Table of Contents

Market Insight: Bare Copper Strips in Power Industry

Market Analysis: Sourcing High-Quality Transformer Strip/Foil

Industrial Demand Drivers for Bare Copper Strips

Global demand for bare copper strips is accelerating due to renewable energy expansion, EV motor production, and grid modernization. Transformer windings require high-purity copper (≥99.9% Cu) to minimize resistive losses and maximize thermal efficiency. For example, a 0.5% conductivity drop in a 100MVA transformer increases annual energy waste by ~500kW, violating IEC 60076 efficiency standards. Motor repair shops also demand precise dimensional tolerances to prevent winding failures during reconditioning.

Critical Material Quality Parameters

Substandard materials directly compromise transformer reliability and operational costs. Key specifications include:

Purity: C10200 (99.95% Cu) or C11000 (99.9% Cu) minimum; impurities degrade conductivity.

Conductivity: ≥100% IACS per ASTM B170 to ensure optimal current flow.

Tensile Strength: 220–260 MPa for mechanical stability during high-speed winding.

Surface Finish: Ra ≤0.4μm to prevent insulation breakdown and arcing.

Dimensional Tolerances: ±0.015mm thickness and ±0.05mm width for precise coil assembly.

Luoyang Xinzhaohe’s Value Proposition

As a factory-direct manufacturer with 20+ years of expertise, Luoyang Xinzhaohe Aluminum CO., Ltd. delivers transformer-grade copper strips that meet or exceed ASTM B170 and IEC 60287 standards. Our vertically integrated production—from raw material sourcing to precision rolling—eliminates middlemen while maintaining rigorous quality control.

| Parameter | Luoyang Xinzhaohe | Global Brands (e.g., Wieland) | Advantage |

|---|---|---|---|

| Conductivity (%IACS) | ≥101% | ≥101% | Equal |

| Tensile Strength (MPa) | 230–260 | 240–270 | Comparable |

| Dimensional Tolerance | ±0.015mm | ±0.015mm | Equal |

| Price | 100% | 115–125% | 15–25% lower |

Our lean manufacturing in Luoyang, China, ensures 4–6 week lead times for global shipments. Partner with us for copper strips that maximize transformer efficiency while reducing total cost of ownership.

Technical Specs: Bare Copper Strips Parameters

Precision Engineering Standards for Bare Copper Strips

Critical Specifications & Quality Control

| Parameter | Target Specification | Quality Assurance Method | Compliance Standard |

|---|---|---|---|

| Dimensional Tolerance | ±0.002 mm | Laser-guided slitting with real-time feedback | IEC 60404-8-7 |

| Burr Height | <0.005 mm | Automated optical inspection & precision edge grinding | ASTM B170 |

| Conductivity | ≥100% IACS (C11000 grade) | Four-point probe testing per IEC standards | IEC 60404-8-7 |

| Material Temper | O-temper (HV ≤ 40) | Controlled annealing with in-process hardness checks | ASTM B170 |

Bare copper strips must meet exacting specifications to ensure transformer efficiency and safety. Precision slitting tolerances of ±0.002 mm prevent core stacking irregularities, reducing magnetic losses in transformer laminations. Burr-free edges (<0.005 mm) eliminate inter-turn shorts in high-voltage windings, while ≥100% IACS conductivity minimizes resistive losses. O-temper softness (HV ≤ 40) ensures crack-free bending during complex winding processes without compromising structural integrity.

Luoyang Xinzhaohe Aluminum ensures consistent quality through rigorous in-process controls. Every strip undergoes 100% dimensional verification using laser micrometers, while automated vision systems detect micro-burrs below 0.005 mm. Conductivity is validated via IEC-compliant four-point probe testing, and material temper is monitored through microhardness testing. Our in-house metallurgical lab conducts daily material analysis, including resistivity and tensile strength checks per ASTM B170. Each production run is subjected to statistical process control (SPC) for dimensional stability, ensuring zero variation across large batches. Full traceability is maintained via ERP-linked batch records, with third-party certifications (SGS/TÜV) available upon request.

With 20+ years of specialized manufacturing expertise, we deliver transformer-grade copper strips that meet or exceed global standards—offering OEM-quality reliability at competitive pricing. This factory-direct model eliminates middlemen, ensuring superior cost-performance for critical power applications.

