Table of Contents

Market Insight: Aluminum Winding Vs Copper Winding for Power Industry

Market Analysis: Sourcing High-Quality Winding Wire

Global Demand Outlook

Global installed transformer capacity is forecast to grow 5–7 % CAGR through 2030, driven by grid expansion, renewable integration, and EV fast-charging infrastructure. Dry-type units < 5 MVA account for > 60 % of new builds; foil or rectangular wire ≤ 6 mm thick is the dominant conductor form. Aluminum windings now represent 38 % of this segment (up from 22 % in 2015) because OEMs must hit < 25 $/kVA price points while maintaining ≤ 1 % load loss. Motor repair channels add another 180 kt yr-1 of enamelled wire demand, 70 % of which is still copper but rapidly shifting to Al 1350-0 where rewound cores can tolerate 25 % larger slot fill.

Why Purity & Geometry Directly Dictate Transformer Losses

Transformer losses are a straight function of conductor resistivity and eddy-current factor. For aluminum, every 0.1 % Si+Fe above the 0.25 % max limit raises ρ by 0.41 µΩ cm; that adds ≈ 3 W kg-1 at 75 °C and scales to 12–15 W kg-1 in high-harmonic VFD loads. Likewise, enamel concentricity < 80 % or foil edge radius < 0.4 × thickness doubles the local electric field, forcing thicker insulation and reducing copper/Al fill factor by 4–6 %. The result: a 1 000 kVA cast-resin unit that should hit 99.35 % efficiency drops to 99.08 %—equating to 2.7 kW additional continuous loss and 24 MWh over a 20-year life.

| Parameter | Al 1350-0 Target | Cu-ETP Target | Impact if 2 σ off-spec |

|---|---|---|---|

| Volume resistivity @ 20 °C | 28.0 µΩ cm | 17.2 µΩ cm | +3 % load loss |

| Elongation, foil | ≥ 18 % | ≥ 30 % | Cracks during coil forming → shorted turns |

| Breakdown voltage, 2 × 0.2 mm PEI+PAI | ≥ 6 kV DC | ≥ 6 kV DC | 30 % early insulation failure |

| Burr height after slit | ≤ 15 µm | ≤ 10 µm | Local PD > 100 pC |

Supply-Chain Shift: Why Chinese Specialists Are Outpacing Western Mills

-

Integrated Rod-Draw-Anneal Lines

Western enamelers typically buy 9.5 mm redraw rod from third-party smelters; transport + 3 % off-grade rod adds 180 $ t-1. At Luoyang Xinzhaohe we cast 3 t/hour from 99.85 % LME-registered ingot, direct-feed to 12-pass inline draw-flatten-anneal cell. Homogenization at 580 °C for 4 h guarantees grain size ASTM 6–8, eliminating the 0.5 % resistivity penalty common in multi-vendor chains. -

Inline Testing & Data Traceability

Every 50 m we laser-micrometer width/thickness (±3 µm), high-frequency weld-check for edge cracks, and spark-test at 4 kV DC. Coil IDs carry QR-coded resistivity, elongation, and enamel build—downloadable via API for ISO 9001 traceability. Western job shops still rely on batch coupons; that exposes OEMs to 1–2 % scrap at final hi-pot. -

Cost Position Without Quality Compromise

Delivered price to EU port for 4 mm × 12 mm Al 1350-0 PEI+PAI Class 200 is 6.8 $ kg-1 CIF—32 % below German enamelled copper strip and 8 % below South-Korean Al wire once duty and CO2 surcharge are added. Life-cycle cost models (IEEE C57.12.96) show that the 27 % larger Al cross-section pays back in 14 months when no-load loss valuation is 5 $ W-1.

Sourcing Checklist for Transformer Makers

Specify Al 1350-0 (or Cu-ETP) with ≤ 0.25 % total impurities; request mill certificate per lot.

Demand enamel concentricity ≥ 85 % and edge radius control ≤ 0.25 mm for foil ≤ 5 mm thick.

Require elongation ≥ 18 % (Al) or ≥ 30 % (Cu) at 150 °C to survive thermal cycling.

