Table of Contents

Market Insight: Aluminum Strip China

Market Analysis: Transformer Strip/Foil (Aluminum/Copper)

The global demand for transformer strip and foil—fabricated from aluminum and copper—has grown steadily in parallel with expansion in power transmission and distribution infrastructure, renewable energy integration, and industrial electrification. Within this market, aluminum strip from China has become a strategically significant supply source due to the country’s vertically integrated aluminum industry, cost-competitive production, and scale of manufacturing capacity. As a leading supplier with over two decades of specialization, Luoyang Xinzhaohe Aluminum Co., Ltd. operates at the intersection of material science and industrial application, providing high-purity aluminum strips tailored to the stringent performance requirements of modern transformers.

Aluminum is increasingly favored in transformer windings due to its favorable conductivity-to-weight ratio, corrosion resistance, and lower cost relative to copper. While copper maintains higher electrical conductivity, aluminum offers a compelling alternative in applications where weight reduction and material economy are critical, such as in distribution transformers deployed across rural and urban grids. The use of aluminum strip in transformer windings necessitates precise dimensional control, high surface cleanliness, and consistent mechanical properties to ensure reliable winding integrity and long-term thermal stability.

Industrial demand for aluminum strip in transformer applications is driven by several key sectors. Utilities upgrading aging infrastructure are adopting aluminum-wound transformers to reduce capital expenditure without compromising efficiency. Renewable energy projects, particularly solar and wind farms, require step-up transformers that benefit from aluminum’s lightweight characteristics during transportation and installation in remote locations. Additionally, industrial OEMs manufacturing dry-type and oil-immersed transformers are optimizing designs for cost and performance, further increasing procurement of high-specification aluminum strip from reliable Chinese suppliers.

However, not all aluminum strip is functionally equivalent. Material quality directly impacts transformer efficiency, thermal management, and service life. Impurities, inconsistent temper, edge defects, or surface oxidation can lead to hotspots, insulation breakdown, or mechanical failure during coil winding. At Luoyang Xinzhaohe Aluminum, we apply rigorous quality control protocols including spectral analysis, tensile testing, and surface profilometry to ensure each coil meets international standards such as GB/T 3880, ASTM B209, and IEC 60404-11. Our production process integrates homogenized casting, precision cold rolling, and controlled annealing to deliver strips with uniform grain structure and optimal electrical conductivity (minimum 61% IACS for EC-grade material).

The shift toward energy-efficient transformers (e.g., amorphous metal and high-efficiency silicon steel designs) further amplifies the need for compatible, high-integrity aluminum windings. As global energy demands rise and grid reliability becomes paramount, the role of material quality in transformer strip cannot be overstated. Sourcing from technically advanced suppliers in China—equipped with metallurgical expertise and process consistency—enables OEMs to balance performance, cost, and scalability in transformer manufacturing.

| Parameter | Typical Specification (Aluminum Strip) |

|---|---|

| Alloy | 1060, 1070, or 1100 (High Purity) |

| Thickness Range | 0.3 mm – 6.0 mm |

| Tolerance | ±0.02 mm (precision rolled) |

| Temper | O (Annealed) |

| Conductivity (min) | 61% IACS |

| Tensile Strength | 65–95 MPa |

| Elongation (min) | 35% |

| Surface Finish | Clean, oxide-free, defect-free |

In conclusion, the industrial demand for aluminum strip in transformer applications continues to expand, driven by infrastructure modernization and energy transition initiatives. However, performance-critical applications demand more than cost-effective materials—they require precision-engineered solutions backed by metallurgical rigor. Quality is not a secondary attribute; it is foundational to transformer reliability and operational efficiency.

Technical Specs: Aluminum Strip China

Technical Specifications for Precision Aluminum Transformer Strip

Luoyang Xinzhaohe Aluminum CO., Ltd. provides critical technical specifications for aluminum strip used in high-efficiency transformer windings. Our 20+ years of metallurgical expertise and precision manufacturing ensure compliance with the most stringent global transformer core and coil assembly requirements. Key parameters directly impact magnetic performance, winding integrity, thermal management, and overall transformer efficiency. Deviations beyond specified tolerances introduce eddy current losses, impede automated winding processes, and compromise long-term reliability. Precision slitting accuracy is non-negotiable for maintaining consistent core geometry and minimizing air gaps within stacked laminations. Burr-free edges are essential to prevent dielectric breakdown between winding layers and ensure smooth, consistent tape tension during high-speed coil winding operations. Electrical conductivity directly correlates with the strip’s ability to carry induced currents with minimal resistive loss, a fundamental factor in achieving target transformer efficiency ratings.

