Table of Contents

Market Insight: Aluminum Tape China

Market Analysis: Transformer Strip/Foil (Aluminum/Copper)

The global demand for aluminum tape in transformer manufacturing has seen sustained growth, driven by the expansion of power infrastructure, renewable energy integration, and the ongoing electrification of industrial and residential sectors. As a critical component in both distribution and power transformers, aluminum tape—particularly in the form of continuously cast and rolled strip—serves as a cost-effective and lightweight alternative to copper windings. China has emerged as a dominant producer and exporter of high-purity aluminum strip and foil, with manufacturers such as Luoyang Xinzhaohe Aluminum CO., Ltd leveraging over two decades of metallurgical expertise to meet stringent international quality standards.

Industrial demand for aluminum tape in transformers is primarily influenced by its electrical conductivity, formability, and thermal performance. While copper remains the benchmark for conductivity, aluminum offers a favorable conductivity-to-weight ratio, reducing the overall mass of transformer windings by up to 50%. This is particularly advantageous in distribution transformers mounted on utility poles, where weight impacts structural load and installation costs. Moreover, aluminum’s abundance and lower material cost compared to copper make it an economically viable choice for large-scale power projects, especially in developing markets.

However, the performance of aluminum tape in transformer applications is highly dependent on metallurgical precision and process control. Impurities, inconsistent thickness tolerances, or inadequate surface finish can lead to localized hot spots, increased eddy current losses, and premature insulation failure. High-quality aluminum tape must meet strict specifications for resistivity (typically ≤0.028264 Ω·mm²/m for 1060/1070 alloys), tensile strength (90–110 MPa), and elongation (≥25%) to ensure reliable performance under continuous thermal cycling. Additionally, precise edge trimming and defect-free surfaces are essential to prevent dielectric breakdown in wound coils.

China’s aluminum tape manufacturing sector has evolved significantly, with leading suppliers adopting advanced continuous casting and cold rolling technologies to achieve tight dimensional tolerances (±0.01 mm) and superior surface quality. At Luoyang Xinzhaohe Aluminum, rigorous in-line monitoring, OCS (Online Control System) thickness measurement, and full batch traceability ensure consistency across production runs. The company’s adherence to GB/T 3880, ASTM B209, and IEC 60404-1 standards underscores its commitment to supplying material suitable for high-reliability transformer applications.

In conclusion, while aluminum tape from China offers compelling economic and logistical advantages, sourcing decisions must prioritize material quality and process integrity. Substandard products may result in increased no-load losses, reduced transformer lifespan, and non-compliance with energy efficiency regulations such as DOE 2016 or EU Ecodesign. For OEMs and tier-1 transformer manufacturers, partnering with technically proficient suppliers that combine metallurgical expertise with robust quality management systems is essential to ensuring long-term performance and compliance in modern power systems.

Technical Specs: Aluminum Tape China

Technical Specifications for Precision Aluminum Tape in Transformer Applications

Luoyang Xinzhaohe Aluminum CO., Ltd leverages 20+ years of specialized metallurgical expertise to deliver aluminum tape meeting the most stringent transformer manufacturing requirements. Our production process integrates advanced slitting technology, rigorous in-line metrology, and ISO 9001-certified quality control to ensure dimensional stability, electrical performance, and edge integrity critical for high-efficiency transformer windings. Below are the core technical parameters governing our aluminum tape products, validated per ASTM B209-20 and IEC 60137 standards.

| Parameter | Specification | Test Standard | Tolerance/Range |

|---|---|---|---|

| Alloy & Temper | 1060, 1070, 8079 (Custom options) | ASTM B209 | H18, O, H24 |

| Thickness | 0.10 mm – 1.50 mm | ASTM E29 | ±0.002 mm |

| Width | 5.0 mm – 150.0 mm | ASTM E29 | ±0.02 mm |

| Edge Burr Height | Maximum 5 μm | ISO 1302 | <5 μm (measured via profilometry) |

| Surface Roughness (Ra) | ≤0.4 μm | ISO 4287 | 0.2–0.4 μm |

| Electrical Conductivity | ≥59.0 %IACS | IEC 60468 | 59.0–61.0 %IACS |

| Tensile Strength | 110–130 MPa (H18) | ASTM E8 | ±5 MPa |

| Elongation | ≥3.0% | ASTM E8 | 3.0–5.0% |

| Waviness | ≤0.15 mm/m | Internal Protocol | Laser-scanned |

Precision slitting accuracy of ±0.002 mm is non-negotiable for transformer foil applications, as deviations exceeding this threshold induce uneven magnetic flux distribution and localized heating during operation. Our proprietary tension-controlled slitting lines utilize carbide-tipped rotary knives with automated edge monitoring, ensuring consistent width tolerances even at high production speeds. This precision directly correlates with reduced core losses (per IEC 60076-1) and enhanced transformer lifespan.

Burr-free edges are equally critical; burrs exceeding 5 μm act as stress concentrators during winding, risking insulation puncture and premature dielectric failure. Xinzhaohe employs real-time optical edge inspection systems coupled with post-slitting electropolishing where required, guaranteeing burr heights remain below 5 μm. This process eliminates micro-tearing and ensures smooth conductor-to-insulation interfaces.

