Table of Contents

Market Insight: Aluminum Strip For Transformer

Market Analysis: Transformer Strip/Foil (Aluminum/Copper)

Global demand for aluminum strip in transformer manufacturing continues to expand, driven by the imperative for grid modernization, renewable energy integration, and weight-sensitive applications such as distribution and traction transformers. Aluminum has progressively displaced copper in core-wound and foil-wound windings due to its favorable conductivity-to-weight ratio (approximately 61% IACS minimum), cost efficiency, and reduced logistical burden. Industry data indicates aluminum strip now constitutes over 75% of new distribution transformer windings in emerging markets, with annual growth projected at 4.2% through 2030, primarily fueled by Asia-Pacific infrastructure investments and European grid decarbonization mandates. Copper retains niche dominance in high-voltage applications requiring absolute minimal resistive losses, but aluminum’s technical refinements have narrowed performance gaps significantly for voltages up to 36kV.

Quality parameters for transformer aluminum strip are non-negotiable due to direct impacts on transformer efficiency, thermal stability, and lifecycle reliability. Impurities exceeding 0.3% (particularly iron and silicon) elevate electrical resistivity, directly increasing no-load losses per IEC 60076-1 standards. Surface defects—scratches, pits, or residual rolling lubricants—act as initiation points for partial discharges under high electric fields, accelerating insulation degradation. Precise thickness tolerance (±0.01mm for strips below 0.5mm) is critical to maintain consistent interlayer capacitance and mitigate eddy current losses. Crucially, uniform annealing homogeneity ensures stable mechanical properties; localized hardness variations induce micro-stresses during coil winding, risking conductor fracture during thermal cycling. Substandard strip manifests as 0.8–1.5% higher total losses in operation, translating to significant energy waste over a 25-year service life.

Luoyang Xinzhaohe Aluminum leverages 20+ years of metallurgical process control to address these demands. Our production integrates real-time spectrographic analysis of molten metal, precision cold-rolling with laser-based thickness monitoring, and continuous annealing furnaces calibrated to ±3°C. This ensures consistent Al99.70+ purity, surface roughness Ra ≤0.4μm, and tensile strength of 40–60 MPa—parameters validated against CIGRÉ TB 782 test protocols. The supply chain consequences of inadequate quality are severe: field failures from strip-induced hotspots incur recall costs exceeding 20x material value and damage OEM reputations irreparably. For transformer manufacturers, partnering with suppliers possessing deep metallurgical expertise and auditable process traceability is not merely a technical requirement but a strategic risk mitigation imperative. Aluminum strip performance directly dictates the asset’s operational efficiency curve; precision in material science is thus inseparable from the transformer’s commercial viability.

Technical Specs: Aluminum Strip For Transformer

Technical Specifications for Aluminum Strip in Transformer Applications

Luoyang Xinzhaohe Aluminum Co., Ltd. provides high-precision aluminum strips engineered specifically for use in transformer windings. These strips are manufactured under stringent quality controls to ensure optimal electrical performance, mechanical consistency, and dimensional accuracy required in power and distribution transformers. The material is primarily produced from high-purity aluminum alloys (1060, 1070, or 1350), selected for their superior conductivity and formability. Each batch undergoes rigorous testing to meet international standards including ASTM B418, IEC 60164, and GB/T 3190.

Dimensional precision is critical in transformer strip applications to ensure uniform winding tension and minimize interlayer stress. Our aluminum strips are slit using advanced precision slitting lines capable of maintaining width tolerances within ±0.002 mm. This level of accuracy ensures consistent coil geometry, reduces the risk of dielectric breakdown, and enhances thermal management within the transformer core-winding assembly. Strip thickness ranges from 0.10 mm to 3.0 mm, with standard widths from 10 mm to 300 mm, customizable based on customer tooling and design requirements.

Edge quality is a defining factor in preventing insulation damage during winding operations. All strips are processed to achieve burr-free edges through optimized slitting parameters and edge conditioning techniques. Burr height is consistently maintained below 3% of material thickness, verified through optical profilometry and metallurgical cross-section analysis. This ensures smooth handling and eliminates the risk of puncturing insulating films such as Nomex or kraft paper.

