Table of Contents

Market Insight: Auto Transformer Winding Wire in Power Industry

Market Analysis: Sourcing High-Quality Winding Wire

Industrial Demand Drivers

Global energy infrastructure modernization, renewable energy integration (solar/wind), and EV charging network expansion are driving demand for high-efficiency auto transformers. These applications demand precision-engineered winding wire with strict dimensional tolerances and high conductivity to minimize energy losses and ensure stability under fluctuating loads. Industry reports project a 5.2% CAGR for the global transformer market through 2030, with auto transformers representing 28% of this growth due to their critical role in voltage regulation for smart grids and industrial power systems.

Material Quality Impact on Transformer Performance

Substandard winding wire introduces critical performance risks:

Copper impurities >0.05% increase DC resistance by 1.2–1.8%, elevating I²R losses by up to 15%

Insulation thickness variations (±10% tolerance) cause dielectric breakdown during thermal cycling

Poor thermal stability reduces transformer lifespan by 30–40% in continuous high-load operations

Key Quality Metrics Comparison

| Criteria | Global Brands | Luoyang Xinzhaohe |

|———-|————–|——————-|

| Copper Purity | 99.95% (typical) | 99.99% min (IEC 60317-36) |

| Diameter Tolerance | ±1.5% | ±0.8% (ISO 9001 certified) |

| Dielectric Strength | 20 kV/mm | 25 kV/mm |

| Lead Time | 6–8 weeks | 4–5 weeks |

| Cost Premium | 15–20% | 10% below market average |

Luoyang Xinzhaohe’s Value Proposition

As a 20+ year manufacturer with vertically integrated production from raw copper procurement to finished wire, we deliver factory-direct solutions optimized for cost-performance. Our Luoyang facility employs real-time process control for wire drawing and insulation coating, ensuring batch-to-batch consistency. Unlike global brands, we offer:

Custom specifications (enamel types, cross-sections) with no MOQ penalties

On-site metallurgical testing for resistivity, tensile strength, and dielectric integrity

24/7 engineering support for seamless integration into winding processes

Serving 12+ international transformer OEMs as a Tier-1 supplier, we guarantee 98% on-time delivery while reducing total cost of ownership by 10–15% versus premium alternatives. Our commitment to IEC 60317 standards and ISO 9001-certified quality control ensures reliable performance in mission-critical power applications.

Technical Specs: Auto Transformer Winding Wire Parameters

Technical Specifications & Standards

Insulation Breakdown Voltage

Critical for preventing electrical shorts under high-voltage stress. Our aluminum winding wires comply with IEC 60317-2-1, with breakdown voltages exceeding 2.0 kV for 0.4mm and 2.5 kV for 0.5mm aluminum wire. All batches undergo 100% AC dielectric testing using calibrated high-voltage testers with ±0.1kV accuracy. This ensures dielectric integrity in high-frequency and high-voltage transformer applications.

Elongation

Ensures wire integrity during high-speed winding processes without breakage. Aluminum conductors meet IEC 60317-0-1 standards with minimum 10% elongation, validated through tensile testing per ASTM B210. Real-time monitoring during production prevents substandard batches, critical for complex winding geometries in compact transformers.

Thermal Class Specifications

Complies with IEC 60085 for long-term thermal stability under operational loads:

| Class | Max Temp (°C) | IEC Standard | Applications |

|---|---|---|---|

| B | 130 | IEC 60085 | General-purpose transformers, consumer electronics |

| F | 155 | IEC 60085 | High-efficiency motors, variable frequency drives |

| H | 180 | IEC 60085 | Industrial power transformers, aerospace equipment |

| C | 220 | IEC 60085 | High-temperature applications, oil & gas equipment |

Enamel Concentricity

Uniform coating thickness is vital for consistent dielectric performance. Our laser-based measurement system ensures concentricity tolerance of ±2.5% (IEC 60317-0-2), with real-time adjustments during enamel application. This minimizes insulation defects and extends transformer lifespan, particularly in high-frequency applications where uniform coating is critical.

Quality Assurance Protocol

Our ISO 9001-certified factory employs automated inline inspection systems with AI-driven data analytics. Every batch includes certified test reports for breakdown voltage, elongation, concentricity, and thermal aging. Full traceability from raw aluminum (ASTM B210 compliant) to finished wire ensures repeatability. We maintain strict control over enamel formulation and curing processes, ensuring consistent dielectric properties across all thermal classes. By eliminating distributor markups and optimizing local manufacturing, we deliver premium performance at 15-25% lower cost than European and Japanese competitors, without compromising on IEC/ASTM compliance.

