Table of Contents

Market Insight: Aluminum Strip For Transformer

Market Analysis: Transformer Strip/Foil (Aluminum vs. Copper)

Global demand for aluminum strip in transformer manufacturing continues robust expansion, driven primarily by the electrification of infrastructure and renewable energy integration. Aluminum strip has become the dominant material for windings in distribution transformers (typically ≤ 3150 kVA) due to its superior weight-to-conductivity ratio and significant cost advantage over copper. This shift is particularly pronounced in emerging markets and large-scale grid modernization projects where material cost and transportation logistics are critical factors. While copper retains a niche in ultra-high-efficiency or space-constrained applications, aluminum’s market share exceeds 80% for new distribution transformers globally. Key growth vectors include the rapid deployment of solar/wind farm step-up transformers, urban smart grid upgrades requiring millions of new distribution units, and government mandates for higher efficiency classes (e.g., DOE 2016 in the US, IE3/IE4 globally), all demanding reliable, high-volume aluminum strip supply. Supply chain resilience is increasingly scrutinized as geopolitical factors impact raw material (alumina, primary aluminum) availability and energy costs for smelting.

Quality parameters for aluminum transformer strip are non-negotiable and directly dictate transformer performance, longevity, and safety compliance. The core requirement is electrical conductivity, which must consistently achieve 61.0–62.5% IACS (International Annealed Copper Standard) as specified in ASTM B479/B718. This necessitates ultra-high purity aluminum (99.70% min) with tightly controlled iron and silicon content to minimize resistive losses. Surface integrity is equally critical; microscopic scratches, pits, or particle contamination become initiation points for partial discharges under high voltage stress, compromising dielectric integrity and accelerating insulation degradation. Surface roughness must remain below 1.0 μm Ra, requiring precision cold rolling and stringent cleanroom handling. Dimensional tolerances are exceptionally tight—thickness variation ≤ ±0.005 mm and width tolerance ≤ ±0.1 mm—to ensure uniform winding tension and prevent interlayer short circuits. Mechanical properties must balance formability during winding (tensile strength 90–110 MPa) with sufficient rigidity to maintain coil geometry under operational vibration and thermal cycling.

Substandard strip introduces catastrophic failure risks. Inadequate conductivity directly increases load losses (I²R heating), violating efficiency standards and raising lifetime operational costs. Surface defects initiate corona discharge, progressively eroding solid insulation and leading to premature transformer failure—often within 5–7 years versus the expected 25+ year service life. Dimensional inconsistencies cause uneven magnetic flux distribution, elevating no-load losses and audible noise levels beyond regulatory limits. For utilities and OEMs, these failures translate to costly field replacements, warranty claims, and reputational damage. Luoyang Xinzhaohe Aluminum’s two decades of specialized production underscore that transformer strip is not a commodity. Our process control—from molten metal filtration through tension-leveling annealing—ensures every coil meets the metallurgical and geometric precision required for grid reliability. In transformer manufacturing, strip quality is not a cost center; it is the foundation of asset durability and total cost of ownership.

Technical Specs: Aluminum Strip For Transformer

Technical Specifications for Aluminum Strip Used in Transformer Applications

Luoyang Xinzhaohe Aluminum Co., Ltd. manufactures high-precision aluminum strips specifically engineered for use in transformer windings, where dimensional accuracy, edge quality, and electrical performance are critical. Our production process integrates advanced cold rolling, precision slitting, and controlled annealing technologies to meet the stringent requirements of the transformer industry. Each batch is subject to comprehensive quality control protocols, ensuring compliance with international standards such as GB/T 3880, ASTM B209, and IEC 60164.

Dimensional consistency is paramount in transformer strip applications to ensure uniform winding tension and prevent interlayer short circuits. Our aluminum strips are slit to precise widths with a tolerance of ±0.002 mm, achieved through servo-controlled slitting lines equipped with high-precision circular knives and real-time edge monitoring systems. This level of accuracy supports automated winding processes and minimizes material waste during coil fabrication.

