Table of Contents

Market Insight: Aluminum Vs Copper Core Transformer

Market Analysis: Silicon Steel (Electrical Steel) Demand in Transformer Core Applications

The selection of conductor material in transformer windings—aluminum versus copper—has significant implications on the performance, efficiency, and cost structure of power transformers. While both materials are used in conjunction with grain-oriented silicon steel (GOES) cores to optimize magnetic flux transfer and minimize core losses, the choice between aluminum and copper directly influences design parameters, thermal behavior, and lifecycle reliability. As a leading supplier of high-grade electrical steel with over two decades of metallurgical expertise, Luoyang Xinzhaohe Aluminum Co., Ltd. provides critical insights into the evolving industrial demand dynamics and the role of material quality in transformer manufacturing.

Copper has traditionally been the preferred conductor due to its superior electrical conductivity (approximately 100% IACS) and mechanical robustness. Transformers with copper windings typically exhibit lower resistive losses, higher overload capacity, and compact designs, making them ideal for high-efficiency applications such as utility substations and industrial power systems. However, copper’s higher density and cost have driven interest in aluminum as an alternative, particularly in distribution transformers where weight and material cost are critical factors. Aluminum offers a favorable conductivity-to-weight ratio (around 61% IACS) and is significantly lighter, reducing transportation and installation burdens.

