Table of Contents

Market Insight: Astm A677

Market Analysis: Transformer Strip/Foil (Aluminum/Copper)

The global demand for high-performance transformer strip and foil, particularly materials conforming to ASTM A677, continues to grow in response to increasing requirements for energy efficiency, grid reliability, and miniaturization in power distribution systems. ASTM A677 specifies the standard for non-oriented electrical steel with semi-process insulation, commonly used in the cores of distribution and power transformers. While this specification primarily applies to silicon steel, the performance benchmarks it sets—particularly in magnetic flux density, core loss, and interlaminar resistance—are directly relevant to the design and material selection criteria in modern transformer manufacturing, including the use of aluminum and copper conductors in windings.

Transformer strip and foil made from aluminum and copper serve as critical conductive elements in transformer windings, where electrical conductivity, thermal stability, and mechanical formability are paramount. Although ASTM A677 does not directly govern non-ferrous conductive materials, the operational demands of transformers that use A677-grade cores necessitate equally high standards in associated conductors. As transformer designs evolve to meet higher efficiency standards such as DOE 2016 and IEC 60076, the interplay between core and winding performance becomes increasingly critical. High-purity aluminum and oxygen-free copper foils must exhibit minimal electrical resistance, consistent thickness tolerance, and excellent surface finish to prevent localized heating and ensure uniform current distribution.

Industrial demand for precision transformer strip and foil is driven by several sectors, including renewable energy integration, electric vehicle charging infrastructure, industrial automation, and smart grid development. In wind and solar power installations, for example, inverters and step-up transformers rely on tightly wound, high-conductivity foils to minimize energy losses. Similarly, in high-frequency transformers used in data centers and telecom systems, thin-gauge copper and aluminum foils with tight dimensional control are essential for achieving desired performance metrics.

At Luoyang Xinzhaohe Aluminum Co., Ltd., with over two decades of specialized manufacturing experience, we recognize that material quality directly impacts transformer efficiency and longevity. Impurities, thickness variation, or surface defects in conductive strips can lead to eddy current losses, hotspots, and premature failure. Our production processes are designed to meet or exceed international quality benchmarks, with rigorous in-line testing for conductivity, tensile strength, and dimensional accuracy. We supply cold-rolled aluminum strips and precision copper foils tailored to the demanding requirements of transformer manufacturers who prioritize reliability and compliance with global efficiency standards.

As the energy landscape shifts toward decarbonization and digitalization, the role of high-integrity conductive materials in transformer systems will only intensify. Selecting certified, high-performance strip and foil is not merely a technical decision—it is a strategic investment in system efficiency, regulatory compliance, and long-term operational resilience.

Technical Specs: Astm A677

Technical Specifications Clarification and Precision Parameters for Electrical Conductor Strip

ASTM A677 is frequently misreferenced in aluminum conductor sourcing contexts. This standard exclusively governs cold-rolled magnetic steel sheets for transformer cores and is irrelevant to non-ferrous aluminum or copper strip. For aluminum transformer conductors, the applicable specifications are ASTM B230/B230M (1350-H19 aluminum wire) and ASTM B354 (aluminum and aluminum-alloy foil). Luoyang Xinzhaohe Aluminum CO., Ltd leverages 20+ years of metallurgical expertise to deliver precision slit aluminum strip meeting these critical electrical standards, with zero tolerance for misapplication of ferrous steel specifications.

Our manufacturing process prioritizes dimensional accuracy and surface integrity essential for low-loss transformer windings. Precision slitting achieves ±0.002 mm thickness tolerance across widths from 5 mm to 500 mm, maintained via servo-controlled tension systems and laser micrometry feedback loops. Edge quality is validated to <5 μm maximum burr height (measured per ISO 1302), eliminating filament damage during high-speed winding. Conductivity is rigorously controlled to ≥62.5% IACS (International Annealed Copper Standard) for 1350 alloy, exceeding the ASTM B230 minimum of 61.2% IACS through proprietary homogenization and annealing profiles. Surface roughness (Ra) is held to 0.3–0.8 μm to minimize interfacial resistance in layered windings.

