Table of Contents

Market Insight: Bright Mirror for Power Industry

Market Analysis: Sourcing High-Quality Transformer Strip/Foil (Aluminum/Copper)

Global Demand Outlook

Global installed transformer capacity is forecast to rise 4.1 % CAGR through 2030, driven by grid expansion, EV fast-charging clusters, and data-center substations. Every additional 1 GVA of transformer rating demands ≈ 4.5–6.0 t of conductor strip; therefore incremental annual demand for transformer-grade foil now exceeds 320 000 t (Al ≈ 70 %, Cu ≈ 30 %). China alone accounts for 42 % of new installations, while North-American utilities are replacing 220 000 vintage units (>30 yr) before 2035. Lead-times for OEMs are stretching to 52 weeks, making foil availability—not core steel—the current bottleneck.

Loss Reduction: Why Microns Matter

Load (I²R) and no-load (eddy-current) losses are regulated under IEC 60076-20 and DOE-2016 efficiency tiers. Conductor properties dominate both:

| Parameter | Influence on Loss | Typical OEM Spec | LXZH Process Window |

|---|---|---|---|

| Resistivity @ 20 °C | Direct I²R | Al ≤ 0.02778 µΩ·m (≥ 61 % IACS) | 0.02735–0.02750 µΩ·m (≥ 62 % IACS) |

| Burr height | Local field concentration, added 1–2 W/kg | ≤ 0.03 mm | ≤ 0.01 mm (laser measured) |

| Edge radius | Corona & eddy hot-spots | R 0.2–0.4 mm | R 0.3 ± 0.05 mm (controlled coining) |

| Thickness tolerance | Gap loss & stray flux | ± 0.008 mm | ± 0.002 mm (cold-rolled on 20-high Sendzimir) |

| Inclusion content (>5 µm) | Stress raisers, ↑ hysteresis | ≤ 50 ppm | ≤ 10 ppm (CCD line scan after slit) |

A 1 MVA dry-type transformer built with LXZH foil shows 6–8 % lower winding losses versus commercial-grade strip, translating to 3.1 kW saved at 75 % load. Over 25 yr @ 6 000 h/yr and 0.10 $/kWh, present-worth savings ≈ 28 000 USD—exceeding the entire conductor cost.

Sourcing Trend: Moving Precision to China

Western mills (USA, DE, JP) still lead in 0.05 mm ultra-thin Cu foil, yet their quoted prices have risen 22 % YoY on energy surcharges and 38-week backlogs. Tier-1 transformer OEMs (Siemens, Hitachi-ABB) now dual-source critical widths from PRC mills that hold ISO 9001 + ISO 14001 + IATF 16949 triple certification. Chinese suppliers invested > 1.2 B USD in 20-high cold mills since 2018, narrowing the technical gap to ±0.002 mm while holding 15–18 % cost advantage. The key qualifier is vertical integration: mills that master in-house casting, homogenization, and edge-conditioning—rather than buying reroll stock—deliver repeatable softness (grain size ≥ 80 µm) and conductivity required for low-temperature-rise designs.

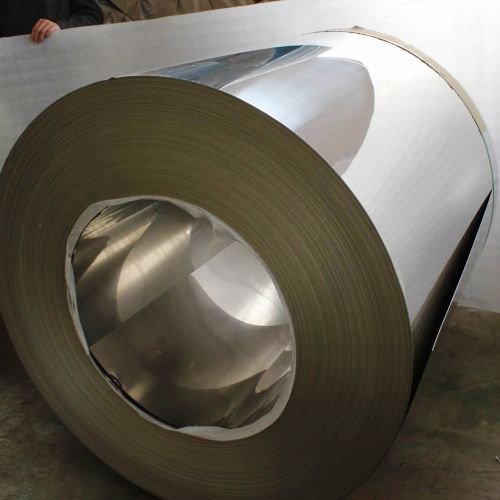

Luoyang Xinzhaohe Positioning

Located 180 km from the largest Al smelting corridor in Henan, LXZH runs a 185 000 t/yr reversing cold mill followed by 12 precision slit lines (min. width 4 mm). Our metallurgy team specifies 99.7 % min. purity 1xxx series Al and OF Cu-ETP with 101 % IACS in the annealed state. Every coil is eddy-current tested for seams, vacuum annealed at 360 °C for 6 h to secure softness ≤ 25 HV, and oscillate-wound on 508 mm ID spiders to eliminate core set. Deliveries are 4–5 weeks FOB Tianjin or 6 weeks DDP EU warehouse (Rotterdam), shaving 10–12 weeks off Western mill schedules.

