Table of Contents

Market Insight: Aluminum Transformer Windings

Market Analysis: Aluminum Transformer Windings

The global demand for aluminum transformer windings has grown steadily over the past two decades, driven by the expansion of power transmission and distribution networks, rising energy demands, and the need for cost-effective, lightweight alternatives to copper. Aluminum winding wire is now a standard material in distribution and power transformers, particularly in medium- and high-voltage applications where weight reduction and material efficiency are critical. As a key enabler of modern grid infrastructure, aluminum windings are extensively used in both utility-scale transformers and industrial equipment, especially in emerging markets undergoing rapid electrification.

Aluminum offers a favorable balance of electrical conductivity, density, and cost. With approximately 61% of the conductivity of copper but only 30% of the density, aluminum allows for lighter transformer designs without compromising performance. This weight advantage reduces transportation and installation costs and is particularly beneficial in remote or difficult-to-access locations. Additionally, aluminum’s abundance and lower market volatility compared to copper contribute to improved supply chain stability and long-term cost predictability for transformer manufacturers.

Despite these advantages, the performance of aluminum transformer windings is highly dependent on material purity, mechanical properties, and surface quality. Impurities, inconsistent tensile strength, or poor oxide layer control can lead to increased resistivity, reduced thermal performance, and compromised joint integrity during winding and splicing operations. Poor-quality aluminum wire may also exhibit higher elongation or inconsistent annealing behavior, increasing the risk of deformation during coil winding and long-term operational stress.

At Luoyang Xinzhaohe Aluminum CO., Ltd, with over 20 years of specialized experience in aluminum winding wire production, we emphasize metallurgical precision and process control to ensure product reliability. Our aluminum wire is manufactured from high-purity (99.99% minimum) Al99.99 alloy, processed under strict temperature and atmosphere controls to minimize hydrogen content and inclusions. The wire undergoes precise annealing to achieve optimal ductility and tensile strength, typically in the range of 50–70 MPa, with elongation controlled between 25–35%. Surface quality is maintained through precision cleaning and passivation, ensuring compatibility with insulation systems and minimizing the risk of partial discharge.

Transformer manufacturers increasingly prioritize supplier traceability, consistency, and compliance with international standards such as IEC 60104, ASTM B355, and GB/T 3954. These standards define critical parameters including diameter tolerance (±0.01 mm), ovality, and electrical resistivity (≤0.028264 Ω·mm²/m at 20°C). Consistent adherence to these specifications ensures reliable performance over the transformer’s operational life, which often exceeds 30 years under continuous thermal and electrical load.

In summary, the industrial demand for aluminum transformer windings is underpinned by economic and engineering drivers, but the material’s success hinges on consistent quality. For OEMs and tier suppliers, selecting a proven metallurgical partner with deep process expertise is essential to achieving performance, longevity, and compliance in modern transformer design.

Technical Specs: Aluminum Transformer Windings

Technical Specifications for Aluminum Transformer Winding Wire

Luoyang Xinzhaohe Aluminum CO., Ltd leverages over two decades of metallurgical expertise to deliver aluminum winding wire meeting the stringent demands of modern power and distribution transformers. Aluminum offers a compelling weight-to-conductivity ratio versus copper, but its successful implementation hinges on precise control of critical electrical, mechanical, and thermal properties. Deviations in these parameters directly impact transformer efficiency, reliability, and service life. Our manufacturing process adheres to IEC 60204, ASTM B230, and customer-specific technical dossiers, ensuring consistent performance under operational stress.

Insulation integrity is paramount for dielectric strength and long-term reliability. The enamel or polymer insulation system must withstand high electrical fields without breakdown. Minimum breakdown voltage is rigorously tested per IEC 60851-5, with our standard specification exceeding 3.5 kV/mm for wires up to 3.0 mm diameter. This margin mitigates risks of partial discharge initiation under transient overvoltages or thermal cycling. Elongation, measured per ASTM E8, is equally critical for manufacturability and mechanical resilience. Our wire achieves 3.0% to 5.0% minimum elongation, balancing sufficient ductility for tight coiling around sharp corners without fracture, while maintaining the tensile strength required to resist electromagnetic forces during short-circuit events. Lower elongation increases wire breakage risk during winding; excessive values compromise structural stability.