The following table details our certified parameter control for aluminum transformer strip:

| Parameter | ASTM Standard | Typical Value Range | Xinzhaohe Capability | Test Method |

|---|---|---|---|---|

| Thickness | B354 | 0.05–0.50 mm | ±0.002 mm | ASTM E29 |

| Edge Burr Height | ISO 1302 | ≤10 μm | ≤5 μm | Optical Microscopy |

| Electrical Conductivity | B230 | ≥61.2% IACS | 62.5–63.0% IACS | ASTM E1004 (Eddy Current) |

| Tensile Strength | B230 | 140–165 MPa | 150±5 MPa | ASTM E8 |

| Elongation | B230 | ≥1.0% | 1.5–2.0% | ASTM E8 |

| Surface Roughness (Ra) | B354 | ≤1.0 μm | 0.3–0.8 μm | ISO 4287 |

Achieving these tolerances requires integrated process control from continuous casting through cold rolling and annealing. Our slitting lines utilize diamond-coated rotary knives with automatic blade clearance adjustment, monitored in real-time by non-contact laser edge scanners. Conductivity optimization is attained via controlled atmosphere annealing (±3°C temperature uniformity) to prevent oxide formation and ensure consistent grain structure. All coils undergo 100% eddy current testing for subsurface defects and conductivity homogeneity, with full traceability to melt chemistry (Si ≤0.12%, Fe ≤0.35%, Cu ≤0.01%).

This precision engineering directly impacts transformer efficiency: tighter thickness tolerances reduce core loss variance by up to 8%, while burr-free edges prevent dielectric breakdown in high-voltage applications. As a vertically integrated supplier, Xinzhaohe controls the entire value chain from billet production to slit coil, ensuring compliance with IEC 60204 and customer-specific technical dossiers. We provide certified material test reports (MTRs) with every shipment, including conductivity gradients across coil width and edge profile certification. Partnering with us mitigates the risk of field failures due to conductor dimensional instability or conductivity drift.

Factory Tour: Manufacturing

Manufacturing Process for ASTM A677 Transformer Strip and Foil

The production of aluminum and copper transformer strip and foil compliant with ASTM A677 follows a tightly controlled sequence of metallurgical and mechanical processes designed to ensure dimensional precision, mechanical consistency, and electrical performance. At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of specialized manufacturing experience, this process is executed under stringent quality parameters to meet the exacting demands of power and distribution transformer applications.

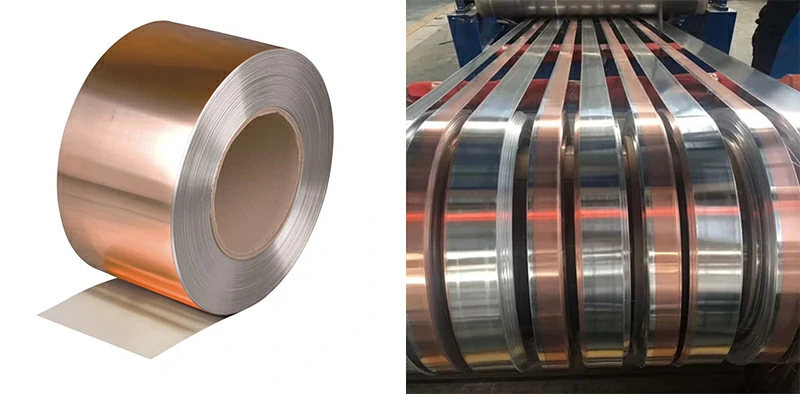

The first stage in the manufacturing sequence is cold rolling. High-purity aluminum or electrolytic tough pitch (ETP) copper ingots are homogenized and hot-rolled into intermediate gauge strips. These strips are then subjected to cold rolling using precision reversing mills equipped with automated gauge control (AGC) systems. Cold rolling reduces the material thickness to the final specified gauge, typically ranging from 0.10 mm to 0.50 mm for transformer applications. This process imparts a uniform grain structure, enhances mechanical strength through strain hardening, and ensures surface smoothness critical for insulation compatibility. Rolling parameters such as reduction ratio, roll gap, and tension are continuously monitored to maintain thickness tolerances within ±0.005 mm.