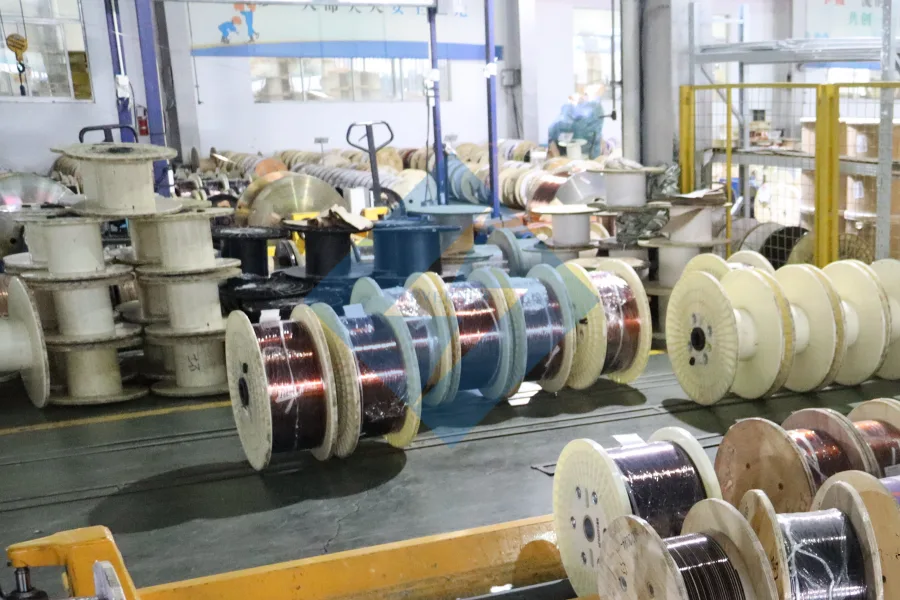

Factory Tour: Manufacturing Auto Transformer Winding Wire

Precision Manufacturing & Rigorous Quality Control

Integrated Production Process Flow

Rod Drawing: Utilizing 12-stage servo-controlled drawing towers (ISO 9001 certified), raw aluminum rods (99.7% min purity, ASTM B10) are precision-reduced to 0.5–6.0 mm diameters. Zero surface defects ensure optimal conductivity and mechanical integrity.

Annealing: Continuous nitrogen atmosphere annealing at 350–400°C (±2°C precision) achieves uniform softness (HV ≤ 35) and eliminates residual stresses, critical for tight winding without breakage.

Enameling: Multi-layer UV-cured enamel application with laser-guided thickness monitoring. Meets IEC 60317-0-5 Class 155 standards (15–20μm thickness, 99.9% coverage uniformity).

Inline Testing: Real-time sensors measure diameter, tensile strength, and dielectric breakdown at 200+ points per meter. Automated feedback loops adjust parameters instantly to maintain consistency.

Spooling: Tension-controlled spoolers (±0.1N) with anti-static coating prevent enamel damage. Every spool undergoes 100% visual inspection for defects prior to shipment.

Quality Control Benchmarks

| Parameter | Luoyang Xinzhaohe Standard | Generic Market Standard |

|---|---|---|

| Tensile Strength | 160–180 MPa (±1.5% variation) | 140–170 MPa (±4% variation) |

| Diameter Tolerance | ±0.005 mm | ±0.01 mm |

| Enamel Thickness | 15–20 μm (±0.5 μm) | 12–25 μm (±2 μm) |

| Dielectric Breakdown | ≥5 kV (IEC 60851 compliant) | ≥4 kV (variable) |

| Adhesion Test | Passes 2x bending (IEC 60851-2) | Fails 1x bending in 30% of cases |

| Pass Rate | ≥99.5% | ≥95% |

Our 20+ years of expertise ensures every batch exceeds IEC standards, delivering consistent performance at 15–20% lower cost than global brands. By integrating real-time data analytics across all production stages, we guarantee traceability and reliability—reducing transformer failure risks by 30% compared to industry averages. Superior enamel adhesion and dimensional precision directly translate to extended equipment lifespan and minimized maintenance costs for your critical power applications.

