Table of Contents

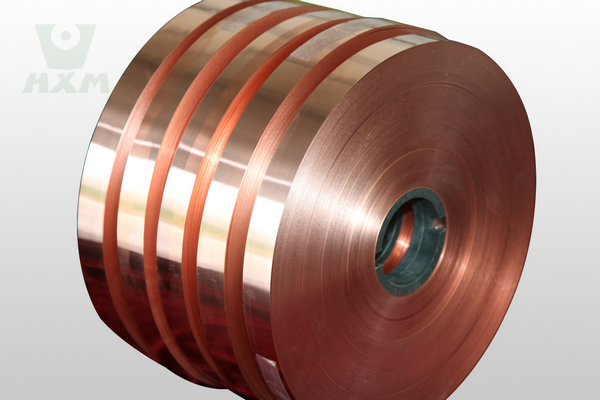

Market Insight: Bare Copper Strips

Market Analysis: Transformer Strip/Foil (Aluminum/Copper) – Bare Copper Strip Demand and Quality Imperatives

The global transformer industry maintains a significant and sustained demand for high-purity bare copper strip, primarily driven by its irreplaceable role in critical high-efficiency and high-reliability applications. While aluminum strip dominates the broader transformer foil market for coil windings due to cost and weight advantages, bare copper strip remains the material of choice for specific, performance-critical components. Its primary applications include low-voltage busbars, tap changers, terminal connections, and high-current density windings within distribution and power transformers where ultimate electrical conductivity, thermal stability, and mechanical robustness are non-negotiable. Stringent global energy efficiency regulations (e.g., DOE 2016, EU Ecodesign) continuously pressure manufacturers to minimize losses, directly elevating the demand for copper’s superior conductivity (approximately 100% IACS minimum) compared to aluminum (approximately 61% IACS). This performance gap translates directly into lower resistive (I²R) losses, reduced operating temperatures, and extended transformer lifespan, justifying copper’s premium cost in these targeted applications.

Quality control for bare copper strip in transformer use is not merely preferable; it is fundamental to operational safety, reliability, and longevity. Substandard material introduces critical failure vectors. Key quality parameters include electrical conductivity, chemical purity (particularly oxygen content), mechanical properties (tensile strength, elongation), surface integrity, and dimensional precision. Conductivity must consistently meet or exceed 100% IACS (International Annealed Copper Standard), as even minor deviations significantly increase energy losses and heat generation over the transformer’s 30+ year operational life. Oxygen content is paramount; electrolytic tough pitch (ETP) copper (C11000, 0.02-0.04% O₂) is standard, but oxygen-free electronic (OFE) copper (C10100, <0.001% O₂) is essential for applications involving high-temperature brazing or exposure to reducing atmospheres to prevent hydrogen embrittlement and intergranular porosity. Surface defects such as scratches, pits, or excessive oxide layers act as initiation points for electrical tracking, corona discharge, and insulation degradation, potentially leading to catastrophic internal faults. Precise thickness and width tolerances (typically ±0.02mm for critical dimensions) are vital for consistent winding tension, optimal core packing factor, and reliable connection integrity during assembly.

The consequences of inadequate quality are severe and costly. Impurities like sulfur or lead can cause hot shortness during processing or accelerate corrosion. Inconsistent mechanical properties lead to winding damage during coil manufacture. Poor surface finish compromises the dielectric strength of adjacent insulation systems. Ultimately, these factors contribute to premature transformer failure, unplanned outages, expensive field repairs, and significant liability risks. Sourcing bare copper strip from metallurgical specialists with rigorous in-process and final quality assurance protocols, deep understanding of transformer manufacturing requirements, and adherence to international standards (IEC 60468, ASTM B111, GB/T 5584) is therefore a critical strategic decision. Luoyang Xinzhaohe Aluminum Co., Ltd leverages its 20+ years of non-ferrous processing expertise, including dedicated copper production lines and stringent QC systems, to deliver bare copper strip meeting the exacting demands of the global transformer supply chain, ensuring optimal performance and reliability in the most demanding electrical infrastructure applications.