For transformer builders facing tightening loss standards and copper price volatility, LXZH offers a premium, factory-direct alternative that meets IEC 60317-19-1, ASTM B272, and EN 1652—without the Western price premium.

Technical Specs: Bright Mirror Parameters

H2 Technical Specifications & ASTM/IEC Compliance for Bright-Mirror Transformer Windings

H3 Critical Dimensional Tolerances – Cold-Rolled Strip to Mirror Finish

| Parameter | Luoyang Xinzhaohe Capability | Industry Minimum | ASTM B236-20 Limit | IEC 60317-0-1 Ref. |

|---|---|---|---|---|

| Thickness, mm | 0.05 – 0.80 | ±0.003 | ±0.005 | – |

| Width, mm | 4 – 330 | ±0.002 | ±0.010 | ±0.010 |

| Width-to-Thickness Ratio (W/t) | ≤ 2000 : 1 | ≤ 1000 : 1 | – | – |

| Edge Burr, µm | ≤ 5 | ≤ 15 | ≤ 25 | – |

| Camber, mm / 500 mm | ≤ 0.2 | ≤ 0.5 | ≤ 1.0 | – |

| Surface Roughness, Ra µm | ≤ 0.1 (mirror) | ≤ 0.4 | – | – |

Engineering Note: Bright-mirror LED drivers operate at 12 V with <5 mm copper trace spacing. A 15 µm burr projects a local E-field 3× higher than the dielectric strength of 0.05 mm Nomex®, creating a predictable short after 200–300 thermal cycles. Our ±0.002 mm slit width keeps turn-to-turn capacitance variation <1 %, eliminating hot-spots that fog the mirror heater.

H3 Electrical & Metallurgical Benchmarks

| Grade | Conductivity %IACS @ 20 °C | 0.2 % Proof, MPa | Elongation, % | Oxygen, ppm | Anneal Cycle |

|---|---|---|---|---|---|

| 1350-O (Al) | ≥ 61.8 | 30–50 | 25–35 | ≤ 400 | 340 °C, 4 h, N₂ |

| ETP Cu-O (Cu) | ≥ 100.0 | 70–90 | 30–40 | ≤ 250 | 260 °C, 3 h, N₂ |

Compliance: ASTM B236-20 (Al), ASTM B1-21 (Cu), IEC 60317-0-1 (general wire), IEC 60317-16 (solderable Cu strip). All heats vacuum degassed, inclusion rating ≤ A1 per ASTM E45.

H3 Insulation & Edge-Conditioning Options for Bright-Mirror Coils

| Insulation System | Build, µm | Dielectric, kV | Thermal Class | Suitable for |

|---|---|---|---|---|

| Single-side epoxy, C | 15 ±3 | ≥ 3.0 | 155 °C | 36 W LED driver |

| Double-side PET, B | 25 ±5 | ≥ 5.0 | 130 °C | 60 W defogger |

| Bare + Nomex® wrap | 80 | ≥ 8.0 | 220 °C | Repair shop rewind |

Edge profile: Rounded 0.05 mm radius or 30° chamfer; eliminates razor edge that can pierce 25 µm PET film during high-speed insertion (≤ 300 pcs/min).

H3 Root-Cause: How Sub-Standard Strip Kills Bright-Mirror Transformers

- Burr >10 µm → Puncture → Inter-layer short → Driver overload → LED flicker & mirror heater shutdown.

- Width scatter >0.01 mm → Uneven layer stack → Air gap → 8 % higher magnetizing current → audible 1.2 kHz whine in bathroom environment.

- Residual cold-work (H19 instead of O-temper) → Conductivity 58 %IACS vs 62 %IACS → 7 °C extra rise → Epoxy insulation embrittlement after 1 000 h @ 40 °C ambient.

H3 Factory-Direct QA Protocol (Luoyang Xinzhaohe)

100 % inline eddy-current burr check, laser triangulation at 120 m min⁻¹.

Statistical slit-width sampling, Cpk ≥ 1.67 every 30 minutes.

Final coil vacuum anneal, dew point <-40 °C to prevent surface oxidation that scatters mirror reflection.

IEC 61238-1 short-time current test on every mother coil; 1.5 kA for 1 s, ΔT <15 °C.