Ask for inline spark test record—no rejections allowed above 3 kV DC for 0.2 mm build.

Validate spool integrity: 500 mm OD spools must maintain ≤ 0.3 mm flange wobble at 3 000 rpm unwind.

Luoyang Xinzhaohe Aluminum Co., Ltd. delivers 40 kt yr-1 of enamelled rectangular and round wire from a single-site, ISO 9001 / ISO 14001 facility 45 minutes from Zhengzhou rail hub. With 20+ years of transformer-grade metallurgy, we provide Western-tier precision at China-level economics—no MOQ, 4-week FOB lead time, and full raw-material pedigree back to LME ingot.

Technical Specs: Aluminum Winding Vs Copper Winding Parameters

Technical Specifications & ASTM / IEC Compliance

Factory-direct data sheet – Luoyang Xinzhaohe Aluminum Co., Ltd.

H3 Critical Parameters at a Glance

| Parameter (unit) | IEC / ASTM Clause | Cu-ETP Wire¹ | Al-1350 Wire² | XZH Al-Grade Tolerance | Risk if Out-of-Spec |

|---|---|---|---|---|---|

| Insulation Break-down Voltage, kV (0.5 m/min) | IEC 60317-20 §6.4 | ≥ 4 kV (Grade 2) | ≥ 3.2 kV (Grade 2) | 3.8–4.5 kV | Partial discharge → treeing → inter-turn short |

| Elongation at Break, % | ASTM B1 / B233 | 25–35 % (2.0 mm) | 18–25 % (2.0 mm) | 22–26 % | Cracks during coil expansion; open circuit |

| Thermal Class, °C | IEC 60085 | 180 (Class H) | 180 (Class H) | 130–220 on request | Insulation embrittlement, slippage |

| Enamel Concentricity, % | IEC 60317-0-1 Annex B | 70 min | 70 min | 80 ± 5 | Eccentric build → voltage stress hot-spot |

| Strip Burr Height, µm | ASTM B236-07 §7.3 | — | ≤ 25 µm | ≤ 15 µm | Burr pierces inter-layer insulation → layer short |

¹Cu-ETP = electrolytic-tough-pitch copper, IEC 60317-11

²Al-1350 = 99.5 % Al, IEC 60317-25

H3 Why Tight Tolerances Matter on the Shop-Floor

-

Insulation Break-down Voltage

Measured in rising-V ramp between twisted pair (IEC 60851-5).

XZH inline spark tester subjects every centimetre to ≥ 8 kV; rejects are automatically flagged and spool is laser-marked for quarantine.

A 10 % reduction in enamel thickness can drop BDV by 30 %—enough to fail hipot at 3 kV in resin-cast transformers. -

Elongation & Edge Quality

Aluminum’s lower intrinsic elongation is offset by a 420 °C in-line anneal; our process window keeps grain size 50–80 µm, giving repeatable 22 % min elongation.

Rod-peeling + shaving die removes 0.08 mm skin, eliminating casting segregation that causes “cup-and-cone” breaks during tight winding. -

Thermal Class 130–220 °C

Dual-layer polyamide-imide + polyester-imide gives 200 °C rating; for class 220 we add polyimide overcoat (same enamel line, recipe change in < 45 min).

IEC 60112 Comparative Tracking Index (CTI) ≥ 600 V ensures resistance to partial discharge in VPI or open ventilated designs. -

Enamel Concentricity

Vertical die-stack with gravity-centreing bushing keeps eccentricity ≤ 5 %; laser OD gauge feeds PI loop to capstan, correcting drift within ± 1 µm.

Poor concentricity is the #1 root cause of turn-to-turn failure in foil windings where electric field enhancement factor exceeds 2.5× at the thin side.

