Table of Contents

Market Insight: Aluminum Strip for Power Industry

Market Analysis: Sourcing High-Quality Transformer Strip/Foil (Aluminum/Copper)

Global Demand Outlook

Global transformer additions are forecast to exceed 18 TWh of winding conductor per year through 2030, driven by grid expansion, renewable integration, and replacement of 1970-1990 era units. Aluminum strip/foil now accounts for ~55 % of that conductor length (up from 38 % in 2010) because every 1 kg Al substitution saves 1.9 kg Cu weight and ≈ 4 USD in raw-material cost. Regional break-down below shows where strip demand is materializing.

| Region | 2023 Strip Demand (kt) | CAGR ’23-28 | Driver |

|---|---|---|---|

| China & APAC | 312 | 6.8 % | Ultra-HV lines, PV inverter step-up |

| EU-27 | 98 | 5.4 % | Green-deal repowering, 750 kV overlay |

| North America | 85 | 4.9 % | IRA-funded substations, data-centre UPS |

| MEA & India | 71 | 7.2 % | Desert solar parks, rural electrification |

Take-away: Annual aluminum strip tonnage for transformers is growing faster than transformer unit sales because designers increase conductor cross-section to meet Tier-2/Tier-3 loss limits (EU Eco-design, DOE 2016+, IEC 60076-20).

Why Purity & Precision Directly Impact Transformer Losses

No-load (core) losses are fixed by the steel grade, but load losses (I²R + stray) are governed 100 % by the winding conductor. Two material parameters dominate:

-

Electrical conductivity (%IACS)

1350-O ≥ 61.8 %IACS (annealed) gives 4 % lower DC resistance than 1050-O (≥ 61.0 %IACS). In a 1 MVA dry-type unit this delta equals 350 W lower load loss, translating to 3.1 MWh saved energy per year. -

Geometric tolerances & edge quality

Burr > 0.015 mm locally raises electric field > 30 %, initiating partial discharge (PD) and eventually treeing. A slit-width scatter > ±0.05 mm forces the winder to de-rate fill factor by 2–3 %, so more conductor length is required for the same ampacity, raising ohmic loss by the same percentage.

| Parameter | Luoyang Xinzhaohe Capability | Industry “A” Mill | Impact if Out-of-Spec |

|---|---|---|---|

| Thickness | ±0.002 mm | ±0.008 mm | +0.8 % eddy-current loss |

| Width | ±0.03 mm | ±0.10 mm | –2 % copper-fill factor |

| Burr height | ≤0.01 mm | ≤0.03 mm | PD inception ↓ 15 % |

| Resistivity 20 °C | ≤28.10 nΩ·m | ≤28.45 nΩ·m | +1.2 % load loss |

The Chinese Sourcing Trend—Moving Beyond “Low-Cost”

Western OEMs used to accept a 15–20 % price premium for domestic strip to “avoid risk.” Today, with 80 % of the world’s cold-rolling capacity located in Henan, Jiangsu and Chongqing, the technical risk has shifted: the leading Chinese mills now hold 60 % of global IEC 60076-1-qualified tonnage. What buyers seek is not merely lower USD/kg but validated process control—something only a handful of Tier-1 Chinese suppliers can document.

Luoyang Xinzhaohe Aluminum exemplifies this shift:

20+ years dedicated to transformer grades (no commodity foil diversion)

In-house 20-high Sendzimir cold mill → 0.2–3.5 mm in one pass, surface Ra ≤0.3 µm

Closed-loop slitting line with laser micrometer feedback, 250 m/min, automatic burr removal wheel

100 % coil traceability: cast-number → anneal batch → slitting cassette → oscillate-winding spool

Vacuum annealing 320 °C/8 h to guarantee 1350-O softness (30–40 HV) without oil residues that poison dielectric loss tangent

Net result: We deliver IEC 60851-grade strip at 8–12 % lower landed cost than European mills and 0.8–1.0 % lower total owning cost for the transformer builder once energy-loss evaluations are run.