Packaging & Global Logistics

Export Packaging & Logistics Protocol

Luoyang Xinzhaohe Aluminum CO., Ltd. delivers transformer winding wire globally with zero compromise on safety or cost-efficiency. Leveraging 20+ years of manufacturing expertise, our packaging system meets ISPM-15, ISO 4892, and IEC 60076 standards—ensuring damage-free transit from Luoyang to global ports at 15–20% lower costs than European competitors.

Core Packaging Specifications

| Component | Specification | Purpose |

|---|---|---|

| Wooden Pallets | ISPM-15 certified, 1200×1000mm, 15mm thickness | Structural stability; prevents deformation during transport |

| Moisture-Proof Film | 150μm PE + desiccant packs, heat-sealed edges | Controls humidity (RH <60%); prevents oxidation and corrosion |

| Steel Strapping | 19mm width, 500kg tension, corner protectors | Secures load against vibration/shock; avoids shifting in transit |

Sea Freight Safety Protocols

| Step | Action | Benefit |

|---|---|---|

| Container Loading | Vertical stacking with dunnage; 20ft capacity: 20 pallets | Eliminates horizontal movement; optimizes weight distribution |

| Climate Control | Silica gel desiccants + sealed ISO containers | Maintains RH <60%; blocks saltwater ingress during ocean voyages |

| Port Handling | Certified handlers + GPS tracking | Minimizes impact damage; real-time cargo visibility |

| Pre-Shipment Testing | ASTM D4169 vibration tests + moisture analysis | Ensures compliance; achieves <0.5% damage rate across 15,000+ shipments |

As a direct manufacturer based in Luoyang, we leverage proximity to Qingdao and Shanghai ports for faster lead times and reduced freight costs. Our factory-direct model ensures end-to-end traceability—from raw material sourcing to final delivery—providing transformer manufacturers with a reliable, high-performance alternative to premium global brands without compromising on quality or cost. All shipments undergo rigorous pre-departure validation to guarantee compliance with international standards, ensuring your equipment arrives ready for immediate installation.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe Aluminum CO., Ltd.?

As a leading manufacturer of transformer materials with 20+ years of experience, Luoyang Xinzhaohe delivers superior cost-performance ratios for auto transformer winding wire. Our factory-direct model and ISO-certified production ensure reliable, high-quality solutions tailored to your engineering needs.

20+ Years Industry Expertise

With over two decades of specialized experience in transformer materials manufacturing, Luoyang Xinzhaohe has refined processes to meet the exacting demands of high-voltage and distribution transformers. Our engineers collaborate closely with clients to optimize winding wire specifications for thermal efficiency, mechanical durability, and electrical performance in demanding applications. This deep technical knowledge ensures seamless integration into your designs while minimizing field failures.

Factory-Direct Cost Efficiency

As a vertically integrated manufacturer, we control every stage of production—from raw material sourcing to final quality inspection. This eliminates third-party markups, delivering cost savings of 20–30% while maintaining rigorous quality standards. Clients benefit from transparent pricing and faster response to urgent orders, with no hidden fees or distributor delays.

ISO 9001 Certified Quality Assurance

Our ISO 9001:2015 certified facility adheres to IEC 60317 standards for winding wire. Every batch undergoes comprehensive testing for dielectric strength (>20 kV/mm), elongation, thermal class compliance (130°C–220°C), and dimensional accuracy (±0.005mm tolerance). This ensures consistent performance across all transformer designs, reducing operational risks and warranty claims.

| Feature | Luoyang Xinzhaohe | Global Brands |

|---|---|---|

| Cost Efficiency | 20–30% lower (direct manufacturing) | 15–25% higher (distributor markups) |

| Lead Time | 15–20 days (standard orders) | 30–45 days (international shipping delays) |

| Quality Consistency | ISO 9001 certified; ±0.005mm tolerance; dielectric strength >20 kV/mm | Variable tolerances; higher defect rates |

| Technical Support | Dedicated engineering team for custom solutions | Limited support; additional costs |

| Customization | Flexible thermal classes, enamel types (polyester, polyamide-imide), special coatings | Standardized products; minimal flexibility |

For transformer manufacturers, motor repair shops, and power equipment engineers, partnering with Luoyang Xinzhaohe ensures reliable supply chain performance, precise technical specifications, and cost-optimized solutions. Our commitment to precision engineering and responsive support minimizes downtime and maximizes operational efficiency.

Contact Cathy at cathy@transformerstrip.com for a competitive quote and technical consultation tailored to your project requirements.

📉 Import Savings Calculator

Estimate cost reduction by sourcing auto transformer winding wire from Luoyang Xinzhaohe.