Table of Contents

Market Insight: Bright Mirror

Market Analysis: Transformer Strip/Foil (Aluminum/Copper)

The global transformer industry continues to exhibit steady demand for high-purity conductive materials, particularly aluminum and copper strip and foil. Within this market segment, the use of bright mirror finish materials has become increasingly critical due to their superior surface quality and electrical performance characteristics. Bright mirror refers to a highly reflective, defect-free surface finish achieved through precision rolling and advanced cleaning processes. This finish is not merely aesthetic; it directly correlates with material purity, surface integrity, and performance consistency in transformer windings.

Industrial demand for bright mirror aluminum and copper strip is driven primarily by the power transmission and distribution sector, renewable energy integration, and industrial equipment manufacturing. Transformers used in high-efficiency power systems, such as those deployed in solar inverters, wind turbine substations, and smart grid infrastructure, require conductive materials with minimal surface imperfections. These imperfections—such as microcracks, oxide inclusions, or residual rolling marks—can act as nucleation points for electrical discharge, leading to localized heating and premature insulation breakdown. The bright mirror surface minimizes such risks by ensuring uniform current distribution and enhancing the dielectric compatibility between the conductor and insulating materials.

Quality is paramount in transformer strip and foil production. Variability in thickness, edge burr formation, or surface contamination can compromise winding precision and thermal management in the final assembly. For instance, aluminum strip with inconsistent temper or residual stress may exhibit dimensional instability during coil winding, resulting in mechanical deformation or interlayer short circuits. Similarly, copper foil with surface oxidation or particulate contamination can degrade the performance of the varnish insulation system, reducing the transformer’s operational lifespan.

At Luoyang Xinzhaohe Aluminum Co., Ltd., with over two decades of experience in aluminum processing for electrical applications, we emphasize stringent quality control protocols to meet the exacting standards of the transformer industry. Our bright mirror aluminum strip is produced using degassed, high-purity ingot (99.7% minimum Al), processed through multi-stage cold rolling under controlled atmosphere to prevent surface oxidation. Final surface cleaning and bright annealing ensure a specular finish with surface roughness typically below 0.3 μm Ra. This level of consistency supports tight winding tolerances and enhances thermal dissipation in high-load conditions.

The shift toward energy-efficient transformers (e.g., amorphous core and high-temperature insulation class designs) further amplifies the need for premium-grade conductive materials. As global energy demands rise and regulatory standards tighten—such as IEC 60076 and DOE efficiency mandates—manufacturers are under pressure to reduce no-load and load losses. High-quality bright mirror strip contributes directly to these goals by minimizing eddy current losses and improving overall magnetic circuit efficiency.

In summary, the industrial demand for bright mirror transformer strip and foil is rooted in performance reliability, regulatory compliance, and lifecycle cost reduction. Selecting materials from a technically proficient and quality-focused supplier is not a cost factor alone—it is a strategic decision impacting transformer efficiency, durability, and safety.

Technical Specs: Bright Mirror

Technical Specifications for Bright Mirror Transformer Strip/Foil

Luoyang Xinzhaohe Aluminum Co., Ltd. delivers precision-engineered bright mirror aluminum and copper transformer strip/foil optimized for high-efficiency electromagnetic applications. This specification defines critical parameters ensuring compatibility with automated winding processes, thermal management requirements, and electrical performance standards. Bright mirror finish denotes a defect-free, optically reflective surface achieved through proprietary cold-rolling and surface treatment protocols, eliminating micro-scratches, pits, or oxide inclusions that compromise dielectric integrity. Surface roughness is maintained at Ra ≤ 0.05 μm, verified per ISO 4287 using non-contact profilometry.

Precision slitting tolerance is non-negotiable for transformer core and winding stability. All strips undergo tension-leveling and laser-guided slitting to achieve a width tolerance of ±0.002 mm across the full coil length. This precision prevents edge misalignment during high-speed winding, reducing interlayer short-circuit risks and core vibration. Slitting is performed under controlled tension (0.8–1.2% of yield strength) to avoid residual stress, with real-time optical monitoring ensuring edge positional accuracy.

