Table of Contents

Market Insight: Bright Sheet

Market Analysis: Transformer Strip/Foil (Aluminum/Copper)

The global transformer industry continues to drive steady demand for high-purity aluminum and copper strip and foil, commonly referred to in technical contexts as “bright sheet” due to its reflective, oxide-free surface finish. Bright sheet is a critical material in the fabrication of windings for both power and distribution transformers, where electrical conductivity, mechanical formability, and surface integrity directly influence performance and reliability. As energy infrastructure expands—particularly in emerging markets and renewable integration projects—the demand for precision-rolled transformer strip has intensified, placing greater emphasis on material consistency and manufacturing excellence.

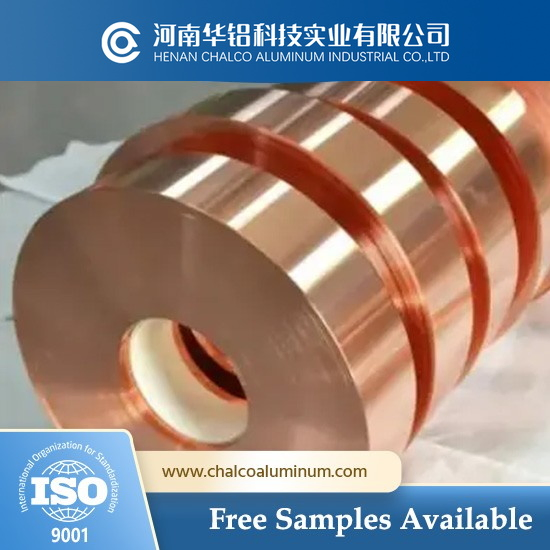

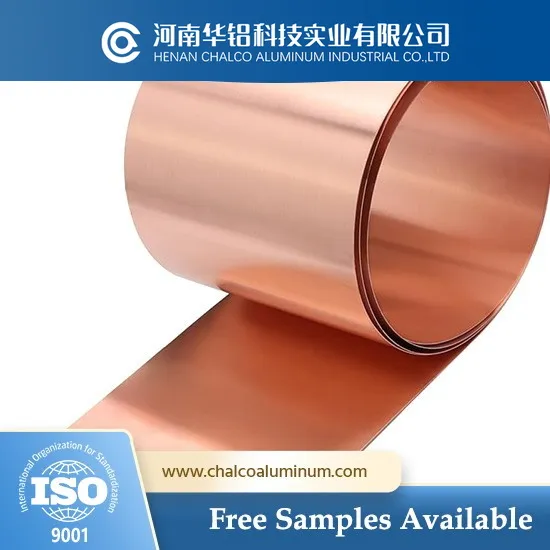

Aluminum bright sheet, typically supplied in alloys 1060, 1070, or 1100 with purities exceeding 99.6%, is favored for its favorable conductivity-to-weight ratio and corrosion resistance. Copper strip, while denser and more expensive, remains indispensable in high-efficiency and high-current applications due to its superior electrical conductivity. In both materials, the “bright” surface condition is not merely aesthetic; it indicates a tightly controlled rolling and cleaning process that minimizes surface oxides, residual lubricants, and micro-defects. These contaminants, if present, can lead to insulation breakdown, partial discharges, and premature transformer failure under operational stress.

Industrial demand is increasingly shaped by energy efficiency regulations such as IEC 60076 and DOE 2016 standards, which mandate lower no-load and load losses in transformers. Achieving compliance requires windings with minimal electrical resistance and uniform cross-sectional geometry. This necessitates tight tolerances in thickness (±0.01 mm typical), high edge straightness, and precise coil alignment—all attributes directly influenced by the quality of the incoming strip. Furthermore, automated winding lines in modern transformer manufacturing demand consistent mechanical properties, including controlled tensile strength and elongation, to ensure defect-free processing at high speeds.

At Luoyang Xinzhaohe Aluminum CO., Ltd, with over two decades of specialization in aluminum transformer strip, we recognize that material quality is inseparable from system reliability. Our bright sheet products undergo rigorous process controls, including degreasing, tension leveling, and precision slitting, to achieve surface cleanliness levels suitable for Class A insulation systems. Each batch is verified for dimensional accuracy, electrical resistivity, and surface profile using inline and laboratory-based metrology systems.

