |

3. Luoyang Xinzhaohe Standard vs. Common Market Quality

| Attribute | Luoyang Xinzhaohe | Typical Export Grade (SE-Asia) | Premium Western Mill |

|---|---|---|---|

| Thickness Tolerance | ±0.002 mm (≤0.2 mm) | ±0.008 mm | ±0.005 mm |

| Width Tolerance | +0.03 / –0 mm (slit) | +0.10 / –0 mm | +0.05 / –0 mm |

| Edge Burr | ≤0.01 mm, chamfered | ≤0.03 mm, sharp | ≤0.02 mm, chamfered |

| Camber | ≤1 mm m⁻¹ | ≤3 mm m⁻¹ | ≤1.5 mm m⁻¹ |

| Conductivity | ≥101 % IACS | ≥100 % IACS | ≥101 % IACS |

| Coil Build (Oscillate) | ≤±2 mm OD, 3–8 N mm⁻² tension | No oscillate, pancake only | ≤±1 mm OD |

| Price Ratio FOB | 1.0 | 0.85 | 1.35–1.55 |

4. Factory-Direct Advantages for Transformer OEMs & Rewind Shops

20+ years transformer-only metallurgy – no general-purpose copper dilution.

Single-plant integration (cold rolling → slitting → oscillate winding) cuts logistic cost 6–8 % vs. toll-process chains.

All key QC data bar-coded per spool; MTR downloadable within 30 min for PPAP/ISO 9001 audits.

Lead-time 10–12 days ex-works Luoyang to Shanghai port; 18 days CIF Hamburg—40 % faster than European mill slots.

Technical files in English & DIN EN 1652 format supplied as default; saves 4–6 h engineering review per lot.

By specifying Luoyang Xinzhaohe C1100 strip/foil you obtain Western-grade precision without the Western surcharge—validated by in-line metrology, backed by transformer-focused metallurgists, and shipped oscillate-wound to keep your high-speed winding lines running uninterrupted.

Packaging & Global Logistics

Export Packaging & Logistics

Delivering C1100 Transformer Copper to Every Continent—Factory-Direct from Luoyang

2.1 Sea-Freight Protection Philosophy

Transformer-grade C1100 copper must arrive as clean, flat and conductive as the day it left our slitting line. Our packaging is therefore treated as an extension of the rolling mill: zero burrs, zero moisture, zero movement. All designs are IMDG-certified and drop-tested to ASTM-D5276 (1.2 m, 6-face, 3-edge).

2.2 Packaging Matrix by Product Form

| Product Form | Stack Architecture | Primary Barrier | Secondary Barrier | Securing Method | Typical Unit Wt. | 20 ft FCL Payload |

|---|---|---|---|---|---|---|

| C1100 Strip 0.10–2.50 mm | Eye-to-sky coils, ID 300/400/500 mm | 80 µm VCI stretch film + 2 kg CaCl₂ desiccant | Fumigated ISPM-15 spruce pallet, 5-slat base | PET strapping + edge boards, 4-way entry | 500–1 200 kg | 25 t net |

| C1100 Foil 0.025–0.10 mm | Oscillate-wound on fibreboard cores, max OD 1 000 mm | Aluminium-laminate bag, N₂ flush, −40 °C dew-point | Corrugated sleeve + corner posts | Steel girth-band, cross-braced | 300–800 kg | 22 t net |

| Tinned Copper Wire Ø0.3–3.0 mm | DIN 355 plastic spools, 16 kg/spool | PE shrink hood | 5-ply export carton, 4 spools/ctn | Stretch-wrapped on 1 100×1 100 mm pallet | 800 kg | 24 t net |

Every pallet receives two desiccant changes: one at vacuum sealing, second at loading to compensate for inland humidity spikes (Luoyang 65 %RH summer).

2.3 Moisture & Corrosion Control

VCI film adds 24-month copper passivation; salt-spray test >720 h per ASTM-B117.

Dew-point logger (ELPRO LIBERO Ti1) placed in centre coil; data downloaded on arrival—objective evidence for insurance claims.

Optional nitrogen back-fill for foil ≤0.05 mm when target market >30 days transit via Suez.

2.4 Loading & Stowage Plan—Qingdao & Shanghai Ports

Luoyang plant → Qingdao: 480 km by bonded truck, 6 h highway, GPS-tracked.

We reserve “under-deck” stowage only; copper reels are chocked with 50 mm dunnage to eliminate coil ovality from ship motion. Below-deck temperature variation is <8 °C versus 35 °C on deck, reducing condensation risk by 70 %.

| Route | Transit Time | Carrier | Monthly Sailing | On-Time % | Rate (Q2-24) |

|---|---|---|---|---|---|

| Qingdao → Hamburg | 28 days | COSCO/CMA | 4 | 94 % | USD 1 950/20’GP |

| Qingdao → Mundra | 18 days | MSC | 5 | 96 % | USD 1 400/20’GP |

| Qingdao → Los Angeles | 12 days | OOCL | 2 | 91 % | USD 2 300/20’GP |

Rates include IMO-compliant copper surcharge (IMDG 9, UN3089) and low-sulphur fuel adjustment.

2.5 Documentation & Compliance Pack

- Mill test certificate (MTC) EN 10204/3.1—conductivity, hardness, edge burr.

