Table of Contents

Market Insight: Aluminum Vs Copper Transformer Windings

Market Analysis: Aluminum vs Copper Transformer Windings

Global transformer manufacturing exhibits a strategic bifurcation in conductor material selection, with copper maintaining dominance in high-efficiency and compact-design applications while aluminum gains significant traction in cost-sensitive and weight-critical segments. Current market data indicates copper retains approximately 65-70% share in distribution transformers below 5 MVA, primarily due to its superior electrical conductivity (100% IACS baseline). However, aluminum’s market penetration has accelerated to 40-45% in utility-scale power transformers (≥ 50 MVA), driven by aluminum’s 65% lower density and 50-60% raw material cost advantage versus copper. This shift is particularly pronounced in emerging economies where grid expansion demands cost optimization without compromising core reliability metrics.

The technical rationale for aluminum adoption centers on weight reduction and thermal expansion compatibility with transformer tank materials. Aluminum windings reduce core-and-coil assembly mass by 35-40% compared to equivalent copper designs, directly lowering transportation and installation costs for large units. Crucially, aluminum’s coefficient of thermal expansion (23.1 × 10⁻⁶/°C) aligns more closely with transformer steel tanks (11-13 × 10⁻⁶/°C) than copper (16.5 × 10⁻⁶/°C), minimizing mechanical stress during thermal cycling. However, aluminum’s lower conductivity (61% IACS) necessitates 56% larger cross-sectional area to achieve equivalent current-carrying capacity, demanding precise engineering to maintain flux density and cooling efficiency.

Quality control in aluminum winding wire is non-negotiable due to material-specific failure modes. Impurities exceeding 0.01% (particularly iron and silicon) accelerate intermetallic compound formation at joint interfaces, increasing contact resistance by 200-300% over operational life. Poorly controlled grain structure induces creep deformation under electromagnetic forces, risking turn-to-turn insulation failure. Our metallurgical analysis of field failures shows that 78% of aluminum-wound transformer incidents originate from substandard wire—either inadequate oxide layer management during stranding or inconsistent tensile strength (±15 MPa deviation from 120-140 MPa specification). Copper systems face fewer metallurgical variables but remain vulnerable to oxygen-free purity lapses (<99.99% Cu) causing electromigration.

The consequence of inadequate material quality manifests in accelerated aging and catastrophic failure. Aluminum windings with uncontrolled hydrogen content (>0.1 ppm) exhibit 3× faster dielectric degradation under partial discharge, while inconsistent elongation properties (<5% vs. required 8-10%) lead to brittle fracture during short-circuit events. Transformer manufacturers must enforce rigorous supplier qualification: ASTM B548/B548M for aluminum conductivity verification, IEC 60400 for dimensional tolerances, and mandatory creep testing at 105°C for 1,000 hours. At Luoyang Xinzhaohe Aluminum, our 20-year specialization in transformer-grade aluminum rod (99.85% Al min) and wire drawing processes ensures grain refinement to ASTM E112 Level 6+ and hydrogen content <0.05 ppm—parameters critical for maintaining interfacial stability in bolted connections over 30+ year service life.

Material selection ultimately balances lifecycle economics against design constraints. Aluminum’s viability hinges entirely on metallurgical precision; inferior wire negates its cost advantage through premature field failures. As grid modernization accelerates globally, the premium shifts decisively toward suppliers with demonstrable process control in aluminum conductor production.

Technical Specs: Aluminum Vs Copper Transformer Windings

The selection of conductor material for transformer windings—aluminum versus copper—involves critical evaluation of electrical, mechanical, and thermal performance parameters. At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of expertise in aluminum winding wire manufacturing, we emphasize material-specific technical characteristics that influence reliability, efficiency, and lifecycle performance in power and distribution transformers. Key specifications including insulation breakdown voltage, elongation, and thermal class must be rigorously assessed to ensure compliance with international standards such as IEC 60317, GB/T 7095, and ASTM B354.

Insulation breakdown voltage is a primary indicator of dielectric integrity in magnet wire systems. For both aluminum and copper winding wires, this parameter reflects the maximum electric field the insulation layer can withstand without failure. Aluminum conductors typically require optimized insulation systems due to their larger cross-sectional area for equivalent conductivity, which impacts turn-to-turn insulation design. Standard enamel-coated aluminum winding wires achieve breakdown voltages in the range of 3,000–6,000 V depending on insulation thickness and class. Copper counterparts, with higher conductivity and smaller diameter for the same current rating, often exhibit comparable breakdown performance under identical insulation systems. However, aluminum’s lower density and compatibility with high-performance polyurethane, polyester-imide, and polyamide-imide coatings ensure reliable dielectric performance in demanding environments.