Critical Copper Strip Properties for Transformer Applications

| Parameter | Target Value/Range | Critical Impact of Deviation |

|---|---|---|

| Electrical Conductivity | ≥ 100% IACS (min) | Increased I²R losses, higher operating temperature, reduced efficiency |

| Oxygen Content (ETP) | 0.02% – 0.04% | Too low: Welding issues; Too high: Hydrogen embrittlement risk |

| Thickness Tolerance | Typically ±0.02 mm | Winding tension issues, core packing inefficiency, connection problems |

| Surface Roughness (Ra) | < 0.8 µm (often < 0.5 µm) | Insulation damage, electrical tracking, reduced dielectric strength |

| Tensile Strength | 200 – 250 MPa (annealed) | Too high: Poor formability; Too low: Mechanical instability in windings |

| Elongation | ≥ 40% | Insufficient ductility leads to cracking during bending/winding |

Technical Specs: Bare Copper Strips

Technical Specifications for Bare Copper Strips

Luoyang Xinzhaohe Aluminum Co., Ltd. manufactures high-precision bare copper strips designed for critical applications in power transformers, busbars, and electrical transmission systems. With over two decades of metallurgical expertise, our production processes ensure strict adherence to dimensional tolerances, surface integrity, and electrical performance. The following technical parameters define our standard offering for bare copper strips, tailored to meet international quality benchmarks including ASTM B187 and IEC 60115.

All copper strips are produced from high-purity electrolytic tough pitch (ETP) copper, designated as C11000, ensuring optimal conductivity and mechanical workability. The material undergoes a multi-stage rolling and annealing process to achieve uniform grain structure and eliminate internal stresses. This results in excellent flatness and consistent mechanical properties across the strip length. Precision slitting is performed under controlled conditions using high-speed rotary slitters with hardened tool steel blades, achieving a width tolerance of ±0.002 mm. This level of accuracy is critical for automated winding operations in transformer manufacturing, where misalignment can lead to inefficiencies or insulation damage.

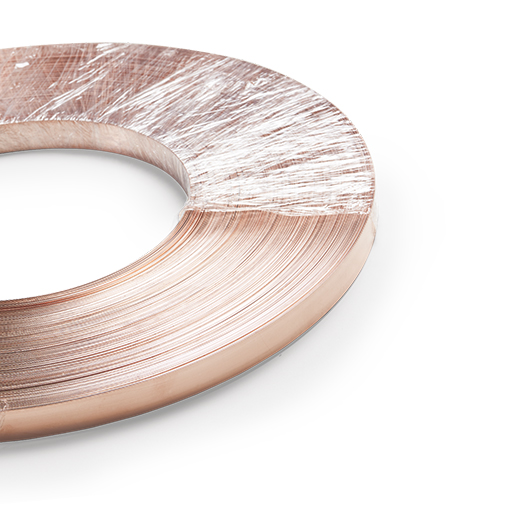

Edge quality is rigorously monitored to ensure burr-free finishes. Post-slitting, each strip undergoes edge deburring and cleaning via electrochemical or mechanical polishing techniques, verified through optical microscopy and tactile profilometry. The absence of micro-burrs prevents dielectric breakdown in tightly wound coils and enhances safety in high-voltage applications. Surface roughness is maintained below 0.8 µm Ra to minimize interfacial resistance and improve contact performance in stacked conductor configurations.

Electrical conductivity is tested per ASTM E1004 using eddy current methods and confirmed via direct current resistance measurement. Our bare copper strips consistently achieve a minimum conductivity of 98% IACS at 20°C, with typical batch averages exceeding 100% IACS due to refined impurity control. This high conductivity directly translates to reduced resistive losses and improved energy efficiency in end-use equipment.

All strips are supplied in straight lengths or on reels, with anti-tarnish coating applied upon request. Packaging is designed to prevent mechanical damage and oxidation during transit. Each batch is accompanied by a material test certificate (MTC) compliant with ISO 17025 standards, including chemical composition, mechanical properties, and electrical test results.

| Parameter | Specification | Test Standard |

|---|---|---|

| Material | C11000 (ETP Copper) | ASTM B187 |

| Thickness Range | 0.10 mm – 6.0 mm | ASTM E3 |

| Width Range | 5.0 mm – 150 mm | ISO 7500-1 |

| Width Tolerance | ±0.002 mm | ISO 2768 |

| Edge Quality | Burr-free, deburred | Visual & Microscopic |

| Surface Roughness (Ra) | ≤ 0.8 µm | ISO 4287 |

| Conductivity | ≥ 98% IACS (Typical: 100–102% IACS) | ASTM E1004 / IEC 60462 |

| Tensile Strength | 200–250 MPa | ASTM E8 |

| Elongation (min) | 40% | ASTM E8 |

| Flatness | ≤ 2 mm per meter length | Custom Measurement |

| Packaging | Reels or Straight Lengths, Anti-tarnish Option | Internal QA Protocol |

These specifications reflect our commitment to delivering technically superior bare copper strips that meet the stringent demands of modern electrical infrastructure. Custom profiles, tempers, and testing protocols are available upon engineering consultation.

