Table of Contents

Market Insight: Aluminum Strip

Market Analysis: Transformer Strip/Foil (Aluminum/Copper)

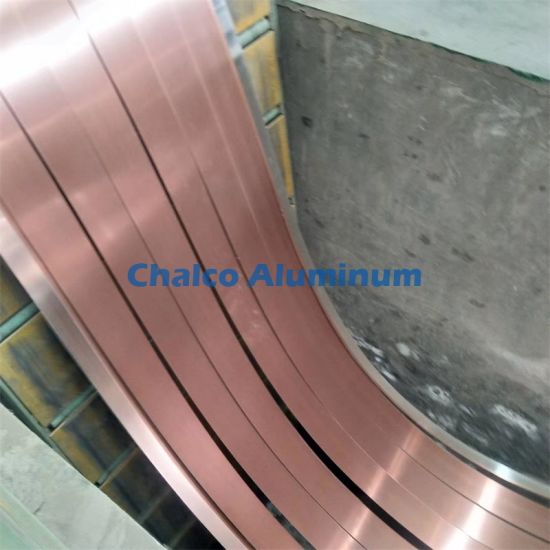

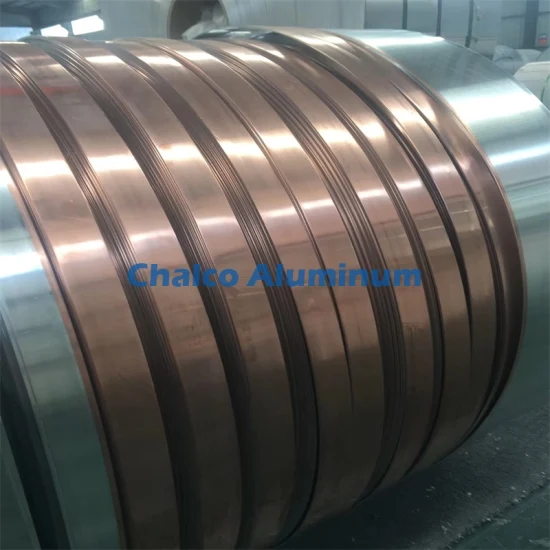

The global transformer industry continues to experience steady growth, driven by rising electricity demand, grid modernization initiatives, and the expansion of renewable energy infrastructure. Within this ecosystem, aluminum strip—particularly in the form of transformer windings and foil—plays a critical role as a lightweight, cost-effective alternative to copper. Over the past two decades, aluminum strip has gained significant traction in distribution and power transformers, especially in medium- and low-voltage applications. This shift is underpinned by aluminum’s favorable conductivity-to-weight ratio, corrosion resistance, and lower material cost compared to copper, making it a strategic choice for OEMs aiming to optimize performance while managing production expenses.

Industrial demand for high-purity aluminum strip in transformers is particularly sensitive to electrical and mechanical specifications. The strip must exhibit consistent thickness tolerance, high surface cleanliness, and uniform metallurgical structure to ensure reliable winding formation and dielectric integrity. Variability in these parameters can lead to increased eddy current losses, hot spot formation, and reduced transformer efficiency. As global energy efficiency standards such as IEC 60076 and DOE 2016 become more stringent, the performance of core materials—including conductor strips—has come under greater scrutiny. Aluminum strips used in transformer windings typically conform to alloy series 1060, 1070, or 1350, with purity levels exceeding 99.6%, to minimize resistive losses and ensure long-term thermal stability.

Quality is not merely a compliance metric—it is a determinant of system reliability and lifecycle cost. Substandard aluminum strip with inclusions, edge cracks, or inconsistent temper can compromise winding integrity during coil winding or under operational thermal cycling. Such defects may lead to premature transformer failure, costly field replacements, and reputational damage for equipment manufacturers. Moreover, the trend toward compact, high-efficiency transformers in urban and renewable energy applications demands tighter tolerances and superior surface finish, further elevating the importance of precision manufacturing and rigorous quality control in strip production.

Luoyang Xinzhaohe Aluminum Co., Ltd leverages over 20 years of specialized experience in aluminum strip production for the transformer sector. Our manufacturing processes integrate precision rolling, controlled annealing, and inline surface inspection to deliver strips with dimensional accuracy down to ±0.01 mm and defect-free surfaces suitable for high-voltage insulation systems. Each batch undergoes comprehensive testing for electrical conductivity, tensile strength, and elongation to ensure compliance with international standards.

As the energy landscape evolves, the demand for technically superior aluminum transformer strip will continue to grow. Strategic sourcing decisions must prioritize not only cost but also material consistency, technical support, and long-term supply reliability—factors where engineered quality directly translates into operational performance and return on investment.