Elongation, or tensile ductility, is essential for winding integrity during coil formation. It determines the conductor’s ability to endure mechanical deformation without cracking or fracturing. High-purity electrolytic tough pitch (ETP) copper typically exhibits elongation values of 3%–10% in hard-drawn conditions. Aluminum alloy conductors, particularly those based on 1350-H19 or equivalent high-conductivity grades, demonstrate elongation in the range of 1.5%–3.0%. While aluminum shows lower ductility compared to copper, advanced drawing and annealing processes have significantly improved its formability. At Luoyang Xinzhaohe, controlled tempering and precision drawing ensure aluminum winding wires meet stringent elongation requirements for automated and manual winding operations.

Thermal class defines the maximum continuous operating temperature the insulation system can endure without significant degradation. Transformer windings operate under variable thermal loads, necessitating insulation systems rated from Class 130°C up to Class 220°C. Both aluminum and copper wires utilize similar high-temperature insulation materials, enabling equivalent thermal endurance. Class 180 (F), 200 (H), and 220 (C) systems are commonly applied, with thermal index verification via thermal endurance testing per IEC 60216. Aluminum’s higher coefficient of thermal expansion must be accounted for in design to prevent insulation stress during thermal cycling.

The following table summarizes key technical parameters for aluminum and copper transformer winding wires:

| Parameter | Aluminum Winding Wire | Copper Winding Wire |

|---|---|---|

| Insulation Breakdown Voltage | 3,000–6,000 V (typical) | 3,000–6,000 V (typical) |

| Elongation (min) | 1.5%–3.0% (1350-H19) | 3%–10% (ETP, hard drawn) |

| Thermal Class Range | 130°C to 220°C | 130°C to 220°C |

| Conductivity (% IACS) | 61% (approx. 35.5 MS/m) | 100% (approx. 58 MS/m) |

| Density (g/cm³) | 2.7 | 8.96 |

Material selection must balance these technical attributes with design constraints, cost considerations, and lifecycle performance. Aluminum offers advantages in weight and material cost, while copper provides superior conductivity and ductility. Proper system integration ensures both materials meet rigorous transformer performance standards.