Conductivity performance is maintained at 59.0–61.0 %IACS through strict control of iron and silicon impurities (<0.25% combined) and optimized annealing cycles. High-purity aluminum (99.70% min) ensures minimal resistive losses, directly supporting efficiency classifications per DOE/CEC standards. Surface roughness (Ra ≤0.4 μm) prevents insulation adhesion issues and reduces partial discharge risks in high-voltage windings.

All parameters undergo 100% inline verification during production, with batch-specific mill test reports provided. Xinzhaohe’s slitting technology—refined over two decades of transformer industry collaboration—delivers the dimensional and electrical consistency required for Tier-1 transformer OEMs. This technical rigor minimizes scrap rates in winding operations and ensures compliance with global energy efficiency mandates.

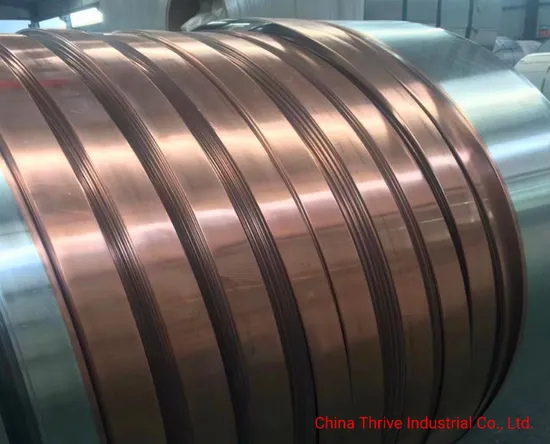

Factory Tour: Manufacturing

Manufacturing Process for Aluminum Transformer Strip and Foil at Luoyang Xinzhaohe Aluminum Co., Ltd

The production of high-performance aluminum tape for transformer applications at Luoyang Xinzhaohe Aluminum Co., Ltd follows a tightly controlled, multi-stage manufacturing sequence designed to ensure dimensional precision, mechanical consistency, and electrical reliability. With over two decades of metallurgical and industrial process expertise, our facility employs advanced cold rolling, precision slitting, and edge conditioning technologies to meet the stringent requirements of power and electronic transformer manufacturers.

The process begins with high-purity aluminum ingots, typically graded 1060, 1070, or 8011, which are homogenized and cast into slabs before undergoing hot rolling to reduce thickness and refine grain structure. The resulting hot bands are then fed into our cold rolling mills, where they are reduced to final gauge with exceptional thickness uniformity. Cold rolling is critical for achieving the desired mechanical properties, including tensile strength and elongation, while maintaining a smooth, defect-free surface. Our 20-high Sendzimir mills and precision backup roll systems ensure thickness tolerances within ±0.005 mm, with surface roughness controlled to Ra ≤ 0.4 µm, minimizing eddy current losses in transformer cores.

Following cold rolling, the aluminum strip undergoes precision slitting to the required width, typically ranging from 10 mm to 500 mm depending on application specifications. Our servo-driven slitting lines utilize tungsten carbide circular knives and advanced tension control systems to maintain edge straightness and minimize camber. Width tolerance is maintained within ±0.1 mm, ensuring compatibility with automated winding equipment used in transformer coil fabrication. During slitting, strip flatness is continuously monitored using laser-based flatness sensors, and real-time feedback adjusts roll crown and tension to correct deviations.

Edge conditioning is a critical final step in the process, especially for transformer-grade aluminum tape. Burrs, micro-cracks, and stress concentrations along the strip edges can initiate electrical discharges and reduce insulation life. At Xinzhaohe, we employ a proprietary edge rounding and deburring system that mechanically smooths edges to a controlled radius, typically between 0.03 mm and 0.08 mm, while preserving edge straightness. This treatment significantly enhances dielectric performance and reduces partial discharge risks in high-voltage applications.

Throughout the manufacturing process, rigorous quality control protocols are enforced. In-process inspections include continuous thickness measurement via beta-gauge systems, surface defect detection using machine vision, and periodic mechanical testing for tensile strength and elongation. Final product certification includes eddy current testing for subsurface flaws, chemical composition verification via OES spectrometry, and dimensional validation using coordinate measuring machines (CMM). All batches are traceable through our ERP system, ensuring full compliance with ISO 9001 and IATF 16949 standards.

This integrated approach to aluminum tape production ensures that every coil delivered meets the exacting demands of modern transformer design, combining electrical efficiency, mechanical precision, and long-term reliability.

Packaging & Logistics

Export Packaging Specifications for Transformer Strip and Foil

Luoyang Xinzhaohe Aluminum CO., Ltd implements rigorously engineered export packaging protocols specifically designed for the secure global shipment of aluminum and copper transformer strip and foil. With over two decades of experience in metallurgical processing and international logistics for precision electrical materials, our packaging system prioritizes absolute product integrity against the significant hazards inherent in ocean freight, particularly moisture ingress and mechanical stress during extended voyages. This system is not merely a container but an integral component of our quality assurance, ensuring the material arrives in the exact condition it left our facility.

