Table of Contents

Market Insight: C Wire Transformer

Market Analysis: Winding Wire Demand for CCA Transformers

The industrial demand for copper-clad aluminum (CCA) wire in transformer manufacturing has intensified over the past decade, driven by strategic cost optimization without compromising core electrical performance. CCA wire serves as a critical material alternative to pure copper in distribution and中小型 power transformers, particularly where weight reduction and material cost constraints are paramount. Global transformer production, especially in emerging markets and renewable energy infrastructure projects, increasingly adopts CCA for windings in units rated below 2500 kVA. This trend is amplified by volatile copper prices and aluminum’s 65% lower base cost, making CCA an economically viable solution for cost-sensitive applications. However, demand remains concentrated in specific segments; high-efficiency (>98%) or high-reliability transformers (e.g., grid substations, critical industrial facilities) still predominantly specify pure copper due to its superior conductivity and thermal stability.

Quality in CCA wire is non-negotiable for transformer longevity and operational safety. Substandard CCA introduces significant failure risks through three primary mechanisms. First, inadequate copper cladding thickness or poor interfacial bonding between copper and aluminum layers creates localized high-resistance zones. Under load, these zones generate excessive heat due to increased I²R losses, accelerating insulation degradation and potentially causing thermal runaway. Second, inconsistent metallurgical bonding permits galvanic corrosion at the Cu/Al interface when exposed to humidity, progressively increasing DC resistance and reducing effective cross-sectional area. Third, impurities or non-uniform annealing in the aluminum core elevate resistivity, directly diminishing the wire’s effective conductivity below the nominal 61% IACS (International Annealed Copper Standard) benchmark. Field failures from inferior CCA manifest as premature winding burnout, reduced overload capacity, and elevated no-load losses—impacting total cost of ownership despite initial material savings.

Luoyang Xinzhaohe Aluminum leverages 20+ years of metallurgical expertise to mitigate these risks through rigorous process controls. Our CCA wire undergoes continuous monitoring of cladding ratio (typically 10–15% Cu by volume), interfacial shear strength (>60 MPa), and resistivity uniformity (±0.5% across spools). This precision ensures stable performance under thermal cycling and mechanical stress during winding operations. The table below summarizes critical quality parameters differentiating industrial-grade CCA:

| Parameter | Industrial Standard | Consequence of Deviation |

|---|---|---|

| Cladding Ratio | 10–15% Cu | <10%: Rapid corrosion; >15%: Cost inefficiency |

| Interfacial Shear Strength | ≥60 MPa | <50 MPa: Delamination under thermal stress |

| Resistivity (20°C) | ≤0.02826 Ω·mm²/m | Higher values: Increased load losses, overheating |

| Elongation | 25–35% | <20%: Wire breakage during high-speed winding |

Transformer manufacturers must prioritize certified CCA suppliers with auditable quality systems. Compromising on wire quality incurs hidden costs through warranty claims, field failures, and reputational damage—far outweighing material savings. At Luoyang Xinzhaohe, our ASTM B566-compliant production and in-line eddy current testing guarantee dimensional and electrical consistency, enabling transformers to meet IEC 60076 efficiency standards. Strategic sourcing of CCA wire is not merely a procurement decision but a foundational element of transformer reliability engineering. Buyers should evaluate suppliers based on metallurgical traceability and real-world performance data, not isolated price points.