The cost of material failure in transformer applications extends far beyond replacement value—it includes downtime, warranty liabilities, and reputational risk. As such, leading OEMs are shifting from price-based sourcing to long-term partnerships with suppliers capable of delivering technical consistency, traceability, and process transparency. In this environment, bright sheet is not a commodity, but a performance-critical component where metallurgical precision directly translates into operational efficiency and grid reliability.

| Material | Typical Alloy | Conductivity (IACS %) | Common Thickness Range (mm) | Key Application |

|---|---|---|---|---|

| Aluminum | 1060, 1070, 1100 | 59–61 | 0.20 – 3.0 | Distribution transformers, bus ducts |

| Copper | C11000 (ETP) | ≥100 | 0.15 – 2.5 | High-efficiency power transformers |

Technical Specs: Bright Sheet

Technical Specifications for Precision Bright Sheet Transformer Strip

Luoyang Xinzhaohe Aluminum Co., Ltd leverages over two decades of specialized metallurgical and precision slitting expertise to deliver bright sheet transformer strip meeting the most stringent global electrical industry demands. Our manufacturing process is rigorously controlled to ensure dimensional accuracy, surface integrity, and electrical performance critical for high-efficiency transformer core construction. The following specifications define the baseline quality parameters for our aluminum bright sheet products, reflecting our commitment to zero-defect delivery in mission-critical applications.

| Parameter | Specification (Aluminum) | Measurement Standard | Critical Control Method |

|---|---|---|---|

| Thickness Range | 0.10 mm – 0.50 mm | ISO 2178 | Laser micrometry, in-line gauging |

| Slit Width Tolerance | ± 0.002 mm (max deviation) | ASTM E3030 | Precision slitting with servo-controlled knives, post-slit CMM verification |

| Edge Burr Height | ≤ 0.003 mm (max) | ISO 1302 | Optical profilometry, tactile edge scanning |

| Edge Straightness | ≤ 0.05 mm per 1000 mm length | Internal Standard | Laser alignment systems, tension leveling |

| Surface Roughness (Ra) | 0.15 μm – 0.40 μm | ISO 4287 | Stylus profilometer (25.4 mm cutoff) |

| Conductivity (%IACS) | 61.0% – 61.8% (min 61.0%) | ASTM E1004 | Eddy current testing, calibrated reference standards |

| Tensile Strength | 85 MPa – 110 MPa | ASTM E8 | Universal testing machine (sub-size samples) |

| Elongation | ≥ 2.5% | ASTM E8 | Universal testing machine |

| Coil ID | 508 mm (20″) standard | Customer drawing | Mandrel sizing, laser ID verification |

| Max Coil Weight | 5000 kg | Customer requirement | Scale verification pre-shipment |

Achieving the critical ±0.002 mm slit width tolerance necessitates our proprietary tension leveling system integrated directly with servo-driven precision slitters. This eliminates edge wave and center buckle, ensuring consistent strip geometry essential for tight stacking factors in transformer cores. Edge quality is non-negotiable; burr formation is mitigated through optimized knife geometry, precise knife clearance control (maintained at 2-3% of material thickness), and real-time edge defect monitoring. All coils undergo 100% edge profile validation using non-contact optical measurement prior to shipment.

Electrical conductivity is maintained at 61.0% IACS minimum through strict control of alloy composition (primarily 1070, 1060, 1350 series) and thermal processing parameters within our continuous annealing line. Each production lot undergoes certified conductivity verification per ASTM E1004, with traceable results provided in the Material Test Report. Surface roughness is optimized within the 0.15-0.40 μm Ra range to balance core loss performance with interlayer insulation requirements, achieved through precision cold rolling and controlled skin-passing.

Our bright sheet exhibits exceptional flatness, with edge straightness held to ≤0.05 mm per meter, preventing misalignment during core stacking. This is achieved through multi-stage tension leveling and precise winding tension profiles. Strict handling protocols in our clean coil storage area prevent surface damage. All specifications are validated against customer drawings and international standards, with full process traceability from ingot to finished coil. This precision engineering foundation ensures optimal magnetic performance and manufacturability for our transformer manufacturing partners.

Factory Tour: Manufacturing

Manufacturing Process of Transformer Strip/Foil at Luoyang Xinzhaohe Aluminum CO., Ltd

The production of high-performance transformer strip and foil at Luoyang Xinzhaohe Aluminum CO., Ltd follows a tightly controlled, multi-stage manufacturing sequence designed to ensure dimensional accuracy, surface integrity, and electrical consistency. With over two decades of metallurgical expertise, our process integrates advanced cold rolling technology with precision slitting and edge conditioning to meet the stringent demands of transformer and inductor manufacturers globally.