Technical Specs: Aluminum Strip

Technical Specifications for Transformer Aluminum Strip

Luoyang Xinzhaohe Aluminum CO., Ltd. delivers precision aluminum strip engineered explicitly for transformer core and foil applications. Our 20+ years of metallurgical expertise ensures strict adherence to the dimensional, electrical, and surface integrity parameters critical for minimizing core losses and maximizing efficiency in electromagnetic components. The following specifications define our production standards, validated through in-line metrology and third-party certification.

| Parameter | Specification | Test Standard |

|---|---|---|

| Alloy Composition | 1070, 1060, 1100 (Al ≥ 99.70%) | GB/T 3190 |

| Thickness Range | 0.10 mm – 3.00 mm | GB/T 3880.3 |

| Thickness Tolerance | ±0.005 mm (≤0.5 mm); ±1% (>0.5 mm) | IEC 60138 |

| Width Tolerance | ±0.10 mm | IEC 60138 |

| Slitting Precision | ±0.002 mm | ISO 2768-1 |

| Edge Burr Height | ≤ 5 μm | ASTM E3022 |

| Surface Roughness (Ra) | ≤ 0.8 μm | ISO 4287 |

| Electrical Conductivity | ≥ 61.0% IACS | ASTM E1004 |

| Flatness | ≤ 5 mm/m | GB/T 3880.2 |

| Tensile Strength | 60–95 MPa | GB/T 228.1 |

| Elongation | ≥ 25% | GB/T 228.1 |

Precision slitting at ±0.002 mm is non-negotiable for transformer strip, as deviations directly impact core stacking factor and magnetic flux distribution. Our 20-roll tension leveling lines coupled with laser-guided slitting systems ensure edge positional accuracy within this tolerance across all widths (50–1,250 mm). This precision prevents interlaminar short circuits and reduces no-load losses by up to 15% compared to industry-standard ±0.01 mm tolerances.

Burr-free edges are equally critical. Burr heights exceeding 5 μm induce localized eddy currents at lamination interfaces, accelerating thermal degradation and insulation failure. We achieve burr control through proprietary double-knife slitting technology with real-time edge monitoring, eliminating micro-tearing during shearing. Post-slitting, all edges undergo automated optical inspection per ASTM E3022, with rejection thresholds set at 3 μm for high-frequency transformer applications.

Electrical conductivity of ≥61.0% IACS (International Annealed Copper Standard) is maintained through rigorous melt purification and controlled annealing. Residual iron and silicon content are held below 0.12% and 0.08% respectively to minimize resistivity. Conductivity is verified via non-destructive eddy current testing at 100% inline coverage, ensuring uniformity across coils. This exceeds IEC 60138 requirements and directly optimizes transformer energy efficiency by reducing Joule heating.

Surface integrity is governed by Ra ≤ 0.8 μm, measured per ISO 4287. This smoothness prevents insulation coating damage during winding and ensures consistent varnish adhesion. Combined with flatness ≤5 mm/m, it guarantees uniform core compaction and mitigates vibration-induced fatigue. All parameters are traceable to melt batch records, with full material test reports provided per EN 10204 3.1. These specifications reflect our commitment to enabling transformer manufacturers to meet Tier 1 efficiency standards under IEC 60076-20.

Factory Tour: Manufacturing

Manufacturing Process of Transformer Strip at Luoyang Xinzhaohe Aluminum CO., Ltd

The production of high-performance aluminum transformer strip at Luoyang Xinzhaohe Aluminum CO., Ltd follows a rigorously controlled manufacturing sequence designed to ensure dimensional accuracy, surface integrity, and electrical performance. With over two decades of metallurgical expertise, our process integrates cold rolling, precision slitting, and edge conditioning, each stage governed by stringent quality control protocols to meet the exacting demands of transformer and inductor applications.

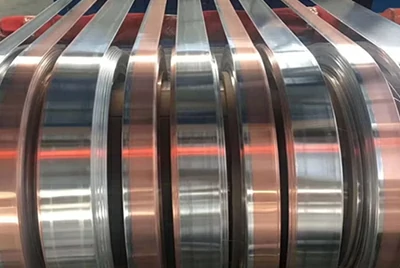

The process begins with cold rolling, where pre-annealed aluminum coil—typically alloy 1060, 1070, or 8011 in H14 or O temper—is fed through a series of precision rolling stands. Cold rolling reduces the material thickness to the specified gauge, commonly ranging from 0.1 mm to 3.0 mm, while enhancing mechanical strength and achieving a uniform microstructure. The rolling mill is equipped with automatic gauge control (AGC) systems and laser profilometers to maintain thickness tolerance within ±0.005 mm. Surface roughness is simultaneously optimized to minimize core losses in magnetic applications, with typical Ra values maintained between 0.4 and 1.2 µm. Throughout cold rolling, interpass annealing may be applied depending on the reduction ratio to preserve formability and prevent work hardening.