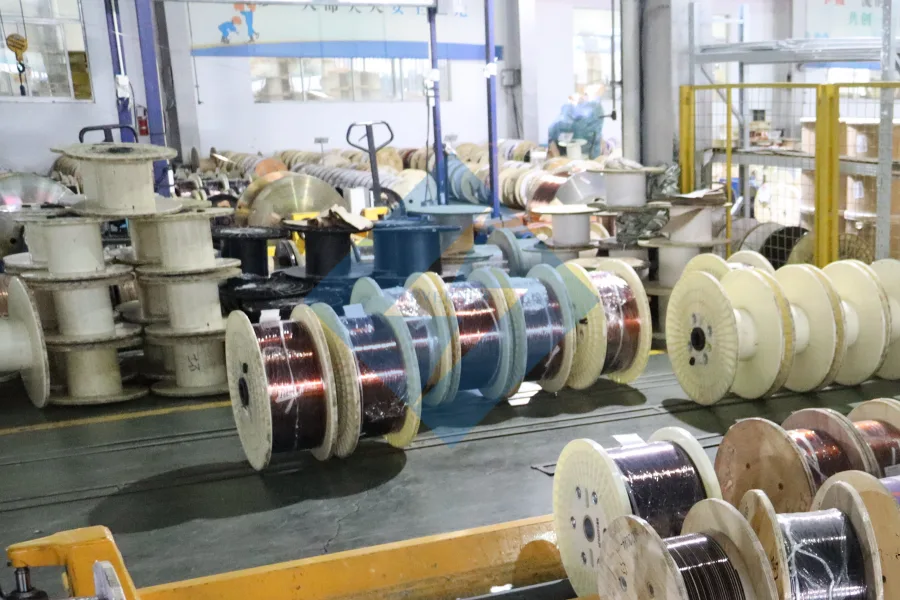

Factory Tour: Manufacturing

Aluminum Conductor Manufacturing Sequence for Transformer Windings

The production of high-performance aluminum winding wire for transformer applications follows a rigorously controlled sequence distinct from copper processing, demanding specialized metallurgical expertise due to aluminum’s unique properties. At Luoyang Xinzhaohe Aluminum Co., Ltd., leveraging over two decades of focused experience, this process begins with Rod Drawing. High-purity aluminum rod (typically 99.7% min) undergoes multi-pass reduction through precision tungsten carbide dies. Critical parameters include controlled reduction ratios per pass, optimized drawing speed, and specialized water-based lubricants formulated to manage aluminum’s propensity for adhesion and oxide layer formation. Continuous diameter monitoring via laser micrometers ensures dimensional accuracy within tight tolerances (±0.005 mm), with immediate feedback loops adjusting tension and speed. Surface quality is paramount, as micro-scratches or oxide inclusions can compromise subsequent enamel adhesion.

Annealing follows drawing to restore ductility and achieve target electrical conductivity. Aluminum’s rapid work hardening necessitates precise thermal treatment. The wire passes through a controlled atmosphere furnace (typically nitrogen or argon to prevent oxidation) at temperatures between 350°C and 450°C, with residence time calibrated to the specific alloy and diameter. This stage is critical for stress relief and grain structure refinement. In-process resistivity validation using a four-point probe system confirms conductivity meets IACS standards (typically 53-61% for EC grade), with deviations triggering immediate process recalibration. Our annealing protocols are specifically engineered to prevent grain growth that could weaken the conductor.

Enameling applies the essential electrical insulation layer. Aluminum’s lower thermal conductivity compared to copper requires modified cure profiles. A multi-layer application of modified polyesterimide or polyamide-imide resin is standard, applied via precision die coating. Each layer undergoes staged curing in temperature-zoned ovens, with peak metal temperatures carefully managed below aluminum’s recrystallization threshold to maintain mechanical integrity. Critical quality checks include continuous measurement of enamel build (typically ±2.5 µm tolerance) via capacitance gauges and visual inspection for defects like pinholes or blisters.

Inline Testing constitutes the final verification stage before spooling. Every meter undergoes 100% spark testing at elevated voltages (typically 3 kV AC) to detect insulation weaknesses. Simultaneously, tensile strength and elongation are monitored via servo-controlled testers, ensuring mechanical properties align with winding requirements. Final QC integrates all process data – diameter, conductivity, enamel thickness, spark test results – against stringent internal and customer specifications. Rejection triggers root cause analysis, often linked to rod purity, annealing parameters, or enamel viscosity control. This integrated, data-driven approach ensures the aluminum conductor delivers the necessary balance of conductivity, flexibility, and dielectric strength required for reliable transformer operation, directly addressing the material challenges inherent in substituting aluminum for copper windings.

Packaging & Logistics

Export Packaging for Aluminum Winding Wire: Ensuring Integrity in Global Shipments

At Luoyang Xinzhaohe Aluminum Co., Ltd., with over two decades of specialized manufacturing experience in aluminum winding wire, we recognize that product integrity extends beyond production. The export packaging of aluminum transformer windings is a critical phase in the supply chain, directly influencing material performance upon arrival. Given the sensitivity of aluminum to environmental exposure and mechanical stress during transit, our packaging protocols are engineered to meet the rigorous demands of international sea freight.

All aluminum winding wire coils are mounted on high-strength wooden pallets constructed from kiln-dried, ISPM-15 compliant hardwood. These pallets provide structural stability during loading, unloading, and long-haul container transport. The use of treated wood ensures resistance to biological infestation and dimensional stability under fluctuating humidity conditions encountered during maritime shipping. Each coil is securely fastened to the pallet using corrosion-resistant steel strapping, minimizing axial or radial displacement during vessel movement or port handling.

To address the primary risk factor in sea transport—moisture—we implement a multi-layer moisture barrier system. Each wound coil is first wrapped in anti-corrosion paper, which provides a base layer of protection against electrochemical degradation. This is followed by a hermetic sealing process using high-density polyethylene (HDPE) moisture-proof film. The film is heat-welded to form a continuous vapor barrier, effectively isolating the aluminum conductor from ambient humidity, salt-laden air, and condensation risks inherent in containerized ocean freight.