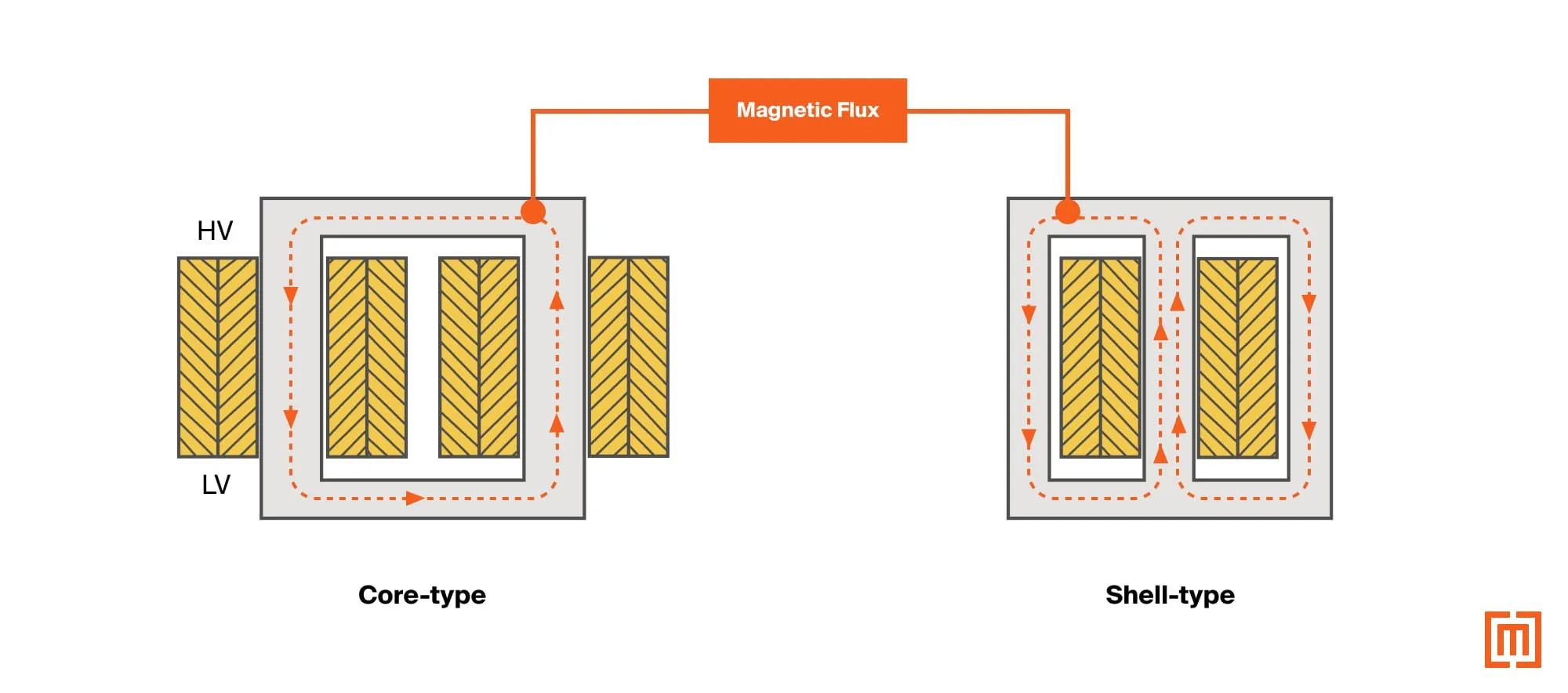

Despite aluminum’s economic advantages, its use necessitates careful engineering of the transformer core and winding configuration. Due to aluminum’s lower conductivity, larger cross-sectional conductors are required to achieve equivalent current-carrying capacity, which increases the window height of the core and affects the overall footprint. This directly impacts the design and utilization of grain-oriented silicon steel, requiring precise control over lamination stacking, core joint geometry, and magnetic flux distribution to mitigate eddy current and hysteresis losses. Inferior electrical steel in aluminum-core designs can exacerbate inefficiencies, leading to higher no-load losses and reduced service life.

The industrial demand for aluminum-core transformers remains strong in cost-sensitive markets, particularly in rural electrification and emerging economies. However, the trend toward energy efficiency standards (e.g., DOE 2016, IEC 60076-20) is driving renewed emphasis on total ownership cost, favoring high-performance materials across the entire transformer assembly. In this context, the quality of silicon steel becomes paramount. High-permeability, low-loss GOES grades—such as M4, M5, or M6—enable tighter magnetic coupling and reduced excitation current, compensating for the inherent limitations of aluminum windings.

At Luoyang Xinzhaohe Aluminum Co., Ltd., we supply silicon steel products engineered to meet stringent international standards, ensuring compatibility with both aluminum and copper core transformer designs. Our metallurgical processes emphasize consistent grain orientation, minimal impurity content, and optimized coating adhesion, all of which contribute to stable core performance under variable load conditions. As transformer manufacturers navigate the trade-offs between material cost and operational efficiency, the integration of high-quality electrical steel remains a decisive factor in achieving long-term reliability and compliance with global efficiency benchmarks.

Technical Specs: Aluminum Vs Copper Core Transformer

Technical Specifications: Aluminum vs Copper Core Transformer Core Performance

Transformer core material selection directly impacts efficiency, thermal performance, and lifecycle cost. While conductor material (aluminum or copper) influences winding design, the electrical steel core’s properties are paramount for managing iron losses, flux density, and structural integrity. Luoyang Xinzhaohe Aluminum Co., Ltd emphasizes that core performance is predominantly governed by the silicon steel grade, regardless of conductor choice. Optimized core design using high-grade non-oriented electrical steel mitigates inherent differences between aluminum and copper windings. Key parameters must be rigorously specified to ensure target efficiency and reliability.

Core loss (iron loss), comprising hysteresis and eddy current losses, is the primary indicator of core efficiency under magnetic excitation. Copper core transformers typically exhibit marginally lower core losses (approximately 5-10%) compared to aluminum core equivalents at identical flux densities and frequencies, primarily due to copper’s higher conductivity enabling slightly smaller core cross-sections. However, this differential is effectively minimized through strategic core design using premium silicon steel. Xinzhaohe’s high-permeability, low-loss electrical steel grades (e.g., 35W230, 50W270 per IEC 60404-2) reduce total core loss by 15-25% compared to standard grades, offsetting conductor-related inefficiencies. Core loss must be measured at the operational flux density (typically 1.5-1.7 T) and frequency (50/60 Hz) per standardized test procedures.

Magnetic flux density saturation limits define the maximum usable induction before permeability drops sharply. Both aluminum and copper core transformers utilize silicon steel cores with identical saturation characteristics, generally reaching 1.9-2.0 T. Practical design flux density is constrained to 1.70-1.80 T for 50 Hz operation to balance core size, losses, and cost. Aluminum conductors necessitate approximately 56% larger cross-sectional area than copper for equivalent resistance, potentially influencing core window utilization but not the fundamental flux density capability of the steel itself. Precise flux density control during operation is critical to avoid saturation-induced losses and overheating.

Flatness tolerance of electrical steel laminations is critical for minimizing interlaminar eddy currents and ensuring tight core stacking. Poor flatness creates air gaps, increasing reluctance and no-load losses. Xinzhaohe mandates a maximum flatness deviation of 0.03 mm per meter for all core-grade silicon steel, exceeding standard industry tolerances (typically 0.05-0.10 mm/m). This stringent control ensures optimal magnetic circuit continuity, directly reducing core loss by 3-8% and enhancing thermal stability, irrespective of the conductor material used in the windings. Flatness must be verified per ASTM A977/A977M or equivalent.