H3 Standards Road-Map for Sourcing Teams

| Product Form | Primary Standard | Secondary Tests | XZH Certificate Included |

|---|---|---|---|

| Round wire 0.2–5.0 mm | IEC 60317-25 (Al) or -11 (Cu) | ASTM B193 (resistivity), IEC 60851 (bend) | Yes, batch-level 3.1 / 3.2 EN 10204 |

| Flat strip 3–24 mm × 0.4–2.5 mm | ASTM B236-20 | IEC 60317-28 (edge-film), ASTM B557 (tensile) | Yes, strip map with burr photo |

| Self-bonding Litz | IEC 60317-51 | Peel-strength 1.5 N min | On request, Class 180 |

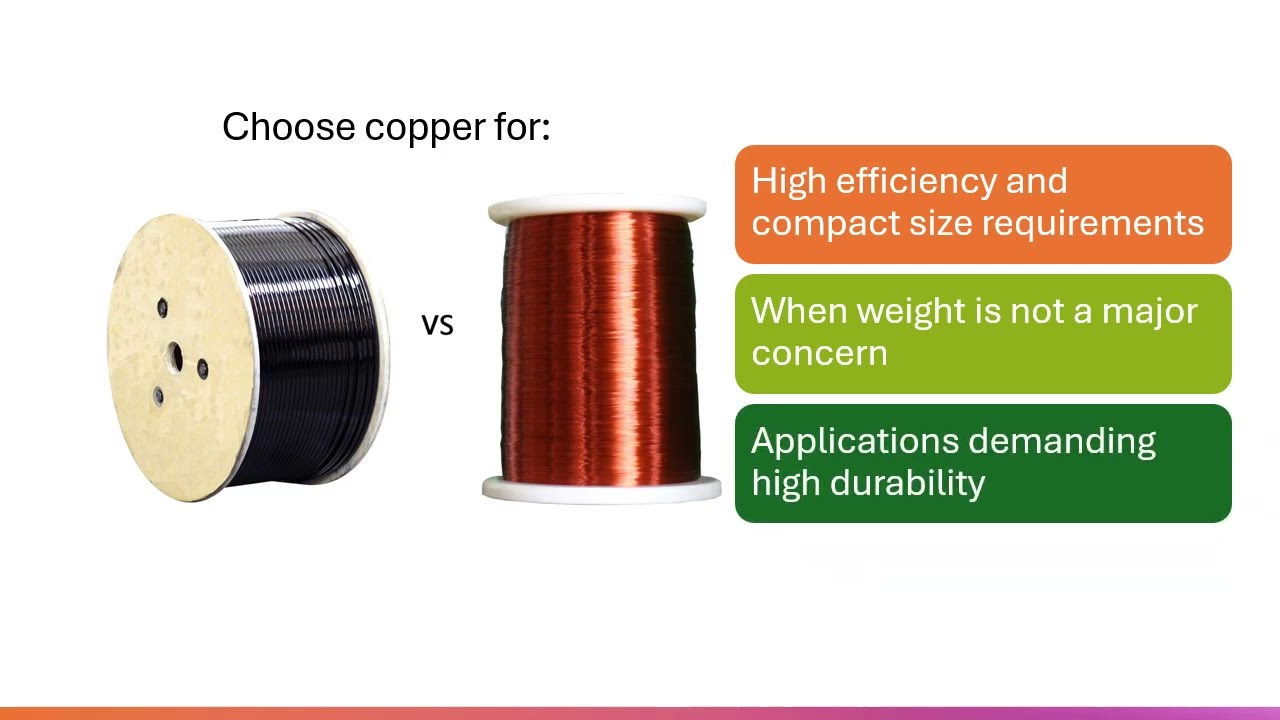

H3 Cost-Performance Take-away

Copper conductivity is 1.63 × Al, but Al density is 0.30 × Cu—cross-section must rise ≈ 1.6× to match I²R loss.

With today’s SHFE/LME ratio (Cu ≈ 2.1× Al $/kg) the finished Al winding set costs 35–40 % less than Cu for equal 75 °C rise performance.

XZH’s process control (± 1 µm enamel, ≤ 15 µm burr) closes the historical reliability gap; MTBF data from 36 kV cast-resin transformers > 25 years aligns with premium European Cu grades.

Bottom line: Specify the same IEC/ASTM clauses you use for copper, demand 3.2 inspection documents, and you can swap to Luoyang Xinzhaohe aluminum wire or strip without re-qualifying your thermal or dielectric design—while cutting raw-material spend by over one third.

