Table of Contents

Market Insight: Bifilar Transformer Wire

Market Analysis: Winding Wire – Industrial Demand for Bifilar Transformer Wire

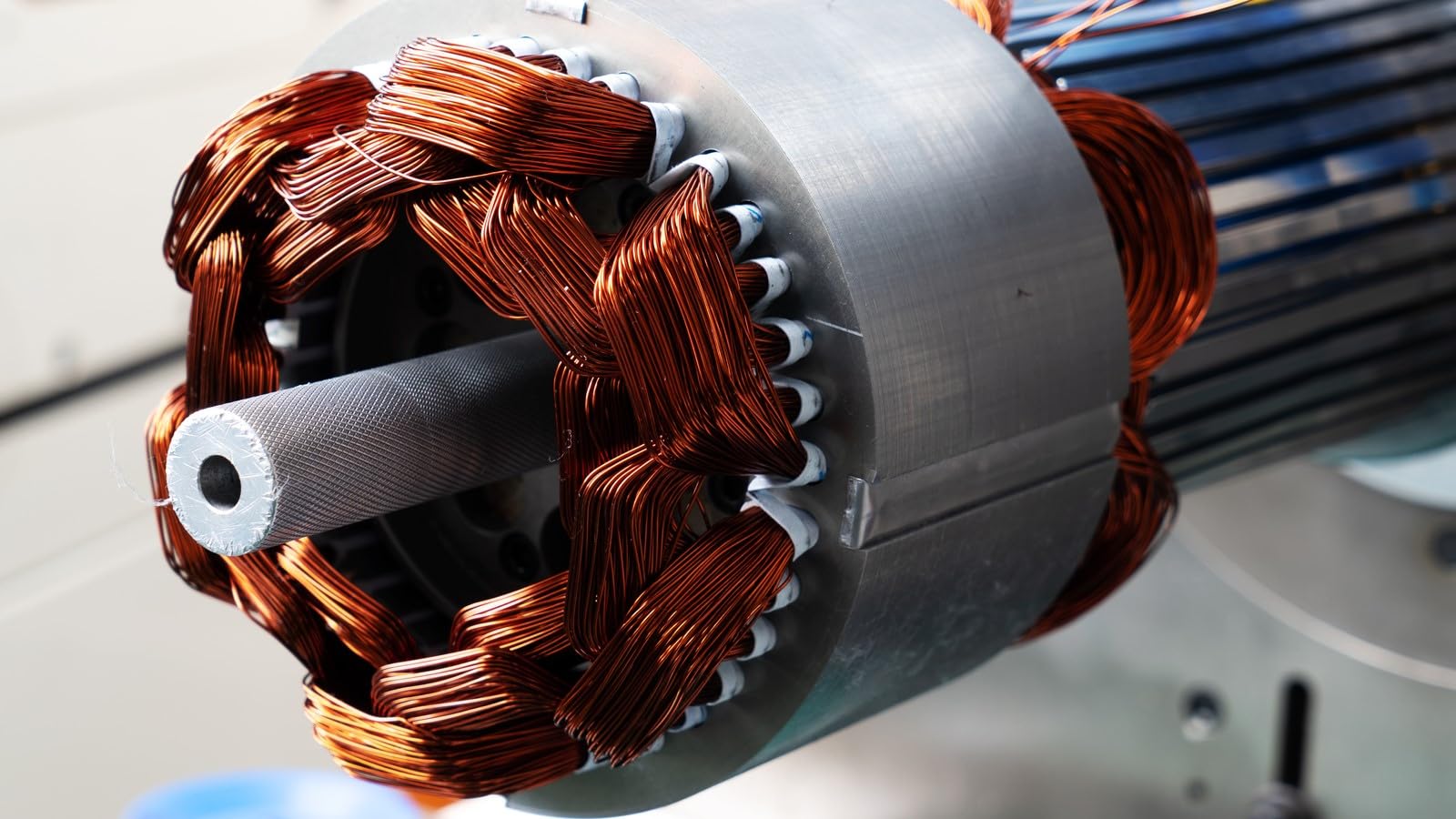

The global demand for bifilar transformer wire remains a critical segment within the broader electromagnetic winding wire market, driven primarily by its specialized application in low-voltage, high-efficiency transformers used across power electronics, telecommunications, and industrial automation systems. Bifilar winding—where two insulated wires are wound in parallel—enables precise coupling between windings, minimizing leakage inductance and enhancing signal integrity. This configuration is particularly advantageous in pulse transformers, gate drive transformers, and common-mode chokes, where balanced impedance and tight magnetic coupling are essential for reliable performance.