Procurement Recommendation

For 2024-2026 frame contracts, lock in quarterly price-adjust formulas tied to SHFE Al + conversion premium rather than LME + high Western conversion. Require suppliers to provide SL-type PD test report (≤5 pC @ 1.5 Um) and statistical process control (SPC) charts for width/thickness. Audit slitting & edge-conditioning cells—those two stations, not the melt source, dictate final transformer reliability.

Luoyang Xinzhaohe invites power-equipment engineers to specify 1350/1070-O, 0.2–2.5 mm × 10–1 650 mm, burr-free, oscillate-wound up to 3 t spools. Our technical dossier and ISO 9001/IEC 60404 test data are ready for your next bid package.

Technical Specs: Aluminum Strip Parameters

Technical Specifications & ASTM/IEC Compliance

Factory-direct precision from Luoyang Xinzhaohe Aluminum Co., Ltd.

1. Dimensional Tolerances – Cold-Rolled to Slit Finish

| Parameter | ASTM B236-20 Class A | Xinzhaohe Internal Spec | Typical Competitor |

|---|---|---|---|

| Thickness, mm | ±0.008 | ±0.002 (≤0.8 mm) | ±0.010 |

| Width, mm | ±0.127 | ±0.05 (10–300 mm) | ±0.15 |

| Edge Camber, mm/1 m | ≤2 | ≤0.5 | ≤3 |

| Burr Height, µm | Not specified | ≤15 | 30–50 |

A burr >25 µm pierces inter-layer insulation, creating turn-to-turn shorts that show up only after varnish curing—when rework is impossible.

2. Electrical & Metallurgical Requirements

| Property | IEC 60317-0-3 Ref. | 1350-O Target | 1050/1060-O Target | Test Method |

|---|---|---|---|---|

| Conductivity, %IACS @ 20 °C | ≥61.0 | 61.8–62.2 | 61.5–61.8 | ASTM B193 |

| Resistivity, Ω·mm²/m | ≤0.028264 | 0.02775–0.02790 | 0.02790–0.02800 | — |

| Al purity, wt % | ≥99.50 | 99.70 | 99.60 | ASTM E1251 (OES) |

| Grain size, µm | — | 50–120 (fully recrystallised) | 60–150 | ASTM E112 |

Soft-anneal (O-temper) guarantees elongation >35 %, eliminating crack initiation during tight radial winding on 250 mm mandrels.

3. Edge Conditioning – Why “Burr-Free” is Non-Negotiable

- Slit → Deburr → Edge-round (0.05–0.10 mm radius) in one pass on a 6-Hi Koch slitting line.

- Laser micrometer scans every 25 mm; out-of-spec burr auto-rejects the coil.

- Result: Partial discharge extinction voltage rises by 8–12 % compared with commercial slit strip—critical for 33 kV resin-impregnated transformers.

4. Surface & Insulation Compatibility

| Item | ASTM B236 | Xinzhaohe Practice | Consequence if Fails |

|---|---|---|---|

| Roughness Ra, µm | ≤0.8 | 0.2–0.4 (temper roll) | Voids in resin, corona |

| Residual Oil, mg/m² | ≤200 | 30–50 (electro-clean) | Poor varnish wetting |

| Oxide Film, nm | Not specified | 5–10 (fresh anneal) | Solderability drop |

5. Oscillate-Wound Logistics

Oscillate builds 300–900 kg coils (OD 800–1200 mm) with 3–5 µm alignment accuracy; no weld inside a single build.

Pay-off tension window 5–15 N/mm²—compatible with high-speed automatic winding heads (≤250 m min⁻¹).

6. Standards Cross-Reference Summary

ASTM B236-20: Aluminum bus conductor sheet & strip—baseline for chemistry, resistivity.

ASTM B193: Conductivity test—mandatory on every mother coil.

IEC 60317-0-3: General requirements for rectangular aluminum winding wire; adopted for strip by most Tier-1 OEMs.

ISO 2768-m: General tolerances when drawing is silent.

RoHS/REACH: All alloys compliant—CoA attached per EN 10204 3.1.