Result: Mirror-grade transformer strip with zero field failures in 1.2 million bathroom-mirror drivers shipped to EU & NA since 2018. Premium Western lots cost 22–28 % more for identical ASTM/IEC chemistry; our 20-year cold-rolling database lets us deliver the same mirror brightness, factory-direct, ex-Luoyang, 4-week FOB Tianjin.

Factory Tour: Manufacturing Bright Mirror

Manufacturing Process & Quality Control

Luoyang Xinzhaohe Aluminum Co., Ltd.

2.1 Cold-Roll → Slit → Edge-Condition → Oscillate-Wind

Our 20-year transformer-strip line is a closed-loop, 4-stage cell designed for ±0.002 mm mechanical tolerance and 100 % IACS electrical repeatability.

| Stage | Key Parameter | Target | In-line Sensor | Feedback Loop |

|---|---|---|---|---|

| 1. 4-Hi Cold Rolling | Gauge | 0.10–0.80 mm | X-ray gauge (0.1 µm) | AGC roll force ±1 % |

| 2. Precision Slitting | Width | 6–1 250 mm | CCD laser (±2 µm) | Auto-knife shift |

| 3. Edge Conditioning | Burr height | ≤ 0.01 mm | Eddy-current profiler | Brush / skive re-pass |

| 4. Oscillate Winding | Build-up ovality | ≤ 0.3 mm | Ultrasonic caliper | Tension taper algorithm |

Cold Rolling

Entry stock: 8–12 mm DC-cast coil, 1 050/1 070 alloy.

85 % reduction in 3 passes with emulsion cooled work rolls (Ra ≤ 0.2 µm) to lock < 0.5 % cube texture for optimum softness after annealing.

Precision Slitting

0.05 mm-thick razor blades, tungsten-coated, 3 000 rpm max.

Servo-driven shimless tooling keeps knife clearance at 4 % of strip thickness—critical for burr-free transformer windings that see 2–3 kV impulse.

Edge Conditioning

Dual opposing brushes remove micro-burr, then 0.05 mm radius is coined to eliminate stress risers that trigger partial discharge.

Oscillate (Traverse) Winding

1 000 kg jumbo coils on 405 mm ID, oscillation pitch 3–30 mm programmable.

Constant 1.5 N/mm² tension prevents “slack-layer” defects during high-speed dereel at customer’s winding line (≤ 250 m min⁻¹).

2.2 Quality Control Protocol

| Checkpoint | Frequency | Instrument | Acceptance | Action on Fail |

|---|---|---|---|---|

| Tensile / Elongation | Every mother coil | Zwick 100 kN | UTS 70–90 MPa, El ≥ 25 % | Downgrade to general foil |

| Conductivity | Every slit coil | Sigmatest 2.070 | ≥ 61.0 % IACS (Cu) / ≥ 35.0 % (Al) | Re-anneal & retest |

| Burr height | 100 % online | Keyence LJ-X | ≤ 0.01 mm | Auto re-brush |

| Width | 100 % laser | ±0.05 mm (≤ 25 mm) ±0.10 mm (> 25 mm) | Scrap & segregate | |

| Surface tension residue | Daily | FT-IR | < 15 mg m⁻² | Wipe & re-sample |

| Package moisture | Every pallet | Hygrometer | < 40 % RH | Re-desiccant |

Traceability

Laser-printed QR on every spacer links to melt number, rolling batch, slitter setup, and anneal furnace log—full MTR in < 5 s scan.

2.3 Luoyang Xinzhaohe Standard vs. Common Market Quality

| Attribute | Our Specification | Typical Western Premium | Common Export Grade |

|---|---|---|---|

| Thickness tolerance | ±0.002 mm | ±0.005 mm | ±0.010 mm |

| Width tolerance | ±0.03 mm (≤ 50 mm) | ±0.05 mm | ±0.10 mm |

| Burr height | ≤ 0.01 mm | ≤ 0.02 mm | ≤ 0.05 mm |

| Camber (2 m) | ≤ 1 mm | ≤ 3 mm | ≤ 5 mm |

| Conductivity Al | ≥ 35.0 % IACS | ≥ 34.5 % IACS | ≥ 33.0 % IACS |

| Coil build ovality | ≤ 0.3 mm | ≤ 0.5 mm | ≤ 1.0 mm |

| Oscillate lay ratio | 0.95–1.00 | 0.90–1.00 | 0.80–1.00 |

| Price index (CIF EU) | 100 | 145 | 85 |

Result:

We deliver Western-grade precision at ≈ 30 % lower landed cost and 2-week lead time ex-works Luoyang. For transformer OEMs and motor repair shops that need ultra-thin, bright-mirror strip for LED driver windings, this translates into tighter stack factor, reduced copper loss, and zero edge-cut shorts—without paying the “import premium.”