Industrial adoption of bifilar transformer wire has grown in parallel with advancements in switch-mode power supplies (SMPS), renewable energy inverters, and electric vehicle (EV) charging infrastructure. These applications require components that support high-frequency operation, thermal stability, and minimal electromagnetic interference (EMI). As power densities increase and system footprints shrink, the precision of the winding process and the consistency of wire characteristics become paramount. Bifilar configurations help achieve these goals by ensuring symmetrical electrical parameters between paired windings, directly influencing transformer efficiency and operational reliability.

At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of expertise in aluminum-based winding wire manufacturing, we recognize that the performance of bifilar transformer wire is not solely determined by its geometric configuration but is deeply influenced by material quality, insulation integrity, and dimensional precision. Aluminum winding wire, while lighter and more cost-effective than copper, presents unique challenges in maintaining consistent conductivity, tensile strength, and surface finish. High-purity aluminum (Grade 1350 or equivalent) with controlled oxide layer formation is essential to ensure uniform drawing and reliable bonding during automated winding processes.

Insulation quality is equally critical. Bifilar wires are typically coated with polyurethane, polyesterimide, or polyamide-imide resins, each offering distinct thermal classes (130°C to 220°C) and mechanical resilience. In high-density windings, insulation must withstand shear forces during co-winding while maintaining dielectric strength between adjacent conductors. Any inconsistency in coating thickness or adhesion can lead to inter-wire shorts or premature thermal degradation—failures that compromise entire transformer assemblies.

Moreover, the trend toward automation in transformer manufacturing demands winding wire with precise diameter tolerance (±0.005 mm or better), consistent elongation, and controlled springback characteristics. These parameters directly affect machine feed rates, loop control, and turn-to-turn placement accuracy. At Xinzhaohe, our production lines integrate real-time diameter monitoring, tension-controlled take-up systems, and rigorous batch testing to ensure compliance with IEC 60317 and ASTM B356 standards.

In conclusion, the industrial demand for bifilar transformer wire is shaped by the evolving requirements of high-efficiency power systems. Quality is not an incremental advantage but a foundational requirement. As manufacturers push the boundaries of miniaturization and performance, the reliability of the winding wire—its material purity, insulation system, and dimensional consistency—becomes a decisive factor in the functional lifespan and safety of the final product.

Technical Specs: Bifilar Transformer Wire

Technical Specifications for Bifilar Transformer Wire

Bifilar transformer wire, a critical component in high-efficiency transformer and inductor manufacturing, demands stringent metallurgical and insulation properties to ensure reliable strand-to-strand isolation and mechanical stability during precision winding operations. As a specialized aluminum conductor producer with 20+ years of metallurgical expertise, Luoyang Xinzhaohe Aluminum CO., Ltd. emphasizes three non-negotiable parameters for bifilar applications: insulation breakdown voltage, elongation, and thermal class. These parameters directly impact transformer longevity, safety margins, and manufacturing yield.

Insulation breakdown voltage is paramount for bifilar configurations due to the inherent risk of strand-to-strand electrical contact under operational stress. Standard single-conductor testing is insufficient; bifilar wire requires strand-to-strand breakdown validation at elevated voltages. Our aluminum bifilar wire consistently achieves a minimum strand-to-strand breakdown voltage of 2000 V AC (rms) at 50 Hz for 60 seconds, per IEC 60317-0-5. This exceeds typical single-wire requirements by 30–50% to accommodate the close proximity of parallel strands during winding and thermal cycling. Lower breakdown values risk inter-strand arcing, leading to premature transformer failure.

