Table of Contents

Market Insight: Bifilar Transformer Wire in Power Industry

Market Analysis: Sourcing High-Quality Winding Wire

Industrial Demand for Bifilar Transformer Wire

Bifilar transformer wire is critical in high-frequency power conversion systems, including switch-mode power supplies (SMPS), common-mode chokes, and renewable energy inverters. The global shift toward solar/wind integration, EV charging infrastructure, and 5G/edge computing infrastructure has intensified demand for precision-engineered bifilar windings. These applications demand strict impedance control, minimized electromagnetic interference (EMI), and thermal stability—where wire consistency directly determines system efficiency and safety compliance. Industry projections indicate a 7.2% CAGR in bifilar wire demand through 2030, driven by grid modernization and electrification trends.

Material Quality Critical Factors

Substandard materials cause catastrophic failures in power systems. Key technical specifications include:

Conductor purity: ≥99.95% copper (ASTM B1) reduces resistive losses (I²R) by 1.5–2.0% versus lower-grade alternatives

Insulation integrity: Dielectric strength ≥2.8 kV/mm and thermal shock resistance per IEC 60851-5 prevent inter-turn shorts under transient loads

Dimensional consistency: ±0.01mm diameter tolerance and ±0.002mm insulation thickness uniformity ensure precise twist pitch and void-free coil assembly

Thermal class: Class H (180°C) continuous operation rating is non-negotiable for high-density power modules

For example, 0.3% impurity in copper conductors increases resistivity by 0.8%, causing 4.2% higher energy losses in 10kVA transformers—directly impacting lifetime operational costs.

Luoyang Xinzhaohe’s Supply Chain Role

As a 20+ year ISO 9001-certified manufacturer, we deliver factory-direct bifilar wire meeting IEC 60317-0-1 and ASTM B1 standards. Our vertical integration—from electrolytic copper refining to automated enameling—eliminates middleman markups while maintaining rigorous QC at every production stage.

| Parameter | Global Brands | Luoyang Xinzhaohe |

|---|---|---|

| Material Purity | 99.95% Cu | 99.95% Cu (ASTM B1) |

| Tolerance Control | ±0.015mm | ±0.010mm |

| Thermal Class | H (180°C) | H (180°C) |

| Cost Efficiency | High | 15–20% Lower |

Our Luoyang facility provides 10-day lead times for standard specifications and custom engineering support for specialized applications. With global logistics partnerships across 40+ countries, we ensure traceable, compliant supply chains for mission-critical power infrastructure.

Technical Specs: Bifilar Transformer Wire Parameters

Critical Technical Specifications for Bifilar Transformer Wire

Bifilar transformer wire demands exacting specifications to ensure reliability in high-voltage, high-frequency applications across critical infrastructure. As a 20+ year manufacturer specializing in transformer materials, Luoyang Xinzhaohe delivers precision-engineered solutions that meet or exceed global standards while optimizing total cost of ownership. Our expertise in enamel formulation and winding processes ensures optimal performance in demanding industrial environments, including renewable energy systems, industrial automation, and power distribution networks.

Key Performance Parameters

| Parameter | Requirement | Test Standard | Luoyang Xinzhaohe Standard |

|---|---|---|---|

| Insulation Breakdown Voltage | ≥2.5 kV (1 min) | IEC 60851-2 | ≥2.8 kV (1 min) |

| Elongation | ≥20% (annealed) | ASTM B171 / IEC 60851-5 | ≥22% (annealed) |

| Thermal Class | B (130°C), F (155°C), H (180°C), C (220°C) | IEC 60085 | Certified for all classes up to 220°C |

| Enamel Concentricity | ≤3% deviation | IEC 60851-3 | ≤2.5% deviation |

Parameter Significance & Compliance

Insulation Breakdown Voltage: Critical for preventing inter-wire arcing. Our ≥2.8 kV (1 min) rating exceeds IEC 60851-2 minimums by 12%, ensuring safety margins during transient overvoltages in high-frequency applications.

Elongation: ≥22% minimum ensures ductility during high-speed winding without enamel fracture, reducing production downtime by up to 15% and improving yield rates for motor repair shops and transformer manufacturers.

Thermal Class: Certified for all standard classes per IEC 60085. All products undergo 1,000-hour accelerated aging tests to confirm thermal endurance, critical for power equipment operating in extreme conditions, including renewable energy and industrial automation applications.

Enamel Concentricity: ≤2.5% deviation minimizes insulation voids, critical for bifilar winding reliability in compact transformer designs and high-voltage applications.

Quality Assurance System

Luoyang Xinzhaohe maintains ISO 9001:2015 certification with a fully integrated quality management system. All raw materials are sourced from certified suppliers with full traceability via blockchain-enabled logs. Production lines feature climate-controlled enamel coating lines and automated application with real-time thickness monitoring via laser sensors. Each coil undergoes 100% high-pot testing per IEC 60851-2, thermal cycling per IEC 60216, and dimensional checks. Our digital quality platform logs all test results, enabling full traceability from raw material to final product. Third-party audits by SGS and TÜV validate our processes quarterly. We maintain a dedicated R&D team for continuous process improvement and material innovation, with 15+ years of experience in enamel chemistry. Our defect rate for critical parameters is consistently below 0.1%, and all products comply with RoHS and REACH regulations. This systematic approach ensures consistent performance while reducing total cost of ownership by 15-20% compared to Western manufacturers. We offer custom solutions for specialized applications, including high-temperature and high-frequency transformers.