Electrical conductivity is a core performance metric. Our aluminum strips achieve a minimum conductivity of 61.0% IACS (International Annealed Copper Standard) in the annealed (O) temper condition, with typical values reaching 61.8–62.5% IACS due to low iron and silicon content. This high conductivity contributes to reduced resistive losses (I²R losses), improving transformer efficiency and meeting energy performance standards such as DOE 2016 and EU EcoDesign Directive.

Surface finish is controlled to minimize oxidation and contamination. Strips are cleaned and passivated post-annealing, with surface roughness typically maintained between 0.4 µm and 1.2 µm Ra, depending on application-specific needs. The material is supplied in coil form, with inner diameters of 508 mm or 610 mm, and maximum coil weights up to 5,000 kg, depending on strip dimensions.

All products are traceable via batch certification, including mechanical, electrical, and dimensional test reports.

| Parameter | Specification |

|---|---|

| Alloy | 1060, 1070, 1350 (high purity) |

| Temper | O (Annealed) |

| Thickness Range | 0.10 mm – 3.0 mm |

| Width Range | 10 mm – 300 mm |

| Width Tolerance | ±0.002 mm |

| Burr Height | ≤ 3% of thickness |

| Conductivity | ≥ 61.0% IACS (typ. 61.8–62.5%) |

| Surface Roughness (Ra) | 0.4 – 1.2 µm |

| Coil ID | 508 mm or 610 mm |

| Max Coil Weight | 5,000 kg (varies by dimensions) |

| Applicable Standards | ASTM B418, IEC 60164, GB/T 3190 |

Factory Tour: Manufacturing

Manufacturing Process for Transformer Aluminum Strip

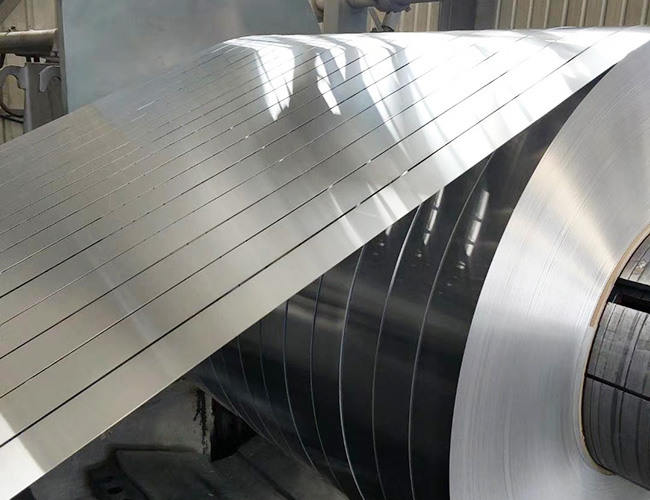

Luoyang Xinzhaohe Aluminum CO., Ltd leverages over two decades of specialized expertise to produce high-purity aluminum strip meeting stringent transformer core requirements. Our integrated manufacturing sequence ensures optimal magnetic properties, dimensional precision, and surface integrity critical for minimizing core losses and enhancing transformer efficiency. The core process comprises three sequentially controlled stages: Cold Rolling, Precision Slitting, and Edge Conditioning, each incorporating rigorous quality control protocols.

Cold rolling forms the metallurgical foundation. Starting from high-conductivity (1350 or 1235 alloy) cast and homogenized ingots, hot-rolled coils undergo multi-stand cold rolling mills under precisely controlled reduction schedules. This stage achieves the target final thickness, typically ranging from 0.20 mm to 0.80 mm for transformer applications, while simultaneously refining the grain structure and inducing the necessary texture for superior magnetic performance. Critical parameters such as rolling speed, interstand tension, and coolant application are continuously monitored via integrated sensors to maintain uniform thickness tolerance (±0.01 mm) and surface roughness (Ra 0.3 – 0.8 µm). Tension leveling immediately follows rolling to eliminate coil set and residual stress, ensuring flatness essential for subsequent processing and core lamination stability. Inline X-ray fluorescence and ultrasonic thickness gauging provide real-time feedback for immediate process correction.