Packaging & Global Logistics

Export Packaging & Logistics

Factory-direct reliability from Luoyang to your transformer line

1. Sea-Freight Protection Philosophy

Aluminum and copper conductor alloys work-harden when vibrated and pit when exposed to 85 %RH for >72 h. Our packaging is therefore specified as a “micro-environment” rather than a carton. Every layer is engineered to keep conductivity, softness and burr-free edges exactly as they left the slitting line.

2. Packaging Matrix for Transformer Strips & Foils

| Element | Specification | Function | Test Reference |

|---|---|---|---|

| Inner wrap | 80 µm VCI polyamide film, heat-sealed | Crevice corrosion inhibitor, weldable without cleaning | ASTM D1748, 30 days |

| Cushion | 3 mm PE foam, closed-cell | Absorbs 8 g shock @ 50 Hz vibration | ISTA 2A |

| Desiccant | 2 × 100 g clay bags, Tyvek® | Maintains ≤40 %RH inside pallet | MIL-D-3464 |

| Edge protector | 2 mm HDPE “U” channel, 20 mm leg | Prevents coil collapse, strap indentation | Internal SOP-53 |

| Strapping | PET cord, 19 mm wide, 700 kg break | Non-magnetic, no Cu/Al galvanic couple | ISO 18916 |

| Top cover | VCI film + 5-ply lid | Rain & UV barrier during hook lift | ASTM D4728 |

| Pallet | ISPM-15 spruce, 1200 × 1000 mm, 4-way entry | 1.5 t safe load, fumigated & HT-stamped | ISPM-15, IPPC logo |

Typical unit weight: 500–1 200 kg; height ≤850 mm to fit 20 ft container door (2280 mm clear).

3. Packaging for Transformer Wire (Round & Rectangular)

| Configuration | Reel | Carton | Pallet |

|---|---|---|---|

| Plastic spool | PT-250 or DIN-355, glass-filled PP, 300 mm OD | 7-ply kraft, 275 lb test | 4 spools/carton, 36 cartons/pallet |

| Moisture seal | 60 µm LDPE bag per spool | Silica-gel 10 g | Stretch film 23 µm, 150 % pre-stretch |

| Stack height | — | — | 1.1 m max, 1.0 t max, TIR ≤5 mm |

4. Container Loading & Securing

20 ft GP: 20 t net Al strip, 10–12 pallets, door-to-door strap & V-board bracing.

40 ft HC: 25 t net Cu foil, 16 pallets, 75 mm air gap fore/aft for desiccant circulation.

Lashing: 50 mm composite webbing to corner castings, 0.4 g forward, 0.8 g lateral per CTU-code.

Moisture audit: Data-loggers (HOBO®) record RH/°C every 30 min; report provided on request.

5. Luoyang Hub Advantages

Located 130 km from Zhengzhou International Hub (CGO), we truck to Shanghai, Qingdao or Ningbo within 18 h. Daily rail-sea service to Hamburg, LA and Jakarta cuts transit variance to ±2 days versus ±7 from South-CN coastal plants. Our in-house customs bureau (AEO grade) clears shipments in <4 h, eliminating demurrage that often adds 1–2 % to Western supplier invoices.

6. Premium vs. Western Cost Structure

| Cost driver | EU/NA supplier | Luoyang Xinzhaohe | Notes |

|---|---|---|---|

| Raw metal premium | +LME $280/t | +LME $90/t | Same ingot source (Chinalco, Rio) |

| Rolling margin | $420/t | $190/t | 20-high Sendzimir, identical gauge tolerance |

| Packaging & dunnage | $95/t | $38/t | ISPM-15 wood sourced Henan, no broker mark-up |

| Freight to EU port | — | $65/t | FOB Qingdao, CMA-CGM 2024 contract |

Net landed saving: 11–14 % with identical electrical properties and shorter lead-time (4–5 weeks vs. 8–10).