Elongation, measured as the percentage increase in conductor length at fracture during tensile testing, dictates winding process stability. Aluminum’s lower ductility versus copper necessitates precise control. Our bifilar wire maintains an elongation range of 1.0–3.0% (ASTM B557), optimized for automated winding machinery. Values below 1.0% increase wire breakage during high-speed winding, while exceeding 3.0% compromises dimensional stability under tension, causing layer misalignment. This parameter is intrinsically linked to our proprietary annealing process, which refines grain structure without compromising tensile strength (150–180 MPa).

Thermal class defines the maximum continuous operating temperature of the insulation system. For aluminum bifilar wire, classes spanning 130°C (B) to 220°C (C) are standard, selected based on end-application demands. Higher classes (e.g., 200°C, H) utilize polyimide or ceramic coatings but require compatible aluminum surface treatments to prevent insulation adhesion failure. Thermal endurance is validated via IEC 60172 thermal aging tests, where insulation retains ≥50% of initial elongation after 20,000 hours at rated temperature. Crucially, aluminum’s higher coefficient of thermal expansion versus copper necessitates insulation systems with superior elasticity to avoid cracking during thermal cycling.

The following table summarizes critical specifications for Luoyang Xinzhaohe’s aluminum bifilar transformer wire:

| Parameter | Standard Range | Test Method | Critical Notes |

|---|---|---|---|

| Strand-to-Strand Breakdown Voltage | ≥2000 V AC (rms) | IEC 60317-0-5 | Tested at 50 Hz, 60s duration; no punctures allowed |

| Elongation | 1.0–3.0% | ASTM B557 | Measured at 25 mm gauge length; critical for winding yield |

| Tensile Strength | 150–180 MPa | ASTM B557 | Optimized for balance between drawability and rigidity |

| Thermal Class | 130°C (B) to 220°C (C) | IEC 60172 | Class dependent on insulation; aluminum requires elastic coatings |

| Conductor Resistivity | ≤28.26 nΩ·m (20°C) | ASTM E8 | Meets IACS 61% standard; critical for efficiency calculations |

Metallurgical precision in aluminum alloy composition (e.g., 1350-H19) and surface oxide control underpins these specifications. Our vertically integrated production ensures traceability from molten metal to finished wire, eliminating interfacial defects that compromise insulation adhesion. For mission-critical transformer applications, adherence to these parameters mitigates field failures and supports design flexibility in high-frequency and high-temperature environments. Luoyang Xinzhaohe Aluminum’s process rigor guarantees conformance to global standards while addressing aluminum-specific challenges in bifilar winding systems.

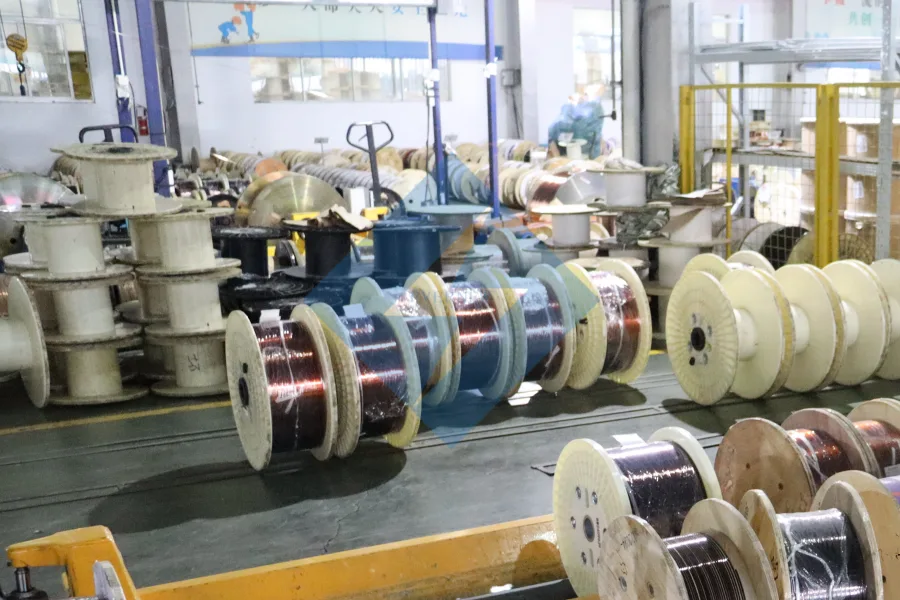

Factory Tour: Manufacturing

Manufacturing Process of Bifilar Transformer Wire at Luoyang Xinzhaohe Aluminum Co., Ltd