The following table details critical core performance parameters relevant to both aluminum and copper core transformer designs, emphasizing the decisive role of silicon steel quality:

| Parameter | Copper Core Transformer Typical | Aluminum Core Transformer Typical | Critical Considerations for Core Steel Selection |

|---|---|---|---|

| Core Loss (P1.5/50) | 1.10 – 1.30 W/kg | 1.15 – 1.35 W/kg | Premium grades (e.g., 35W230) achieve ≤1.10 W/kg. Loss differential is minimized by optimized core design using high-grade steel. Measured per IEC 60404-2 at 1.5 T, 50 Hz. |

| Operating Flux Density | 1.65 – 1.75 T | 1.65 – 1.75 T | Saturation limit (~1.95 T) identical for both. Design density constrained by loss targets and core size. Requires precise steel permeability control. |

| Lamination Flatness | ≤ 0.05 mm/m | ≤ 0.05 mm/m | Xinzhaohe standard: ≤ 0.03 mm/m. Tighter flatness reduces air gaps, lowering no-load loss by 3-8%. Critical for core stacking factor >97%. |

| Core Stacking Factor | 96% – 97.5% | 96% – 97.5% | Directly impacted by flatness and lamination burr control. Premium steel with superior flatness achieves >97.2%. |

Transformer designers must prioritize silicon steel core specifications—core loss, flux density capability, and dimensional precision—over conductor material when optimizing for efficiency and longevity. Xinzhaohe’s advanced electrical steel solutions ensure aluminum core transformers achieve performance parity with copper core equivalents through superior core material science and manufacturing control.

Factory Tour: Manufacturing

Manufacturing Process of Electrical Steel for Aluminum and Copper Core Transformers

The production of high-performance electrical steel, a critical component in both aluminum and copper core transformers, involves a tightly controlled sequence of metallurgical and mechanical processes designed to optimize magnetic properties, reduce core losses, and ensure dimensional precision. At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of experience in supplying advanced materials for power applications, our manufacturing process adheres to international standards and integrates rigorous quality control at every stage.

The process begins with slitting, where wide master coils of cold-rolled grain-oriented (CRGO) or non-oriented electrical steel are longitudinally cut into narrower strips to meet specific width requirements dictated by transformer core designs. This operation is performed on precision slitting lines equipped with high-tolerance rotary knives to ensure edge consistency and minimize burring, which could otherwise lead to interlaminar short circuits in the final core assembly. Coil tension and line speed are carefully regulated to prevent edge wave or camber defects.

Following slitting, the material undergoes annealing, a heat treatment process critical for stress relief and magnetic domain optimization. The steel strips are passed through continuous annealing furnaces under a controlled nitrogen-hydrogen atmosphere to prevent oxidation and decarburization. For grain-oriented steel, this step facilitates the development of the Goss texture (110)[001], significantly enhancing permeability and reducing hysteresis losses. Temperature profiles are precisely managed, typically ranging from 800°C to 1,100°C depending on the grade, with strict dwell time control to ensure uniform recrystallization.

After annealing, the strips proceed to insulation coating application. A thin, uniform layer of inorganic or semi-organic insulating coating is applied via roll-coating or spray methods. This coating serves multiple functions: it provides interlaminar electrical resistance to minimize eddy current losses, enhances mechanical durability, and improves resistance to moisture and corrosion. Coating weight is monitored in real time using beta-gauge systems, with typical targets between 0.5 g/m² and 1.5 g/m² per side, depending on the application.

The final stage is precision cutting, where the annealed and coated strips are transversely cut into laminations using high-speed turret presses or laser-cutting systems. Advanced CNC control ensures tight dimensional tolerances—typically ±0.05 mm—critical for minimizing air gaps in stacked or wound cores. Step-lap joint cutting may be employed for three-phase transformer cores to optimize magnetic flux distribution.

Quality control is embedded throughout the process. Incoming material is verified for chemical composition and magnetic properties using spectrographic analysis and Epstein frame testing. During production, continuous monitoring includes surface defect inspection via machine vision systems, coating adhesion testing (quadruple bend test), and core loss measurement on sample strips. Final inspection includes dimensional checks, lamination burr assessment, and batch traceability documentation. All data is recorded for full process validation, ensuring consistent delivery of electrical steel suitable for high-efficiency transformers using either aluminum or copper windings.

Packaging & Logistics

Export Packaging Specifications for Electrical Steel Cores in Transformer Applications

Proper export packaging represents a critical quality assurance step for silicon steel laminations destined for aluminum core transformer manufacturing. At Luoyang Xinzhaohe Aluminum CO., Ltd, with over two decades of specialized experience in electrical steel production, we implement rigorous packaging protocols designed explicitly to mitigate the primary risks inherent in global ocean freight: moisture ingress, mechanical shock, and contamination. These risks directly threaten the magnetic properties and dimensional integrity of the core material, potentially leading to increased core losses and premature transformer failure upon installation. Our standardized export system addresses these challenges through engineered material selection and structural design.