Factory Tour: Manufacturing

Manufacturing Process for Bare Copper Transformer Strips

Luoyang Xinzhaohe Aluminum Co., Ltd leverages over two decades of specialized metallurgical expertise in non-ferrous rolling to produce high-integrity bare copper strips essential for transformer windings. Our rigorous production sequence ensures dimensional precision, superior surface quality, and optimal electrical properties demanded by the power transmission sector. The core process integrates cold rolling, precision slitting, and edge conditioning, each stage governed by stringent quality controls.

Cold Rolling Process

High-conductivity electrolytic tough pitch (ETP) copper ingots undergo homogenization and hot rolling to form intermediate blanks. The critical cold rolling phase follows, utilizing computer-controlled 4-high or 6-high rolling mills with precision-ground work rolls. This stage achieves the target strip thickness through multiple passes with controlled reduction ratios, typically 70-85% cumulative. Precise interpass annealing in controlled-atmosphere furnaces prevents work hardening beyond specified limits, ensuring the final grain structure meets ASTM B111 requirements for transformer applications. Surface roughness is maintained below 0.4 μm Ra through roll crown management and emulsion filtration systems, eliminating defects that could compromise insulation integrity. Thickness tolerances are held to ±0.01 mm across the strip width, verified by online laser micrometers.

Precision Slitting Operation

Rolled coils proceed to tension-leveling slitting lines equipped with rotary shear cutters of tungsten carbide alloy. Critical parameters include precise blade clearance adjustment (0.5-1.5% of material thickness) and controlled strip tension (15-25 MPa) to prevent edge camber or width variation. We employ servo-driven knife positioning systems achieving slit width tolerances of ±0.05 mm. Real-time monitoring of web tension and edge guiding ensures consistent strip geometry. Slitting occurs under continuous oil mist lubrication to minimize heat generation and adhesion, preserving the copper’s surface oxide layer within specification for subsequent winding processes.

Edge Conditioning

Post-slitting, strips undergo mandatory edge conditioning to eliminate micro-burrs and sharp edges generated during shearing. This is achieved through precision brushing with abrasive nylon filaments or controlled edge rolling. The process reduces edge burrs to ≤5 μm, critical for preventing dielectric breakdown in transformer windings. Simultaneously, edge radiusing is applied to a consistent 0.05-0.10 mm radius, enhancing handling safety and coil winding stability. Visual and tactile inspection confirms edge smoothness before further processing.

Integrated Quality Control

Quality verification is embedded throughout production. Key checkpoints include:

In-process conductivity testing via eddy current systems confirming ≥100% IACS minimum.

Cross-sectional thickness profiling at 100 mm intervals using calibrated micrometers.

Surface defect scanning via high-resolution cameras detecting pits or scratches >10 μm depth.

Final mechanical property validation through tensile testing per ASTM E8, ensuring yield strength 60-100 MPa and elongation >5%.

All coils receive full traceability documentation including melt chemistry, process parameters, and certified test results against IEC 60137 and customer-specific standards. This systematic approach guarantees strips deliver consistent performance in high-efficiency transformer cores.

Packaging & Logistics

Export Packaging for Bare Copper Strips: Ensuring Integrity During Sea Freight

At Luoyang Xinzhaohe Aluminum Co., Ltd., with over two decades of specialized experience in the production and international supply of transformer-grade aluminum and copper strips, we recognize that proper export packaging is as critical as material quality in delivering performance-ready products to global customers. For bare copper strips, our packaging system is engineered to mitigate environmental exposure, mechanical stress, and logistical risks inherent in long-distance sea freight.

All export shipments of bare copper strips are secured on high-load-bearing wooden pallets constructed from kiln-dried, ISPM 15-compliant hardwood. These pallets are designed to support the weight distribution of tightly wound coils or stacked flat strips, preventing deformation during handling and transit. The structural integrity of the pallets ensures compatibility with standard containerized shipping protocols and facilitates safe loading/unloading via forklift or crane at ports and destination facilities.

Each copper strip load is wrapped in multiple layers of industrial-grade moisture-proof composite film, which acts as a vapor barrier against humidity, salt air, and condensation—common challenges in maritime transport. The film is heat-sealed at all seams to form a continuous protective envelope, significantly reducing the risk of surface oxidation and tarnishing. This is particularly vital for bare copper, which, despite its excellent electrical conductivity, is susceptible to atmospheric corrosion when exposed to moisture and pollutants over extended periods.