Technical Specs: C Wire Transformer

Technical Specifications for C Wire Used in Transformer Windings

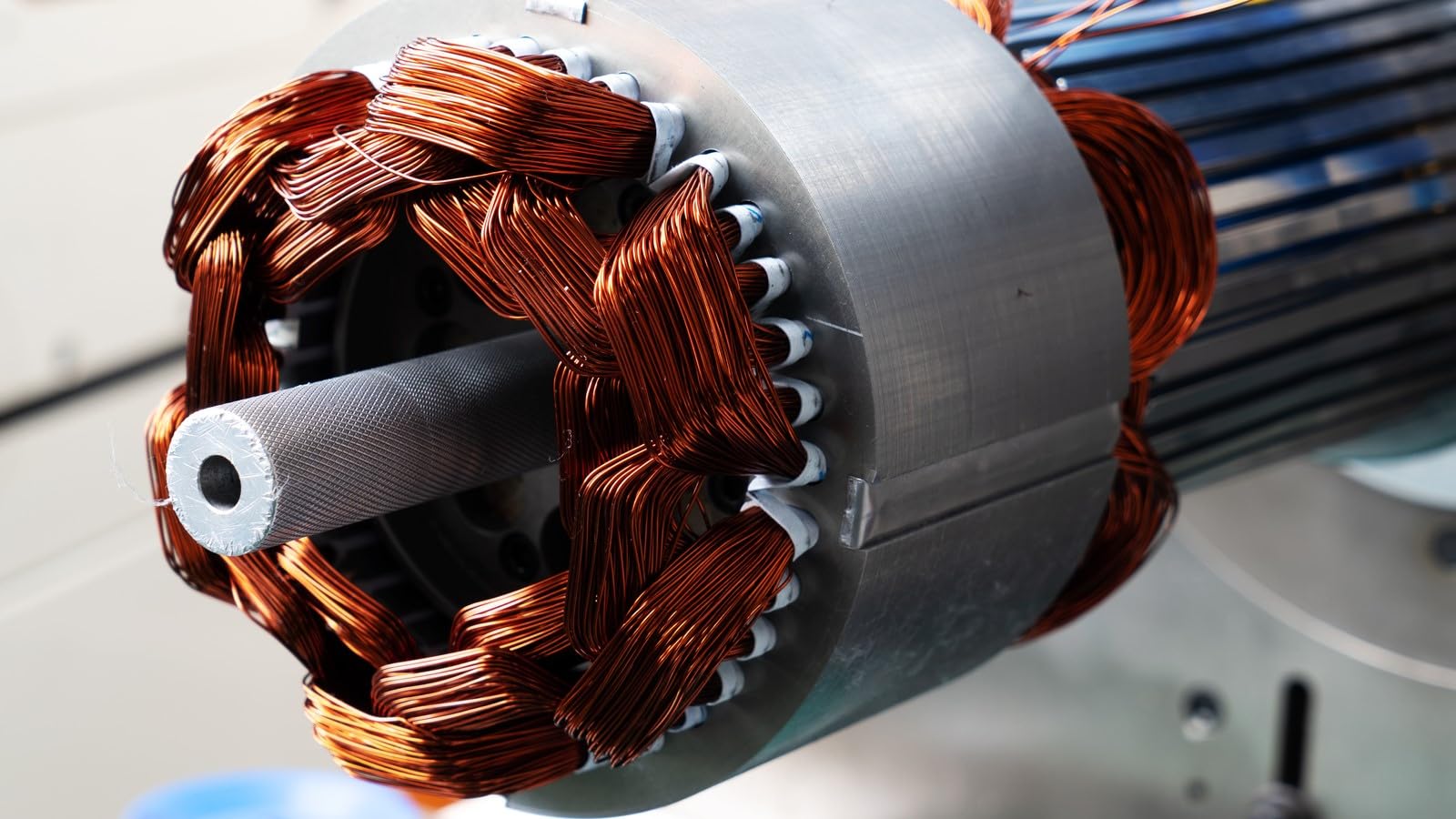

C wire, commonly referred to in the industry as rectangular or shaped aluminum winding wire, is a critical component in the construction of power and distribution transformers. At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of specialized manufacturing experience, we produce high-purity aluminum C wire engineered to meet stringent electrical and mechanical performance standards. The technical specifications governing this product are essential to ensure reliable operation under high electromagnetic stress, thermal cycling, and long-term service conditions.

A key parameter in assessing the performance of C wire in transformer applications is insulation breakdown voltage. This value indicates the dielectric strength of the insulation coating applied to the conductor. For standard grades, the minimum breakdown voltage is maintained at 6 kV AC, with high-reliability variants achieving up to 12 kV AC under controlled test conditions (per IEC 60317 and GB/T 23640 standards). This ensures robust protection against inter-turn short circuits and dielectric failure during overvoltage events. The insulation system typically consists of thermosetting polyurethane, polyester-imide, or polyamide-imide coatings, selected based on the required thermal class and environmental resistance.