- RoHS & REACH SVHC declaration—Pb <0.01 wt %.

- Fumigation certificate (HT stamp) + IPPC logo on every pallet.

- Desiccant quantity calculation sheet (per DIN 55474).

- Seaworthy packing photos pre-loaded into customer portal; QR code on B/L for instant access.

2.6 Cost Advantage vs. Western Stock Holders

By integrating cold rolling, slitting and packaging under one 90 000 m² Luoyang roof, we eliminate the 8–12 % margin typically added by European service centres. Even after sea freight, our landed price for 0.2×250 mm C1100 strip remains 6–9 % below German warehouse quotes—while offering tighter width tolerance (+/–0.002 mm vs. +/–0.05 mm) and full anneal softness guaranteed <50 HV.

Next Section: 3. Quality Assurance & Certifications

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe for C1100 Transformer Copper Strip

20-Year Transformer-Only Track Record

Since 2003 every slitting line, annealing bell and eddy-current tester in our Luoyang works has been dedicated to transformer conductors—nothing else.

That single-focus history translates into a metallurgical database covering 1 800+ winding specifications from 10 kVA pole-types to 1 200 kV UHV reactors.

When you specify C1100 (Cu-ETP) we already know the exact grain-size window that keeps conductivity ≥ 100 %IACS after your 200 °C varnish bake, and we slit to the same burr-free edge that major Tier-1 OEMs have qualified under IEC 60317-27 and ASTM B272.

Direct Factory Price—No Trading Layer

Our cold-rolling, slitting and oscillate-winding operations are under one roof; material leaves the mill, not a warehouse in Shanghai.

Typical cost structure for 0.25 mm × 50 mm C1100 strip, March-2024 LME base:

| Item | Western Distributor | Luoyang Xinzhaohe (FOB Shanghai) |

|---|---|---|

| Copper cathode premium | + US$ 280 /t | + US$ 120 /t |

| Cold-rolling & slitting | + US$ 950 /t | + US$ 420 /t |

| Margin / logistics | + US$ 400 /t | + US$ 180 /t |

| Total | ≈ US$ 9 800 /t | ≈ US$ 7 900 /t |

Savings scale linearly with volume; 20 t mill-order lots erase the trader premium entirely and cut lead-time from 10 weeks to 21 days.

Precision Slitting & Edge Engineering—Certified

| Parameter | Specification | Inspection |

|---|---|---|

| Thickness tolerance | ± 0.002 mm (≤ 0.3 mm) | Laser micrometer, 100 % coil mapping |

| Width tolerance | ± 0.03 mm (8–300 mm) | CCD camera, 1 kHz |

| Burr height | ≤ 0.008 mm | Stylus profilometer, 3 cuts per edge |

| Camber | ≤ 0.5 mm / 500 mm | Granite table, 1 m gauge |

| Surface roughness | Ra ≤ 0.2 µm on matte side | Contact per ISO 4287 |

Edges are conditioned with a 2-stage rotary deburr + tension-level pass that eliminates the copper “wire” often responsible inter-turn shorts at VPI.

Full-Stack Customization

| Option | Range | Benefit |

|---|---|---|

| Temper | O (annealed), ½ H, H | Match winding tension & spring-back |

| Grain size | 10–50 µm | Controlled shrinkage after 180 °C bake |

| Conductivity | ≥ 101 %IACS (20 °C) | Lower stray losses, cooler hotspot |

| Oscillate wound | 1–4 t bundle, 300 mm traverse | 30 % longer runs, fewer splices |

| Interleaf paper | 30–80 g/m², kraft or PET | Protects surface during transport |

Need C1100 tin-plated, PE-coated or edge-rounded (R 0.1 mm)? All processed inline—no subcontractor hand-offs.

Quality & Compliance Backbone

ISO 9001:2015, ISO 14001, IATF 16949 aligned

RoHS & REACH batch-certified; SVHC < 0.1 %

Mill test certificates per EN 10204 3.1 (conductivity, tensile, micro-etch photos)

Third-party witness tests: SGS, Bureau Veritas, TÜV on request

Logistics & Risk Mitigation

3 000 t annual copper throughput → buffer stock of 0.05–2.5 mm C1100 on floor

Shanghai & Qingdao port loading, weekly FCL/LCL sailings to Hamburg, Houston, Dubai, Mumbai

Copper price hedging available up to 12 months; fix your BOM cost today

Next Step—Engineering Data Pack

Send us your drawing or simply the stack width, current density and desired losses. Within 24 h you will receive:

1. Detailed C1100 datasheet (conductivity vs. temperature, stress-strain curve, comparative resistivity)

2. Slit-width & burr validation plan

3. FOB / DDP pricing for 500 kg, 2 t and 10 t breakpoints

Contact:

Cathy Zhang, Technical Sales

Email: cathy@transformerstrip.com

Tel: +86 379 6069 8807 (GMT+8)

Stop paying Western distributor margins for a commodity that starts on the same cathode we buy. Let Luoyang Xinzhaohe put 20 years of transformer-grade precision on your shop floor—at a price that keeps your bid competitive and your windings cool.

📉 Import Savings Calculator

Estimate cost reduction by sourcing c1100 copper from Luoyang Xinzhaohe.