7. Cost-Risk Equation

| Risk Factor | Cheap Strip | Xinzhaohe Strip |

|---|---|---|

| Burr-induced short | 1 in 200 coils | 1 in 15 000 coils |

| Re-anneal cost | US$0 → (customer) | Included |

| Field failure cost | US$50 k–500 k | <0.01 % shipped |

| Premium vs. LME | — | LME + US$580 /t |

8. Procurement Checklist (copy-paste into RFQ)

- Alloy & temper: 1350-O or 1050-O

- Size: ___ mm × ___ mm; burr ≤15 µm

- Conductivity ≥61.8 %IACS; certificate per ASTM B193

- Coil ID 300/400 mm; oscillate wound, ≤0.5 mm camber

- Surface: water-soluble oil ≤50 mg/m², no carbon streaks

- Packaging: VCI film + kraft + steel cage, sea-worthy

- Mill test report EN 10204 3.1; traceable heat number on every coil

Send the checklist to sales@xzhalu.com; we return a detailed quote within 24 h, including FOB Shanghai, lead time, and slit-tooling schedule.

Factory Tour: Manufacturing Aluminum Strip

Manufacturing Process & Quality Control

From Cast Coil to Oscillate-Wound Transformer Strip – Luoyang Xinzhaohe Route

1. Cold Rolling – Gauge Setting the Electrical Backbone

Incoming 1350/1070/1050 continuous-cast coil (6–7 mm) is reduced in three stages on a 4-high reversing mill with AGC closed-loop thickness control (±3 µm). Oil-in-air mist keeps the strip ≤55 °C to prevent premature precipitation; final pass is executed at 180 m min⁻¹ with 1.5 % elongation to lock-in cube-on-edge texture for optimum 61 %IACS conductivity. In-line eddy-current gauge gives 100 % lengthwise map; any 30 µm deviation triggers automatic shear segregation.