Precision slitting transforms the master coil into the exact strip widths demanded by transformer core designs, commonly between 20 mm and 500 mm. Utilizing high-precision slitting lines with servo-controlled knives and advanced edge guiding systems, we achieve width tolerances of ±0.05 mm. This stage is critical for minimizing edge burr formation and maintaining consistent strip geometry. Laser micrometers continuously measure width and edge profile, while automated vision systems detect surface defects like scratches or dents introduced during handling. Strict control of knife geometry, clearance, and strip tension prevents work hardening at the edges, preserving the material’s magnetic characteristics crucial for low core loss.

Edge conditioning represents a vital, often overlooked step where Xinzhaohe applies significant process innovation. Following slitting, strip edges undergo proprietary mechanical brushing and deburring. This meticulously controlled process removes micro-burrs and surface imperfections generated during slitting, achieving a final edge radius and surface finish (Ra ≤ 0.02 µm) that prevents interlaminar short circuits within the wound core. Smooth, defect-free edges are paramount for reducing eddy current losses and ensuring long-term operational reliability. The conditioned edges also enhance the strip’s ability to accept insulating coatings applied by the transformer manufacturer.

Quality control is embedded throughout the entire production flow, not confined to final inspection. Key parameters are monitored continuously and documented for full traceability. Final product verification includes comprehensive testing against critical specifications.

| Parameter | Test Method | Typical Requirement | Verification Frequency |

|---|---|---|---|

| Thickness | Micrometer / X-ray | ±0.01 mm | 100% Inline + Lab Spot |

| Width | Laser Micrometer | ±0.05 mm | 100% Inline |

| Edge Burr Height | Optical Profilometer | ≤ 3 µm | Hourly Lab Test |

| Surface Roughness | Contact Profilometer | Ra ≤ 0.02 µm (Edge) | Per Coil |

| Core Loss (W/kg) | Epstein Frame (IEC 60404) | As per Customer Spec | Per Melt Batch |

| Resistivity | 4-Point Probe | ≥ 2.824 µΩ·cm (20°C) | Per Coil |

This disciplined, integrated approach from cold rolling through to edge conditioning, underpinned by systematic quality assurance, guarantees the aluminum strip delivered by Xinzhaohe meets the exacting performance demands of modern, high-efficiency power and distribution transformers.

Packaging & Logistics

Export Packaging for Aluminum Strip in Transformer Applications

At Luoyang Xinzhaohe Aluminum Co., Ltd., with over two decades of specialized production and export experience in aluminum and copper strip for transformer applications, we recognize that packaging is not merely a logistical necessity but a critical component in preserving material integrity during international transit. Our export packaging system is engineered to meet the stringent demands of global sea freight, ensuring that high-purity aluminum strips arrive at their destination in optimal condition, free from mechanical damage, oxidation, or contamination.

All aluminum strip shipments destined for transformer manufacturing are systematically palletized on robust, ISPM 15-compliant wooden pallets. These pallets are constructed from kiln-dried hardwood or engineered timber, providing superior load-bearing capacity and resistance to compression during stacking in container holds. The structural rigidity of the pallets prevents coil deformation, especially critical for thin-gauge strips used in wound-core transformers where dimensional precision directly impacts electromagnetic performance.

Prior to palletization, each aluminum coil is wrapped in multiple layers of high-density, moisture-proof polyethylene film. This vapor barrier film is heat-sealed to form a fully enclosed protective shroud, effectively isolating the strip from ambient humidity, salt spray, and condensation—common hazards in maritime environments. The film also acts as a primary defense against dust, grease, and other airborne particulates that could compromise surface cleanliness, a key parameter in insulation layer adhesion and dielectric strength.

Additional protection is provided through the integration of desiccant packs within the sealed film envelope. These moisture-absorbing agents actively mitigate residual humidity and prevent the formation of water droplets during temperature fluctuations encountered during long-haul shipping across varying climatic zones. For orders requiring enhanced protection, vacuum packaging or nitrogen flushing can be implemented upon request, particularly for ultra-thin strips (below 0.1 mm) or alloys with elevated susceptibility to surface oxidation.