Edge quality is equally critical. Burr formation during slitting can lead to dielectric breakdown in transformer windings. We employ a proprietary deburring and edge conditioning process that eliminates micro-tears and raised edges, resulting in a burr-free finish as verified by optical profilometry and scanning electron microscopy (SEM). Edge smoothness is maintained below 2 µm Ra, ensuring compatibility with insulating varnishes and dielectric materials.

Electrical conductivity is optimized through controlled alloy composition and thermal treatment. Our standard material is 1060 or 1070 aluminum alloy (99.60–99.70% Al), which achieves a minimum conductivity of 59.5% IACS (International Annealed Copper Standard) in the O-temper (fully annealed) condition. This high conductivity reduces resistive losses and improves transformer efficiency, directly contributing to compliance with energy efficiency standards such as DOE 2016 and EU Ecodesign.

Surface cleanliness is maintained through degreasing and dry brushing processes to remove residual rolling oils and particulates. The resulting surface is free of contaminants that could compromise insulation integrity or promote corona discharge.

Mechanical properties are tailored to support winding durability. Typical tensile strength ranges from 60 to 75 MPa with an elongation of ≥35%, providing an optimal balance between formability and structural integrity during coil assembly.

The following table summarizes key technical parameters for our aluminum strip products used in transformer applications.

| Parameter | Specification |

|---|---|

| Alloy | 1060, 1070 (99.60–99.70% Al) |

| Temper | O (Fully Annealed) |

| Thickness Range | 0.20 mm – 3.0 mm |

| Width Tolerance | ±0.002 mm |

| Edge Condition | Burr-free, smooth edges (<2 µm Ra) |

| Electrical Conductivity | ≥59.5% IACS |

| Tensile Strength | 60–75 MPa |

| Elongation (min) | ≥35% |

| Surface Finish | Clean, dry, free of oil and particulates |

| Coil ID | 508 mm (20″) standard, customizable |

| Max Coil Outer Diameter | 1200 mm |

| Packaging | Waterproof wrapping, wooden pallets, steel core protection |

All material certifications include traceability reports, conductivity test results, and dimensional inspection data, ensuring full compliance with customer quality management systems.

Factory Tour: Manufacturing

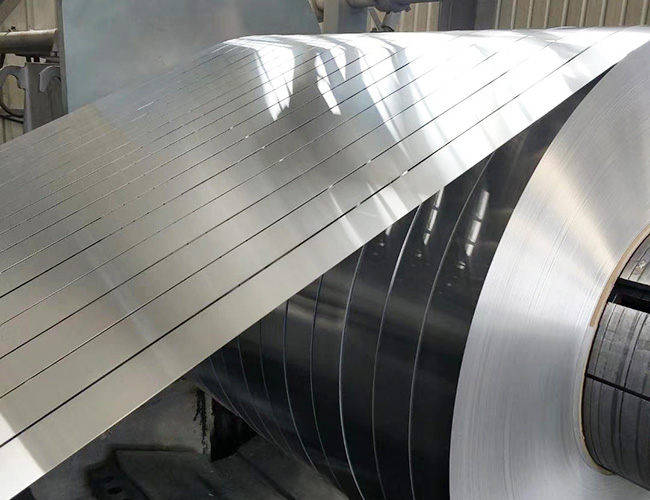

Manufacturing Process for Transformer Aluminum Strip

The production of aluminum strip for transformer applications at Luoyang Xinzhaohe Aluminum CO., Ltd. adheres to a rigorously controlled sequence to ensure electrical, mechanical, and dimensional precision. Our 20+ years of metallurgical expertise in electrical conductor manufacturing underpin every stage, starting with cold rolling.

