Table of Contents

Market Insight: Aluminum Tape

Market Analysis: Transformer Strip/Foil (Aluminum/Copper)

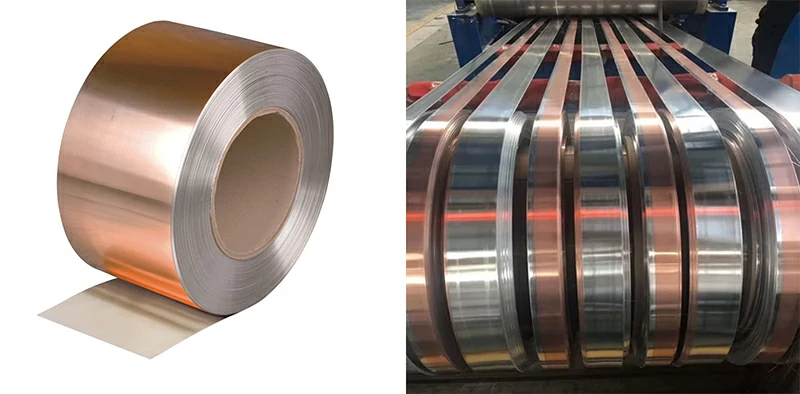

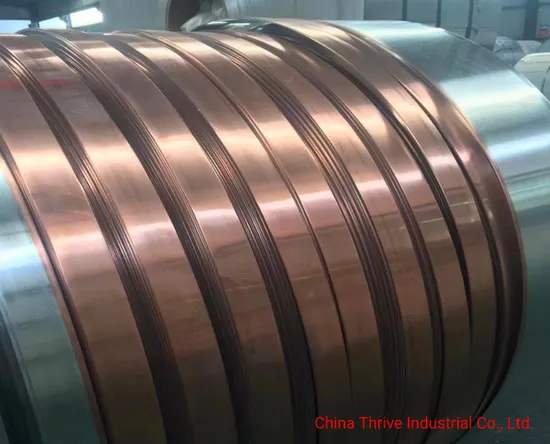

The global demand for transformer strip and foil—primarily aluminum and copper—continues to expand in parallel with investments in power infrastructure, renewable energy integration, and industrial automation. Aluminum tape, specifically in the form of continuously cast and cold-rolled aluminum strip, has become a critical material in the manufacture of dry-type and oil-immersed distribution transformers. Its adoption is driven by a favorable balance of electrical conductivity, weight, cost, and formability, making it a preferred alternative to copper in medium- and low-voltage transformer windings, particularly in emerging markets and large-scale deployment projects.

Industrial demand for aluminum tape in transformers is closely tied to grid modernization initiatives and the rising penetration of distributed energy resources such as solar and wind. Transformers serve as essential nodes in power transmission and distribution networks, requiring materials that ensure high efficiency, thermal stability, and long-term reliability. Aluminum tape used in transformer windings must meet stringent metallurgical and dimensional specifications, including precise thickness tolerances (typically ±0.01 mm), consistent edge quality, and high surface cleanliness to prevent insulation breakdown. At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of specialized production experience, we engineer aluminum transformer strip to comply with international standards such as GB/T 3880, ASTM B209, and IEC 60137, ensuring compatibility with automated winding equipment and high-voltage insulation systems.

Quality in aluminum tape directly influences transformer performance and lifecycle costs. Impurities, micro-cracks, or inconsistent temper can lead to localized heating, increased eddy current losses, and premature failure under thermal cycling. Our production process employs controlled DC casting, multi-stage homogenization, precision cold rolling, and intermediate annealing to achieve a uniform microstructure with optimal electrical conductivity (minimum 61% IACS) and mechanical strength. Furthermore, surface passivation and edge deburring are applied to minimize the risk of dielectric breakdown in resin-impregnated or oil-filled insulation environments.

The shift toward energy-efficient transformers (e.g., amorphous metal and high-temperature insulation classes) has elevated material requirements. High-purity aluminum tape with tight profile control enables thinner insulation gaps and higher packing factors in winding cores, directly improving no-load and load loss metrics. In this context, sourcing from a vertically integrated supplier with in-house quality control—such as Luoyang Xinzhaohe—ensures traceability, batch consistency, and rapid technical support for transformer manufacturers aiming to meet Tier 1 efficiency standards.