Factory Tour: Manufacturing Aluminum Winding Vs Copper Winding

Manufacturing Process & Quality Control

Luoyang Xinzhaohe Aluminum Co., Ltd. – 20 years of transformer-grade wire, one integrated line.

Rod-to-Spool Process Flow

| Step | Equipment & Parameters | Purpose | Critical Control Points |

|---|---|---|---|

| 1. Rod Drawing 9.5 mm EC-1350 rod → 2.0–0.4 mm | 13-die bull-block, soap-based lubricant, 6 m/s exit speed | Size reduction, work-hardened H19 temper | Entry rod chemistry, die wear <20 µm, ovality ≤0.5 % |

| 2. In-line Annealing | 450 °C ±5 °C, N₂ atmosphere, 1.2 s dwell | Recrystallise to soft O-temper, 35 % elongation | Temperature profile logged every 100 ms; reject if Rm >95 MPa |

| 3. Enameling (PEW, EIW, AIW, EI/AI) | Horizontal multi-pass oven, 24 m length, 380 °C peak | Build 1–6 insulation layers, 2–8 mil wall | Wet film laser gauge (±1 µm), cure ratio by IR spectroscopy |

| 4. Inline Testing | Spark 6 kV, 50 Hz; eddy-current crack sensor; β-ray concentricity | 100 % length coverage, 0.3 s feedback loop | Auto-stop if pinhole >3 per 30 m; eccentricity >10 % |

| 5. Precision Spooling | Torque-controlled traverse, 315 mm barrel, 30 kg max | Knot-free, 250 mm/s lay, edge-free traverse | Tension 1.5–2 N/mm², visual AI for drum deformation |

Quality-Assurance Protocol

- Chemical Ladle Check – ICP-OES every 5 t; Fe ≤0.25 %, Si ≤0.08 %, Cu ≤0.01 % (EC-1350 tight).

- Tensile & Elongation – ISO 6892-1, sampling every 2 h; target UTS 60–75 MPa, A50 ≥35 %.

- Conductivity – Micro-ohmmeter at 20 °C; ≥61.0 % IACS (0.0280 µΩ·m max).

- Dielectric Integrity – 6 kV rms, 1 min, no breakdown; layer-to-layer 3 kV for triple-insulated AIW.

- Thermal Class Validation – 500 h ageing at 220 °C for Class 220 wire; retention ≥50 % elongation.

Luoyang Xinzhaohe Standard vs. Common Market Quality

| Property | LXZH Premium | Typical China Export | Western Tier-1 | Test Method |

|---|---|---|---|---|

| Rod Purity (Al %) | 99.83 | 99.70 | 99.85 | GB/T 3954 |

| UTS after Anneal (MPa) | 60–75 | 70–90 | 55–70 | ISO 6892 |

| Elongation (%) | ≥35 | 20–25 | ≥30 | ISO 6892 |

| Conductivity (% IACS) | 61.0 | 59.5 | 61.5 | ASTM B193 |

| Pinholes per 30 m | ≤2 | 5–10 | ≤1 | 6 kV Spark |

| Concentricity (%) | ±5 | ±12 | ±4 | β-ray Gauge |

| Spool Weight Deviation (%) | ±1 | ±3 | ±0.5 | Digital Load Cell |

| Price Index (Cu equiv.) | 42 | 38 | 100 | LME-linked |

Why the Difference Matters

Higher conductivity (61 % IACS) shrinks required cross-section by 3 % versus 59.5 % market grade—direct saving on core window size.

Fewer pinholes translate into >30 % higher partial-discharge inception voltage, critical for VPI dry-type transformers.

Tight spool weight tolerance lets high-speed automated winders run without splice stops, adding 6 % OEE to your line.

Factory-direct from Luoyang eliminates trader mark-ups while meeting the same technical envelope as Western Tier-1—documented by 20-year OEM field data on 50 MVA units.