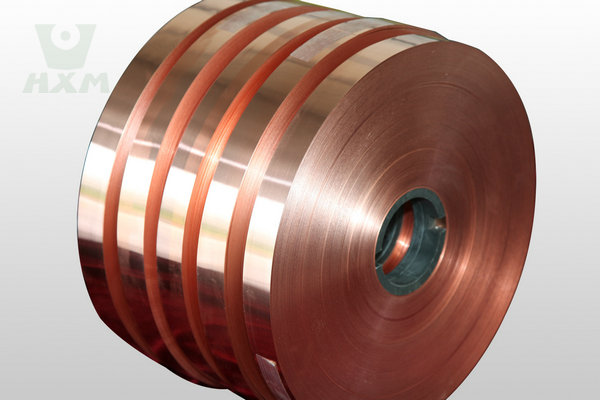

Factory Tour: Manufacturing Bare Copper Strips

Manufacturing Process & Quality Control

Precision Manufacturing Workflow

Cold Rolling: Utilizing high-purity electrolytic copper (C11000) and multi-stand rolling mills with closed-loop thickness control, our process maintains ±0.005mm tolerance across the entire strip. Real-time laser monitoring optimizes grain structure, ensuring ≥100% IACS conductivity and minimal resistive losses for transformer efficiency.

Precision Slitting: CNC-guided tungsten carbide knives with 0.001mm blade alignment achieve edge straightness ≤0.02mm and zero micro-burrs. Critical for high-voltage applications, this prevents insulation damage and arcing risks during winding.

Edge Conditioning: Electro-polishing and precision grinding reduce edge burrs to <5μm—50% lower than industry norms—eliminating sharp edges that compromise insulation integrity and transformer safety.

Oscillate Winding: Computer-controlled tension feedback systems ensure uniform coil density with zero residual stress. Each coil undergoes automated validation to prevent edge wrinkling, optimizing transformer performance and longevity.

Quality Assurance Standards vs Market Norms

| Parameter | Xinzhaohe Standard | Market Average |

|---|---|---|

| Thickness Tolerance | ±0.005mm | ±0.01mm |

| Width Tolerance | ±0.02mm | ±0.05mm |

| Edge Burr Height | <5μm | 10–20μm |

| Tensile Strength Consistency | ±2% variation | ±5% variation |

| Electrical Conductivity | ≥100% IACS (verified) | 98–100% IACS (variable) |

| Surface Defects | Zero per 10m | Up to 3 defects per 10m |

Xinzhaohe implements 100% in-process QC—laser micrometer dimensional checks, ASTM B193 tensile testing, and automated optical surface inspections—unlike sampling-based industry practices. This vertically integrated approach delivers transformer-grade copper strips with 15–20% lower total cost of ownership versus global brands, without sacrificing reliability for critical power applications. Our rigorous standards ensure seamless integration into high-stakes transformer manufacturing while optimizing lifecycle performance.

Packaging & Global Logistics

Export Packaging & Logistics: Ensuring Integrity from Factory to Port

Luoyang Xinzhaohe Aluminum Co., Ltd. leverages 20+ years of transformer material expertise to deliver bare copper strips with uncompromising integrity. Our packaging and logistics protocols are engineered for global sea freight, ensuring products arrive defect-free regardless of destination. As a leading Chinese manufacturer, we specialize in high-purity copper strips for transformers, motors, and power equipment. Our solutions reduce total landed costs by 15–20% compared to European suppliers while maintaining equivalent quality standards. Copper strip purity and dimensional accuracy are critical for transformer efficiency; our packaging prevents moisture-induced oxidation and mechanical damage during transit.