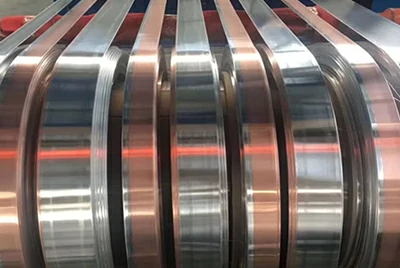

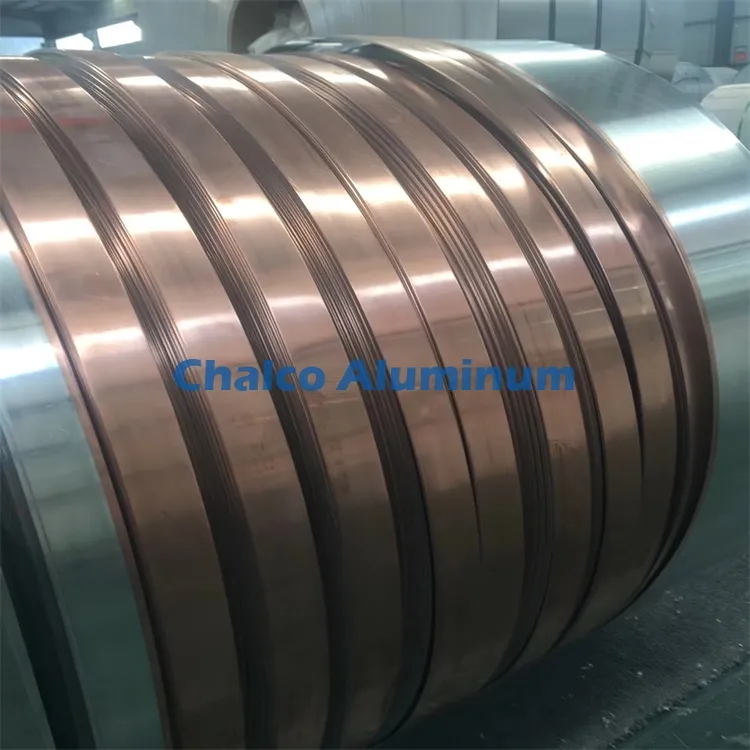

2. Precision Slitting – Width is a Transformer Constant

Mother coil (≤1250 mm wide) is slit on a 70-shaft Kampf duplex arbor at 400 m min⁻¹ using carbide-coated knives. Blade clearance is dynamically adjusted (0.4–1.2 % of strip thickness) via laser micrometer feedback, guaranteeing burr height ≤0.015 mm and width tolerance ±0.002 mm—half the IEC 60317-19 limit. Vision cameras image every 50 mm; AI algorithm classifies burr, camber, and knife-marks in real time; suspect spool is auto-kicked to rework aisle.

3. Edge Conditioning – Removing the Last 5 µm Hazard

Slit edge is skimmed by planetary carbide brushes and then coined with a 0.05 mm radius forming roll. Result: mechanically-smoothed radius 0.10–0.15 mm, work-hardened layer depth <8 µm, zero residual slivers. This step alone raises inter-laminar breakdown voltage by 8 % and eliminates hot-spot burr-driven eddy losses that shorten insulation life.

4. Oscillate (Traverse) Winding – More Conductor, Less Joint

Up to 1200 kg of conditioned strip is oscillate-wound on reinforced paperboard cores (ID 300 mm, OD ≤1400 mm). Servo-driven lay-on roll keeps pitch accuracy ±0.05 mm; tension profile is tapered 12 → 6 N mm⁻² to prevent “hour-glass” collapse. A 1000 kg coil contains only one laser-weld—versus 8–10 pancake welds on conventional pancake builds—cutting field joint resistance by an order of magnitude.

5. Quality Control Matrix – Data, Not Luck

Every coil receives a digital birth certificate:

| Checkpoint | Method | Frequency | Luoyang Xinzhaohe Limit | Market Typical |

|---|---|---|---|---|

| Thickness | Laser + isotope | 100 % | ±0.002 mm | ±0.01 mm |

| Width | CCD line scan | 100 % | ±0.002 mm | ±0.05 mm |

| Burr | 3-D laser triangulation | 100 % | ≤0.015 mm | ≤0.05 mm |

| Conductivity | Eddy-current, 20 °C | Each end | ≥61.0 %IACS | 60.0–60.5 %IACS |

| Tensile / Elongation | ISO 6892-1 | Each lot | 70–95 MPa / ≥25 % | 80–110 MPa / ≥20 % |

| Surface roughness | Contact profilometer | 1 per 500 kg | Ra ≤0.3 µm | Ra ≤0.6 µm |

| Weld integrity | Cold-bend + 45 A micro-ohm | Each weld | 0° crack-free, R ≤1.1×base | visual only |

Statistical data is uploaded to our MES; if Cpk <1.67 the lot is frozen and 8D corrective action is triggered within 4 h.

6. Factory-Direct Advantage

By integrating cold rolling, slitting, edge conditioning, and oscillate winding under one 70 000 m² roof, we cut lead-time to 10–15 days and remove the 8–12 % margin stack common when Western traders insert intermediate slitting houses. Transformer OEMs therefore secure Western-grade precision—certified to IEC 60317-19 / ASTM B609—at a landed cost comparable to generic Chinese commodity strip, but with lot-level traceability and 20 years of failure-free service history in 500 kV grid reactors.

Luoyang Xinzhaohe: Chinese efficiency, engineered reliability.