Coils are secured to the pallet using high-tensile steel or PET strapping, tensioned to industry standards to prevent lateral movement during vessel motion. Edge protectors, fabricated from corrugated fiberboard or plastic, are affixed to the coil’s outer diameter to resist impact damage during handling. Each packaged unit is labeled with durable, weather-resistant tags indicating batch number, alloy designation, temper, dimensions, and handling instructions, ensuring full traceability and compliance with international shipping regulations.

Our packaging protocol has been validated through extensive real-world performance across major trade routes, including trans-Pacific and trans-Indian Ocean shipments. It aligns with ISO 9001 quality management standards and has been accepted by leading transformer OEMs in Europe, Southeast Asia, and South America. By integrating material science with logistics engineering, Luoyang Xinzhaohe ensures that every meter of aluminum strip maintains its specified surface quality, flatness, and electrical properties upon delivery.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe for Precision Transformer Strip and Foil Solutions

Luoyang Xinzhaohe Aluminum CO., Ltd leverages over two decades of specialized metallurgical expertise to deliver mission-critical aluminum and copper strip and foil for transformer core manufacturing. Our vertically integrated production ecosystem ensures uncompromising control over material properties, directly addressing the stringent demands of high-efficiency transformer design and performance.

Our facility operates advanced continuous casting and rolling lines engineered for micron-level dimensional stability. Aluminum strip products consistently achieve thickness tolerances of ±0.005 mm and width tolerances of ±0.1 mm across coils up to 1,650 mm wide, meeting IEC 60137 and GB/T 3880 standards. For copper foil applications, we maintain surface roughness (Ra) below 0.35 µm and tensile strength uniformity within ±3 MPa, critical for minimizing core losses in high-frequency transformers. All alloys undergo rigorous homogenization and stress-relief annealing in oxygen-controlled furnaces, eliminating residual stresses that compromise magnetic performance.

Metallurgical precision defines our process. Primary aluminum ingots are refined to 99.70% minimum purity using fractional crystallization, while copper feedstock adheres to C11000 specifications. In-line eddy current testing and laser micrometry monitor defects and thickness deviations at production speeds up to 1,200 m/min. Every coil undergoes final validation via our ISO/IEC 17025-accredited laboratory, including DC conductivity measurements (≥58.0 MS/m for Al 1070), intergranular corrosion testing per ASTM G67, and peel strength verification for laminated cores.

Supply chain resilience is engineered into our operations. We maintain strategic raw material buffers for 45+ days of continuous production and operate dual slitting lines capable of processing 8,000 metric tons monthly. Our JIT logistics framework integrates with global ERP systems, enabling batch traceability from smelter to shipment via blockchain-secured digital passports. Customers receive real-time updates on heat numbers, mechanical test results, and shipping milestones through our customer portal.

Quality management extends beyond compliance. Xinzhaohe holds IATF 16949, ISO 9001, and ISO 14001 certifications, with annual third-party audits validating our zero-defect initiatives. Statistical process control (SPC) data from 120+ process parameters is analyzed using AI-driven models to preemptively correct deviations, achieving a 99.98% on-time-in-full delivery rate over the past five years.

Partnering with Xinzhaohe mitigates technical and operational risk in your transformer supply chain. Our engineering team collaborates directly with customers during prototyping to optimize alloy selection, temper, and surface treatment for specific core loss targets. We provide comprehensive technical documentation packages including material test reports (MTRs), RoHS/REACH compliance certificates, and custom coil configuration schematics.

Initiate a technical consultation to qualify Xinzhaohe as your strategic supplier. Contact Cathy Zhang, Head of International Sales, at cathy@transformerstrip.com to request sample coils, review our production capacity schedule, or schedule a virtual factory audit. Specify your required alloy grade, thickness range, and annual volume for a tailored capability assessment within 24 hours.

Production Capacity and Technical Parameters

| Material Type | Thickness Range | Width Range | Monthly Output | Key Standard Compliance |

|—————|—————–|————-|—————-|————————–|

| Aluminum Strip | 0.15–3.0 mm | 100–1,650 mm | 6,500 MT | IEC 60137, GB/T 3880-2012 |

| Copper Foil | 0.05–0.5 mm | 200–1,200 mm | 1,800 MT | ASTM B152, JIS H3100 |

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing aluminum strip for transformer directly from China.