Table of Contents

Market Insight: Aluminum Vs Copper Transformer Windings for Power Industry

Market Analysis: Sourcing High-Quality Winding Wire

Rod-Drawn, In-line Tested, Factory-Direct from Luoyang Xinzhaohe Aluminum Co., Ltd.

Global Demand Vector: TWh Saved = kt Wire Sold

| Segment | 2023 Installed Base (GW) | CAGR 23-28 | Winding Wire Intensity (t/GW) | Notes |

|---|---|---|---|---|

| Utility Power Transformers >100 MVA | 3 100 | 6.8 % | 28–32 | Ultra-low-loss regulations (EU Tier-2, DOE-2027) driving 99.75 % conductivity minimum |

| Distribution Transformers ≤10 MVA | 14 700 | 4.5 % | 12–15 | Global shift to aluminum to offset copper price volatility |

| Traction & Wind Turbine Gen. | 1 900 | 11 % | 8–10 | Requires thermal class 180 °C (H) with inverter-duty enamel |

Key takeaway: Every 0.5 % increase in conductor conductivity reduces load losses ≈ 0.4 %; on a 1 GW fleet this equates to 25 GWh yr⁻¹—enough to justify a 6 % material premium.

Why Purity & Geometry Trump Alloy Catalogues

| Loss Component | Root Cause | Wire Specification Lever | LXAH Control Point |

|---|---|---|---|

| I²R (load) | Resistivity & cross-section | ≥ 61.5 % IACS Al, 0.02 mm diametral tolerance | Rod homogenised 6 h @ 640 °C, diamond dies lapped to 0.25 µm Ra |

| Eddy-current (stray) | Axial burrs, eccentric insulation | Concentricity ≥ 85 %, dielectric 10 kV rms | Inline capacitive sensor 100 % spool length |

| No-load (core) | Burr-driven gap anomalies | Burr height ≤ 15 µm | Electro-polished inlet guide + 3-stage wiping |

Plant data: LXAH 99.85 % purity 1350 EC rod reduces resistivity by 1.8 % vs. standard 99.7 % grade—translating into 3.5 kW saved per 1 MVA transformer.