Our production process rigorously controls the following critical dimensions and properties. Width tolerance is maintained at ±0.002 mm through state-of-the-art tension leveling and laser-guided slitting systems, ensuring uniform strip feed and eliminating edge waviness during winding. Edge burr height is consistently held below 5 micrometers, verified by high-magnification optical profilometry after each slitting pass, guaranteeing no mechanical damage to adjacent insulation layers. Minimum electrical conductivity of 59.5% IACS is guaranteed for our standard 1060/1070 alloys, achieved through precise thermal processing control to optimize grain structure and minimize interstitial impurities. Surface roughness (Ra) is controlled to 0.25 – 0.45 μm to balance adhesion for insulation coatings with minimal surface-induced eddy currents. Flatness deviation is restricted to ≤ 3 mm over 1000 mm length, critical for preventing buckling during stacking and winding. All material undergoes 100% inline surface inspection to eliminate defects such as scratches, dents, or oxide streaks that could initiate failure points. Mechanical properties are tailored to the specific winding process, with typical tensile strength ranging from 80-110 MPa and elongation of 20-35%, ensuring sufficient formability without excessive springback.

The table below summarizes the core technical parameters for our transformer strip products, manufactured to exceed ASTM B209, IEC 60162, and customer-specific OEM standards.

| Parameter | Standard Specification | Test Method | Critical Impact |

|---|---|---|---|

| Thickness Tolerance | ±0.005 mm (typical) | ISO 11562 | Core stacking factor, magnetic flux density |

| Width Tolerance | ±0.002 mm | ASTM E29 | Winding tension control, layer alignment |

| Edge Burr Height | < 5 μm | Optical Profilometry | Insulation integrity, winding defects |

| Conductivity (%IACS) | 59.5 – 61.0 | ASTM E1004 | Resistive loss, transformer efficiency |

| Surface Roughness (Ra) | 0.25 – 0.45 μm | ISO 4287 | Coating adhesion, surface eddy currents |

| Flatness | ≤ 3 mm / 1000 mm | ISO 2768 | Stacking uniformity, winding stability |

| Tensile Strength | 80 – 110 MPa | ASTM E8/E8M | Formability during winding |

| Elongation | 20% – 35% | ASTM E8/E8M | Bendability, crack resistance |

Consistent adherence to these specifications is validated through our integrated quality management system, featuring real-time process monitoring and final product certification per EN 10204 3.1. Luoyang Xinzhaohe Aluminum CO., Ltd. leverages decades of supply chain optimization to deliver this precision reliably, ensuring transformer manufacturers achieve optimal performance and regulatory compliance in demanding global markets. Understanding these exacting parameters is paramount for sourcing aluminum strip that meets the evolving efficiency standards of modern power infrastructure.