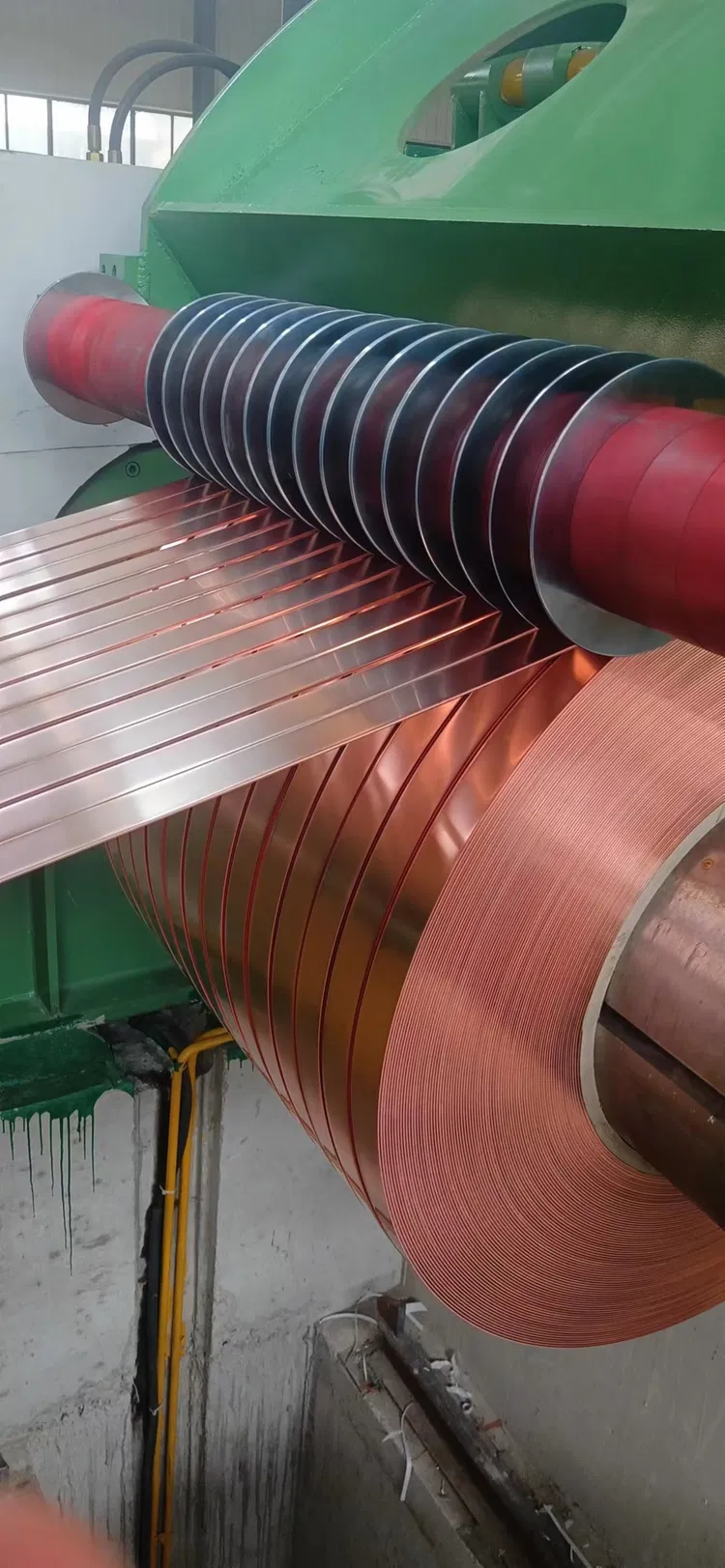

The process begins with cold rolling, where high-purity aluminum or copper ingots are first homogenized and hot-rolled into intermediate gauge coils. These coils are then subjected to cold rolling under precisely regulated reductions and tension control. Cold rolling enhances the material’s mechanical strength and ensures uniform thickness across the entire coil. Our state-of-the-art rolling mills are equipped with laser micrometers and automatic gauge control (AGC) systems, enabling thickness tolerances as tight as ±0.005 mm. Surface roughness is concurrently optimized to support dielectric performance in transformer windings, with typical Ra values maintained between 0.3 and 0.8 µm depending on customer specifications.