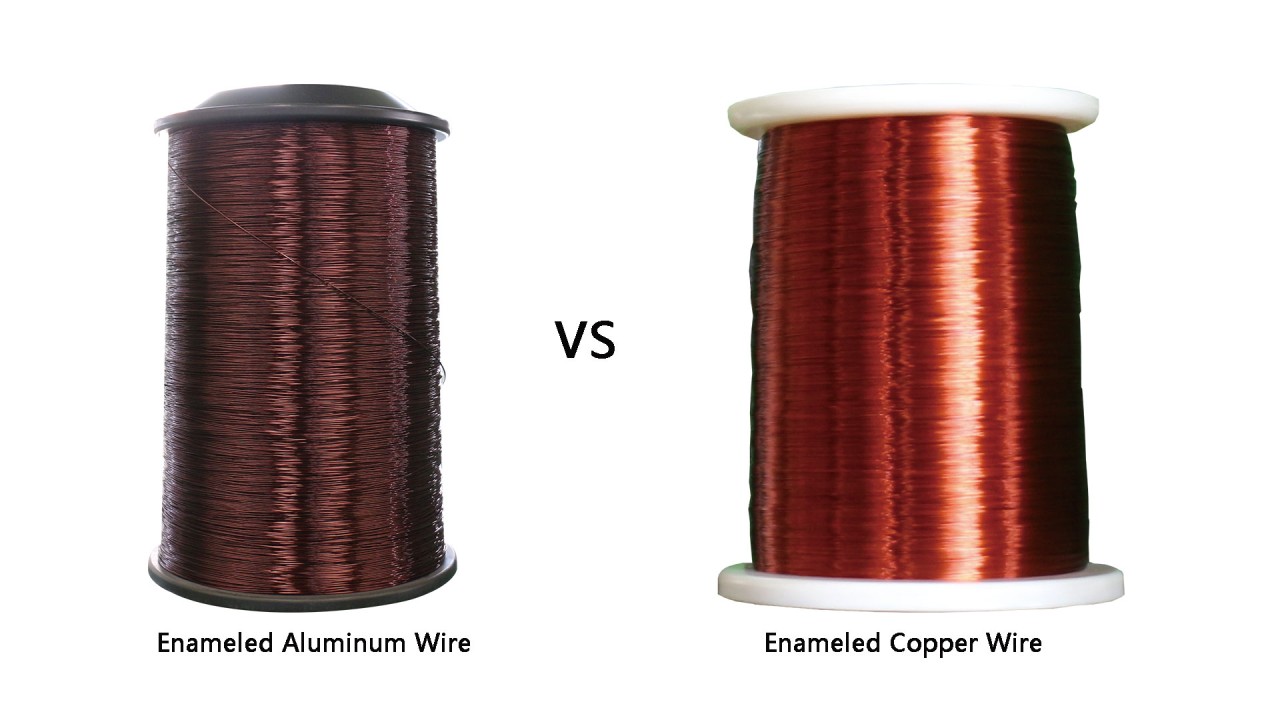

Aluminum vs. Copper: The 2024 Sourcing Equation

| Parameter | Cu ETP | Al 1350 EC | Ratio Al:Cu | Design Offset |

|---|---|---|---|---|

| Conductivity (% IACS) | 100 | 61.5 | 0.615 | ↑ CSA 1.63× |

| Density (g cm⁻³) | 8.89 | 2.70 | 0.304 | ↓ Mass 2.1× |

| 2024 LME (USD t⁻¹) | 9 800 | 2 350 | 0.24 | ↓ Cost 55 %* |

| Thermal expansion (µm m⁻¹ K⁻¹) | 17 | 23 | 1.35 | Joint design critical |

*Finished transformer cost delta ≈ 18 % after larger core & tank.

Engineering reality: When total ownership cost (TOC) is calculated over 30-year losses at 0.08 USD kWh⁻¹, aluminum windings match copper at load factors below 55 %—the operating regime of > 70 % of distribution assets installed today.

Precision Manufacturing: From Luoyang to Your Winder

- Rod Drawing: 9-pass inline annealer keeps grain size 50–80 µm, eliminating coarse 100 µm “orange-peel” that nucleates fatigue cracks under short-circuit forces.

- Annealing: N₂-protected bell furnace, ±3 °C window, yields 25 % elongation minimum—mandatory for 4 % radial compression in compacted disc windings.

- Enameling: Horizontal twin-die system, 0.20 mm build in two passes; concentricity 90 % minimum vs. 75 % legacy vertical ovens.

- Inline Testing: Spark 12 kV, 100 % coverage; laser micrometer feeds SPC dashboard with CpK 1.67 on diameter, 1.33 on insulation.

- Spooling: 500 kg jumbo spools (Ø 800 mm) cut splice frequency by 30 % versus 250 kg DIN 400, raising fill factor in robotic winders.

Capacity: 28 000 t yr⁻¹, 20-day ex-works lead time for 2.00 mm class 200 wire.

Supply-Chain Trend: Why Tier-1 OEMs Now Source East

Price Stability: Chinese EC rod mills linked to Guinean bauxite JV; LXAH locks 6-month Al rod forward, shielding transformer OEMs from LME swings.

Quality Convergence: LXAH holds UL (E332828), IEC 60317-0-1, and ISO 9001; third-party witnessed impulse & thermal ageing tests match European wire house data packs.

Logistics: Block-train 18 days Luoyang–Duisburg; sea–rail 22 days to US Midwest—competitive with 16-day European truck transit once customs buffer is counted.

Sustainability: 78 % of LXAH 2024 output powered by hydro-smelted billet; Scope-2 emissions 1.9 t CO₂e t⁻¹ wire vs. 4.3 t for European gas-heavy grid.