Elongation, measured as a percentage during tensile testing, reflects the ductility of the aluminum conductor. For 1350-H19 or equivalent high-conductivity aluminum alloys used in C wire, the typical elongation ranges from 1.5% to 3.0%, depending on cross-sectional dimensions and temper. Higher elongation values are critical during the winding process, where the wire undergoes bending and tensioning; insufficient ductility can lead to microcracking, increased resistance, or mechanical failure. Our manufacturing process includes precise annealing control and cold-drawing calibration to ensure consistent elongation across production batches.

Thermal class defines the maximum continuous operating temperature the insulated wire can withstand without significant degradation of electrical or mechanical properties. C wire for transformer use is available in thermal classes ranging from 130°C to 220°C. Class 130 (B) and Class 155 (F) are commonly used in dry-type transformers, while Class 180 (H) and Class 220 offer enhanced thermal stability for high-efficiency or high-overload designs. The thermal endurance is validated through thermal aging tests per NEMA MW 1000 and IEC 60172, ensuring insulation life expectancy of over 20,000 hours at rated temperature.

The following table summarizes key technical parameters for C wire used in transformer windings:

| Parameter | Standard Value Range | Test Standard | Notes |

|---|---|---|---|

| Insulation Breakdown Voltage | 6–12 kV AC (min) | IEC 60317, GB/T 23640 | Depends on insulation grade |

| Elongation | 1.5–3.0% | ASTM B562 | Measured on finished wire |

| Thermal Class | 130°C to 220°C | NEMA MW 1000, IEC 60172 | Based on insulation system |

| Electrical Conductivity | ≥61% IACS | ASTM B230 | For 1350 alloy |

| Dimensional Tolerance | ±0.05 mm (width/thickness) | Custom tooling control | Tight tolerances ensure winding precision |

These specifications are rigorously maintained through in-line monitoring, batch testing, and third-party certification. Luoyang Xinzhaohe Aluminum Co., Ltd adheres to ISO 9001 quality management protocols to ensure consistency, traceability, and compliance with global transformer manufacturing requirements.

Factory Tour: Manufacturing

Manufacturing Process for Aluminum Winding Wire in Transformer Applications

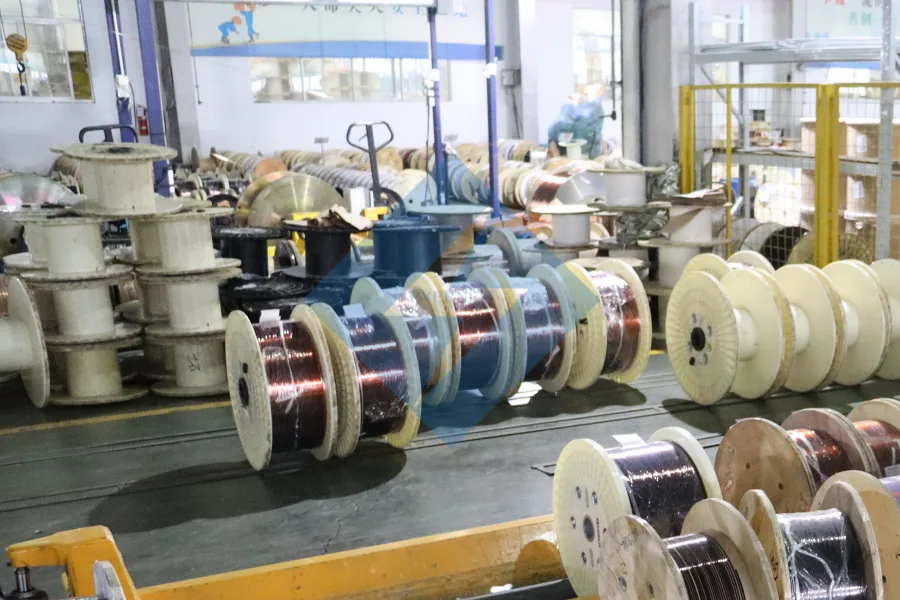

Luoyang Xinzhaohe Aluminum Co., Ltd leverages two decades of specialized metallurgical expertise to produce high-reliability aluminum winding wire for transformer cores. Our rigorously controlled process ensures optimal electrical conductivity, mechanical formability, and enamel insulation integrity essential for demanding power and distribution transformers. The sequence begins with high-purity aluminum rod conforming to GB/T 3954 standards, typically grades 1350 or 1370, verified for chemical composition via optical emission spectroscopy prior to processing.