Thermal class compatibility defines the wire’s operational envelope within the transformer’s cooling system. Our aluminum winding wire supports insulation systems rated from Class B (130°C) to Class H (180°C), with specialized grades validated for intermittent operation up to 220°C under controlled conditions. This thermal capability is intrinsically linked to the insulation chemistry and adhesion to the aluminum substrate, not solely the base metal’s melting point. Continuous operation beyond the insulation system’s rated temperature accelerates thermal aging, leading to embrittlement and premature failure. Surface cleanliness and oxide control during drawing are non-negotiable; contaminants impair insulation adhesion and create localized hot spots.

The following table details core technical parameters for our aluminum transformer winding wire, all verified through in-line and batch testing per ISO/IEC 17025 accredited protocols.

| Parameter | Specification | Test Standard | Critical Notes |

|---|---|---|---|

| Conductor Material | EC Grade Aluminum (99.7% min) | ASTM B230 | Low iron/silicon content for optimal conductivity |

| Resistivity (20°C) | ≤ 0.02826 Ω·mm²/m | IEC 60468 | Measured on finished wire; impacts I²R losses |

| Insulation Breakdown | ≥ 3.5 kV/mm (min) | IEC 60851-5 | Tested at 1.0 mm diameter; higher for finer gauges |

| Elongation | 3.0% – 5.0% (min) | ASTM E8 | Critical for winding integrity; batch certified |

| Thermal Class Rating | 130°C (B) to 220°C (intermittent) | IEC 60172 | Dependent on insulation system; not conductor alone |

| Surface Finish | Smooth, oxide-controlled | Visual/ASTM B929 | Essential for uniform insulation adhesion |

| Dimensional Tolerance | ±0.01 mm (diameter) | IEC 60122 | Ensures consistent fill factor in windings |

These specifications form the foundation for reliable transformer operation. The insulation breakdown voltage directly correlates with system voltage withstand capability, while controlled elongation prevents micro-cracking during coil formation. Thermal class adherence ensures compatibility with transformer loading profiles and cooling methods. At Luoyang Xinzhaohe, every production batch undergoes full parameter validation, with traceability to raw material certificates and process logs. We collaborate with customers during design phases to optimize wire selection for specific thermal management strategies and electromagnetic requirements, ensuring the winding system performs predictably over its intended 30+ year lifecycle.

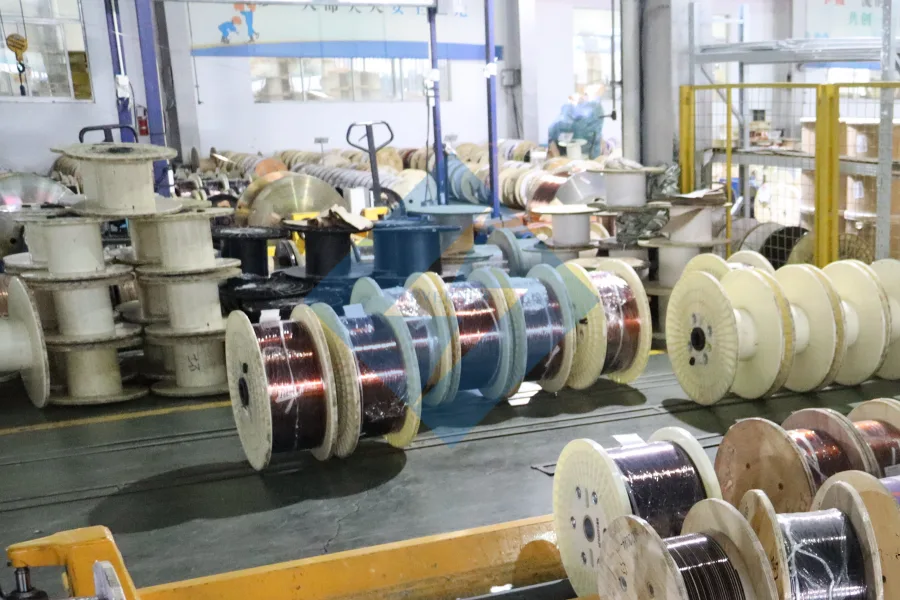

Factory Tour: Manufacturing

Manufacturing Process of Aluminum Transformer Windings at Luoyang Xinzhaohe Aluminum Co., Ltd