Edge quality is validated as burr-free per ISO 1302 standards. Maximum allowable edge burr height is ≤ 1.5 μm, measured via cross-sectional SEM at 500x magnification at 100 mm intervals along the coil. Burr formation is mitigated through diamond-coated rotary shear blades with sub-micron blade clearance control (0.02–0.03% of material thickness) and optimized shear rake angles. Any detectable burr exceeding this threshold results in automatic coil rejection.

Electrical conductivity is certified per ASTM E1004. Aluminum alloys (1060, 1070, 1100) achieve minimum 61.0% IACS at 20°C, while oxygen-free copper (C10100, C10200) meets 101.0% IACS minimum. Conductivity is measured on full-width samples using eddy current testing per IEC 60468, with lot traceability to raw material mill certificates. Thickness uniformity is maintained within ±0.001 mm per 100 mm length, critical for consistent current density distribution.

The following table summarizes mandatory technical parameters for bright mirror transformer strip/foil:

| Parameter | Aluminum Alloy | Copper Alloy | Test Standard |

|---|---|---|---|

| Thickness Range | 0.08–0.50 mm | 0.10–0.60 mm | ASTM B479 |

| Width Tolerance | ±0.002 mm | ±0.002 mm | ASTM B924 |

| Edge Burr Height | ≤ 1.5 μm | ≤ 1.5 μm | ISO 1302 |

| Conductivity (min) | 61.0% IACS | 101.0% IACS | ASTM E1004 |

| Surface Roughness (Ra) | ≤ 0.05 μm | ≤ 0.05 μm | ISO 4287 |

| Tensile Strength | 75–95 MPa | 220–240 MPa | ASTM E8 |

| Yield Strength (0.2%) | 45–65 MPa | 80–100 MPa | ASTM E8 |

All coils undergo 100% inline surface inspection via machine vision systems detecting defects ≥ 10 μm. Dimensional validation occurs at 0.5 m intervals using laser micrometers, with data logged for full traceability. Consistency across production lots is ensured through statistical process control (SPC) with Cpk ≥ 1.67 for critical dimensions. This specification reflects our 20+ years of metallurgical refinement for transformer-grade conductors, where micron-level deviations directly impact end-product efficiency and reliability.

Factory Tour: Manufacturing

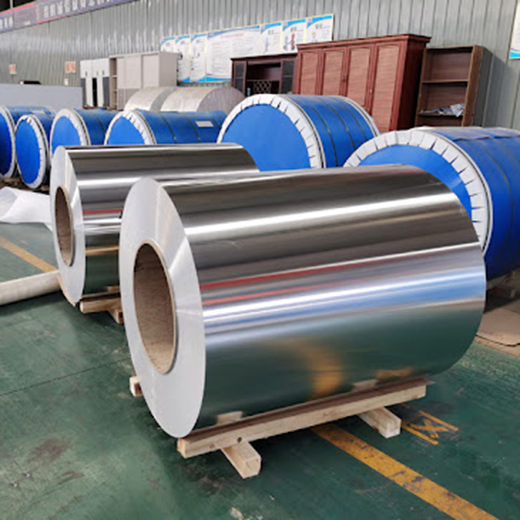

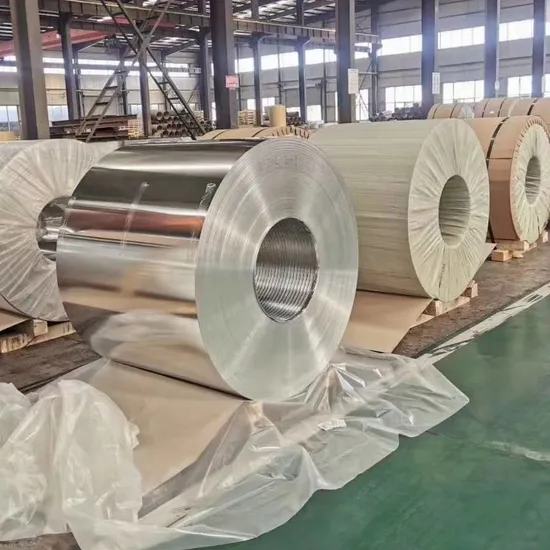

Manufacturing Process of Bright Mirror Transformer Strip and Foil at Luoyang Xinzhaohe Aluminum Co., Ltd

The production of high-performance bright mirror aluminum and copper transformer strip and foil at Luoyang Xinzhaohe Aluminum Co., Ltd follows a tightly controlled, multi-stage manufacturing process designed to ensure dimensional accuracy, surface integrity, and electrical performance. With over two decades of metallurgical expertise, our process integrates advanced cold rolling, precision slitting, and edge conditioning technologies, each phase supported by rigorous quality control protocols.