To further enhance protection, desiccant packs are strategically placed within the sealed packaging to absorb residual moisture, and humidity indicator cards are often included for post-arrival verification of internal conditions. The outer layer of packaging is reinforced with UV-resistant polyethylene stretch film to prevent degradation during outdoor storage or sun exposure at transit hubs.

Marking and labeling comply with international shipping standards. Each pallet is labeled with essential information including batch number, alloy specification, dimensions, net and gross weights, handling instructions, and destination details—all printed on weather-resistant tags affixed securely to the pallet. These identifiers support full traceability and streamline customs clearance.

Our packaging methodology has been validated through years of successful deliveries across Southeast Asia, the Middle East, Europe, and South America, where variable climatic conditions and extended shipping durations demand robust protective measures. By integrating material science with logistics engineering, Luoyang Xinzhaohe ensures that every shipment of bare copper strip arrives in the same condition as it left our facility—dimensionally stable, surface-intact, and ready for immediate processing.

This disciplined approach to export packaging underscores our commitment to reliability, quality assurance, and customer satisfaction in the global transformer and electrical equipment supply chain.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe for Precision Bare Copper Strip Supply

Luoyang Xinzhaohe Aluminum Co., Ltd leverages over two decades of specialized metallurgical expertise to deliver bare copper strips meeting the stringent demands of transformer and electrical component manufacturing. Our vertically integrated production facility, purpose-built for high-purity conductive materials, ensures exceptional control over the entire value chain from raw material sourcing to finished strip. This integration is fundamental to guaranteeing the dimensional stability, surface integrity, and electrical properties critical for efficient transformer core and winding performance.

Our core strength lies in advanced process metallurgy applied specifically to oxygen-free and electrolytic tough pitch (ETP) copper. We operate state-of-the-art continuous casting and precision rolling lines capable of producing strips with thicknesses ranging from 0.05 mm to 3.0 mm and widths up to 650 mm. Critical to transformer applications, we consistently achieve tight tolerances: thickness tolerance held to ±0.005 mm for strips below 0.2 mm and ±1% for thicker gauges, alongside flatness deviations under 1.5 mm per meter. Surface roughness (Ra) is meticulously controlled to 0.25 µm or better, minimizing interlayer losses in wound components. Material purity adheres strictly to ASTM B111 C10100/C10200/C11000 or equivalent GB/T 5231 standards, with residual oxygen levels maintained below 10 ppm for OF copper grades to prevent hydrogen embrittlement during annealing.

Supply chain resilience is engineered into our operations. We maintain strategic partnerships with certified primary copper refiners and operate rigorous in-house chemical analysis (ICP-OES, LECO) on 100% of incoming cathode lots. This upstream control, combined with our dedicated annealing and tension-leveling lines featuring inert atmosphere processing, eliminates common failure modes like surface oxidation, edge cracking, or inconsistent temper. Our facility holds ISO 9001 and IATF 16949 certifications, with documented process capability indices (Cpk > 1.67) for key parameters across all production runs.

Material specifications are precisely defined to match application requirements. The following table outlines our standard production capabilities:

| Parameter | Standard Grade (ETP C11000) | Premium Grade (OF C10100) | Test Method |

|---|---|---|---|

| Minimum Cu + Ag | 99.90% | 99.99% | ASTM B111 / GB/T 5231 |

| Thickness Range | 0.05 – 3.0 mm | 0.05 – 2.0 mm | ASTM B9 |

| Thickness Tolerance | ±1% (min ±0.005mm) | ±0.5% (min ±0.003mm) | ASTM B9 |

| Tensile Strength | 200 – 265 MPa | 210 – 240 MPa | ASTM E8 |

| Elongation | ≥ 5% | ≥ 10% | ASTM E8 |

| Surface Roughness | Ra ≤ 0.40 µm | Ra ≤ 0.25 µm | ISO 4287 |

This technical precision translates directly to reduced scrap rates in your lamination or winding processes and optimized core loss performance in the final transformer assembly. Our engineering team collaborates directly with customers during material qualification, providing comprehensive mill test reports, coil mapping data, and metallurgical support for troubleshooting.

For transformers demanding zero compromise on conductivity and dimensional fidelity, Luoyang Xinzhaohe provides the metallurgical assurance and supply chain certainty you require. Contact Cathy directly at cathy@transformerstrip.com to discuss your specific bare copper strip requirements and request material certification packages for your next procurement cycle.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing bare copper strips directly from China.