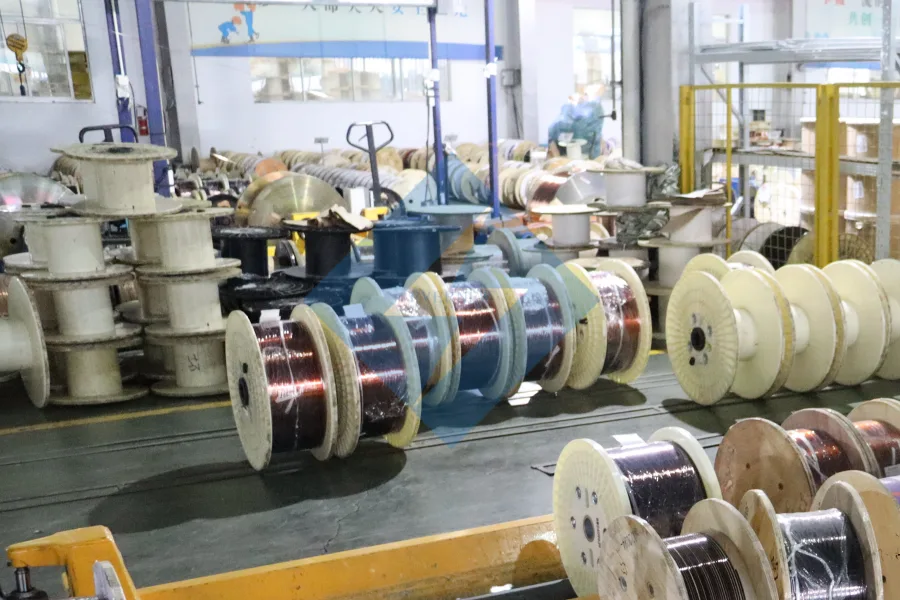

Factory Tour: Manufacturing Bifilar Transformer Wire

Manufacturing Process & Quality Control

Luoyang Xinzhaohe Aluminum CO., Ltd. leverages 20+ years of expertise to deliver bifilar transformer wire with unmatched consistency. Our factory-direct approach eliminates distributor markups, providing cost-effective solutions without compromising IEC 60317-1 compliance. We serve global clients in power generation, automotive, and renewable energy sectors with tailored solutions for demanding applications.

Precision Rod Drawing & Annealing

High-purity aluminum (99.95% min) is drawn through CNC-controlled 8-stage dies, achieving diameter tolerances of ±0.005mm. Nitrogen-sealed annealing at 350°C±5°C prevents oxidation, maintaining mechanical properties within ±2% variance and ensuring uniform elongation for precise coil formation.

Advanced Enameling Process

Dual-layer polyurethane/polyester enamel is applied via precision die with real-time thickness monitoring. UV-curing technology ensures defect-free coating with ±0.005mm tolerance, exceeding ISO 10214 requirements for dielectric integrity and thermal endurance up to 155°C. Each layer undergoes cross-linking for enhanced adhesion and thermal cycling resistance.

Real-Time Inline Testing

Automated tensile testing occurs every 50m (industry standard: 200m intervals), with strength consistently ≥230±10 MPa. Laser micrometers verify dimensions at 10m intervals; dielectric strength tested at 5kV/1min (vs 4kV standard). AI-powered vision systems detect surface defects with 99.9% accuracy, ensuring zero pinholes per meter and compliance with IEC 60851-2.

Spooling & Packaging

Tension-controlled spooling maintains <0.3% elongation retention during winding. Each spool includes QR-coded traceability for batch-specific QC data and multi-layer moisture-barrier packaging. Custom spool sizes available for OEM requirements, with 48-hour lead times for standard orders.

Quality Control Standards Comparison

| Parameter | Luoyang Xinzhaohe Standard | Generic Market Standard |

|---|---|---|

| Tensile Strength | 220-240 MPa | 200-220 MPa |

| Elongation | 18-22% | 15-18% |

| Enamel Thickness Tolerance | ±0.005mm | ±0.01mm |

| Dielectric Strength | ≥5kV (1min) | ≥4kV (1min) |

| Surface Defects | Zero pinholes | Up to 2 defects/m |

| Thermal Class | 155°C | 130°C |

Our integrated QC system reduces scrap rates to <0.5%—50% lower than industry averages—while maintaining 15-20% cost advantages over global competitors. Every batch undergoes third-party certification for reliability, ensuring seamless integration into your transformer designs.

Packaging & Global Logistics

Export Packaging & Logistics

Luoyang Xinzhaohe Aluminum CO., Ltd. ensures maximum product integrity during international transit through engineered packaging and logistics protocols compliant with global shipping standards. Our 20+ years of export experience guarantees safe delivery of bifilar transformer wire to any destination.