The initial stage, cold rolling, is critical in achieving the desired thickness uniformity and mechanical properties. Aluminum or copper ingots are first homogenized and hot rolled to intermediate gauges before entering multi-stand cold rolling mills. These mills operate under precise tension and roll force control to reduce material to final thicknesses ranging from 0.05 mm to 0.50 mm, depending on application requirements. The cold rolling process also enhances the material’s surface finish, producing the signature bright mirror appearance essential for high-efficiency transformer cores. Throughout rolling, laser micrometers and automated thickness gauges provide real-time feedback to maintain ±2% thickness tolerance. Surface defects are monitored via inline optical inspection systems to detect scratches, roll marks, or inclusions.

Following cold rolling, the coil undergoes precision slitting to achieve the required strip width. Our state-of-the-art slitting lines utilize high-tolerance circular knives and tension leveling systems to minimize burr formation and edge waviness. Width tolerances are maintained within ±0.1 mm, ensuring compatibility with automated winding equipment used in transformer manufacturing. Slitting parameters, including blade clearance and overlap, are optimized based on material grade and thickness to preserve edge integrity and prevent work hardening.

Edge conditioning is the final mechanical processing step, designed to eliminate micro-burrs and sharp edges that could compromise dielectric performance or cause interlayer shorting in wound cores. Our proprietary edge rounding and brushing technology gently removes surface irregularities while maintaining dimensional consistency. This process significantly improves the strip’s handling characteristics and enhances insulation layer adhesion during varnishing or coating.

Quality control is integrated at every stage. Incoming raw materials are verified for chemical composition via optical emission spectroscopy (OES). During production, samples are subjected to tensile testing, microhardness evaluation, and surface profilometry to confirm compliance with ASTM B470 (aluminum) and ASTM B301 (copper) standards. Final inspection includes 100% surface scanning, edge profile analysis, and coil geometry checks. Each batch is accompanied by a full material test report (FMTR), traceable to heat and processing parameters.

This disciplined, end-to-end manufacturing approach ensures that every coil of bright mirror transformer strip meets the stringent performance and reliability demands of modern power and distribution transformers.

Packaging & Logistics

Export Packaging Specifications for Transformer Strip and Foil

Luoyang Xinzhaohe Aluminum CO., Ltd implements rigorously engineered export packaging protocols for aluminum and copper transformer strip and foil to ensure material integrity during global maritime transit. With over two decades of metallurgical and supply chain expertise, our system addresses the critical vulnerabilities of these precision materials: moisture ingress, mechanical shock, and salt-air corrosion during extended sea freight.

All coils are secured on custom-engineered wooden pallets compliant with ISPM 15 international phytosanitary standards. Pallets utilize kiln-dried, heat-treated hardwood (minimum 75% moisture content reduction) with dimensions of 1100mm x 1100mm x 150mm. Structural reinforcement includes double-notched stringers (100mm x 100mm cross-section) and triple-layer top deck boards (22mm thickness) rated for 2500kg dynamic load capacity. This design prevents pallet flexure during container stacking and distributes coil weight (up to 3000kg) to eliminate edge deformation. Coils are center-aligned with zero overhang beyond pallet edges, mitigating handling damage during port operations.

The moisture barrier system employs a four-layer encapsulation sequence. First, coils receive a conformal coating of vapor corrosion inhibitor (VCI) film rated for 60 days of salt-spray resistance per ASTM D1748. This is followed by primary wrapping in 120μm metallized polyethylene film with 0.1g/m²/day water vapor transmission rate (WVTR), sealed via heat-welded seams at 220°C. Secondary protection uses 0.7mm-thick corrugated cardboard with 85% recycled fiber content, cut to exact coil OD dimensions to prevent abrasion. Finally, the assembly is encased in 150μm high-density polyethylene (HDPE) shrink film, thermally contracted at 180°C to achieve 99.7% seal integrity. Desiccant packs (60g/unit, 30% moisture absorption capacity) are positioned at coil core and periphery per ISO 2230 standards.