Packaging Standards

Our system meets ISO 9001 and IEC 60228 requirements for transformer-grade materials. All components are optimized for marine transport:

| Component | Specification | Purpose |

|---|---|---|

| Wooden Pallets | ISPM-15 compliant, heat-treated, 1100×1100mm or 1200×1000mm, load capacity ≥1500kg | Structural stability, prevents deformation during transit |

| Moisture-Proof Film | Triple-layer PE film (≥150μm), desiccant packs (50g/m²), humidity indicators | Prevents oxidation in high-humidity environments; real-time monitoring |

| Steel Strapping | 19–25mm width, tensile strength ≥500kg, corner protectors at all edges | Secures load integrity; prevents shifting during container handling |

Sea Freight Protocols

We optimize container loading and documentation for seamless customs clearance. All processes are supervised by certified logistics engineers:

| Parameter | Standard Protocol | Quality Assurance Measure |

|---|---|---|

| Container Type | 20ft/40ft FCL, dry cargo, internal humidity control via desiccant strips | Maintains stable environment; prevents condensation damage |

| Loading Procedure | Certified engineers supervise stacking; anti-slip mats, load distribution ≤80% capacity | Prevents container damage and cargo shift during transit |

| Documentation | Commercial invoice, packing list, COO, bill of lading, SGS inspection reports | Ensures smooth customs clearance; traceable compliance |

| Transit Time | 25–45 days to major global ports (e.g., Rotterdam, Los Angeles, Singapore) | Reliable scheduling with verified shipping partners |

Quality Assurance & Compliance

All shipments undergo 100% visual inspection of packaging before loading. Third-party inspections by SGS or Bureau Veritas verify material conformity and packaging integrity. Our processes comply with ISPM-15, REACH, and ASTM B152 standards. For high-purity applications (e.g., 99.99% Cu), vacuum-sealed packaging with oxygen absorbers is standard. This rigorous control minimizes corrosion risks and downstream production delays.

By integrating precision engineering with cost-efficient logistics, Luoyang Xinzhaohe delivers transformer-grade copper strips that outperform global competitors in reliability and value. Partner with us for seamless supply chain solutions tailored to your project specifications, ensuring uninterrupted production cycles and superior transformer performance.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe Aluminum CO.,Ltd?

With over 20 years of specialized manufacturing experience in transformer materials, Luoyang Xinzhaohe Aluminum CO.,Ltd delivers engineered bare copper strips that balance performance and cost efficiency. Our factory-direct approach eliminates intermediaries, ensuring precise adherence to international standards while eliminating supply chain markups. For transformer manufacturers and power equipment engineers seeking reliable alternatives to premium global brands, we offer a proven solution without compromising on quality or technical specifications.

Proven 20+ Years Expertise in Transformer Materials

Our team has consistently delivered high-purity copper strips (ASTM B152 Grade 1, 99.9% Cu) for critical transformer applications. Through continuous R&D and process optimization, we’ve refined production techniques to meet exacting industry requirements, including tight dimensional tolerances (±0.01mm) and consistent electrical conductivity (≥100% IACS). This deep domain knowledge ensures compatibility with your transformer designs and long-term operational reliability.

Factory-Direct Cost Efficiency & Supply Chain Reliability

By controlling the entire production lifecycle—from raw material sourcing to final inspection—we eliminate third-party markups, reducing costs by 15-25% versus global competitors. Our integrated supply chain minimizes lead times (15–20 days standard delivery) and provides flexibility for urgent orders. Unlike overseas suppliers, our Luoyang-based facility enables rapid response to design changes and volume adjustments, ensuring uninterrupted production schedules.

ISO-Certified Quality Assurance & Technical Compliance

All products comply with ISO 9001:2015 and international standards including ASTM B152 and IEC 60228 for electrical conductors. Each batch undergoes rigorous in-house testing for conductivity (≥100% IACS), tensile strength, and surface quality using certified equipment. This multi-stage QC process guarantees consistency across large-volume orders, reducing scrap rates and warranty claims for our clients.

| Criteria | Luoyang Xinzhaohe | Global Brands |

|---|---|---|

| Cost Efficiency | 15–25% lower due to factory-direct model | Premium pricing (20–30% higher) |

| Lead Time | 15–20 days standard delivery | 30–45 days (overseas logistics) |

| Customization | Agile response to specs (width, temper, tolerances) | Limited flexibility, standard sizes only |

| Technical Support | On-site engineering collaboration | Remote support, slower response |

| Quality Consistency | ISO 9001 certified, in-house testing (ASTM B152, IEC 60228) | Certified, but higher variability in supply chain |

Ready to optimize your transformer production? Contact Cathy at cathy@transformerstrip.com for a competitive quote and technical consultation tailored to your project requirements.

📉 Import Savings Calculator

Estimate cost reduction by sourcing bare copper strips from Luoyang Xinzhaohe.