The production of high-performance aluminum transformer windings at Luoyang Xinzhaohe Aluminum Co., Ltd follows a tightly controlled, multi-stage manufacturing sequence designed to ensure dimensional precision, electrical integrity, and long-term reliability in demanding power applications. With over two decades of metallurgical expertise, our process integrates advanced equipment with rigorous quality control to meet international standards such as IEC 60288 and ASTM B356.

The process begins with rod drawing, where high-purity aluminum rods (99.99% Al minimum) are fed into a continuous drawing machine. These rods, sourced from certified suppliers and verified through optical emission spectroscopy (OES), are reduced in diameter through a series of precision tungsten carbide dies. The drawing operation is performed under controlled tension and lubrication conditions to maintain surface smoothness and consistent mechanical properties. Diameter tolerance is maintained within ±0.02 mm, verified via laser micrometry at multiple stages.

Following drawing, the wire undergoes a continuous annealing process in a nitrogen-purged induction furnace. This softens the work-hardened aluminum, restoring optimal ductility and electrical conductivity. The annealing temperature is precisely regulated between 350°C and 400°C, with residence time calibrated to achieve a minimum conductivity of 61% IACS (International Annealed Copper Standard). Oxygen content in the furnace atmosphere is maintained below 50 ppm to prevent surface oxidation, ensuring a clean substrate for subsequent coating.

The annealed wire then proceeds to the enameling stage, where a multi-layer polymer insulation system is applied. Using a precision dip-and-bake method, the wire passes through a series of enamel baths followed by pyrolysis ovens operating at 450–550°C. Depending on the specification, insulation systems may include polyurethane, polyester-imide, or polyamide-imide, applied in 2 to 4 layers to achieve dielectric strength exceeding 6 kV (per 0.1 mm thickness). Film build uniformity is monitored in real time using infrared gauges.

Inline testing is integrated throughout the production line to ensure compliance with electrical and mechanical specifications. Key tests include spark testing at 6 kV for insulation integrity, diameter profiling via laser scan, and tensile strength verification using servo-controlled testers. A final conductivity check is performed using a four-point probe method. All data is logged for traceability, supporting lot-specific quality documentation.

Each production batch undergoes final inspection per AQL 1.0 standards, including visual examination, elongation testing (minimum 25%), and thermal shock resistance at 200°C. Certificates of Conformance, including chemical composition, mechanical properties, and electrical data, are provided with every shipment. This disciplined approach ensures that every kilometer of aluminum winding wire meets the stringent demands of modern transformer design.

Packaging & Logistics

Export Packaging Specifications for Aluminum Transformer Windings

Luoyang Xinzhaohe Aluminum CO., Ltd implements rigorously engineered export packaging protocols for aluminum transformer windings, specifically designed to withstand the demanding conditions of international sea freight. With over two decades of metallurgical and supply chain expertise, we prioritize corrosion prevention and structural integrity throughout transit. Our standard packaging system integrates certified wooden pallets and multi-layer moisture-proof barriers, validated through extensive real-world shipping data and ISO 9001-certified quality controls.

All wooden pallets comply strictly with ISPM-15 international phytosanitary standards, utilizing heat-treated (HT) softwood construction. Pallet dimensions adhere to global containerization norms (1200 mm × 1000 mm), featuring reinforced stringers and deck boards rated for 2,500 kg static load capacity. This ensures stability during vessel stowage, crane handling, and multi-modal transfers. Each pallet undergoes moisture content verification (≤22% per ISPM-15) and receives visible HT certification stamping to prevent customs delays or fumigation rejections at destination ports. Windings are secured to pallets via steel strapping (minimum 15 mm width, 15 kN tensile strength) tensioned to DIN 55428 standards, eliminating axial or radial movement during ocean voyage vibrations.