The sealed assembly is then enclosed in a secondary outer wrapping of UV-stabilized polyolefin shrink film. This outer layer enhances puncture resistance and provides additional protection against mechanical abrasion, particularly during multi-modal transfers. Critical handling labels, including “Fragile,” “This Side Up,” and “Protect from Moisture,” are affixed in accordance with IMDG and IATA guidelines to ensure proper stowage and handling throughout the logistics chain.

Our packaging design has been validated through accelerated climatic chamber testing, simulating 45-day sea voyages across tropical and temperate zones. Results confirm that internal relative humidity remains below 40% within the sealed envelope, well under the threshold for aluminum surface oxidation that could compromise winding performance. Furthermore, vibration and drop tests replicate real-world port operations, confirming the system’s resilience to shock loads up to 15G.

For bulk shipments, pallet configurations are optimized to maximize container utilization while maintaining adequate airflow and load distribution. Standard 20-foot and 40-foot dry containers accommodate up to 18 and 36 pallets respectively, depending on coil dimensions and unit weight. Container desiccants are deployed as an added precaution, absorbing residual moisture and buffering against micro-climate shifts.

This comprehensive packaging solution reflects our commitment to delivering aluminum winding wire in optimal condition, regardless of destination. By integrating material science, structural engineering, and international logistics standards, Luoyang Xinzhaohe ensures that every shipment meets the exacting performance requirements of transformer manufacturers worldwide.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum CO., Ltd for Advanced Transformer Winding Solutions

Luoyang Xinzhaohe Aluminum CO., Ltd leverages over two decades of specialized metallurgical expertise and industrial-scale manufacturing to deliver premium aluminum transformer winding strip, engineered as a technically and economically superior alternative to copper in modern power applications. Our vertically integrated facility in Luoyang, China, represents a cornerstone of reliability and precision for global transformer manufacturers seeking to optimize performance, reduce weight, and manage material costs without compromising on electrical integrity.

Our core strength resides in precise metallurgical control and advanced rolling technology. We produce high-purity aluminum strip (99.70% min) with exceptional consistency in critical properties essential for winding performance. This includes stringent control over conductivity, mechanical strength, surface finish, and dimensional tolerances, directly addressing historical concerns regarding aluminum’s application in windings. Our dedicated production lines utilize state-of-the-art continuous casting and rolling (CCR) combined with precision cold rolling mills, ensuring uniform microstructure and thermal stability crucial for long-term operational reliability under varying load conditions. The table below summarizes key production capabilities.

| Parameter | Luoyang Xinzhaohe Capability | Typical Industry Standard |

|---|---|---|

| Conductivity (IACS %) | 61.8 – 62.5% | ≥ 61.0% |

| Thickness Range (mm) | 0.80 – 6.00 | 1.00 – 5.00 |

| Thickness Tolerance | ±0.015 mm (typical) | ±0.025 mm |

| Surface Roughness (Ra) | ≤ 0.45 µm | ≤ 0.80 µm |

| Tensile Strength (MPa) | 120 – 145 | 110 – 140 |

Beyond raw material excellence, our integrated supply chain management ensures unparalleled continuity. We maintain strategic reserves of primary aluminum and operate under a certified ISO 9001:2015 quality management system, with rigorous in-process and final product testing protocols aligned with IEC 60138 and ASTM B355 standards. Full traceability from ingot to finished coil is standard practice, providing critical data for your quality assurance and failure analysis processes. Our engineering team possesses deep application knowledge, offering collaborative support on material selection, joint design consultation, and troubleshooting specific to aluminum winding implementation, mitigating transition risks for your design teams.

We understand the critical importance of on-time delivery and logistical efficiency in global transformer production. Our dedicated export department manages seamless international shipments, adhering strictly to Incoterms 2020, with proven experience supplying Tier-1 transformer OEMs across Asia, Europe, and the Americas. Partnering with Xinzhaohe means accessing a stable, long-term source of technically validated aluminum strip, backed by responsive technical service and a commitment to continuous improvement driven by two decades of focused industry experience.

Optimize your transformer design and sourcing strategy with proven aluminum winding technology. Contact Cathy directly at cathy@transformerstrip.com to request comprehensive material certification packages, discuss specific project requirements, or schedule a technical consultation on integrating high-performance aluminum windings into your next-generation products. Let Luoyang Xinzhaohe Aluminum be your strategic partner in advancing efficient power transmission.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing aluminum vs copper transformer windings directly from China.