The production of bifilar transformer wire at Luoyang Xinzhaohe Aluminum Co., Ltd follows a tightly controlled, multi-stage manufacturing process designed to ensure superior electrical performance, mechanical consistency, and long-term reliability in demanding transformer applications. With over two decades of expertise in aluminum winding wire production, our facility integrates advanced process control systems and rigorous quality assurance protocols throughout each phase: rod drawing, annealing, enameling, and inline testing.

The process begins with high-purity aluminum rod (99.99% Al), sourced from certified suppliers and verified through spectrographic analysis. The rod undergoes precision cold drawing through a series of tungsten carbide or diamond dies to achieve the target wire diameter, typically ranging from 0.30 mm to 2.00 mm for bifilar applications. This rod drawing stage is conducted under controlled tension and lubrication conditions to maintain dimensional accuracy and surface integrity. Diameter tolerances are maintained within ±0.005 mm, with continuous laser micrometer monitoring ensuring real-time compliance.

Following drawing, the aluminum wire enters a continuous annealing line. This step is critical to relieve internal stresses induced during cold working and to restore optimal electrical conductivity and ductility. The annealing process utilizes an inert nitrogen atmosphere to prevent oxidation, with precise temperature control (typically 350–450°C) and dwell time calibrated to achieve a fully recrystallized microstructure. Post-annealing, the wire is rapidly quenched using deionized water to stabilize mechanical properties. Conductivity is verified to meet or exceed 61% IACS, in accordance with IEC 60889 standards.

The next stage is dual-wire enameling, specifically configured for bifilar construction. Two parallel aluminum wires are simultaneously coated with a thermosetting polymer insulation system—commonly polyurethane (PU), polyesterimide (PEI), or a dual-layer PU/PEI system—applied via precision die coating. The coating thickness is tightly controlled, typically between 30–60 μm per layer, to ensure dielectric strength (minimum 3 kV AC) and thermal class compliance (up to 180°C). Curing occurs in a multi-zone oven with progressive temperature profiling to eliminate solvent residues and achieve full cross-linking.

Inline quality control is embedded at every stage. Automated optical inspection systems detect surface defects such as scratches, protrusions, or coating irregularities. Continuous spark testing at 5 kV ensures insulation integrity. Diameter, elongation, springback, and winding behavior are monitored in real time, with data logged for traceability. Final samples undergo destructive testing, including thermal shock (2H at 155°C), needle penetration, and solderability (280°C/3s), to validate conformance to IEC 60317 and customer-specific specifications.

This integrated manufacturing approach ensures that each spool of bifilar transformer wire delivered by Luoyang Xinzhaohe meets the highest standards of performance and consistency required in modern power electronics and transformer systems.

Packaging & Logistics

Export Packaging Specifications for Bifilar Transformer Wire: Ensuring Global Shipment Integrity

Luoyang Xinzhaohe Aluminum CO., Ltd implements rigorously engineered export packaging protocols specifically designed to safeguard the critical dimensional and electrical properties of bifilar transformer wire during extended international sea freight. Ocean transport exposes sensitive aluminum and copper-clad aluminum winding wire to high ambient humidity, salt-laden air, and significant temperature fluctuations, creating substantial corrosion and oxidation risks. Standard packaging is insufficient; our methodology addresses these challenges through integrated material science and logistics expertise honed over 20+ years in global wire supply.

All bifilar wire reels are systematically secured onto robust, ISPM 15 certified wooden pallets constructed from kiln-dried, non-resinous softwood. Pallet dimensions are standardized at 1200mm x 1000mm x 150mm, engineered to withstand stacking loads exceeding 2000kg without deformation, ensuring structural stability throughout multi-modal handling and container stowage. Reels are precisely centered and mechanically fastened to prevent axial or radial movement during transit vibration. The primary moisture barrier consists of a dual-layer system: an initial wrap of 100μm thick, high-density polyethylene (HDPE) film with ultra-low water vapor transmission rate (WVTR < 1.0 g/m²/day) directly contacts the reel assembly. This is followed by a secondary outer layer incorporating a metallized polyester laminate film, providing an additional oxygen barrier and enhanced puncture resistance against handling impacts. All film seams are hermetically sealed using industrial-grade polypropylene tape, creating a continuous, impermeable envelope.