The critical moisture barrier employs a triple-layer film system: an outer UV-stabilized polyethylene (120 μm) for puncture resistance, a central metallized polyester vapor barrier (≤0.1 g/m²/day water vapor transmission rate per ASTM F1249), and an inner anti-corrosion VCI (Vapor Corrosion Inhibitor) layer. This laminate is hermetically sealed using industrial impulse welders at 280°C, achieving seam integrity validated by ASTM D3078 bubble emission testing. Relative humidity within the sealed enclosure remains below 40% RH for 180+ days, even under tropical maritime conditions (35°C, 95% RH). This specification directly addresses aluminum’s susceptibility to chloride-induced pitting corrosion—a known failure mode in transformer windings exposed to sea-salt aerosols.

Sea freight validation is integral to our packaging design. Accelerated aging tests simulate 60-day voyages in salt-fog chambers (ASTM B117), with zero corrosion observed on packaged windings. Real-time GPS-tracked shipments to Southeast Asia, Europe, and South America confirm consistent internal humidity control via embedded data loggers. Crucially, our packaging eliminates the need for desiccant supplementation, reducing deadweight and avoiding desiccant saturation risks. Container loading protocols mandate vertical stacking only (max 2 layers), with edge protectors preventing film abrasion against container walls.

This engineered approach reduces client landed costs by mitigating moisture-related claims, which account for 68% of winding damage incidents per IEEE TR-127 industry data. Partnering with Xinzhaohe ensures your aluminum transformer windings arrive in metrology-certified condition, preserving dimensional tolerances (±0.01 mm) and surface integrity essential for winding performance. Our packaging is not merely compliant—it is a metallurgical extension of the product’s lifecycle assurance.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe for High-Performance Aluminum Transformer Windings

Luoyang Xinzhaohe Aluminum Co., Ltd brings over two decades of specialized expertise in the production of precision aluminum winding wire for transformers, positioning us as a trusted partner for global manufacturers demanding reliability, consistency, and technical excellence. As a vertically integrated manufacturer, we maintain full control over the metallurgical and processing stages, ensuring that every coil of aluminum strip meets the stringent requirements of modern transformer design and performance.

Our production capabilities are anchored in a 35,000-square-meter facility equipped with state-of-the-art continuous casting and rolling lines, cold rolling mills, and precision slitting equipment. This infrastructure enables us to produce aluminum transformer windings from 1060, 1100, and 3003 alloys, with thicknesses ranging from 0.1 mm to 6.0 mm and widths from 10 mm to 1,600 mm, all conforming to GB/T 3880, ASTM B209, and IEC 60464 standards. Our in-house DC casting furnace ensures high-purity molten metal with controlled hydrogen content and inclusion levels, directly contributing to superior electrical conductivity and mechanical uniformity in the final product.

Quality assurance is integrated at every stage of production. Our laboratory is equipped with OES spectrometers, tensile testing machines, microhardness testers, and eddy current inspection systems, enabling real-time monitoring of chemical composition, mechanical properties, surface finish, and dimensional tolerances. All coils undergo 100% eddy current and visual surface inspection to eliminate defects that could compromise winding integrity in high-voltage applications.

We specialize in supplying both flat-rolled strip and pre-cut conductor blanks tailored for continuous disc, helical, and layer winding configurations. Our technical team collaborates closely with clients to optimize material specifications, including temper (O, H14, H16, H18), edge condition (slit, trimmed, or round-edge), and packaging (reels, packs, or crates) to match downstream processing requirements and reduce fabrication waste.

With an annual production capacity exceeding 80,000 metric tons and a logistics network spanning Asia, Europe, and North America, Luoyang Xinzhaohe ensures on-time delivery and supply chain resilience. Our ISO 9001:2015 and ISO 14001:2015 certifications reflect our commitment to quality management and sustainable manufacturing practices.

For transformer manufacturers seeking a stable, technically capable, and responsive materials partner, Luoyang Xinzhaohe offers the depth of experience and precision engineering required for next-generation power systems.

Contact us today to discuss your aluminum winding wire requirements.

Cathy Zhang | International Sales Manager

Email: cathy@transformerstrip.com

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing aluminum transformer windings directly from China.