Rod drawing forms the foundational step, reducing rod diameter to precise wire specifications through multi-die continuous drawing machines. Tension control and die geometry are meticulously managed to achieve target diameters within ±0.005 mm tolerance while maintaining consistent roundness. Critical in-process quality control includes real-time laser micrometer monitoring of diameter and ovality, coupled with surface defect inspection using high-resolution cameras to eliminate scratches or pits that could compromise subsequent enamel adhesion. Drawn wire undergoes immediate cleaning to remove residual lubricants.

The annealing stage employs continuous inline furnaces operating under precisely controlled nitrogen-hydrogen atmospheres to prevent oxidation. Temperature profiles (typically 350-450°C) and residence times are calibrated to achieve the target temper (O-soft annealed) and electrical conductivity exceeding 61% IACS as measured by the four-point probe method per IEC 60028. This step eliminates work hardening from drawing, ensuring the ductility required for tight winding without breakage. Conductivity and tensile strength (100-120 MPa) are verified at defined intervals through automated sampling.

Enameling applies the critical insulating layer via multiple passes through precision applicators and curing ovens. We utilize modified polyester or polyamide-imide resins formulated for thermal class 155°C (F) or 180°C (H) performance. Each pass builds uniform dry film thickness, strictly controlled between 0.05 mm and 0.15 mm depending on wire gauge and application. Key enamel properties are validated through inline and final testing:

| Property | Standard Value | Test Method |

|---|---|---|

| Dielectric Strength | ≥ 3 kV (min 30 sec) | IEC 60851-5 |

| Abrasion Resistance | ≥ 150 cycles | IEC 60851-4 |

| Thermal Shock | Pass (-20°C to 155°C) | IEC 60851-6 |

Inline spark testing at 3.5 kV continuously monitors insulation integrity for pinholes, rejecting any compromised sections. Final quality assurance encompasses 100% diameter verification, elongation testing (≥ 25%), and adhesion checks per IEC 60851 standards. Every production lot receives comprehensive certification, including traceability to raw material heat numbers. This integrated approach, refined over 20 years, guarantees wire capable of withstanding transformer winding stresses and long-term operational demands under varying thermal loads.

Packaging & Logistics

Export Packaging for Aluminum Winding Wire – Ensuring Integrity in Global Shipments

At Luoyang Xinzhaohe Aluminum Co., Ltd., with over two decades of specialized manufacturing experience in aluminum winding wire, we recognize that reliable packaging is a critical component of product performance and customer satisfaction in international trade. Our export packaging system is engineered to preserve the metallurgical and electrical integrity of c wire transformer conductors during extended sea freight logistics, which often involve high humidity, temperature fluctuations, and mechanical stress.

All aluminum winding wire coils designated for export are mounted on robust wooden pallets constructed from kiln-dried, ISPM-15 certified hardwood. These pallets are designed to meet international phytosanitary standards and provide structural stability under dynamic load conditions typical during ocean transport. The use of high-density timber ensures resistance to compression and lateral deformation, minimizing the risk of coil distortion during stacking and handling in containerized shipping environments. Each coil is securely fastened to the pallet using corrosion-resistant steel strapping, with edge protectors applied at critical stress points to prevent mechanical damage to the wound conductor.

To address the primary environmental threat in maritime shipping—moisture—we apply a multi-layer moisture-proof wrapping system. The primary barrier consists of heat-shrunk polyethylene vapor retarder film with a minimum thickness of 125 µm, which encapsulates the entire coil-pallet assembly. This film provides an effective barrier against salt-laden air and condensation, which are prevalent in tropical and coastal transit routes. An additional internal layer of vapor corrosion inhibitor (VCI) film is applied directly around the coil where specified, offering molecular-level protection against oxidation of the aluminum surface. This dual-film strategy ensures that the wire remains free from surface degradation, preserving its conductivity, winding characteristics, and solderability upon arrival.