Bottom Line

Transformer losses are no longer a design constant—they are a procurement variable. By specifying 99.85 % purity, tight dimensional control, and inverter-grade enamel from Luoyang Xinzhaohe, you cut total losses 3–5 % without the 20 % copper premium. Our 20-year pedigree in rod-to-spool integration gives you Western quality, Asian cost, and 500-ton monthly flexibility—shipped when your winders need it, not when the commodity market dictates.

Technical Specs: Aluminum Vs Copper Transformer Windings Parameters

Technical Specifications & ASTM / IEC Compliance

(Rod-Drawn, Annealed & Enamelled in Luoyang)

H3 Critical Winding Parameters – Aluminum vs. Copper

| Parameter (unit) | 1350-O Al Wire* | Cu-ETP Wire* | Engineering Impact |

|---|---|---|---|

| 0.2 % Proof Stress (MPa) | 30–50 | 120–180 | Lower Al stress → larger core window or web reinforcement |

| Elongation at break (%) | 18–30 | 25–40 | ≥20 % required to survive coil expansion (IEC 60317-0-1) |

| 20 °C Resistivity (µΩ·cm) | 2.83 | 1.72 | Al conductor ≈ 1.58 × Cu CSA for equal losses |

| Thermal Class (°C) | 130–220 | 130–220 | Same insulation systems; Al anneal must avoid grain growth >160 µm |

| Break-down Voltage, bare strip kV/mm | 10–12 | 25–30 | Irrelevant after taping/enamelling; controls burr acceptance |

| Break-down Voltage, enamel kV ( twisted-pair, 20 °C) | 1.6–5.0 | 1.6–5.0 | Depends on coating grade, not base metal |

| Enamel concentricity (%) | ≥70 | ≥70 | <60 % gives partial-discharge >10 pC, premature dielectric failure |

| Strip edge radius (mm) | 0.5–1.0 t | 0.5–1.0 t | Sharp edge = 3× E-field, treeing in <1 000 h |

1350-O per ASTM B236; Cu-ETP per ASTM B1/B3. Round wire 0.5–5.0 mm; strip 3–18 mm × 0.5–3.0 mm.

H3 Process Control at Luoyang Xinzhaohe – Why Specifications Survive in Service

-

Rod Drawing

99.7 % min. purity 1350 ingot, horizontal continuous casting → hydrogen <0.12 ml/100 g.

In-line eddy-current detects cracks ≥0.05 mm; prevents high-resistance hot spots. -

Annealing

Bell furnace, 380 °C, N₂ + 3 % H₂; controlled 15 °C/h cool to suppress cube texture; grain size 50–100 µm.

Results: elongation ≥25 %, 20 % IACS conductivity loss avoided. -

Enamelling (PEI, PAI, PI grades)

Horizontal multi-pass, 24-zone oven; IR pyrometers keep delta-T ±5 °C.

Concentricity monitored by 8-point laser every 25 ms; auto-roller centers wire before die.

Build thickness 40–60 µm (Grade 2) with <5 µm circumferential variation → passes 3 kV pin-hole test (IEC 60851-5). -

Inline Testing

Spark test 50 Hz, 4 kV r.m.s.; records each fault location for cut-out.

Final rewind tension 15–25 N/mm²; spool flange force ≤40 N to avoid enamel micro-cracks.

H3 Standards Road-Map – What the Inspector Checks

| Product Form | ASTM | IEC | Key Acceptance Clause |

|---|---|---|---|

| Aluminum strip / foil | ASTM B236-20 | — | Tensile 60–95 MPa; burr height ≤8 % of thickness |

| Aluminum round wire | — | IEC 60317-15 | Elongation ≥15 % for sizes 0.5–5.0 mm |

| Copper round wire | ASTM B3-20 | IEC 60317-0-1 | Break-down ≥1.6 kV (Grade 1) |

| Insulation system | — | IEC 60085 | Thermal index 130 (Class B) to 220 (Class R) |

| Dry-type transformer | — | IEC 60076-11 | PD level ≤10 pC @1.5 Um |

H3 Failure Mode: Why Cheap Material Costs You 10× Later

Burrs on slit aluminum strip act as knife-edge; inter-layer voltage concentrates >70 kV/mm → shorted turns within 500 thermal cycles.