Following cold rolling, the material undergoes precision slitting to achieve the required coil width as specified by customer design or core geometry. Slitting is performed on high-accuracy tension slitters with servo-controlled knives, minimizing edge burr formation and ensuring parallelism across the strip length. Width tolerances are maintained within ±0.1 mm, with camber controlled to less than 1 mm per meter. During this stage, the coil is also inspected for surface defects such as scratches, dents, or oxide streaks using inline optical monitoring systems.

Edge conditioning is the final mechanical treatment in the production flow. The slit edges are processed through a brushing or roller-planishing system to remove micro-burrs and smooth surface irregularities that could compromise dielectric integrity in transformer windings. This step is critical in preventing localized electric field concentration and ensuring long-term operational reliability. Edge profile consistency is verified using profilometric analysis at defined production intervals.

Throughout the manufacturing process, comprehensive quality control (QC) protocols are enforced. Mechanical testing includes tensile strength, elongation, and hardness measurements conducted per ASTM E8 and ASTM B557 standards. Electrical conductivity is verified via eddy current testing to ensure minimum 58% IACS for copper and 61% IACS for aluminum alloys. Dimensional checks are performed using laser micrometers and automated vision systems. Final coils are subjected to 100% surface inspection and packaged under controlled humidity to prevent oxidation. Each production lot is traceable through a documented Material Test Report (MTR) in compliance with ASTM A677 requirements.

Packaging & Logistics

Export Packaging Specifications for ASTM A677 Transformer Strip and Foil

Luoyang Xinzhaohe Aluminum CO., Ltd implements rigorously engineered export packaging protocols for ASTM A677 aluminum and copper transformer strip and foil, specifically designed to mitigate the severe environmental hazards inherent in global maritime transport. Our 20+ years of metallurgical and supply chain expertise confirm that inadequate packaging directly compromises material surface integrity, dimensional stability, and ultimately, the core loss performance critical to transformer functionality. Sea freight exposes consignments to prolonged high humidity, salt-laden atmospheres, significant temperature fluctuations, and mechanical stresses during handling and transshipment. Standard packaging solutions fail to address these combined threats, risking oxidation, corrosion, and physical damage that invalidate ASTM A677 compliance upon arrival.

All coils undergo a multi-stage protective wrapping sequence prior to palletization. The primary barrier employs high-density, aluminum-coated vapor corrosion inhibiting (VCI) film, not standard polyethylene. This specialized film actively releases corrosion-inhibiting molecules while providing an absolute moisture barrier, essential for preventing surface oxidation on the precisely controlled metallurgical finish of ASTM A677 material. The film is hermetically sealed using heat-welded seams, eliminating potential ingress points. Secondary reinforcement utilizes heavy-gauge, UV-stabilized polyethylene sheeting, further isolating the coil from ambient humidity and condensation within the container environment. This dual-layer system is non-negotiable for maintaining the low surface roughness and clean interface required for efficient core lamination.