All packaged units are clearly labeled with UV-resistant, tamper-evident identification tags containing batch numbers, alloy grade (e.g., 1350-O), dimensional specifications, and handling instructions. Critical orientation markers, such as “This Side Up” and “Do Not Invert,” are prominently displayed to maintain proper coil positioning, preventing internal slippage that could compromise dimensional accuracy.

Our packaging protocols are validated through accelerated climatic chamber testing simulating 45-day sea voyages across tropical zones. These tests confirm the efficacy of our moisture barrier systems and structural design under sustained 95% relative humidity and temperature cycling between 20°C and 50°C. As a result, Luoyang Xinzhaohe ensures that every shipment of aluminum winding wire arrives at its destination in the same condition as when it left our facility, meeting the stringent quality expectations of transformer manufacturers worldwide.

This rigor in export packaging underscores our commitment to supply chain reliability and long-term performance in mission-critical electrical applications.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe: Precision Aluminum Winding Wire for Critical Transformer Applications

Luoyang Xinzhaohe Aluminum Co., Ltd. leverages over two decades of specialized metallurgical and manufacturing expertise to deliver aluminum winding wire (specifically C-Wire for transformer applications) meeting the most stringent global electrical industry demands. Our vertically integrated production facility in Luoyang, China, is engineered for uncompromising quality control and process stability, directly addressing the core challenges faced by transformer OEMs: material consistency, long-term reliability under thermal and electromagnetic stress, and supply chain resilience.

Our core strength resides in fundamental metallurgical control. We utilize only primary 99.99% pure aluminum ingot sourced under rigorous supplier qualification protocols, ensuring minimal impurity levels detrimental to conductivity and mechanical performance. Advanced continuous casting and rolling lines operate under precisely calibrated thermal profiles, achieving optimal grain structure and uniform microhardness essential for consistent drawability and post-forming stability in complex winding geometries. Critical to C-Wire performance, our proprietary annealing processes are meticulously monitored and controlled, guaranteeing the target temper (typically H14 or O) with minimal batch-to-batch variation in tensile strength and elongation – parameters directly impacting winding integrity and resistance to deformation during transformer operation. This granular process control translates to dimensional tolerances held within ±0.005mm for diameters ranging from 0.8mm to 5.0mm, exceeding IEC 60122-1 and ASTM B354 standards.

Quality assurance is not an endpoint but an integrated manufacturing philosophy. Every production lot undergoes comprehensive in-house testing before shipment, validating critical properties against both customer specifications and our internal benchmarks. Key parameters are rigorously monitored:

| Test Parameter | Standard Method | Xinzhaohe Typical Performance | Industry Baseline |

|---|---|---|---|

| Electrical Conductivity | IACS % | ≥ 61.0% | ≥ 61.0% |

| Tensile Strength (MPa) | ASTM E8 | 85-105 (H14) / 60-80 (O) | 80-110 / 55-85 |

| Elongation (%) | ASTM E8 | ≥ 15 (H14) / ≥ 30 (O) | ≥ 12 / ≥ 25 |

| Surface Roughness (Ra) | ISO 4287 | ≤ 0.8 µm | ≤ 1.2 µm |

| Dimensional Tolerance | Custom | ±0.005 mm | ±0.01 mm |

Beyond material science, our supply chain infrastructure provides tangible operational advantages. With an annual production capacity exceeding 20,000 metric tons dedicated to electrical conductors, we offer scalable solutions without compromising lead times. Our dedicated logistics team manages JIT and VMI programs globally, utilizing specialized packaging to prevent oxidation and mechanical damage during transit. ISO 9001 and IATF 16949 certifications underpin our systematic approach to defect prevention and continuous improvement, minimizing supply disruption risks for your critical transformer production schedules.

Partnering with Luoyang Xinzhaohe means securing a supplier whose technical depth in aluminum metallurgy and disciplined manufacturing processes directly enhances the performance and longevity of your transformer windings. We eliminate material variability as a failure point, providing the consistent, high-integrity C-Wire essential for efficient, reliable power transmission. Reduce your engineering risk and ensure supply certainty. Contact our Technical Sales Manager Cathy directly at cathy@transformerstrip.com to discuss your specific C-Wire requirements and receive a detailed capability statement. Let us apply our 20+ years of focused expertise to optimize your transformer material sourcing.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing c wire transformer directly from China.