Critical to moisture control is the integrated desiccant system. Silica gel desiccant packs, calibrated to 30% of the enclosed volume’s hygroscopic potential, are strategically placed within the inner film layer prior to final sealing. These packs actively absorb residual atmospheric moisture and counteract any minor permeation over typical 30-60 day voyages. The entire palletized unit is then over-wrapped with a third layer of weather-resistant polyethylene stretch film, tensioned to 250% elongation, providing mechanical protection against abrasion and incidental water ingress during port operations. Each packaged unit undergoes mandatory post-sealing verification: relative humidity sensors confirm internal levels remain below 40% RH at 25°C before container loading, and salt spray chamber testing validates the barrier’s efficacy against ISO 9227 standards.

This multi-barrier approach directly mitigates the primary failure modes observed in transformer wire shipments: inter-strand corrosion in the bifilar configuration, surface oxidation altering resistivity, and reel deformation compromising automated winding processes. Documentation accompanying each consignment includes pallet certification, desiccant saturation reports, and humidity logs, providing full chain-of-custody evidence for the buyer’s quality assurance team. By exceeding IEC 60286-3 export packaging requirements, Xinzhaohe ensures wire arrives with pristine surface integrity and consistent electrical performance, eliminating costly rework or rejection at destination ports. This precision packaging is not merely a shipping step; it is an essential extension of our metallurgical quality control for global supply chain resilience.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum Co., Ltd for Premium Bifilar Transformer Wire Solutions

Luoyang Xinzhaohe Aluminum Co., Ltd brings over two decades of specialized expertise in the production and supply of high-performance winding wire, positioning itself as a trusted partner for global manufacturers of transformers, inductors, and advanced power electronics. As a vertically integrated manufacturer, we maintain full control over the metallurgical and processing stages of aluminum wire production, ensuring unmatched consistency, purity, and electrical performance in our bifilar transformer wire offerings.

Our production facility is equipped with state-of-the-art drawing, annealing, and insulation coating lines, specifically engineered for precision bifilar configurations. We utilize high-conductivity aluminum (EC grade) sourced from certified refineries, processed under strict atmospheric controls to minimize oxide inclusions and ensure uniform grain structure. This metallurgical precision is critical in bifilar applications where balanced impedance, tight coupling, and thermal stability are paramount. All wire undergoes inline eddy current testing, diameter laser gauging, and tensile strength validation to meet IEC 60122-1, ASTM B230, and customer-specific specifications.

We specialize in custom bifilar configurations, including parallel and twisted pair designs, with insulation systems ranging from polyurethane (PU), polyester (PE), to high-temperature polyamide (PA). Our in-house R&D team collaborates directly with clients to optimize wire geometry, pitch tolerance, and dielectric integrity for high-frequency switching environments. With an annual production capacity exceeding 15,000 metric tons and a fully automated warehouse system, we support both high-volume OEM contracts and agile prototyping cycles with lead times averaging 15–25 days from order confirmation.

Quality assurance is embedded at every stage. Our ISO 9001:2015-certified management system governs raw material traceability, process validation, and final product testing. Each batch is accompanied by a full test report including conductivity (≥61% IACS), elongation (≥25%), and bend endurance. We also offer third-party inspection via SGS or TÜV upon request.

As a strategic supplier in the global winding wire market, Luoyang Xinzhaohe is committed to technical collaboration, supply chain resilience, and long-term partnership development. Our engineering team provides on-demand support for material selection, failure mode analysis, and process integration to ensure seamless adoption into your manufacturing workflow.

For reliable, high-performance bifilar transformer wire engineered to exacting industrial standards, contact us today.

Cathy Zhang | International Sales Manager

Email: cathy@transformerstrip.com

Luoyang Xinzhaohe Aluminum Co., Ltd

Established 2003 | ISO 9001 Certified | OEM & ODM Supported

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing bifilar transformer wire directly from China.