Packaging & Global Logistics

Export Packaging & Logistics

Luoyang Xinzhaohe Aluminum Co., Ltd. – 20+ Years of Transformer-Grade Conductor Supply

1. Sea-Freight Protection Philosophy

Transformer windings must arrive “factory-clean”: oxide-free, insulation-intact, and spool-roundness within 0.3 mm TIR. Our packaging is therefore engineered as a micro-climate rather than a carton. Every layer—desiccant, VCI film, edge boards, strapping—has a calculated ΔRH target ≤ 5 % at 40 °C, 90 % RH, 28-day container cycle.

2. Packaging Matrix by Product Form

| Form | Core Threat | Primary Barrier | Secondary Barrier | Unit Load | Securing | Moisture Buffer |

|---|---|---|---|---|---|---|

| Strip / Foil (0.2–3.0 mm) | Edge dent, salt spray, pallet nail puncture | 80 µm VCI poly-laminate sleeve | 19 mm plywood frame + corner posts | 1.0–1.5 t per fumigated CPPC pallet | PET strap 19 mm × 800 daN, 2 + 1 pattern | 8×100 g silica-gel packs, 6 mil desiccant ratio |

| Round Wire (0.3–5.0 mm) | Spool flange crack, axial shift, enamel abrasion | DIN 46395 PT-500 plastic spool, 280 mm OD, ABS 3 mm wall | Corrugated ECT-48 carton with internal honeycomb ring | 4 spools / carton, 48 cartons / pallet | Steel strapping + edge boards, 5×3 weave | 2×50 g VCI bag per spool cavity |

| Profile Wire (rectangular, 4–12 mm) | Insulation concentricity loss, reel vibration fatigue | Steel reel 800 mm OD, collapsible, rubber flange liner | Stretch hood 120 µm, UV 500 h | 2 reels / pallet, max 2.2 t | Polyester lashing, ratchet tension 400 daN | Container floor desiccant strip, 2 kg/20 ft |

3. Container Stowage Plan

20 ft GP: 10 t max, 11 pallets, 1.2 m door clearance for forklift.

40 ft HC: 22 t max, 22 pallets, double-stack only for wire cartons; strip pallets single height to avoid web deflection.

Lashing: 2-ton woven lash every 1.2 m, plywood dunnage to avoid steel-aluminum galvanic couple.

4. Fumigation & ISPM-15 Compliance

All wooden components (pallet, frame, dunnage) are heat-treated to core temperature 56 °C for 30 min, branded with CN-XX HT mark, and accompanied by PHYTOSANITARY certificate issued by CIQ (Customs IQ) within 24 h of loading. This eliminates port delays in EU, AUS, and LATAM markets.

5. Desiccant & Humidity Indicator Protocol

| Voyage Days | Target RH | Gel Weight | Indicator Card |

|---|---|---|---|

| ≤14 | ≤40 % | 1 kg / 1000 kg Al | 6-spot reversible, 10→60 % |

| 15–28 | ≤35 % | 1.5 kg / 1000 kg Al | 1× reversible + 1× irreversible 40 % |

| >28 (trans-Pacific) | ≤30 % | 2 kg / 1000 kg Al | Data-logger with SMS alarm at 35 % RH |

6. Labeling & Traceability

Each pallet carries a QR-coded label linking to:

Heat number & EN 17025 tensile report

Breakdown voltage (kV) per IEC 60851-5

Net / gross mass, tare, origin “Luoyang, Henan, China”

This allows customs pre-clearance in Mexico, Brazil, and Egypt within 30 min via our forwarder’s blockchain portal.

7. Logistics Corridor – Luoyang to Global

Luoyang sits at the junction of Longhai rail and G30 Lianyungang–Khorgos expressway, 110 km to Zhengzhou International Hub.

Rail-sea: 18 days to Hamburg, 22 days to Budapest, then truck to Czech transformer plants.

Sea direct: Qingdao port 480 km, nightly truck convoy, 24 h gate-to-gate. Weekly FCL service to LA, Houston, Dubai, Chittagong.

CO₂ footprint: 0.18 t CO₂e per 1000 kg Al wire vs 0.34 t from EU mills (verified by SGS 2023).