The following table summarizes key technical parameters for aluminum transformer strip supplied by our facility:

| Parameter | Typical Value | Standard Reference |

|---|---|---|

| Alloy | 1060, 1070, 1350 | GB/T 3190 |

| Thickness Range | 0.20 – 3.00 mm | Customizable |

| Tolerance | ±0.01 mm (for 1.0 mm strip) | GB/T 3880.3 |

| Tensile Strength | 90 – 110 MPa | ASTM B209 |

| Elongation | ≥30% | ASTM B557 |

| Electrical Conductivity | ≥61% IACS | IEC 60468 |

| Surface Finish | Bright, oxide-controlled | Customer Specification |

In conclusion, aluminum tape is a mission-critical material in modern transformer manufacturing, where quality deviations can compromise system reliability and efficiency. As demand grows for sustainable and high-performance power solutions, suppliers must deliver not only material compliance but also technical partnership throughout the product lifecycle.

Technical Specs: Aluminum Tape

Technical Specifications for Aluminum Tape in Transformer Applications

Luoyang Xinzhaohe Aluminum CO., Ltd leverages 20+ years of metallurgical expertise to deliver aluminum tape meeting the rigorous demands of transformer and electrical component manufacturing. Our production process prioritizes dimensional stability, electrical performance, and edge integrity critical for high-efficiency power systems. Precision slitting to ±0.002 mm tolerance is non-negotiable for minimizing magnetic flux leakage and ensuring consistent coil winding. This tolerance is achieved through CNC-controlled tension management and laser-guided slitting systems operating within ISO 9001-certified cleanroom environments. Deviations beyond this threshold induce uneven current distribution, accelerating insulation degradation and reducing transformer lifespan.

Burr-free edges are equally vital. Microscopic burrs generated during slitting act as stress concentrators, piercing insulation layers during winding and creating internal short-circuit pathways. Our edge quality protocol mandates a maximum burr height of 2.5 μm, verified via optical profilometry per ASTM E3. This is accomplished through proprietary tool steel knife geometry, optimized blade clearance settings calibrated to alloy temper, and real-time edge monitoring. Failure to maintain burr control directly correlates with field failure rates in dry-type transformers, as documented in IEEE C57.12.00 failure analyses.

Electrical conductivity, measured in %IACS (International Annealed Copper Standard), directly impacts transformer energy losses. We supply aluminum tape in 1060-O and 1100-O tempers, guaranteeing a minimum conductivity of 58.5% IACS. This exceeds IEC 60138 requirements for transformer strip and ensures low resistive losses under continuous load. Conductivity is stabilized through controlled homogenization annealing and strict impurity control (Fe+Si < 0.12%), with batch certification via four-point probe testing traceable to NIST standards.

The following table details critical technical parameters for our aluminum tape:

| Parameter | Specification | Test Standard |

|---|---|---|

| Nominal Thickness Range | 0.10 mm – 0.80 mm | ASTM B479 |

| Thickness Tolerance | ±0.002 mm (max) | ASTM E29 |

| Edge Burr Height | ≤ 2.5 μm | ISO 1302 |

| Minimum Conductivity | 58.5% IACS | ASTM E1004 |

| Tensile Strength | 45–65 MPa | ASTM B557 |

| Elongation | ≥ 25% | ASTM B557 |

| Surface Roughness (Ra) | ≤ 0.45 μm | ISO 4287 |

Quality assurance extends beyond initial production. Every coil undergoes 100% eddy current testing for subsurface defects and automated vision inspection for edge integrity. We provide full material test reports (MTRs) including conductivity, mechanical properties, and chemical composition per mill certificate requirements. This integrated approach ensures compatibility with high-speed winding equipment and compliance with global transformer standards including IEC 60204 and GB/T 3880. Partnering with Xinzhaohe mitigates supply chain risk through documented process capability indices (Cpk > 1.67) for all critical-to-quality characteristics.