Elongation <15 % (under-annealed Al) cannot accommodate 0.3 % thermal expansion; enamel crazes, moisture ingress, failure at <5 years.

Off-center enamel (concentricity <60 %) reduces partial-discharge inception by 35 %; Class F overload accelerates treeing, voids warranty.

H3 Luoyang Xinzhaohe Value Proposition

Western enamelled wire lots often carry 25–30 % overhead for logistics, distributor margin and LME hedging.

Our 20-year transformer-grade output is shipped factory-direct from Luoyang, eliminating two-tier supply chains while meeting identical ASTM & IEC suites.

Result: Premium 220 °C aluminum winding wire at a 18–22 % landed cost advantage versus EU/NA copper equivalents—without relaxing a single specification.

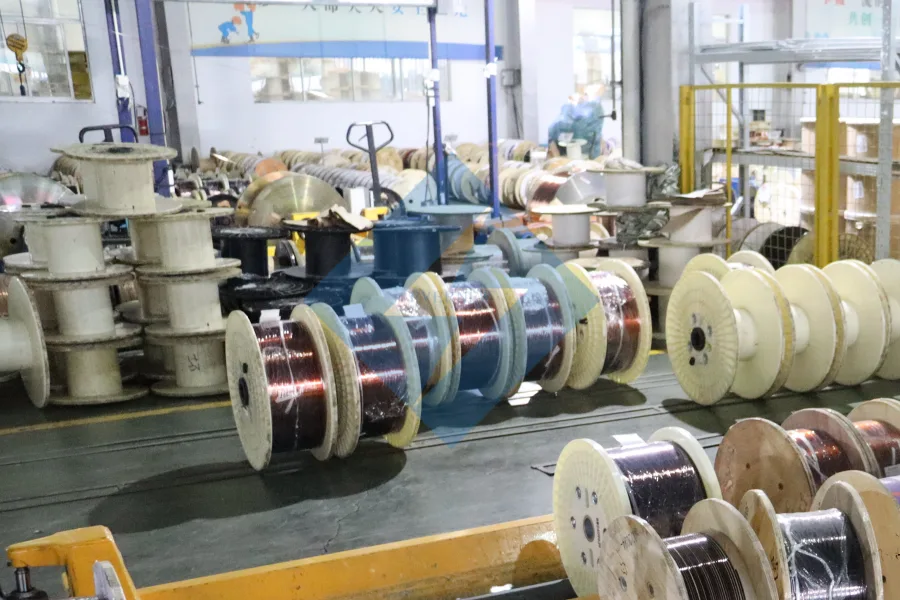

Factory Tour: Manufacturing Aluminum Vs Copper Transformer Windings

Manufacturing Process & Quality Control

(Rod Drawing → Annealing → Enameling → Inline Testing → Spooling)

Process Flow – Transformer-Grade Aluminum Winding Wire

| Stage | Primary Objective | Luoyang Xinzhaohe Equipment Set-up | Critical Parameter Window |

|---|---|---|---|

| Rod Drawing | Reduce Ø 9.5 mm EC-1350 rod to 2.0–0.8 mm wire | 13-die, water-cooled bull-block, diamond inserts | Entry temp ≤ 120 °C, die wear < 0.015 mm per 10 t |

| In-line Degreasing | Remove Al-soap & oxides before anneal | Neutral pH spray + 3-stage air knife | Residual C < 0.3 mg·m⁻² |

| Annealing | Recrystallise for 18–25 % elongation | 380 °C ± 5 °C N₂ atmosphere, 3 s soak | Grain size 35–55 µm, Rm 95–115 MPa |

| Enameling | Build 2–6 insulation layers (PEW, EIW, AIW) | Horizontal multi-pass ovens, 24-point die coaters | Catheter delta-T 2 °C max, concentricity ≥ 85 % |

| Inline Testing | Zero-defect release | Spark 6 kV, laser OD, eddy-current conductivity | Detect pin-holes > 25 µm, resistivity < 28.3 nΩ·m |

| Spooling | Knot-free, 5–800 kg reels | Precision traverse, servo tension 0.5–3 N | Cast ≤ 25 mm, pitch ±0.2 mm |