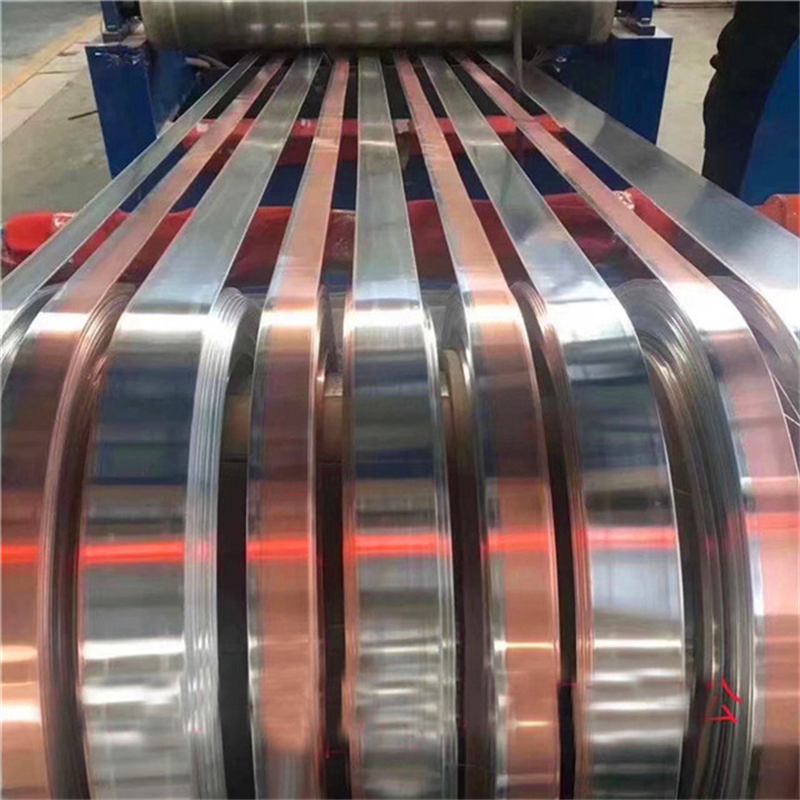

Following cold rolling, coils undergo precision slitting to achieve the required strip widths for transformer core or winding applications. Our slitting lines utilize high-tolerance circular knives with computer-controlled lateral positioning, ensuring edge parallelism within ±0.1 mm. The slit width range spans from 5 mm to 800 mm, accommodating both small-scale instrument transformers and large power transformers. Tension leveling during slitting eliminates coil memory and ensures flatness, critical for consistent winding tension and core stacking efficiency.

Edge conditioning is the final mechanical stage, where slit edges are deburred and radius-formed to eliminate micro-cracks and sharp protrusions. This step is essential to prevent dielectric breakdown and winding damage during coil assembly. Our proprietary edge rounding process uses precision abrasive and roller-based systems to produce a controlled edge radius, typically between 0.05 mm and 0.2 mm, verified through optical edge profiling.

Throughout the manufacturing sequence, comprehensive quality control protocols are implemented at each stage. Incoming billets are spectrometrically analyzed for alloy composition. During cold rolling, continuous surface inspection systems detect defects such as scratches, pits, or inclusions. After slitting, samples are subjected to tensile testing, microhardness evaluation, and eddy current testing for subsurface anomalies. Final inspection includes dimensional verification, edge profile analysis, and surface cleanliness assessment under controlled lighting. All test data is documented and traceable to individual coil batches.

This integrated approach—combining precision engineering with rigorous quality assurance—ensures that every transformer strip and foil product from Luoyang Xinzhaohe meets international standards including GB/T, ASTM, and IEC, delivering reliability and performance in critical electrical applications.

Packaging & Logistics

Export Packaging Specifications for Transformer Strip and Foil

Luoyang Xinzhaohe Aluminum CO., Ltd implements rigorously engineered export packaging protocols for aluminum and copper transformer strip and foil, honed over 20+ years of global logistics experience. Our system prioritizes absolute protection against moisture ingress, physical deformation, and corrosion during extended sea freight transit—a critical requirement for maintaining the metallurgical integrity and electrical performance of these precision materials.

All coils are secured to ISPM 15-certified hardwood pallets, constructed from kiln-dried, knot-free timber with a minimum load-bearing capacity of 2,500 kg. Pallet dimensions adhere to ISO standard container constraints (1,200 mm × 1,000 mm), enabling optimal space utilization while ensuring structural stability under dynamic marine conditions. Each coil is centered and mechanically fastened using steel strapping rated for 1,500 kg tensile strength, preventing lateral shift during vessel motion. Edge protectors fabricated from polyethylene are applied to coil rims to eliminate handling-induced burrs or edge damage.