All silicon steel coil shipments are secured onto robust, ISPM 15 certified wooden pallets constructed from kiln-dried hardwood. These pallets feature a minimum load-bearing capacity of 2500 kg and incorporate reinforced stringers and deck boards to prevent flexing or collapse during container stacking and handling. The wood moisture content is strictly maintained below 19% to eliminate internal condensation sources. Each coil is centered and firmly strapped to the pallet using galvanized steel tension straps rated for marine environments, preventing lateral movement that could cause edge burrs or dimensional distortion during transit vibrations. Pallet dimensions adhere to ISO container standards (typically 1100 x 1100 mm or 1200 x 1000 mm) ensuring optimal space utilization and stability within 20ft or 40ft containers.

The primary moisture barrier consists of a multi-layer, co-extruded moisture-proof film system applied under controlled factory conditions. This system utilizes a minimum 150-micron thick film incorporating a critical aluminum foil vapor barrier layer (12-micron minimum thickness) laminated between polyethylene layers. The film provides a water vapor transmission rate (WVTR) of less than 0.5 g/m²/24hr at 38°C and 90% RH, significantly exceeding standard polyethylene wraps. Each coil is hermetically sealed within this film using heat-sealing techniques that ensure complete seam integrity. Desiccant packs rated for the specific coil mass and voyage duration are placed internally within the sealed envelope, alongside humidity indicator cards for post-transit verification. This multi-barrier approach maintains an internal relative humidity below 40% throughout typical 30-60 day sea voyages, preventing oxidation and rust formation on the critical steel surface.

Verification is integral to our process. Every packaged unit undergoes visual inspection for film integrity and strap tension prior to container loading. We provide customers with a packing list detailing pallet dimensions, gross/net weights, seal numbers, and humidity indicator specifications. This packaging methodology, refined through 20+ years of global shipments, complies with IEC 60404 handling standards and directly supports the performance requirements of modern aluminum core transformers by preserving the electrical steel’s core loss (W/kg) and permeability characteristics. It represents a non-negotiable component of our quality commitment, ensuring the material arrives at the transformer manufacturer’s facility in the precise condition required for optimal core stacking and performance. Safe sea freight for electrical steel is not incidental; it is engineered into every shipment.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum Co., Ltd for High-Performance Electrical Steel Solutions

With over two decades of specialized expertise in the production and supply of electrical steel, Luoyang Xinzhaohe Aluminum Co., Ltd has established itself as a trusted name in the global transformer manufacturing industry. Our deep-rooted experience in metallurgical engineering and precision material processing enables us to deliver silicon steel products that meet the exacting demands of modern aluminum and copper core transformer designs. As a vertically integrated manufacturer, we maintain full control over raw material sourcing, processing, and quality assurance, ensuring consistency, reliability, and performance in every coil we produce.

Our production facility is equipped with advanced cold-rolling and annealing lines, enabling precise thickness control and optimal grain orientation in non-oriented and grain-oriented electrical steel. This technical capability directly translates into reduced core losses, improved magnetic permeability, and enhanced energy efficiency—critical parameters for high-efficiency transformers. Whether your application involves distribution transformers with aluminum windings or high-capacity units with copper cores, our silicon steel grades are engineered to deliver superior performance under continuous operational loads.

We specialize in custom-tailored electrical steel solutions, offering a wide range of thicknesses (0.23 mm to 0.50 mm), widths up to 1,250 mm, and multiple insulation coating options to suit specific lamination and stacking requirements. Our material compliance extends to international standards including IEC 60404, ASTM A664, and GB/T 2521, with full traceability and mill test certifications provided with every shipment. Rigorous in-line and final inspections—covering dimensional accuracy, surface quality, and magnetic properties—ensure that our products consistently meet the highest industrial benchmarks.

As a strategic partner, Luoyang Xinzhaohe provides not only premium materials but also technical collaboration. Our engineering team supports clients in material selection, core loss optimization, and design adjustments to maximize transformer efficiency and minimize total cost of ownership. This consultative approach has made us a preferred supplier for OEMs across Asia, Europe, and North America.

For sourcing professionals and transformer manufacturers seeking a reliable, technically proficient partner in electrical steel, Luoyang Xinzhaohe offers the stability, scalability, and innovation required in today’s competitive energy market. Our commitment to quality, on-time delivery, and long-term partnership underscores every engagement.

Contact us today to discuss your silicon steel requirements.

Cathy Zhang

International Sales Manager

Email: cathy@transformerstrip.com

Luoyang Xinzhaohe Aluminum Co., Ltd

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing aluminum vs copper core transformer directly from China.