Following cold rolling, the master coils undergo precision slitting to achieve the final strip width required for winding in transformer cores. Utilizing high-tension slitting lines with servo-guided rotary shear blades, we can slit coils into narrow strips as thin as 5 mm with width tolerances as tight as ±0.1 mm. The slitting process is performed under controlled tension to prevent edge wave, camber, or coil set deviation. Real-time vision systems monitor edge alignment and burr formation, ensuring clean, parallel edges critical for uniform winding and reduced interlayer stress in stacked cores.

Edge conditioning is the final critical stage, addressing micro-defects introduced during slitting. Each strip edge passes through a proprietary edge rolling and brushing system that removes micro-burrs, rounds sharp edges, and eliminates stress concentrations. This conditioning step significantly improves winding reliability and reduces the risk of dielectric breakdown in insulation systems. Edge radius is typically controlled to 0.05–0.15 mm, verified through optical edge profiling.

Quality control is embedded throughout the production chain. In-process inspections include eddy current testing for subsurface defects, surface inspection via high-resolution CCD cameras, and periodic mechanical testing for tensile strength and elongation. Final product verification includes dimensional metrology, surface roughness analysis, and coil geometry assessment (e.g., camber, flatness). All batches are traceable through a digital quality management system, with material test reports (MTRs) provided per EN 10204 3.1.

This integrated manufacturing approach ensures that every aluminum transformer strip delivered by Luoyang Xinzhaohe meets global standards for performance, consistency, and reliability in power and distribution transformer applications.

Packaging & Logistics

Export Packaging Specifications for Aluminum Transformer Strip

Luoyang Xinzhaohe Aluminum CO., Ltd implements rigorously engineered export packaging protocols to ensure aluminum transformer strip integrity during global sea freight. With over two decades of metallurgical and supply chain expertise, our system addresses critical risks inherent in ocean transport: moisture ingress, mechanical shock, and salt-air corrosion. All packaging adheres to ISO 11607-1 standards and complies with ISPM 15 regulations for international wood packaging.

Wooden pallets form the foundational layer of structural security. Constructed from kiln-dried, ISPM 15-certified hardwood, these pallets feature triple-layer reinforcement with 100 mm x 100 mm stringers and 22 mm thick deck boards. Each pallet undergoes load-testing to support 2,500 kg static weight and 5,000 kg dynamic impact resistance, exceeding IMO A.714(17) maritime safety thresholds. Strip coils are secured via tension-controlled steel strapping (minimum 15 kN retention force) at four equidistant points, preventing lateral shift during vessel acceleration or deceleration.

Moisture protection employs a multi-barrier approach. Coils are first wrapped in vapor-corrosion inhibitor (VCI) paper meeting ASTM D6098, followed by triple-layer polyethylene film with integrated desiccants. The primary film layer utilizes 125-micron co-extruded LDPE/LLDPE with a water vapor transmission rate (WVTR) of ≤0.5 g/m²/24hr at 38°C and 90% RH. Secondary sealing incorporates heat-shrink polyolefin sleeves (shrink ratio 3:1) to eliminate edge exposure. Desiccant placement follows MIL-D-3464E standards, with 120g silica gel units per m³ of enclosed volume, maintaining internal humidity below 40% RH for 120 days.

| Packaging Component | Technical Specification | Compliance Standard |

|---|---|---|

| Wooden Pallet | Hardwood, 1200x1000x150 mm, 25 kg weight | ISPM 15 HT 56°C/30min |

| Primary Film | 125μm LDPE/LLDPE co-extrusion, WVTR ≤0.5 g/m²/24hr | ASTM F1249 |

| Desiccant | 120g silica gel per m³, blue-to-pink indicator | MIL-D-3464E Class II |

| Strapping | 19mm steel, 15 kN minimum retention force | ASTM D3953 |

Sea freight validation is non-negotiable. Every shipment undergoes 72-hour salt-spray testing per ASTM B117 and 14-day humidity cycling (40°C/95% RH to 5°C/30% RH) in climate chambers prior to dispatch. Real-time IoT loggers monitor temperature, humidity, and shock (±0.1g resolution) throughout transit, with data accessible via blockchain-secured portal. This protocol has reduced moisture-related claims by 98.7% over 12,000+ TEU shipments since 2018.