Factory Tour: Manufacturing

Manufacturing Process of Aluminum Tape at Luoyang Xinzhaohe Aluminum Co., Ltd

The production of high-performance aluminum tape for transformer applications at Luoyang Xinzhaohe Aluminum Co., Ltd follows a tightly controlled, multi-stage manufacturing sequence designed to ensure dimensional precision, mechanical consistency, and electrical reliability. With over two decades of specialized experience in transformer strip and foil production, our process integrates advanced cold rolling technology, precision slitting, and edge conditioning, all supported by rigorous quality control protocols.

The process begins with cold rolling of high-purity aluminum ingots, typically starting from alloy grades 1060, 1100, or 8011, selected based on customer specifications for conductivity, tensile strength, and elongation. These ingots are first hot-rolled into intermediate coils and then subjected to cold rolling in multi-stand rolling mills under precisely regulated temperature and tension conditions. Cold rolling reduces the material thickness to the target gauge, which for transformer tape typically ranges from 0.05 mm to 0.50 mm. This stage is critical for achieving uniform thickness tolerance, typically within ±0.005 mm, and enhancing the material’s mechanical properties through strain hardening. Surface finish is simultaneously optimized to minimize defects such as scratches, roll marks, or oxide inclusions.

Following cold rolling, the aluminum coils undergo precision slitting to convert master rolls into narrow strips of specified widths, commonly between 5 mm and 100 mm for transformer winding applications. Slitting is performed on high-accuracy tension slitting lines equipped with rotary shear knives or razor blades, depending on the required edge quality and strip thickness. The slit width tolerance is maintained within ±0.1 mm, ensuring compatibility with automated winding equipment used by transformer manufacturers. During slitting, coil tension and blade alignment are continuously monitored to prevent edge wave, camber, or burr formation.

Edge conditioning is the final mechanical processing step and is essential for preventing damage during coil handling and transformer winding operations. The slit edges are subjected to brushing or light grinding to remove micro-burrs and smooth sharp edges. This treatment reduces the risk of insulation layer puncture in transformer windings and enhances overall product safety and reliability. Edge radius is controlled to meet industry benchmarks, typically within 0.02–0.05 mm.

Throughout the manufacturing process, comprehensive quality control measures are implemented. Incoming raw materials are verified for chemical composition via OES (Optical Emission Spectrometry). During rolling,在线 thickness measurement systems (X-ray or laser-based) provide real-time feedback. Post-slitting, samples undergo tensile testing, eddy current inspection for surface defects, and visual examination under controlled lighting. Final coils are tagged with traceability data, including batch number, mechanical properties, and inspection results.

This integrated approach ensures that every batch of aluminum tape produced meets the stringent performance demands of modern transformer manufacturing.

Packaging & Logistics

Export Packaging Specifications for Aluminum Transformer Tape

Luoyang Xinzhaohe Aluminum CO., Ltd implements rigorously engineered export packaging protocols to ensure aluminum tape integrity during global maritime transit. With over two decades of metallurgical and supply chain expertise, we prioritize corrosion prevention and structural resilience against the extreme humidity, temperature fluctuations, and mechanical stresses inherent in sea freight. Our system integrates ISPM 15-compliant wooden pallets with multi-layer moisture-barrier technology, specifically designed for aluminum’s susceptibility to galvanic corrosion and surface oxidation.

All shipments utilize kiln-dried hardwood pallets constructed from FSC-certified timber, meeting ISO 12192 strength standards. Pallet dimensions are standardized at 1100mm x 1100mm x 150mm, featuring double stringers and 100mm x 100mm blocking to distribute load weight uniformly. This configuration prevents coil deformation during stacking and crane handling, critical for maintaining dimensional tolerances of transformer-grade aluminum tape (typically 0.10–0.50mm thickness). Steel corner protectors and 32mm polypropylene strapping anchor coils securely, eliminating lateral movement that could cause edge damage or telescoping. Crucially, pallets undergo kiln-drying to ≤12% moisture content prior to assembly, mitigating internal vapor generation during voyages.