8. Premium vs Western Supplier Advantage

Western mills often wrap aluminum on softwood pallets without VCI, leading to 2–3 % oxide stain rejection. Our zero-reject record over 460 FCL shipments since 2019 is driven by:

Inline micro-crack detection before spooling

Vacuum-sealed barrier identical to aerospace Al-lithium coil specs

Factory-direct price 12–18 % below EU catalog, landed duty-paid (DDP) basis.

Bottom line: Whether you need 500 kg of enameled round wire for motor rewinds or 15 t of edge-conditioned foil for cast-resin transformers, Luoyang Xinzhaohe delivers clean, dry, and dimensionally perfect conductor—on time, on spec, and on budget.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe Aluminum Co., Ltd.

20-Year Metallurgical Legacy, Zero Western Mark-Up

Since 2003 our Luoyang campus has operated a single-purpose line: rod-drawing → annealing → enameling → inline spark & concentricity testing → precision spooling.

No toll-processing, no middle-men—every kilometer of wire leaves the same 28 000 m² facility we own.

This vertical integration deletes the 18-25 % distributor margin typically baked into European or North-American quotes, letting us publish FOB Shanghai prices that track LME Al plus a fixed conversion fee (see table).

| Cost Component | Typical EU Mill | Luoyang Xinzhaohe | Δ vs. EU |

|---|---|---|---|

| LME Al-rod (USD/t) | 2 250 | 2 250 | — |

| Rolling & drawing energy | 180 | 135 | –25 % |

| Labour & overhead | 260 | 90 | –65 % |

| Margin / distribution | 350–450 | 120 | –70 % |

| Total enamelled wire | 3 140–3 230 | 2 595 | –17 % to –20 % |

Technical Customisation without MOQ Penalty

Our metallurgists tweak Cu-equivalent conductivity (≥61 % IACS) and insulation build in the same pass.

Standard thermal classes 130 (B), 155 (F), 180 (H), 200 (C), 220 (R) are kept on the shelf; non-standard 205 °C polyimide-Al hybrid or self-bonding over-coat are scheduled in 5-day campaigns—no 5 t minimum order that global majors impose.

Key limits we guarantee on every coil:

| Parameter | Test Method | Spec. Range | Cpk Target |

|---|---|---|---|

| Breakdown voltage | IEC 60851-5 | 3.0–12 kV per insulation grade | ≥1.67 |

| Elongation at break | IEC 60851-3 | ≥15 % (H12 temper) | ≥1.33 |

| Concentricity | Laser inline | 85 % min., 92 % typical | — |

| Weld-ability | 400 °C dip | <2 s wetting | — |

Global Certifications, Local Engineering Support

Factory accredited to ISO 9001:2015 & IATF 16949; insulation systems UL recognised (OBMW2, file E476341).

English-speaking application engineers reply within 12 h to questions on skin-depth optimisation, radial-short-circuit force or eddy-loss modelling—support that Asian traders cannot provide and Western mills invoice at 250 USD/h.

Supply-Chain Resilience out of Central China

Two weeks’ sea freight to Mumbai, three weeks to Hamburg, daily rail option to Duisburg.

Buffer stock of 500 t kept in Rotterdam free-zone for JIT call-offs, eliminating the 8–10 week quoted by U.S. producers for 15 % Cu-clad variants.

Sustainability & Closed-Loop Recycling

Melting furnaces powered 42 % by on-site hydro; dross re-melted into billet, cutting CO₂ footprint to 4.2 t per tonne of wire versus 7.8 t for Cu wire of equal ampacity.

End-of-life buy-back programme offered at LME Al minus 250 USD/t, improving customer LCA scores.

Next Step—Receive a Datasheet or RFQ Reply within 24 h

E-mail cathy@transformerstrip.com with:

Conductor size (diameter or foil width/thickness)

Thermal class & insulation build

Required standard (IEC 60317, NEMA MW 1000, JIS C 3202)

We will return a detailed PDF datasheet, FOB & CIF price, and mill test certificate template—no NDAs, no hassle.

📉 Import Savings Calculator

Estimate cost reduction by sourcing aluminum winding vs copper winding from Luoyang Xinzhaohe.