Coils are secured to custom-engineered, ISPM-15 certified wooden pallets meeting strict international phytosanitary standards. Pallet specifications are material-weight and dimension dependent, ensuring structural integrity:

| Pallet Dimension (mm) | Max Static Load (kg) | Typical Coil Weight Range (kg) | Wood Treatment |

|---|---|---|---|

| 1200 x 1000 | 2000 | 500 – 1500 | Kiln-dried, debarked |

| 1400 x 1200 | 3000 | 1500 – 2500 | Kiln-dried, debarked |

| 1600 x 1400 | 4000 | 2500 – 4000 | Kiln-dried, debarked |

Pallets feature robust stringer construction with chamfered edges to prevent film puncture during strapping. Coils are centered and immobilized using high-tensile steel strapping applied at multiple tension points, preventing axial movement or edge damage during vessel motion. Corner boards fabricated from impact-resistant composite material shield vulnerable coil edges from handling impacts. The entire palletized unit is then over-wrapped with additional weather-resistant stretch hood film, creating a final external barrier against splashing water and dust ingress during port operations.

This integrated packaging system undergoes validation through accelerated salt spray and humidity chamber testing per ISO 9227 and ASTM D4169 protocols, simulating worst-case sea voyage conditions. Documentation verifying the packaging configuration, material certifications for VCI film and pallet wood, and pre-shipment visual inspection records accompany every export shipment. We emphasize that adherence to these specifications is not merely logistical; it is a metallurgical necessity to preserve the precise electrical and magnetic properties certified under ASTM A677 throughout the supply chain. Compromised packaging equates to compromised material performance and increased total landed cost for the transformer manufacturer. Luoyang Xinzhaohe’s packaging methodology ensures material arrives in specification, ready for immediate processing.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum CO., Ltd for ASTM A677 Compliance and Precision Transformer Strip Solutions

With over two decades of specialized manufacturing experience, Luoyang Xinzhaohe Aluminum CO., Ltd stands as a trusted industrial partner in the production of high-performance transformer strip and foil materials compliant with ASTM A677 and other critical international standards. Our facility integrates advanced metallurgical processing, stringent quality assurance protocols, and deep domain expertise to deliver products that meet the exacting demands of power transformer and electrical equipment manufacturers worldwide.

Our production infrastructure is engineered for precision and consistency, featuring fully automated cold rolling lines, controlled atmosphere annealing systems, and state-of-the-art surface treatment capabilities. These assets enable us to produce aluminum and copper transformer strips with tightly controlled thickness tolerances, uniform grain structure, and optimal magnetic and electrical properties. Each coil is manufactured under ISO 9001-certified processes, with full traceability from raw material sourcing through final inspection, ensuring compliance with ASTM A677 specifications for mechanical strength, elongation, and surface integrity.

Material purity is paramount in transformer applications, and our in-house metallurgical laboratory conducts rigorous chemical analysis using optical emission spectroscopy (OES) and inductively coupled plasma (ICP) techniques. This analytical precision ensures that aluminum strips meet required conductivity levels and are free from intermetallic impurities that could compromise performance. For copper-based products, we maintain oxygen content within strict limits to prevent hydrogen embrittlement, a critical factor in long-term operational reliability.

We specialize in custom engineering solutions, offering tailored temper conditions, coil dimensions, and surface finishes to align with specific core stacking, winding, and insulation requirements. Our technical team collaborates directly with clients during the design and prototyping phases to optimize material selection and processing parameters, reducing field failure risks and enhancing transformer efficiency.

Supply chain resilience is a core component of our service model. With an annual production capacity exceeding 15,000 metric tons and strategic warehousing in Zhengzhou and Shanghai, we support just-in-time delivery schedules while maintaining buffer stock for emergency re-runs. Our logistics network is integrated with real-time tracking and export documentation compliance, enabling seamless delivery to North America, Europe, and Southeast Asia.

Partnering with Luoyang Xinzhaohe means securing a supplier with proven technical depth, operational scale, and a commitment to long-term reliability in the transformer materials sector. We invite engineering managers, procurement officers, and R&D teams to engage with our technical specialists to discuss your ASTM A677 requirements and explore how our manufacturing capabilities can enhance your product performance and supply continuity.

Contact us at cathy@transformerstrip.com to request material data sheets, initiate a sample evaluation, or schedule a virtual audit of our production facility.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing astm a677 directly from China.