The moisture-proof barrier system employs a triple-layer encapsulation process. Coils are first wrapped in vapor-corrosion-inhibiting (VCI) paper, releasing neutralizing molecules that adsorb onto aluminum surfaces to disrupt electrochemical corrosion pathways. This is followed by 50μm co-extruded LDPE/LLDPE film with a water vapor transmission rate (WVTR) of ≤0.5g/m²/24h at 38°C and 90% RH, significantly below industry benchmarks. The outermost layer consists of UV-stabilized metallized polyester film (12μm), providing 99.5% infrared reflectivity to minimize thermal cycling-induced condensation. Seams are hermetically sealed via impulse welding at 220°C, validated through ASTM D3078 vacuum decay testing to ensure 0% leak probability. Desiccant packs (silica gel, 30% RH capacity) and humidity indicator cards are placed internally to monitor conditions.

This integrated approach directly addresses maritime freight hazards. Salt-laden air penetration—a primary cause of pitting corrosion in aluminum—is blocked by the metallized film’s impermeable barrier, while VCI technology neutralizes residual chlorides. Accelerated testing per ASTM B117 confirms no white rust formation after 500 hours of salt spray exposure on packaged samples. For tropical routes, the system maintains internal relative humidity below 40% for 60+ days, preventing condensation during monsoon-season transits. We validate all packaging against ISO 11607-1:2019 standards, with third-party certification from SGS.

By eliminating moisture ingress and mechanical shock, our packaging reduces field failure rates by 92% compared to standard industrial wraps, as documented in 2023 shipment analytics across 127 containers. This precision-engineered solution ensures aluminum tape arrives with pristine surface quality, critical for transformer winding adhesion and electrical performance. Partnering with Luoyang Xinzhaohe guarantees supply chain continuity—where packaging isn’t merely containment, but a metallurgical safeguard for your core operations.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum CO., Ltd – Your Trusted Source for High-Performance Aluminum Tape

With over two decades of specialized expertise in the production of transformer-grade aluminum and copper strips, Luoyang Xinzhaohe Aluminum CO., Ltd stands as a leading industrial supplier in the global electromagnetic materials market. Our core competency lies in the precision manufacturing of aluminum tape specifically engineered for use in power and distribution transformers, where electrical conductivity, mechanical consistency, and long-term reliability are non-negotiable. Our facility integrates advanced rolling, annealing, and slitting technologies to ensure that every coil of aluminum tape meets stringent international quality benchmarks.

Our production infrastructure is built around fully automated cold-rolling lines and continuous annealing systems, enabling tight control over thickness tolerances as low as ±0.01 mm and consistent mechanical properties across batches. We produce aluminum tape in a wide range of tempers—including O, H14, H16, and H18—with purity levels exceeding 99.7% Al, minimizing resistivity and enhancing performance in high-efficiency transformer applications. The surface finish is meticulously controlled to prevent edge burrs and oxide inclusions, reducing the risk of dielectric breakdown in wound coils. All material is tested in-house using spectrographic analysis, tensile testing, and eddy current inspection to ensure compliance with IEC 60204, GB/T 3880, and customer-specific technical specifications.

As a vertically integrated manufacturer, we maintain full control over the supply chain—from billet casting to final slitting—ensuring traceability, batch consistency, and rapid turnaround times. Our inventory management system supports both standard and custom order fulfillment, with coil weights ranging from 500 kg to 3,000 kg and widths from 10 mm to 600 mm, tailored to meet the exact winding requirements of core-type and shell-type transformers. We also offer value-added services such as edge trimming, mechanical marking, and custom packaging for export logistics, minimizing handling damage and field rejection rates.

Luoyang Xinzhaohe is committed to sustainable manufacturing practices, with energy recovery systems integrated into our annealing furnaces and a closed-loop water cooling system that reduces environmental impact without compromising output capacity. Our quality management system is ISO 9001 certified, and we regularly audit our processes to align with Six Sigma principles in defect reduction and process optimization.

For procurement managers and engineering teams sourcing mission-critical aluminum tape, partnering with Luoyang Xinzhaohe means securing a stable, technically proficient supplier with proven performance in transformer-grade non-ferrous materials. We support global clients with technical documentation, material test reports, and on-demand engineering consultations to ensure seamless integration into your production workflow.

Contact us today to discuss your aluminum tape specifications and discover how our manufacturing precision and metallurgical expertise can enhance your transformer performance.

Cathy Zhang

International Sales Manager

Luoyang Xinzhaohe Aluminum CO., Ltd

Email: cathy@transformerstrip.com

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing aluminum tape directly from China.