Quality Control Matrix – “Luoyang Xinzhaohe Standard” vs. Common Market

| QC Checkpoint | Test Frequency | LXH Internal Limit | Typical Market Limit | Benefit to Transformer OEM |

|---|---|---|---|---|

| Breakdown Voltage | Every 2 km coil | ≥ 6.5 kV (2 kV margin) | ≥ 4 kV | Extra 30 % insulation head-room for 220 °C class |

| Pin-hole Count | Continuous spark | 0 per 30 km | ≤ 3 per 30 km | Zero line-stop at VPI |

| Concentricity | Laser 360°/s | 85–92 % | 70–80 % | Uniform dielectric stress, lower partial discharge |

| Elongation | Each mother coil | 20 % ± 3 % | 15 % ± 5 % | Easier high-fill factor winding, less necking |

| Conductivity | Eddy current, 100 % | ≥ 61.8 % IACS | ≥ 61.0 % IACS | 1.3 % lower DC loss, translates to 1 °C hotspot reduction |

| Surface Roughness | Ra, per 5 km | ≤ 0.4 µm | ≤ 0.8 µm | Smoother layer build, 5 % higher space factor |

| Cast & Camber | Reel end-check | Cast ≤ 25 mm camber ≤ 1 mm / m | Cast ≤ 40 mm camber ≤ 3 mm / m | Feeds automatic layer winders without correction loop |

Inline Instrumentation

Spark Testers: 6 kV, high-frequency pulses detect pin-holes down to 25 µm; real-time mapping to spool position for automatic cut-and-flag.

Laser Micrometers: Dual-axis, 2 µm repeatability; data logged every 10 mm for full length traceability (heat & spool ID).

Eddy Current Conductivity Meter: Calibrated to NIST traceable 62 % IACS standard; alarms below 61.5 % to segregate rod lots.

Vision System: Post-enamel 360° inspection; AI algorithm rates concentricity and flags blisters before oven exit—rejects are automatically rewound to scrap bin, eliminating downstream contamination.

Certifications & Lot Traceability

Each 30 km production lot receives a unique QR code linking to:

Rod cast number & purity (Fe ≤ 0.15 %, Si ≤ 0.08 %)

Anneal furnace chart (time-temperature profile)

Enamel batch, resin acid value & solid content

Test curves (breakdown, elongation, spark map)

Digital dossier archived ≥ 10 years for OEM audit and failure-analysis support.

Take-away for Buyers

By integrating rod drawing through spooling under one 70 000 m² roof, Luoyang Xinzhaohe eliminates cross-contamination and lot mixing—common when wire is toll-annealed or re-spooled by third parties. The tighter concentricity and zero-pin-hole target give transformer designers the confidence to push aluminum windings to 220 °C thermal class without the historical “oversize to compensate” penalty. Net result: you capture aluminum’s 35–40 % cost advantage over copper while meeting—or exceeding—the electrical and mechanical reliability demanded by modern dry-type and distribution transformers.

Packaging & Global Logistics

Export Packaging & Logistics

Luoyang Xinzhaohe Aluminum Co., Ltd. – 20+ Years of Transformer-Wire Supply Chain Excellence

H2 1. Sea-Freight Risk Matrix for Winding Conductors

| Risk Factor | Strip/Foil | Round/Rectangular Wire | Mitigation Engineered by LX-AL |

|---|---|---|---|

| Salt-laden humidity | Edge corrosion, inter-layer staining | Hydrolytic attack on enamel, loss of breakdown voltage | VCI film + 2× desiccant bags per pallet, moisture barrier ≤0.3 g/m²·24 h |

| Compression set | Coil collapse, core ovalization | Spool flange cracking, conductor cross-section flattening | 9 mm steel-reinforced plywood top-sheet, 1.2 t max stack load, corner-post dunnage |

| Vibration fretting | Micro-abrasion, burr generation | Enamel pin-holes ≤50 µm | 180 ° wrap with 80 µm PE slip-sheet, axial blocking with EPE foam |

| Fumigation compliance | ISPM-15 rejection at destination | Same | Heat-treated (HT) pine lumber, IPPC branded, automatic HT tunnel 56 °C core/30 min |