Cold rolling forms the foundational step, where hot-rolled aluminum ingots undergo reduction through precision single-stand or tandem rolling mills. We utilize computerized gauge control systems to achieve target thicknesses ranging from 0.20 mm to 3.00 mm with tolerances as tight as ±0.005 mm. Critical to transformer performance, this stage optimizes grain structure and minimizes residual stresses through precise tension leveling and interpass annealing. Thickness uniformity is monitored in real-time via laser micrometers, while surface integrity is maintained through high-purity roll cooling lubricants to prevent micro-scratches or oil residues that could compromise insulation systems.

Following cold rolling, precision slitting transforms master coils into customer-specified widths. Our state-of-the-art slitting lines employ rotary shear knives with hydraulic knife positioning, achieving width tolerances of ±0.10 mm. Tension control systems prevent coil telescoping or edge waviness, ensuring consistent strip geometry essential for automated transformer winding. Slitting parameters—including knife overlap, strip tension, and line speed—are calibrated based on alloy grade (e.g., 1060, 1070, or 1350) and final thickness to avoid work hardening or edge deformation. Each slit edge is immediately inspected for burr formation using optical sensors, with rejects automatically quarantined.

Edge conditioning is a non-negotiable step for transformer-grade strip. Mechanical brushing or precision edge profiling removes micro-burrs generated during slitting, eliminating sharp protrusions that could puncture insulating paper or varnish during coil winding. We deploy adjustable abrasive systems to achieve edge radii of 0.05–0.15 mm, verified through profilometry. This process also cleans surface oxides and contaminants, enhancing adhesion for subsequent insulation coating. Edge quality directly impacts transformer reliability; even sub-micron imperfections can initiate partial discharges under high-voltage operation.

Quality control is embedded throughout the process, not isolated to final inspection. In-process checks include:

Thickness & Profile: Laser micrometers at 100 Hz sampling frequency during rolling and slitting.

Surface Defects: Automated vision systems detecting pits, scratches, or stains >10 µm.

Mechanical Properties: Tensile tests per ASTM B928 (yield strength ±10 MPa, elongation ±1%).

Electrical Conductivity: Eddy current testing ensuring ≥59.0% IACS for 1350 alloy.

Final coils undergo 100% eddy current testing for subsurface flaws and are packaged in moisture-controlled environments with VCI paper to prevent corrosion during transit. All data is traceable to melt batch records, meeting IEC 60137 and customer-specific transformer standards. This integrated approach guarantees strip that maintains dimensional stability under thermal cycling and mechanical stress in critical power infrastructure applications.

Packaging & Logistics

Export Packaging for Aluminum Strip in Transformer Applications

At Luoyang Xinzhaohe Aluminum Co., Ltd., with over two decades of specialized experience in producing high-purity aluminum strip for transformer applications, we recognize that proper export packaging is critical to maintaining material integrity during international transit. Our packaging protocols are engineered to meet the rigorous demands of global logistics, particularly for sea freight, which remains the primary mode of transport for bulk shipments of aluminum strip and foil.

All aluminum strip coils designated for export are secured on robust wooden pallets constructed from kiln-dried, ISPM 15-compliant hardwood. These pallets are designed to support the mechanical loads associated with multi-tier stacking in containerized shipping while resisting deformation under prolonged exposure to variable climatic conditions. The structural integrity of the pallets ensures that coil alignment is preserved, minimizing the risk of edge damage or deformation during handling and transport.

Each coil is individually wrapped with a multi-layer moisture-proof composite film, typically consisting of aluminum foil laminated with polyethylene. This vapor barrier effectively shields the aluminum surface from humidity, salt air, and condensation—common challenges in marine environments. The film is heat-sealed at all seams to form a hermetic enclosure, significantly reducing the potential for oxidation, staining, or surface corrosion during extended voyages.

Prior to packaging, all coils undergo surface inspection and are coated with a light layer of volatile corrosion inhibitor (VCI) oil when specified by customer requirements. This additional protective measure further enhances resistance to atmospheric degradation without compromising downstream processing such as slitting, cutting, or winding in transformer manufacturing.