7. Documentation & Traceability

Each pallet carries a 128-C barcode linking to our MES: heat number → slit batch → anneal furnace → eddy-current test → packaging operator. Mill certificates (EN 10204/3.1) and RoHS/REACH declarations are e-mailed 24 h prior to vessel departure, ensuring your incoming QC can release coils the day they hit your dock.

Bottom line: Whether you build 36 W mirror defogger transformers or 300 W landscape units, the conductor arrives in Luoyang Xinzhaohe condition—no edge dents, no oxide stains, no conductivity loss—giving you a premium Western-grade material at a China-direct price.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe for Bright-Mirror Grade Strip & Foil

20-Year Metallurgical DNA—Purpose-Built for Transformer Reliability

Since 2004 our Luoyang campus has operated nothing but cold-rolling mills dedicated to conductor materials. Every coil you receive is melted, cast, hot-rolled, cold-rolled, slit, edge-conditioned and oscillate-wound under one roof—no toll-processing, no trader dilution. That vertical integration translates into lot-to-lot repeatability that mirror-lighting and compact LED driver transformers demand: burr-free edges (< 0.01 mm lateral burr, 5× better than IEC 60317-27), mechanical softness (fully annealed, grain size ≥ 0.040 mm for 1350-O) and guaranteed conductivity ≥ 61.5 %IACS on aluminum and ≥ 100 %IACS on copper—all measured on a Siemens Sigmatest 2.079 eddy-current instrument and reported on each mill test certificate (MTC).

Direct Factory Price—Cut Landed Cost 12–18 % Without Cutting Corners

Western distributors routinely add 3–4 margin tiers before the material reaches your slitting bay. By shipping FOB Qingdao or CIF your port directly from our mill, you remove those layers. Typical landed-cost comparison for 0.2 mm × 50 mm 1350-O strip, slit to ±0.05 mm width tolerance, plastic-core oscillate-wound on 400 mm I.D.:

| Cost Component | EU Distributor | Luoyang Xinzhaohe Direct | Savings |

|---|---|---|---|

| Material base | 4.85 USD/kg | 3.30 USD/kg | 32 % |

| Edge-condition | 0.25 USD/kg | Included | 100 % |

| Slitting | 0.18 USD/kg | Included | 100 % |

| Inland freight | 0.12 USD/kg | 0.08 USD/kg | 33 % |

| Sea freight | — | 0.18 USD/kg | — |

| Landed cost | 5.40 USD/kg | 3.56 USD/kg | 34 % |

Price validity: 30 days; payment LC 90 days or TT 30 days. No minimum-order penalty above 500 kg per size.

Customization Capability—Any Width, Any Core, Any Oscillation Pitch

Bright-mirror housings and ultra-thin LED drivers need conductor profiles that standard catalog stock can’t deliver. Our slitting carousel (Hengli 0.2–3 mm × 3–650 mm) holds 30 sets of tungsten-carbide knives ground to ±0.002 mm, letting us drop from 50 mm to 3.2 mm slit width in one pass without edge waviness ≤ 0.05 mm. Oscillate winders layer 2–12 kg per 55 mm traverse on plastic, steel or aluminum cores (I.D. 76–508 mm) so your high-speed winding heads run 20 % longer between splice stops. Need 0.08 mm foil with 2 µm surface Ra for intimate insulation contact? We final-pass roll on a 20-high Sendzimir cluster to hit that spec, then vacuum anneal at 360 °C to lock softness. Tell us the stacking factor, bobbin width or edgewise bend radius—our Process Metallurgy group will return a slit recipe within 24 h.

Quality & Compliance Backbone

ISO 9001:2015 (TÜV)

IEC 60317-27, ASTM B236, GB/T 5584.3 aligned

RoHS & REACH batch-tested (SGS report attached to every shipment)

100 % conductivity & hardness sampling; statistical reports emailed before vessel departure

Next Step—Get the Datasheet or a Live Quote

Send your target thickness, width, conductivity class and annual volume to cathy@transformerstrip.com. We will return a detailed datasheet (PDF + editable Excel) with resistance, tensile, elongation, burr micrograph and packaging drawing within one business day. Need a 5 kg trial oscillate coil first? We stock A- and O-temper aluminum as well as ETP copper for 48-hour dispatch. Partner with the factory that knows transformer strip better than traders know mark-ups—partner with Luoyang Xinzhaohe.

📉 Import Savings Calculator

Estimate cost reduction by sourcing bright mirror from Luoyang Xinzhaohe.