The primary moisture barrier consists of a triple-layer wrapping system. First, coils are encased in aluminized low-density polyethylene (LDPE) film with a minimum thickness of 125 μm, providing a vapor transmission rate (VTR) below 0.5 g/m²/day. This layer is overlaid with high-density polyethylene (HDPE) film (150 μm thick) for puncture resistance. The assembly undergoes vacuum sealing at 0.8 bar pressure to expel ambient humidity, followed by heat welding of all seams to create a hermetic seal. Desiccant packs (silica gel, 50 g/m³ internal volume) are strategically placed within the sealed envelope to absorb residual moisture and buffer against temperature-induced condensation during tropical route transits.

This packaging configuration has been validated against ISO 1496 container testing protocols and real-world ocean freight conditions. Accelerated aging trials simulate 40-day voyages under 95% relative humidity at 35°C, with zero incidence of surface oxidation or interlayer corrosion on aluminum grades up to 1070-O and copper C11000. Critical parameters are monitored via embedded data loggers during shipment, confirming internal humidity remains below 30% RH throughout transit.

Stacking safety is enforced through strict adherence to a maximum unitized height of 1.2 meters per pallet. This limit, validated via finite element analysis (FEA) under ISO 1161 racking impact standards, prevents coil deformation under container stacking loads while accommodating standard 20-foot and 40-foot high-cube container configurations. All external surfaces bear UV-stable, solvent-resistant labeling with serialized batch IDs, material specifications per ASTM B209/B152, and handling icons compliant with IMDG Code Section 5.2.

Our packaging methodology directly mitigates the two dominant failure modes in transformer material shipping: galvanic corrosion from salt-air penetration and micro-scratching from vibration-induced coil slippage. By integrating materials science with freight logistics engineering, Xinzhaohe ensures coils arrive at destination facilities with surface roughness (Ra) and dimensional tolerances unchanged from factory release—eliminating costly rework or rejection. This system is proven across 50+ countries, including high-humidity routes to Southeast Asia and long-haul transpacific voyages.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum CO., Ltd for Precision Transformer Strip and Foil Solutions

With over two decades of specialized manufacturing experience, Luoyang Xinzhaohe Aluminum CO., Ltd stands as a trusted leader in the production of high-purity transformer strip and foil. Our facility integrates advanced metallurgical processes with rigorous quality assurance protocols to deliver materials engineered for optimal electrical conductivity, mechanical stability, and long-term reliability in demanding power applications. As a vertically integrated producer, we maintain full control over the production chain—from raw material selection and alloy refinement to precision rolling, annealing, and slitting—ensuring consistent product integrity and performance traceability.

Our production infrastructure is anchored by state-of-the-art cold rolling mills and continuous annealing lines, calibrated to achieve tight dimensional tolerances down to ±0.005 mm in thickness and superior surface finish critical for insulation winding efficiency. We specialize in both aluminum and copper transformer strips, with aluminum products meeting GB/T 3880.1-2012 and ASTM B209 standards, and copper strips conforming to GB/T 14594-2008 and ASTM B152. Typical product specifications include 1060, 1070, and 1100 series aluminum alloys with purity levels exceeding 99.6%, and ETP copper (C11000) with minimum 99.90% Cu content. All materials are supplied in O (annealed) temper with controlled tensile strength and elongation to meet winding and stacking requirements in distribution and power transformers.

Quality assurance is embedded at every process stage. Our in-house metallurgical laboratory conducts routine spectrographic analysis, mechanical testing, and microstructure evaluation. Surface defect detection is performed using automated optical inspection systems, while eddy current testing ensures subsurface integrity. Each production batch is accompanied by a full material test report (FMTR) compliant with ISO 9001:2015 and IATF 16949 standards, providing full traceability from ingot to coil.

We serve transformer OEMs, winding manufacturers, and electrical component suppliers across Asia, Europe, and North America, supporting both high-volume production runs and custom-engineered solutions. Our supply chain is optimized for on-time delivery, with dedicated logistics coordination and inventory management protocols to minimize lead times and support just-in-time manufacturing models.

Partnering with Luoyang Xinzhaohe means securing a reliable, technically proficient supplier with deep domain expertise in conductive strip materials for the power sector. We are committed to engineering collaboration, continuous improvement, and long-term supply stability.

For technical inquiries, material specifications, or to initiate a sourcing partnership, contact us at cathy@transformerstrip.com.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing bright sheet directly from China.