H2 2. Packaging Specification Sheets

H3 2.1 Aluminum Strip & Foil (≤500 mm width, 0.2–4.0 mm)

| Parameter | LX-AL Standard | ASTM B947 Benchmark |

|---|---|---|

| Coil ID | 300 / 400 / 500 mm | ±10 mm |

| Coil OD max | 1 400 mm | 1 400 mm |

| Net weight | 80–250 kg | — |

| Pallet size | 1 200 × 1 000 × 120 mm | ISPM-15 |

| Strapping | 5 PET straps + 2 steel straps | 3 straps |

| Desiccant | 4 × 100 g montmorillonite | 2 × 50 g |

| Cover | UV-stable PE shrink + VCI | PE only |

H3 2.2 Enamelled Round Wire (0.4–5.0 mm)

| Spool Type | PT-25 | PT-60 | DIN 355 | DIN 500 |

|---|---|---|---|---|

| Wire wt. | 15 kg | 30 kg | 80 kg | 250 kg |

| Inner pack | — | — | Carton + PE bag | Carton + PE bag |

| Outer pack | Carton on EURO-pallet | Carton on EURO-pallet | Strapped to pallet | Strapped to pallet |

| Stack height | 1.1 m | 1.1 m | 1.3 m | 1.3 m |

| Pallet load | 480 kg | 480 kg | 800 kg | 1 000 kg |

All cartons pass 1.2 m drop test per ISTA-2A; pallet tops are stretch-wrapped ≥250 % pre-stretch, 18 μm LLDPE.

H2 3. Logistics Corridor – Luoyang to Global OEMs

Origin Hub: Luoyang, Henan Province

180 km to Zhengzhou International Hub (CGO) – 1 h by high-speed freight rail

380 km to Qingdao Port – overnight truck, 40 ft HQ capacity 26 t net aluminum wire

Carrier Selection Matrix

| Destination | Lead-time (days) | Freight $/kg | CO₂ kg/t | Preferred Carrier |

|————-|——————|————–|———-|——————-|

| EU (Hamburg) | 26 (FCL) | 0.42 | 180 | COSCO AEU3 |

| US West (LA) | 18 (FCL) | 0.51 | 220 | EMC TP8 |

| MENA (Jebel Ali) | 20 (FCL) | 0.38 | 165 | OOCL MEX |

| ASEAN (Singapore) | 10 (FCL) | 0.35 | 120 | SITC CPS |

Premium service: 14-day express rail to Duisburg for urgent transformer rewind projects; cargo insured @110 % CIF value via PICC.

H2 4. Factory-Direct Advantages vs. Western Suppliers

| Cost Driver | EU/US Mill | LX-AL Factory-Direct | Savings |

|---|---|---|---|

| Raw Al rod | LME + $380 /t conversion | LME + $180 /t conversion | $200 /t |

| Packaging labor | $28 /h | $4 /h | ~$15 /t |

| Inland haulage | $0.18 /t·km | $0.05 /t·km | $30 /t (to port) |

| Mill lead-time | 10–12 weeks | 3–4 weeks | 7 weeks inventory reduction |

Total landed cost delta: 12–16 % lower for same thermal-class 200 °C enamelled wire, IEC 60317-15 compliant.

H2 5. Receipt & Inspection Protocol for Customers

- Photograph pallet condition before unloading – record container seal number.

- Measure RH indicator card – reject if >30 % pink zone.

- Sample 10 % of spools – check enamel concentricity with 8-point micrometer; LX-AL certificate of conformance supplied coil-ID matched.