All transformer strip and foil coils are secured onto robust, ISPM 15 certified wooden pallets. These pallets are constructed from kiln-dried, heat-treated hardwood or high-density softwood meeting international phytosanitary standards, eliminating pest risks. Standard dimensions (1200x1000mm EUR-pallet or 1100x1100mm Asia-pallet) provide optimal compatibility with global containerization and material handling equipment. Critical structural elements include double stringers, minimum 18mm deck boards, and reinforced corners capable of supporting coil weights exceeding 2500kg without deflection. This robust foundation prevents coil deformation during container stacking and transoceanic handling, where dynamic forces can exceed static loads by significant margins. Pallets are further stabilized using steel strapping anchored directly to the pallet structure, not merely the coil, ensuring unitization remains intact through multiple handling cycles.

Moisture protection constitutes the paramount concern for sea freight. Our multi-barrier approach begins with primary wrapping: each coil undergoes vacuum sealing using triple-layer co-extruded LDPE film (125μm thickness minimum). This film incorporates a high-barrier EVOH core layer, achieving a water vapor transmission rate (WVTR) below 1.0 g/m²/24hr at 38°C and 90% RH, significantly outperforming standard polyethylene. The vacuum seal eliminates internal air pockets where condensation could form. Secondary protection involves enclosing the entire palletized unit within a heavy-duty, metallized moisture barrier bag (MBB) rated for 30-day salt spray resistance, sealed with heat-welded seams. Finally, the pallet is overwrapped with additional UV-stabilized LDPE stretch film (75μm) for puncture resistance and physical protection during transit. Desiccant packs (calculated at 50g per m³ internal volume) are strategically placed within the primary seal to actively control residual humidity, maintaining internal levels below 40% RH throughout typical 45-day voyages.

This integrated packaging system is validated per ASTM D4169 for performance under simulated sea freight conditions, including vibration, compression, and humidity cycling. It directly addresses the critical failure modes in transformer foil logistics: edge damage from inadequate support, core collapse from pallet flexure, and irreversible surface oxidation or interlayer corrosion from moisture penetration. By exceeding standard industry practices in pallet strength, film barrier properties, and humidity control, Luoyang Xinzhaohe ensures your aluminum tape arrives ready for immediate processing, safeguarding your production schedule and eliminating costly rework or rejection upon arrival. Our proven reliability across 80+ countries underscores this commitment to secure global supply chain execution.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum CO., Ltd – Your Trusted Source for High-Performance Transformer Strip and Foil

With over two decades of specialized expertise in aluminum and copper strip and foil production, Luoyang Xinzhaohe Aluminum CO., Ltd stands as a leading manufacturer in China’s advanced materials sector. Our core focus lies in supplying precision-engineered aluminum tape and transformer strip solutions to global electrical and power transmission industries. As demand for efficient, reliable, and thermally stable conductor materials continues to rise, our facility combines deep metallurgical knowledge with rigorous quality control to deliver products that meet and exceed international performance standards.

Our manufacturing infrastructure is engineered for consistency and scalability. Equipped with fully automated rolling lines, continuous annealing systems, and precision slitting machines, we produce aluminum tape with tight dimensional tolerances—ranging from 0.1 mm to 3.0 mm in thickness and up to 1600 mm in width. All products are manufactured under ISO 9001-certified processes, ensuring traceability, mechanical uniformity, and surface integrity critical for transformer windings, busbar assemblies, and electromagnetic shielding applications. Our in-house metallurgical laboratory conducts routine testing for tensile strength, elongation, electrical conductivity, and surface roughness, enabling full compliance with GB/T, ASTM, and IEC specifications.

Material purity is paramount in transformer performance. We source high-grade 1060, 1070, 1100, and 3003 aluminum alloys, all refined to minimize impurities and ensure optimal conductivity and formability. Custom tempers—including O (annealed), H14, H16, and H18—are available to match specific winding, bending, and thermal cycling requirements. In addition to aluminum tape, we offer copper strip and clad materials for hybrid or high-conductivity applications, providing a comprehensive portfolio for power equipment manufacturers.

Supply chain reliability is a cornerstone of our service model. With an annual production capacity exceeding 60,000 metric tons and strategic warehousing in Henan Province, we support both large-volume OEM contracts and agile prototyping orders. Our logistics network ensures timely delivery to major ports in Shanghai, Qingdao, and Ningbo, with export experience across Southeast Asia, the Middle East, Europe, and North America.

For engineering teams and procurement managers seeking a technically capable, responsive, and quality-driven supplier, Luoyang Xinzhaohe offers a proven partnership grounded in metallurgical excellence and industrial reliability.

Contact us today to discuss your technical specifications and sourcing requirements.

Cathy Zhang | Sales Director

Email: cathy@transformerstrip.com

Luoyang Xinzhaohe Aluminum CO., Ltd

Established 2003 | ISO 9001:2015 Certified | OEM/ODM Supported

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing aluminum tape china directly from China.