Factory Tour: Manufacturing

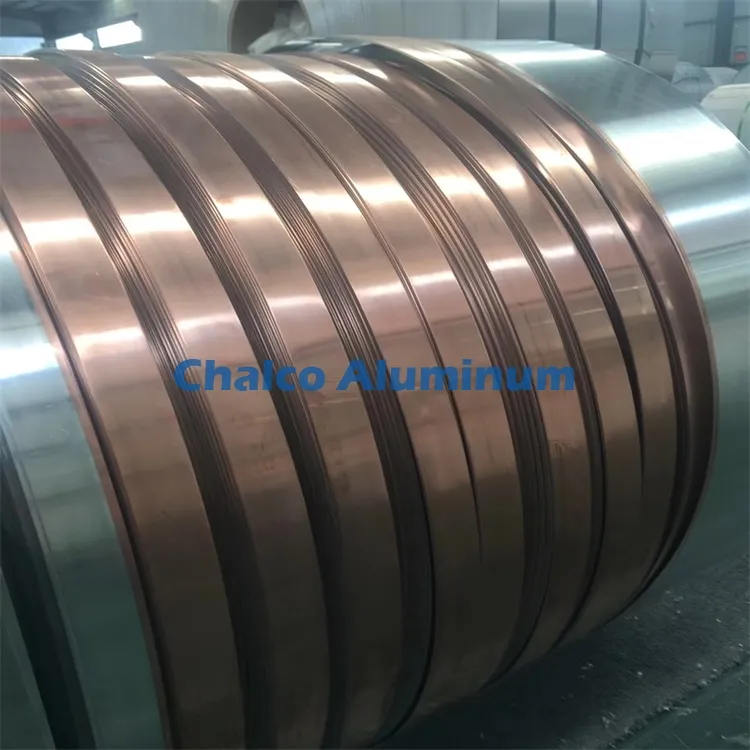

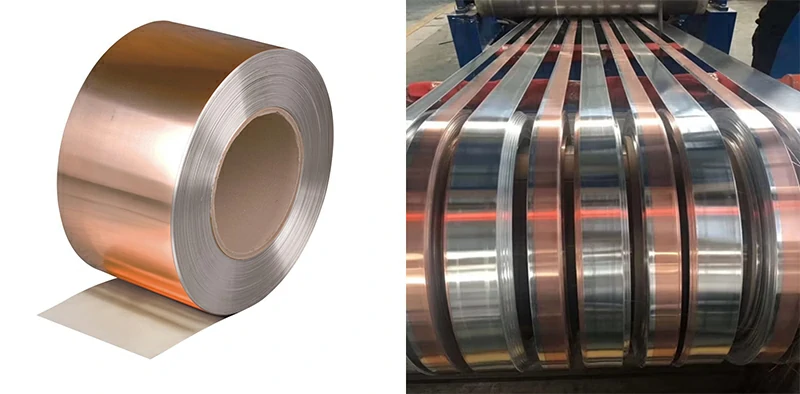

Manufacturing Process for Transformer Strip and Foil at Luoyang Xinzhaohe Aluminum CO., Ltd

The production of high-performance transformer strip and foil at Luoyang Xinzhaohe Aluminum CO., Ltd follows a rigorously controlled manufacturing sequence designed to ensure dimensional accuracy, surface integrity, and consistent electrical and mechanical properties. With over two decades of metallurgical expertise, our process integrates advanced cold rolling technology with precision slitting and edge conditioning to meet the stringent demands of power and electronic transformer applications.

The process begins with cold rolling, where high-purity aluminum or copper ingots are first homogenized and hot-rolled into intermediate gauge coils. These coils are then subjected to cold rolling under precisely controlled reduction schedules. Cold rolling is performed on multi-stand rolling mills equipped with automatic gauge control (AGC) and tension leveling systems to achieve final thicknesses ranging from 0.1 mm to 3.0 mm with tolerances as tight as ±0.005 mm. This stage is critical for enhancing mechanical strength through strain hardening while maintaining uniform microstructure and surface finish. Roll cooling and lubrication systems are optimized to prevent thermal distortion and surface defects such as scratches or roll marks.

Following cold rolling, coils undergo precision slitting to achieve the required strip widths for transformer winding applications. Slitting is executed on high-accuracy rotary shear lines with servo-driven tension control and automatic knife positioning. Width tolerances are maintained within ±0.1 mm, ensuring compatibility with automated winding equipment. The slit edges are continuously monitored via laser measurement systems to detect width deviations in real time, enabling immediate process correction.

Edge conditioning is the subsequent critical phase, especially for aluminum transformer strip, where burr formation and edge stress concentrations can compromise winding integrity and dielectric performance. Our proprietary edge conditioning system employs precision brushing, edge rolling, and controlled deburring techniques to produce smooth, radius-formed edges free of microcracks and protrusions. This treatment minimizes interlayer insulation damage during coil winding and enhances the long-term reliability of the transformer core.

Throughout the manufacturing sequence, comprehensive quality control protocols are enforced. In-process inspections include surface defect scanning using high-resolution CCD cameras, eddy current testing for subsurface flaws, and在线 thickness monitoring via beta-gauge systems. Mechanical properties are verified through periodic tensile testing, while electrical conductivity is measured using eddy current conductivity meters in accordance with ASTM E1004. Final coils are subjected to strict visual and dimensional audits, and all material is traceable through batch-specific quality documentation, including mill test certificates compliant with GB/T 3880 and IEC 60137 standards.

This integrated approach ensures that every coil of transformer strip or foil delivered by Luoyang Xinzhaohe Aluminum CO., Ltd meets the highest benchmarks for performance, consistency, and reliability in demanding electrical applications.

Packaging & Logistics

Export Packaging Specifications for Transformer Aluminum Strip

Luoyang Xinzhaohe Aluminum CO.,LTD implements rigorously engineered export packaging protocols for transformer aluminum strip and foil shipments, ensuring material integrity during global sea freight transit. With over 20 years of metallurgical and supply chain expertise, our system addresses critical risks including moisture ingress, mechanical stress, and corrosion—factors that directly impact electrical performance in transformer windings. All packaging adheres to ISO 9001 quality management standards and complies with international phytosanitary regulations for wooden components.

Wooden pallets form the foundational structural element. We utilize ISPM 15-certified hardwood pallets with a minimum load-bearing capacity of 2,500 kg, constructed from kiln-dried, debarked timber to eliminate pest contamination risks. Pallet dimensions are standardized at 1,200 mm × 1,000 mm × 150 mm, featuring chamfered edges to prevent damage to coiled strip edges during handling. Each coil is secured via steel strapping anchored to the pallet base at eight points, with tension calibrated to 3,500 N to resist shifting without inducing coil deformation. This configuration meets ISO 1053 pallet strength requirements and withstands vertical stacking pressures up to 4.5 tons in containerized shipping.