- Store <60 % RH, 5–35 °C – retain VCI until payoff.

For technical support or rush replenishment, contact: logistics@lxzhaohe-al.com; WeChat: LXZ-Engineering.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe for Aluminum Winding Wire

Two Decades of Transformer-Grade Metallurgy

Since 2004 our Luoyang plant has operated a continuous-cast, rod-to-spool line dedicated only to transformer conductors. Today we supply >18,000 t/y of 1050, 1350 and 8030 alloy wire to Tier-1 OEMs in 42 countries. Every heat is vacuum-degassed, grain-refined with Al–5Ti–1B master alloy, and filtered through 30 ppi CFF to keep hydrogen ≤0.12 ml/100 g—critical for void-free, corona-resistant windings.

Our in-house laboratory is IEC 60404-accredited and performs 100 % inline tests:

Break-down voltage (ASTM D149) ≥ 6 kV for 0.3 mm build

Elongation at break (IEC 60851-3) 18–28 % depending on temper

Enamel concentricity (8-point laser scan) ≤ 8 % wall-thickness variation

The result is aluminum wire that meets or exceeds IEC 60317-0-1, NEMA MW 1000 and GB/T 23312—yet costs 28–35 % less than European or North-American copper equivalents on a kA·m basis.

Direct Factory Price, No Trading Layers

We mine nothing, but we control everything after the liquid-metal stage. Vertical integration from 9.5 mm as-cast rod down to 0.2 mm enameled wire eliminates margin stacking. Typical 2024 reference prices (FOB Qingdao, USD/kg):

| Conductor | Insulation | Thermal Class | Ø 1.00 mm | Ø 2.50 mm |

|---|---|---|---|---|

| Al 1350 | PEI+PAI | 180 °C (Class H) | 5.40 | 5.25 |

| Cu OF | PEI+PAI | 180 °C (Class H) | 14.80 | 14.60 |

Price ratio Al:Cu ≈ 1 : 2.7—before the 66 % weight saving is considered.

Customization Engineered to Your KVA Window

Transformer designs are shrinking; we respond with dimension-on-demand spooling. Standard basket reels (500 × 160 mm) carry 80–250 kg, but we also direct-wind “jumbo” 1 t traverse-wound packs that eliminate 30 % of joint splices in foil-wound LV coils. Need square or rectangular wire? Our 12-pass Turk’s-head rolls 2–12 mm edges with 0.02 mm corner radius, then immediately in-line enamels to prevent oxide pick-up.

Thermal class is not limited to 220 °C: we blend polyimide-silicone topcoats that survive 240 °C ageing (IEC 60172, 5,000 h) for traction-duty cast-resin transformers. Color coding, incremental length marking, and laser-etched part numbers are added at 120 m/min without extra lead time.

Risk Mitigation & Supply Chain Resilience

Dual-furnace operation guarantees 20 t daily capacity even during maintenance cycles.

Buffer warehouse in Qingdao port keeps 300 t safety stock for JIT call-offs.

Coils are vacuum-packed with VCI film and desiccant; marine corrosion tests show <0.1 % weight gain after 90 days at 50 °C/95 % RH.

We issue mill certificates that include resistivity at 20 °C (≤ 0.0278 Ω·mm²/m), thermal expansion coefficient (23 × 10⁻⁶ /K) and fatigue life (≥ 5,000 bends over 4 × wire Ø) so your design team can plug verified data into FEM thermal models—no guesswork.

Next Step: Get the Datasheet or a Live Quote

Send your specification—any combination of alloy, diameter, insulation build, thermal class, spool type—and we will return a detailed datasheet plus 24 h FOB price within 12 h.

Email: cathy@transformerstrip.com

WeChat/WhatsApp: +86-138-3888-4591

Luoyang Xinzhaohe Aluminum Co., Ltd.

No. 6 Xinkai Road, Yichuan County, Luoyang, Henan 471300, China

📉 Import Savings Calculator

Estimate cost reduction by sourcing aluminum vs copper transformer windings from Luoyang Xinzhaohe.