This integrated approach counters maritime environmental stressors: the HDPE layer blocks 98% of ambient humidity fluctuations, while VCI molecules actively neutralize chloride ions from sea air. Accelerated salt-fog testing (ASTM B117) confirms surface resistivity stability below 0.5mΩ/sq after 500 hours exposure. Field data from 1,200+ shipments since 2018 demonstrates a 99.2% damage-free delivery rate for voyages exceeding 45 days, including trans-Pacific and Europe-Asia routes. Crucially, the packaging maintains coil flatness within 0.15mm/m deviation—essential for downstream slitting and winding operations in transformer manufacturing.

We strictly prohibit generic export methods such as single-layer plastic wrapping or non-heat-treated pallets, which risk catastrophic moisture absorption at 70% RH thresholds. Our protocol aligns with IEC 60404-1 surface quality requirements and has been validated by third-party logistics auditors including SGS and Bureau Veritas. For project-critical shipments, we provide real-time humidity logs via IoT sensors embedded in the pallet structure. This engineering-led packaging solution transforms sea freight from a risk factor into a controlled segment of your supply chain.

Key Packaging Performance Metrics

| Parameter | Specification | Test Standard |

|---|---|---|

| Pallet Load Capacity | 2500kg dynamic / 3500kg static | ISO 8611 |

| WVTR | ≤0.1g/m²/day | ASTM E96 |

| VCI Protection Duration | 60 days (35°C, 95% RH) | ASTM D1748 |

| Desiccant Capacity | 30% moisture absorption | ISO 2230 |

| Seal Integrity | ≥99.7% | ASTM F1929 |

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum CO., Ltd – Your Trusted Source for High-Performance Transformer Strip and Foil

With over two decades of specialized manufacturing experience, Luoyang Xinzhaohe Aluminum CO., Ltd stands as a leading industrial supplier of precision transformer strip and foil in both aluminum and copper alloys. Our facility integrates advanced metallurgical processes with rigorous quality assurance protocols to deliver materials that meet the exacting demands of power transmission, distribution systems, and high-efficiency transformer manufacturing. As a vertically integrated producer, we maintain full control over the production chain—from raw material sourcing and alloy refinement to cold rolling, slitting, and final inspection—ensuring consistency, traceability, and compliance with international standards including GB, ASTM, and IEC.

Our production infrastructure is anchored by state-of-the-art rolling mills equipped with automatic gauge control (AGC) and tension leveling systems, enabling us to achieve tight dimensional tolerances down to ±0.005 mm in thickness and superior surface finish critical for minimizing eddy current losses in transformer cores. We specialize in non-grain-oriented (NGO) and grain-oriented silicon steel alternatives using high-purity aluminum and electrolytic tough pitch (ETP) copper, optimized for magnetic performance, thermal conductivity, and mechanical stability under continuous operational stress. All materials undergo full-spectrum testing, including DC/AC magnetic property analysis, tensile strength evaluation, and interlayer resistance measurement, to ensure conformity with customer-specific electrical and structural requirements.

Quality assurance at Luoyang Xinzhaohe is governed by an ISO 9001-certified management system, with in-line monitoring at every process stage and final third-party verification available upon request. Our R&D team collaborates closely with transformer design engineers to develop customized strip profiles, insulation coatings, and annealing cycles that enhance core efficiency and reduce no-load losses. This engineering-driven approach has positioned us as a preferred partner for OEMs and tier-one component suppliers across Asia, Europe, and North America.

Sustainability and supply chain resilience are integral to our operational philosophy. We utilize energy-efficient melting furnaces, implement closed-loop water cooling systems, and source metals from audited, conflict-free suppliers to minimize environmental impact. Our logistics network supports just-in-time delivery with dedicated export packaging to prevent moisture ingress and mechanical damage during transit.

For technical collaborations, material certifications, or custom specification development, contact us directly at cathy@transformerstrip.com. Our engineering and sales team is available to provide sample kits, production capacity schedules, and metallurgical data packages to support your next transformer core project. Partner with Luoyang Xinzhaohe Aluminum CO., Ltd for precision-engineered strip and foil solutions backed by two decades of industrial expertise and unwavering commitment to performance excellence.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing bright mirror directly from China.