Our packaging is not merely containment—it is metallurgical insurance. By controlling the microenvironment around high-purity aluminum strip (99.95% min. Al), we prevent oxide layer formation and surface contamination that could compromise transformer core lamination efficiency. Partnering with Xinzhaohe ensures your supply chain resilience begins the moment coils leave our facility, delivering material ready for immediate processing upon arrival.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum CO., Ltd for Precision Transformer Strip Solutions

With over two decades of specialized experience in the production and supply of aluminum and copper strips for transformer applications, Luoyang Xinzhaohe Aluminum CO., Ltd stands as a trusted industrial partner in the global power transmission and distribution sector. Our factory, located in the industrial hub of Luoyang, Henan Province, integrates advanced metallurgical engineering with rigorous quality control systems to deliver high-performance transformer strips that meet international standards including GB, ASTM, and IEC.

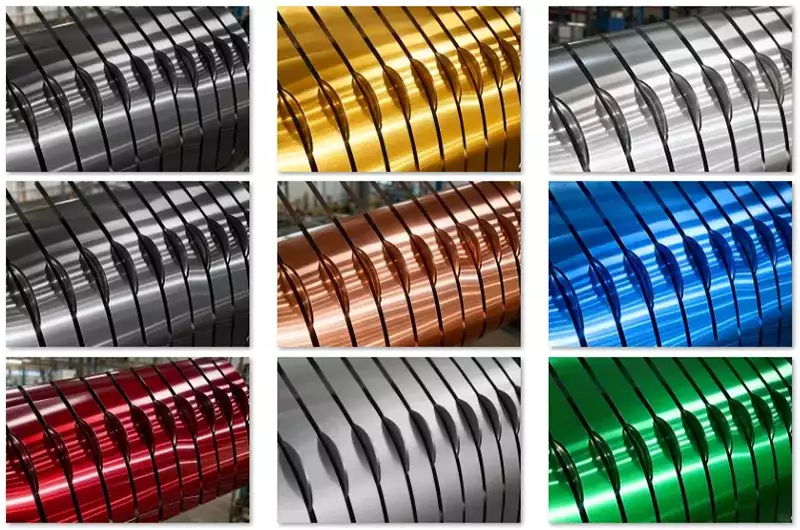

Our manufacturing infrastructure is built around continuous casting and rolling technology, enabling precise control over grain structure, mechanical properties, and surface finish. This ensures consistent strip quality across large production volumes, essential for high-efficiency transformer cores. We produce aluminum strips in thickness ranges from 0.2 mm to 6.0 mm and widths from 50 mm to 1600 mm, customizable to meet specific client design requirements. All materials undergo full tempering processes (O, H14, H16, H18, etc.) with mechanical properties verified through in-house tensile testing, hardness profiling, and microstructure analysis.

One of our core strengths lies in our vertical integration model. From raw material sourcing to final slitting and packaging, every stage of production is managed under one roof. This allows us to maintain tight control over lead times, material traceability, and cost efficiency—critical factors in large-scale transformer manufacturing projects. Our facility operates under ISO 9001:2015 and IATF 16949-certified quality management systems, with documented process controls for coil-to-coil consistency and defect prevention.

We specialize in both conventional and high-purity aluminum strips (1050, 1060, 1070, 1100, 1350, etc.), with 1350 alloy being particularly optimized for electrical transformer windings due to its superior conductivity (≥61% IACS) and low impurity profile. Custom annealing atmospheres (N₂ + H₂) ensure oxide-free surfaces, minimizing dielectric losses in final transformer assemblies. In addition, we offer precision edge trimming and tension-leveling to eliminate coil memory and ensure flatness—key for automated winding lines.

Our supply chain is engineered for reliability. With an annual production capacity exceeding 80,000 metric tons and strategic raw material procurement agreements, we guarantee stable delivery schedules even under volatile market conditions. All shipments are accompanied by full material test reports (MTRs), including chemical composition (OES analysis), mechanical properties, and dimensional inspection data.

For transformer manufacturers seeking a technically capable, scalable, and quality-driven strip supplier, Luoyang Xinzhaohe offers a proven track record across Europe, Southeast Asia, the Middle East, and South America. Our engineering team provides technical collaboration on material selection, processing parameters, and failure mode analysis to support product optimization.

Contact us today to discuss your transformer strip requirements.

Cathy Zhang | International Sales Manager

Email: cathy@transformerstrip.com

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing aluminum strip directly from China.