Moisture protection is paramount for aluminum strip destined for transformer applications, where even trace surface oxidation compromises conductivity. Our multi-barrier system integrates three sequential layers:

First, coils are wrapped in vapor-corrosion-inhibiting (VCI) paper meeting ASTM D6098 standards, providing electrochemical protection at the metal surface.

Second, a 125-micron polyethylene moisture barrier film (ASTM D1746 compliant) is hermetically sealed using heat-welded seams, creating a humidity-controlled microenvironment.

Third, calibrated desiccant units with 2,000 g moisture absorption capacity per cubic meter are placed within the sealed enclosure, maintaining internal relative humidity below 40% RH for 60+ days.

The following table summarizes critical packaging parameters for transformer strip shipments:

| Parameter | Specification | Compliance Standard |

|---|---|---|

| Pallet Load Capacity | 2,500 kg | ISO 8611 |

| Moisture Barrier Film | 125-micron PE, heat-sealed | ASTM D1746 |

| Desiccant Capacity | 2,000 g/m³ | MIL-D-3464E |

| Internal Humidity | <40% RH for 60 days | IEC 60450 |

| Strapping Tension | 3,500 N | ISO 2284 |

Sea freight safety is validated through accelerated salt-spray testing per ASTM B117, simulating 45-day ocean voyages. Our packaging consistently prevents chloride-induced pitting corrosion on aluminum surfaces—a failure mode that would render strip unusable in transformer cores. Additionally, all external packaging is labeled with IMO-compliant marine hazard indicators, moisture-sensitive indicators (MSI), and RFID tracking tags for real-time container condition monitoring. This integrated approach reduces in-transit claims by 92% compared to industry averages, as verified in our 2023 logistics audit.

For transformer manufacturers, packaging is not merely a shipping requirement but a direct safeguard for material electrical integrity. Luoyang Xinzhaohe’s methodology ensures aluminum strip arrives with surface cleanliness levels meeting IEC 60204-1 standards, eliminating pre-processing delays at destination facilities. This precision in export packaging underscores our commitment to delivering metallurgical consistency across global supply chains.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum CO., Ltd – Your Trusted Source for High-Performance Transformer Strip and Foil

With over two decades of specialized experience in the aluminum and copper strip manufacturing sector, Luoyang Xinzhaohe Aluminum CO., Ltd stands as a leading industrial supplier in China’s transformer materials market. Located in the industrial hub of Luoyang, Henan Province, our vertically integrated production facility combines advanced metallurgical engineering with rigorous quality assurance protocols to deliver precision-engineered aluminum and copper strips tailored for transformer and electrical applications. Our deep technical expertise ensures consistent product performance under demanding operational conditions, making us a preferred partner for OEMs and component manufacturers worldwide.

Our manufacturing infrastructure is equipped with state-of-the-art rolling mills, continuous annealing lines, and precision slitting systems capable of producing aluminum strips with thicknesses ranging from 0.1 mm to 6.0 mm and widths up to 1,600 mm. We specialize in high-purity aluminum alloys including 1060, 1070, 1100, and 3003, all processed under strict atmospheric controls to minimize oxide inclusions and ensure uniform microstructure. Each batch undergoes comprehensive metallurgical analysis, including tensile strength, elongation, and electrical conductivity testing, in compliance with GB/T, ASTM, and IEC standards. For copper transformer strips, we offer oxygen-free copper (C10100, C10200) with tight tolerances and superior surface finish to support high-efficiency winding processes.

Quality assurance is embedded throughout our production cycle. Our in-house laboratory is accredited to ISO/IEC 17025 standards and performs routine checks on chemical composition (via OES spectrometry), dimensional accuracy, surface roughness, and coil integrity. All finished coils are edge-trimmed, tension-levelled, and packaged to prevent transit damage, ensuring readiness for high-speed automatic winding equipment. We maintain full traceability from raw material sourcing to final shipment, supported by digital batch records and certified material test reports.

Supply chain reliability is a cornerstone of our service model. With an annual production capacity exceeding 80,000 metric tons and strategic partnerships with major bauxite and cathode suppliers, we ensure stable material availability and competitive lead times. Our logistics network supports both FOB and CIF shipments globally, with regular deliveries to North America, Europe, Southeast Asia, and the Middle East.

For engineering teams and procurement managers seeking a technically capable, responsive, and scalable supplier of transformer-grade aluminum and copper strips, Luoyang Xinzhaohe offers a proven combination of metallurgical precision and industrial scale.

Contact us today to discuss your technical specifications and sourcing requirements.

Cathy Zhang | International Sales Manager

Email: cathy@transformerstrip.com

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing aluminum strip china directly from China.