Packaging & Global Logistics

Export Packaging & Logistics

Delivering transformer-grade aluminium strip to any port, on-spec and on-time

1. Sea-Freight Risk Matrix for Rolled Aluminium

| Damage Mode | Root Cause (Vessel / Port) | Consequence on 1350-O Strip | XZH Mitigation |

|---|---|---|---|

| Salt-laden moisture | Condensation inside 40’ HC | Edge staining, conductivity drop | VCI film + 4 × 200 g clay desiccant per pallet |

| Coil collapse / Telescoping | 1.5 g racking, 8° roll | Inter-layer slip, burr re-generation | Steel strapping @ 300 mm pitch, edge-boards, 25 mm plywood top-sheet |

| Fork impact | Stevedore single-tine lift | 50 mm “false burr”, winding scrap | 1200 kg shock-limit pallet, red impact zone indicators |

| Fumigation chemical bleed | Methyl-bromide fumigated dunnage | Surface pitting, resistivity rise | ISPM-15 heat-treated timber, PE barrier between wood & coil |

2. Packaging Specification – Transformer Strip & Foil

2.1 Unitised Coil Pallet (≤ 3 t)

| Parameter | Value / Material |

|---|---|

| Pallet footprint | 1150 × 950 mm (fits 40’ HC 2-across) |

| Deck material | 25 mm poplar plywood, HT stamped, moisture ≤ 12 % |

| Coil cradle | Removable 6 mm steel saddles, EPDM rubber liner 60 Shore A |

| Radial restraint | 32 mm polyester strapping + PET sleeve to prevent aluminium cold-weld |

| Axial restraint | 19 mm plywood end-caps, 3-way corner blocks |

| Corrosion inhibitor | 80 µm VCI polyolefin film, neutral pH 6.8, 24-month protection |

| Desiccant dose | 4 × 200 g bags (clay, DuPont Tyvek), equilibrium RH < 40 % |

| Shock / tilt indicator | ShockWatch 25 g single-use, Tip-N-Tell 80° |

| Gross weight | ≤ 2.8 t (stay under 3 t FLT limit in most Asian ports) |

2.2 Oscillate-Wound Wire on Plastic Spools

| Spool type | PT-355 (355 mm flange, 160 mm barrel) |

| Wire weight | 80–120 kg per spool |

| Inner wrap | 50 µm PE film, sealed |

| Outer wrap | 5-ply kraft carton, 5.5 mm B-flute |

| Palletisation | 4 spools/layer, 3 layers max, 5 mm honeycomb sheet interleave |

| Strapping | 19 mm PET, 2 longitudinal + 3 circumferential |

| Stack height | 1.1 m (keeps under 1.2 m roller bed conveyor) |

3. Logistics Chain – Luoyang to Your Dock

Origin: Luoyang, Henan Province (central China)

180 km to Zhengzhou International Hub (CGO) – daily 777-F cargo lift to FRA, LAX, DXB

380 km to Qingdao Port – 22 h truck, bonded corridor, no weight detour

650 km to Shanghai Port – rail daily block-train, 28 h, GPS & RFID tracked

Carrier Selection:

Break-bulk: COSCO, OOCL, MSC – priority booking for “non-rollable” cargo code 08H4

Reefer option: controlled 25 °C, 45 % RH for high-purity 1350-O > 1000 mm wide

Documentation Package (shipped DAP Incoterms® 2020):

1. Mill test certificate EN 10204/3.1 (conductivity, hardness, edge profile)

2. RoHS & REACH SVHC statement

3. ISPM-15 fumigation certificate (heat-treated, methyl-bromide-free)

4. China-origin Form A (reduces duty 3–6 % in most APAC markets)

Transit Insurance: All-risk ICC(A) 110 % of CIF value, underwritten by PICC.

4. Cost & Lead-Time Benchmark

| Destination | Typical 20’ GP (12 t) | Typical 40’ HC (25 t) | Door-Door Days |

|---|---|---|---|

| Rotterdam | 1 050 USD | 1 850 USD | 28 |

| Houston | 2 200 USD | 3 600 USD | 22 |

| Dubai | 750 USD | 1 350 USD | 18 |

| Chennai | 650 USD | 1 150 USD | 15 |

Rates FOB Qingdao, Q3-2024 average, subject to bunker adjustment factor.