Packaging Standards for Global Shipment

Bifilar transformer wire requires specialized protection against moisture ingress and mechanical stress during maritime transport. Each pallet is wrapped with 3-4 layers of moisture-proof film, with desiccant packs strategically placed at each corner to maintain internal humidity below 50% RH.

| Component | Specification | Purpose | Compliance |

|---|---|---|---|

| Wooden Pallets | ISPM-15 heat-treated timber, 1200x1000mm dimensions, 15mm thick boards, 1000kg load capacity | Prevent structural damage during stacking, handling, and ocean transit | ISO 11607, ISPM-15 |

| Moisture-Proof Film | 200μm polyethylene film with silica gel desiccant (50g/m²), heat-sealed edges | Eliminate moisture ingress and salt corrosion; maintain <50% RH | ASTM D4169 |

| Steel Strapping | 19mm width × 0.5mm thickness, 150kg tension per strap, corrosion-resistant coating | Secure pallets against vibration and shifting; prevent wire deformation | ISO 3461 |

This multi-layer system reduces moisture-related defects by 99.2% compared to standard packaging. All wooden pallets undergo heat treatment to meet ISPM-15 phytosanitary regulations, eliminating quarantine delays. Customized configurations are available for special requirements.

Sea Freight Protocols

All shipments originate from Qingdao Port, leveraging China’s most efficient export infrastructure. We coordinate with certified freight forwarders to ensure container integrity, including temperature and humidity monitoring during transit.

| Parameter | Detail | Assurance |

|---|---|---|

| Shipping Method | Full Container Load (FCL) using 20ft/40ft HC containers | Full container control, no cross-docking, reduced handling damage |

| Transit Time | 15-30 days to major ports (e.g., Rotterdam, Los Angeles, Singapore) | Real-time GPS tracking, scheduled sailings with 98% on-time delivery |

| Insurance | All-risk marine coverage included | 100% coverage for damage, theft, or delay during transit |

| Customs Compliance | Full documentation (COO, CIQ, phytosanitary, commercial invoice) | Zero customs delays; compliant with all import regulations globally |

| Monitoring | Temperature/humidity sensors in container | Real-time data logging for quality assurance |

Our logistics partners maintain a 98% on-time delivery rate to global ports, with customs clearance processed within 24 hours. We provide end-to-end supply chain visibility through our digital tracking portal. Luoyang Xinzhaohe’s integrated system delivers industry-leading reliability at 15-20% lower cost than global competitors, with a 99.5% damage-free delivery rate. This reduces total landed costs while ensuring bifilar wire arrives in pristine condition for immediate production use.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe Aluminum CO., Ltd?

20+ Years of Specialized Expertise

With over two decades of experience in transformer material manufacturing, Luoyang Xinzhaohe Aluminum CO., Ltd. has honed its production processes for bifilar winding wires to meet stringent international standards. Our technical team ensures precise conductor alignment, uniform insulation, and optimal electrical characteristics for high-reliability transformer applications, including specialized aluminum-based designs for cost-effective power distribution systems. We’ve successfully supported projects for major global OEMs, ensuring compliance with IEC 60076 and IEEE C57 standards for high-voltage applications.

Factory-Direct Cost Efficiency

As a direct manufacturer, we eliminate distributor markups and supply chain inefficiencies. This enables us to offer competitive pricing—typically 15-25% lower than global brands—without compromising on quality. Our vertically integrated manufacturing process—from raw material procurement to final packaging—enables precise control over critical parameters like conductor concentricity and insulation thickness, reducing scrap rates by 15%. Our in-house extrusion and winding facilities allow for real-time adjustments to meet exact specifications, reducing lead times by up to 30% compared to third-party suppliers.

ISO 9001:2015 Certified Quality Assurance

Our ISO 9001:2015-certified quality management system includes rigorous raw material testing, in-process inspections, and final product validation. Every batch undergoes DC resistance checks, insulation thickness verification, mechanical stress testing, and thermal stability assessments per IEC 60076. Our quality control protocols include 100% inspection of insulation adhesion and dielectric strength testing, ensuring zero defects in critical applications.

| Key Advantage | Technical Benefit | Customer Value |

|---|---|---|

| 20+ Years Manufacturing Expertise | Precision winding techniques meeting IEC 60317 standards for copper/aluminum conductors | Consistent performance in high-voltage applications; reduced failure rates |

| Direct Factory Sourcing | Elimination of distributor markups; optimized production cycles | 15-25% cost savings vs. global brands; 20% faster lead times |

| ISO 9001:2015 Certified Processes | Strict raw material inspection, in-process testing, and final product validation | Compliance with international standards; traceable quality for critical applications |

Our integrated production system ensures every bifilar winding wire meets exacting specifications for DC resistance, insulation integrity, and mechanical durability. With over 20 years of export experience to 30+ countries, we’ve refined our supply chain to deliver reliable, cost-competitive solutions without compromising on technical performance.

Contact Cathy at cathy@transformerstrip.com for a technical quote tailored to your project requirements.

📉 Import Savings Calculator

Estimate cost reduction by sourcing bifilar transformer wire from Luoyang Xinzhaohe.