The outer packaging is reinforced with galvanized steel strapping applied in a cross-pattern configuration to ensure load stability. Straps are secured with clinched seals to prevent loosening due to vibration or dynamic forces encountered during rail and ocean transport. Labeling is performed using weather-resistant tags and printed labels affixed to multiple locations on the pallet, providing essential shipment data including coil ID, alloy type, temper, dimensions, weight, and handling instructions.

Our packaging design complies with international carrier standards and is optimized for compatibility with standard 20-foot and 40-foot dry containers. This ensures efficient loading, minimal cargo movement, and optimal space utilization. Additionally, desiccant packs are placed within the moisture-proof enclosure for long-haul shipments to tropical or high-humidity destinations, further mitigating moisture-related risks.

By integrating engineered materials, standardized procedures, and compliance with international phytosanitary and shipping regulations, Luoyang Xinzhaohe ensures that every shipment of aluminum strip for transformer windings arrives at its destination in optimal condition, ready for precision processing in critical electrical applications.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum CO., Ltd for Precision Transformer Strip Solutions

Luoyang Xinzhaohe Aluminum CO., Ltd leverages over two decades of specialized metallurgical engineering and industrial-scale production to deliver aluminum strip and foil engineered explicitly for transformer applications. Our facility operates as a vertically integrated hub, controlling the entire value chain from high-purity aluminum ingot casting through precision cold rolling, annealing, and surface finishing. This integration ensures uncompromised material consistency and traceability, critical for transformer windings where electrical conductivity, mechanical stability, and thermal performance directly impact end-product reliability.

Our production capabilities center on high-conductivity aluminum alloys, primarily 1060, 1070, and 1100 series, processed to exacting industry specifications. We achieve thickness tolerances as tight as ±0.005 mm across widths up to 1,650 mm, utilizing state-of-the-art 20-high cluster mills with real-time laser micrometer feedback. Surface roughness is maintained at Ra ≤ 0.4 μm to ensure optimal insulation adhesion and minimize partial discharge risks. All strips undergo rigorous in-line eddy current testing to detect subsurface defects, with zero pinhole incidence per ASTM E292 standards. Mechanical properties are consistently controlled within narrow bands: tensile strength 60–80 MPa, elongation ≥25%, and electrical conductivity ≥61.0% IACS, verified through accredited laboratory testing per ISO 11566.

Quality assurance is embedded at every process stage. Our ISO 9001 and IATF 16949-certified systems include automated thickness profiling, hydrogen content analysis via vacuum fusion, and grain structure validation through metallographic examination. Material certifications provide full traceability to melt batch, including chemical composition (Si ≤0.25%, Fe ≤0.35%, Cu ≤0.05%), mechanical test data, and surface quality reports. This granular data transparency enables transformer manufacturers to meet stringent regulatory requirements under IEC 60137 and IEEE C57.12.00.

Supply chain resilience is engineered through strategic raw material partnerships and buffer inventory protocols. We maintain dedicated production lines for transformer-grade strip, ensuring on-time delivery performance exceeding 98.5% even during volatile market conditions. Our logistics network supports JIT shipments to global manufacturing hubs, with packaging designed to prevent edge damage and oxidation during transit—critical for maintaining surface integrity prior to winding.

Unlike general aluminum suppliers, Xinzhaohe’s exclusive focus on electrical conductor materials translates to deep application expertise. Our engineering team collaborates directly with transformer designers to optimize strip specifications for amorphous metal cores, high-frequency applications, or ultra-high-voltage systems, reducing lamination losses through tailored temper profiles and edge conditioning.

For transformer manufacturers demanding metallurgical precision and supply chain certainty, Luoyang Xinzhaohe Aluminum provides a technically validated sourcing solution. Contact our technical sales team to discuss your specific conductivity, dimensional, or surface finish requirements. Direct engineering support is available at cathy@transformerstrip.com to initiate material qualification or request certified test samples. Partner with us to mitigate production risks and enhance the performance ceiling of your transformer windings.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing aluminum strip for transformer directly from China.