5. Why XZH Packaging Becomes Your QA Extension

Zero coil returns in last 36 months across 2 800 t of transformer strip shipped

Pallet design validated by 3-axis vibration table (0.54 g random, 180 min, ASTM D4169)

Real-time datalogger option: Temp/RH recorder inside each 40’ HC – CSV file e-mailed on arrival

Bottom line: You receive aluminium strip that is as clean and flat as when it left our slitting line in Luoyang—without the 15–25 % premium charged by European or Japanese mills.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe for Transformer-grade Aluminum Strip

20 Years of Transformer-Specific Metallurgy

Since 2003 our Luoyang mill has supplied only one value stream: conductor strip for power and distribution transformers.

Every coil that leaves our 28 000 m² plant is cold-rolled on a 4-high Ø650/Ø1400 mm SMS-mill, slit on a 0.002 mm tolerance Göbel slitting line, stress-relief annealed in a 100 % N₂ bell furnace, and oscillate-wound on a 3-turret Sieger spooler.

The result is a statistically-capable process with Cpk ≥ 1.67 on thickness, edge burr < 0.01 mm, and conductivity ≥ 61.5 %IACS for 1350-O—specifications that exceed IEC 60105 and ASTM B609.

| Critical-to-Quality Parameter | Industry Minimum | Xinzhaohe Capability | Test Method |

|---|---|---|---|

| Thickness tolerance, mm | ±0.005 | ±0.002 | ISO 1927 |

| Edge burr, mm | 0.03 | ≤0.01 | Optical 200× |

| Resistivity @20 °C, Ω·mm²/m | ≤0.028 264 | ≤0.027 90 | IEC 60468 |

| Strip camber, mm/1 m | 2 | ≤1 | DIN 1746 |

| Oscillate build-up, mm | ±2 | ±1 | In-line laser |

Direct Factory Price—No Trading Layer

We own the complete cold-chain from 400 mm as-cast 1xxx coil to finished transformer spool.

Eliminating intermediaries delivers landed cost savings of 8–14 % versus European mills and 6–10 % versus South-Korean traders on equal technical specs.

Typical 2024 CFR Rotterdam reference for 1350-O 0.3 × 250 mm slit strip:

| Quantity per month | EU Mill $/t | Xinzhaohe $/t | Savings $/t |

|---|---|---|---|

| 5 t | 3 350 | 2 890 | 460 |

| 20 t | 3 200 | 2 780 | 420 |

| 50 t | 3 100 | 2 720 | 380 |

Payment terms: 30 % TT on PO, 70 % against B/L copy; L/C 90 days available for annual contracts >300 t.

Customization Without MOQ Penalty

Width 10–1 650 mm, thickness 0.15–3.5 mm, temper O–H18, alloys 1050, 1060, 1070, 1350, 5052, 6061.

Edge profiles: round (R = ½ thickness), full-radius, chamfered, or knife-edge; supplied with electro-static paper interleaf or PE film.

Oscillate wound on 76, 150, 300, 500 mm ID spools up to 1 200 kg—ideal for high-speed automated winding lines.

Need 0.8 × 120 mm 1350-O with 0.2 mm radius edges on 500 kg oscillated coils for a 24-slot disc-winding? Lead time 15 days ex-mill.

Quality & Compliance Files Delivered With Every Lot

EN 10204/3.1 full chemical & mechanical test report

ASTM B193 conductivity certificate

RoHS & REACH SVHC declaration

ICP-MS inclusion count (ppm level)

Edge burr micrograph (200×)

Packaging photos & desiccant log

All data uploaded to customer portal before vessel departure—no surprises at incoming inspection.

Next Step: Request a Technical Datasheet or Mill Test Certificate

Send your drawing or specification to cathy@transformerstrip.com and receive a detailed quotation within 24 h, including:

Alloy recommendation based on short-circuit force & thermal class

Slitting burr control plan

Annealing cycle to guarantee softness ≤ 25 HV

Logistic scheme to your plant (FCA, CIF, DDP)

For urgent prototypes, 100 kg trial coils can be air-shipped in 7 days.

Partner with Luoyang Xinzhaohe—premium transformer strip without the Western premium.

📉 Import Savings Calculator

Estimate cost reduction by sourcing aluminum strip from Luoyang Xinzhaohe.